ASTM F106-00

(Specification)Standard Specification for Brazing Filler Metals for Electron Devices

Standard Specification for Brazing Filler Metals for Electron Devices

SCOPE

1.1 This specification covers requirements or filler metals suitable for brazing internal parts and other critical areas of electron devices in a nonoxidizing atmosphere (Note 1).

1.2 These materials are available in strip or wire or preforms made by blanking the strip or bending the wire. Powders are also available.

Note 1--Brazing filler metals for general applications are specified in AWS Specification A5.8.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 106 – 00

Standard Specification for

1

Brazing Filler Metals for Electron Devices

This standard is issued under the fixed designation F 106; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

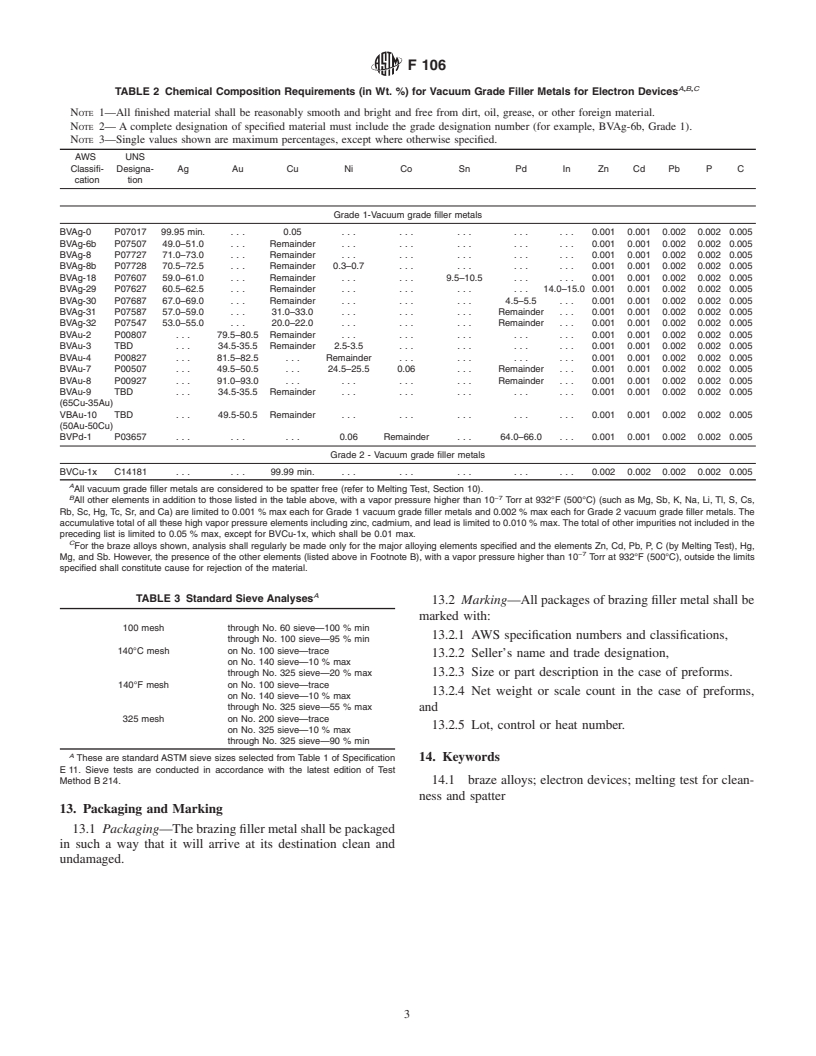

1. Scope 1. The difference between Grade 1 and 2 are the impurity

limitations. Grade 1 required generally lower levels of impu-

1.1 This specification covers requirements or filler metals

rities.

suitable for brazing internal parts and other critical areas of

electron devices in a nonoxidizing atmosphere (Note 1).

4. Ordering Information

1.2 Thesematerialsareavailableinstriporwireorpreforms

4.1 Ordersformaterialtothisspecificationshallincludethe

made by blanking the strip or bending the wire. Powders are

following information:

also available.

4.1.1 Quantity,

NOTE 1—Brazing filler metals for general applications are specified in

4.1.2 Dimensions and tolerances (Table 1),

AWS Specification A5.8.

4.1.3 Form (rod, bar, wire, etc.),

1.3 The values stated in inch-pound units are to be regarded

4.1.4 AWS classification (Table 2),

as the standard. The values given in parentheses are for

4.1.5 Grade 1,

information only.

4.1.6 Special requirements or exceptions, and

4.1.7 Certification— State if certification is required.

2. Referenced Documents

5. Materials and Manufacture

2.1 ASTM Standards:

B214 Test Method for Sieve Analysis of Granular Metal

5.1 The brazing filler metals shall be vacuum grade and

2

Powders

fabricated by any method that yields a product conforming to

E11 Specification for Wire-Cloth Sieves for Testing Pur-

the requirements of this specification.

3

poses

6. Chemical Composition

F19 Test Method for Tension and Vacuum Testing Metal-

4

lized Ceramic Seals 6.1 The finished brazing filler metal shall conform to the

2.2 American Welding Society:

chemical composition shown in Table 2 for Grade 1 material.

5

A5.8 Specification for Brazing Filler Metals

5 7. Mechanical Properties

C3.2 Method for Evaluating the Strength of Brazed Joints

C3.3 RecommendedPracticesforDesign,Manufactureand 7.1 Unless otherwise specified, wire shall be furnished in

Inspection of Critical Brazed Components soft temper most suitable for hand feeding or ring winding on

mandrels. A minimum elongation of 10% in 2 in. (50.8 mm)

3. Classification

indicates that the wire is annealed.

3.1 Brazing filler metals which are vacuum grade and are

7.2 Unless otherwise specified, strip shall be furnished in

classifiedonthebasisofchemicalcompositionshowninTable hard as-rolled temper to facilitate clean blanking of thin shims

or preforms.Amaximum elongation of 5% in 2 in. designates

the strip as hard.

1

This specification is under the jurisdiction of ASTM Committee F01 on

Electronics and is the direct responsibility of Subcommittee F01.03 on Metallic

8. Dimensions and Permissible Variations

Materials.

8.1 These materials must conform to the dimensional limi-

Current edition approved Dec. 10, 2000. Published July 2001. Originally

published as F106–69T. Last previous edition F106–95.

tations listed in Table 2 for strip, wire, and preforms or Table

2

Annual Book of ASTM Standards, Vol 02.05.

3 for size of powdered brazing filler metals.

3

Annual Book of ASTM Standards, Vol 14.02.

4

Annual Book of ASTM Standards, Vol 10.04.

5

Available fromAmericanWelding Society, 2501 Northwest 7th St., Miami, FL

33125.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 106

TABLE 1 Dimensional Tolerances (All Plus or Minus)

Width Tolerances, in. (mm)

Thickness 8 in. (200 mm) wide and under Over 8 in. (200 mm) wide

Less than 0.020 (0.5) 0.005 (0.125) 0.015 (0.38)

0.020 to 0.050 (0.5 to 1.25), incl 0.010 (0.250) 0.015 (0.38)

Thickness Tolerances—Strip

Thickness, in. (mm) 8 in. (200 mm) wide and under Over 8 in. (200 mm) wide

Up to 0.002 (0.05), incl 0.0002 (0.005) 0.0005 (0.0125)

Over 0.002 to 0.003 (0.05 to 0.075), incl 0.0003 (0.0075) 0.0006 (0.015)

Over 0.003 to 0.004 (0.075 to 0.10), incl 0.0004 (0.010) 0.0007 (0.018)

Over 0.004 to 0.006 (0.10 to 0.15), incl 0.0005 (0.0125) 0.0008 (0.02)

Over 0.006 to 0.013 (0.15 to 0.33), incl 0.0010 (0.025) 0.0013 (0.033)

Over 0.013 to 0.021 (0.33 to 0.53), incl 0.0015 (0.038) 0.0018 (0.046)

Over 0.021 to 0.026 (0.53 to 0.66), incl 0.0020 (0.05) 0.0020 (0.05)

Over 0.026 to 0.050 (0.66 to 0.125), incl 0.0020 (0.05) 0.0050 (0.125)

Camber Tolerances—Strip (Edgewise Bowl)

0.5 in. (12.5 mm) max in 6 ft (1.8 m)

Diameter Tolerances—Wire

Diameter, in. (mm) Tolerance, in. (mm)

0.010 to 0.020 (0.250 to 0.5) 0.0003 (0.0075)

Over 0.0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.