ASTM D6133-02(2021)

(Test Method)Standard Test Method for Acetone, p-Chlorobenzotrifluoride, Methyl Acetate or t-Butyl Acetate Content of Solventborne and Waterborne Paints, Coatings, Resins, and Raw Materials by Direct Injection Into a Gas Chromatograph

Standard Test Method for Acetone, <emph type="ital">p</emph>-Chlorobenzotrifluoride, Methyl Acetate or <emph type="ital">t</emph>-Butyl Acetate Content of Solventborne and Waterborne Paints, Coatings, Resins, and Raw Materials by Direct Injection Into a Gas Chromatograph

SIGNIFICANCE AND USE

4.1 With the need to calculate volatile organic content (VOC) of paints, and with acetone, p-chlorobenzotrifluoride, methyl acetate and t-butyl acetate4 considered as exempt volatile compounds, it is necessary to know the content of these analytes. This gas chromatographic test method provides a relatively simple and direct way to determine their content. However, because the detectors used in this test method are not selective, and because some coatings are very complex mixtures, compounds may be present in the sample that coelute with the analyte, giving a result that is erroneously high. Or a component may elute with the internal standard, giving a result that is erroneously low. It is therefore important to know the composition of the sample to ensure that there are no interferences, under the analysis conditions used. Test Method D6438 employs mass-spectral detection of analytes and may be used as an alternative method.

SCOPE

1.1 This test method is for the determination of the total-concentration of acetone, p-chlorobenzotrifluoride, methyl acetate, or t-butyl acetate, or combination of any of the four, in solvent-reducible and water-reducible paints, coatings, resins, and raw materials. Because unknown compounds that co-elute with the analyte being measured or with the internal standard, will lead to erroneous results, this test method should only be used for materials of known composition so that the possibility of interferences can be eliminated. The established working range of this test method is from 1 % to 100 % for each analyte by weight.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D6133 −02 (Reapproved 2021)

Standard Test Method for

Acetone, p-Chlorobenzotrifluoride, Methyl Acetate or t-Butyl

Acetate Content of Solventborne and Waterborne Paints,

Coatings, Resins, and Raw Materials by Direct Injection Into

a Gas Chromatograph

This standard is issued under the fixed designation D6133; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3271 Practice for Direct Injection of Solvent-Reducible

Paints Into a Gas Chromatograph for Solvent Analysis

1.1 This test method is for the determination of the total-

(Withdrawn 2019)

concentration of acetone, p-chlorobenzotrifluoride, methyl

D3272 Practice for Vacuum Distillation of Solvents From

acetate, or t-butyl acetate, or combination of any of the four, in

Solvent-Reducible Paints For Analysis (Withdrawn

solvent-reducible and water-reducible paints, coatings, resins,

2008)

and raw materials. Because unknown compounds that co-elute

D6438 Test Method for Acetone, Methyl Acetate, and

with the analyte being measured or with the internal standard,

Parachlorobenzotrifluoride Content of Paints, and Coat-

will lead to erroneous results, this test method should only be

ings by Solid Phase Microextraction-Gas Chromatogra-

used for materials of known composition so that the possibility

phy

of interferences can be eliminated. The established working

E177 Practice for Use of the Terms Precision and Bias in

range of this test method is from 1 % to 100 % for each analyte

ASTM Test Methods

by weight.

E691 Practice for Conducting an Interlaboratory Study to

1.2 The values stated in SI units are to be regarded as

Determine the Precision of a Test Method

standard. No other units of measurement are included in this

standard.

3. Summary of Test Method

1.3 This standard does not purport to address all of the

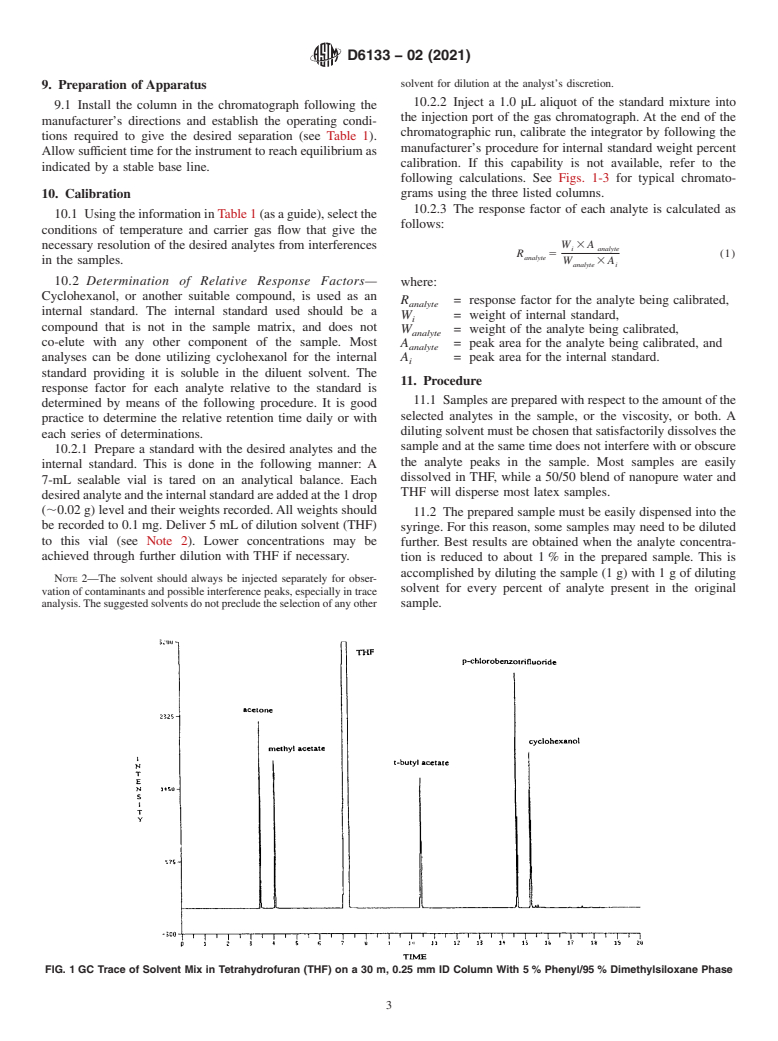

3.1 A suitable aliquot of whole paint is internally

safety concerns, if any, associated with its use. It is the

standardized, diluted with an appropriate solvent, and then

responsibility of the user of this standard to establish appro-

injected into a gas chromatographic column that separates the

priate safety, health, and environmental practices and deter-

chosen analytes from other volatile components. The analyte

mine the applicability of regulatory limitations prior to use.

content is determined from area calculations of the materials

1.4 This international standard was developed in accor-

producing peaks on the chromatogram.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 4. Significance and Use

Development of International Standards, Guides and Recom-

4.1 With the need to calculate volatile organic content

mendations issued by the World Trade Organization Technical

(VOC) of paints, and with acetone, p-chlorobenzotrifluoride,

Barriers to Trade (TBT) Committee. 4

methyl acetate and t-butyl acetate considered as exempt

volatile compounds, it is necessary to know the content of

2. Referenced Documents

these analytes. This gas chromatographic test method provides

2.1 ASTM Standards:

a relatively simple and direct way to determine their content.

However, because the detectors used in this test method are not

selective, and because some coatings are very complex

This test method is under the jurisdiction of ASTM Committee D01 on Paint

mixtures,compoundsmaybepresentinthesamplethatcoelute

and Related Coatings, Materials, andApplications and is the direct responsibility of

with the analyte, giving a result that is erroneously high. Or a

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

Current edition approved Feb. 1, 2021. Published March 2021. Originally

approved in 1997. Last previous edition approved in 2014 as D6133 – 02 (2014).

DOI: 10.1520/D6133-02R21. The last approved version of this historical standard is referenced on

For referenced ASTM standards, visit the ASTM website, www.astm.org, or www.astm.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM At the time of the revision of this test method, t-butyl acetate was not yet

Standards volume information, refer to the standard’s Document Summary page on approved as an exempt solvent, but was under review by the USEPA and was

the ASTM website. expected to be approved. Therefore, it has been included in this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6133−02 (2021)

component may elute with the internal standard, giving a result of 5.1. The use of a reporting electronic integrator or computer

that is erroneously low. It is therefore important to know the based data system is preferred.

composition of the sample to ensure that there are no

interferences, under the analysis conditions used. Test Method 6. Column Peak Interferences

D6438employsmass-spectraldetectionofanalytesandmaybe

6.1 The following compounds are known to co-elute or

used as an alternative method.

otherwise interfere with the analysis on a DB-5 type column:

(a) Acetone—isopropanol, propylene oxide, acetonitrile,

5. Apparatus

and

5.1 Gas Chromatograph—Any instrument with temperature

(b) Cyclohexanol—sec-amyl acetate.

programming capability may be used. It should be equipped

6.2 The following compound is known to co-elute or

with a flame ionization detector (see Table 1).

otherwise interfere with the analysis on an FFAP type column:

5.2 Column—Any column that provides baseline separation

(a) Cyclohexanol—butyl cellosolve.

of the analyte of interest (acetone, p-chlorobenzotrifluoride,

methylacetateor t-butylacetate),theinternalstandard,andany

6.3 The analyst must verify that, under the analysis condi-

volatile present in the samples may be used. It should be

tions being used, none of the components of the sample

understood that column performance may be influenced by

interfere with the analyte being quantitated or with the internal

manufacturing conditions, such as type of deactivation and

standard being used.

chemical bonding/crosslinking used. One or more of the

followingcolumntypesmaybeused.Intermsofdurabilityand

7. Reagents and Materials

over all efficiency, a bonded phase poly (5 % phenyl 95 %

7.1 Purity of Reagents—Use reagent grade chemicals in all

dimethylsiloxane) type of column should be considered first.

tests, unless otherwise specified. Other grades may be used,

(Any reference to specific product brands does not indicate an

provided it is first ascertained that the reagent is sufficiently

endorsement for that particular brand of column).

high purity to permit its use without lessening the accuracy of

5.2.1 Capillary, 25 to 60 m, 0.25 mm-inside diameter, 0.25

the determination.

to 1.0-µm film thickness, fused silica bonded phase poly (5 %

phenyl 95 % dimethylsiloxane (DB-5, HP-5, Rtx-5, Ultra-2,

7.2 Tetrahydrofuran (THF)—high performance liquid chro-

BP-5, CP-Sil 8 CB, etc.)).

matography (HPLC) grade, uninhibited.

5.2.2 Capillary, 25 to 60 m, 0.25-mm inside diameter, 0.25

7.3 Cyclohexanol—98+ %.

to 1.0-µm film thickness, fused silica FFAP (polyethylene

glycol nitrophthalic acid ester phase).

7.4 Acetone—HPLC grade.

5.2.3 Capillary, 25 to 60 m, 0.25-mm inside diameter, 0.25

7.5 p-Chlorobenzotrifluoride—98+ %.

to 1.4-µm film thickness, fused silica bonded phase poly (6 %

cyanopropyl/phenyl, 94 % dimethylsiloxane) (DB-624, SPB-

7.6 Methyl Acetate—99+ %.

624, Rtx-624, etc.).

7.7 t-Butyl Acetate—99+ %.

5.3 Recorder—A recording potentiometer with a full-scale

7.8 Water—nanopure.

deflection of 1 to 10 mV, full-scale response time of2sor less

and sufficient sensitivity and stability to meet the requirements

7.9 Chromatography Gases: Helium of 99.9995 % purity or

higher.

TABLE 1 Suggested Instrument Conditions

Hydrogen of 99.9995 % minimum purity (see Note 1).

Detector Flame Ionization Detection (FID)

Air, “dry” quality, free of hydrocarbons.

Hydrogen Flow 30 mL/min

NOTE 1—The preferred choice of carrier gas is hydrogen, but helium or

Air Flow 400 mL/min

Make-up (Helium) 30 mL/min nitrogen may also be used. Chromatographic analysis time will increase

Carrier Gas (Hydrogen) 40 cm/s and there may be a possible reduction in resolution.

Detector Temperature 250°C

A

Injection Port Temperature 200°C 7.10 Liquid Charging Devices—micro syringes of 10 or 25

B

Split Ratio 50:1

µL capacity.

Initial Oven Temperature 40°C

Initial Temperature Hold Time 5 min

7.11 Analytical Balance—four places (0.0001 g).

Program Rate 1 4°C/min

Program Time 1 5 min

7.12 Sealable Vials—7-mL screw cap.

Final Temperature 1 60°C

Program Rate 2 20°C/min

7.13 Medicine Droppers.

Program Time 2 8 min

Final Temperature 2 220°C

7.14 Autosampler Vials.

Final Temperature Hold Time 2 min

Total Run Time 20 min

7.15 Pipete—5-mL glass or autopipete.

Injection Volume 1.0 µL

A

The injection port temperature can be decreased to permit the analysis of

8. Hazards

thermally unstable samples; however, each case must be individually investigated.

B

The split ratio may be adjusted according to the theoretical level of solvent

8.1 Check the supplier’s Material Safety Data Sheet

composition.

(MSDS) on all chemicals before use.

---------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.