ASTM D7175-05

(Test Method)Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer

Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer

SCOPE

1.1 This test method covers the determination of the dynamic shear modulus and phase angle of asphalt binders when tested in dynamic (oscillatory) shear using parallel plate geometry. It is applicable to asphalt binders having dynamic shear modulus values in the range from 100 Pa to 10 MPa. This range in modulus is typically obtained between 4 and 88C at 10 rad/s. This test method is intended for determining the linear viscoelastic properties of asphalt binders as required for specification testing and is not intended as a comprehensive procedure for the full characterization of the viscoelastic properties of asphalt binders.

1.2 This standard is appropriate for unaged materials, material aged in accordance with Test Method D 2872, material aged in accordance with Practice D 6521, or material aged in accordance with both Test Method D 2872 and Practice D 6521.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7175–05

Standard Test Method for

Determining the Rheological Properties of Asphalt Binder

Using a Dynamic Shear Rheometer

This standard is issued under the fixed designation D 7175; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 6373 Specification for Performance-Graded Asphalt

Binder

1.1 This test method covers the determination of the dy-

D 6521 Practice for Accelerated Aging of Asphalt Binder

namic shear modulus and phase angle of asphalt binders when

Using a Pressurized Aging Vessel (PAV)

tested in dynamic (oscillatory) shear using parallel plate

E77 Test Method for Inspection and Verification of Ther-

geometry. It is applicable to asphalt binders having dynamic

mometers

shearmodulusvaluesintherangefrom100Pato10MPa.This

E 563 Practice for Preparation and Use of an Ice-Point Bath

range in modulus is typically obtained between 4 and 88°C at

as a Reference Temperature

10rad/s.Thistestmethodisintendedfordeterminingthelinear

E 644 Test Methods for Testing Industrial Resistance Ther-

viscoelastic properties of asphalt binders as required for

mometers

specification testing and is not intended as a comprehensive

E 882 Guide for Accountability and Quality Control in the

procedure for the full characterization of the viscoelastic

Chemical Analysis Laboratory

properties of asphalt binders.

2.2 AASHTO Standards:

1.2 This standard is appropriate for unaged materials, ma-

R29 Practice for Grading or Verifying the Performance

terial aged in accordance with Test Method D 2872, material

Grade of an Asphalt Binder

aged in accordance with Practice D 6521, or material aged in

T315 Standard Test Method for Determining the Rheologi-

accordance with both Test Method D 2872 and Practice

cal Properties of Asphalt Binder Using a Dynamic Shear

D 6521.

Rheometer

1.3 This standard may involve hazardous materials, opera-

2.3 Deutsche Industrie Norm (DIN) Standard:

tions, and equipment. This standard does not purport to

43760 Standard for Calibration of Thermocouples

address all of the safety concerns, if any, associated with its

use. It is the responsibility of the user of this standard to

3. Terminology

establish appropriate safety and health practices and deter-

3.1 Definitions of Terms Specific to This Standard:

mine the applicability of regulatory limitations prior to use.

3.1.1 annealing, n—the process of removing the effects of

2. Referenced Documents steric hardening by heating the binder until it is sufficiently

2 fluid so that it can be easily poured.

2.1 ASTM Standards:

3.1.2 asphalt binder, n—an asphalt-based cement that is

C 670 Practice for Preparing Precision and Bias Statements

produced from petroleum residue either with or without the

for Test Methods for Construction Materials

addition of non-particulate modifiers.

D 140 Practice for Sampling Bituminous Materials

3.1.3 calibration, n—process whereby the accuracy and

D 2170 Test Method for Kinematic Viscosity of Asphalts

precision of a device are checked against NIST-traceable

(Bitumens)

standards and where necessary adjustments are made to the

D 2171 Test Method for Viscosity of Asphalts by Vacuum

device to correct its operation or precision and accuracy.

Capillary Viscometer

3.1.3.1 Discussion—Calibration is typically performed by

D 2872 Test Method for Effect of Heat and Air on Rolling

themanufactureroranexternalcommercialcalibrationservice.

Film of Asphalt (Rolling Thin Film Oven Test)

3.1.4 complex shear modulus (G*), n—ratio calculated by

dividing the absolute value of the peak-to-peak shear stress, t,

by the absolute value of the peak-to-peak shear strain, g.

This test method is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.44 on

Rheological Tests.

Current edition approved Sept. 15, 2005. Published October 2005.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Association of State Highway and Transportation

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001.

Standards volume information, refer to the standard’s Document Summary page on Available from Beuth Verlag GmbH (DIN-- DIN Deutsches Institut fur

the ASTM website. Normung e.V.), Burggrafenstrasse 6, 10787, Berlin, Germany.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7175–05

3.1.5 dummy test specimen, n—a specimen formed between 4.2 The standard is suitable for use when the dynamic shear

the DSR test plates from asphalt binder or other polymer for modulus varies between 100 Pa and 10 MPa. This range in

the purpose of determining the temperature in the asphalt modulus is typically obtained between 4 and 88°C, depending

binder between the plates. upon the grade, test temperature, and conditioning (aging) of

the asphalt binder.

3.1.5.1 Discussion—The dummy test specimen is not used

to measure the rheological properties of asphalt binder but is 4.3 Test specimens, nominally 25 mm in diameter by 1 mm

used solely to determine temperature corrections. thick or 8 mm in diameter by 2 mm thick, are formed between

3.1.6 linear viscoelastic, adj—within context of this test parallel metal plates.

4.4 During testing, one of the parallel plates is oscillated

method, refers to a region of behavior in which the dynamic

shear modulus is independent of shear stress or strain. with respect to the other at pre-selected frequencies and

angular deflection (or torque) amplitudes. The required ampli-

3.1.7 loading cycle, n—refers to the application of sinusoi-

tude depends upon the value of the complex shear modulus of

dal stress or strain loading for a specified duration of time.

the asphalt binder being tested. The required amplitudes have

3.1.8 molecular association, n—refers to time-dependent

been selected so that, for most asphalt binders, the testing

associations that occur between asphalt binder molecules

specifiedinthisstandardiswithintheregionoflinearbehavior.

during storage at ambient temperature.

4.5 The test specimen is maintained at the test temperature

3.1.8.1 Discussion—Often referred to as steric hardening in

60.1°Cbyenclosingtheupperandlowerplatesinathermally

the asphalt literature, molecular associations can significantly

controlled environment or test chamber.

increase the dynamic shear modulus of asphalt binders.

4.6 Oscillatory loading frequencies using this standard can

3.1.8.2 Discussion—The effect of molecular association or

range from 1 to 160 rad/s. Specification testing is performed at

steric hardening on the dynamic shear modulus is asphalt

a test frequency of 10 rad/s. The complex modulus (G*) and

specific and may be apparent even after a few hours of storage.

phase angle (d) are calculated automatically as part of the

3.1.9 oscillatory shear, n—refers to a type of loading in

operation of the rheometer using proprietary computer soft-

which a shear stress or shear strain is applied to a test sample

ware supplied by the instrument manufacturer.

in an oscillatory manner such that the shear stress or strain

varies in amplitude about zero in a sinusoidal manner.

5. Significance and Use

3.1.10 parallel plate geometry, n—refers to a testing geom-

5.1 The test temperature for this test is related to the

etry in which the test specimen is sandwiched between two

temperature experienced by the pavement in the geographical

rigid parallel plates and subjected to shear.

area for which the asphalt binder is intended to be used.

3.1.11 phase angle (d), n—the angle in degrees between a

5.2 The complex shear modulus is an indicator of the

sinusoidally applied strain and the resultant sinusoidal stress in

stiffness or resistance of asphalt binder to deformation under

a controlled-strain testing mode, or between the applied stress

load. The complex shear modulus and the phase angle define

and the resultant strain in a controlled-stress testing mode.

the resistance to shear deformation of the asphalt binder in the

3.1.12 steric hardening, n—see molecular association.

linear viscoelastic region.The complex modulus and the phase

3.1.13 portable thermometer, n—refers to an electronic

angle are used to calculate performance-related criteria in

device that is separate from the dynamic shear rheometer and

accordance with Specification D 6373.

that consists of a detector (probe containing a thermocouple or

resistive element), associated electronic circuitry, and readout

6. Interferences

system.

6.1 Particulate material in the asphalt binder is limited to

3.1.14 referencethermometer,n—referstoaNIST-traceable

particles with longest dimensions less than 250 µm. Particles

liquid-in-glass or electronic thermometer that is used as a

with dimensions greater than 250 µm approach the dimensions

laboratory standard.

of the gap (1000 µm). In order to accurately characterize a

3.1.15 temperature correction, n—difference in temperature

two-phase material containing particulate material it is well

between the temperature indicated by the DSR and the test

acceptedthatthethicknessofthetestspecimenmustbeatleast

specimen as measured by the portable thermometer inserted

four times the maximum particle size.

between the test plates.

6.1.1 The calculation of the complex modulus from the data

3.1.16 thermal equilibrium, n—condition where the tem-

obtained from the DSR is highly dependent upon an accurate

perature of the test specimen mounted between the test plates

measurement of the diameter of the test specimen. In the

is constant with time.

procedure, the diameter of the test specimen is assumed equal

3.1.17 verification, n—process of checking the accuracy of

to the diameter of the test plates. This assumption is valid only

a device or its components against an internal laboratory

if the test sample is properly trimmed.

standard. Usually performed internally within the operating

6.1.2 The physical properties of asphalt binders are very

laboratory.

sensitive to test temperature and thermal history. Thermal

history is the number of times asphalt binder sample has been

4. Summary of Test Method

heated prior to testing. Controlling the test temperature to

4.1 This standard contains the procedure used to measure 6 0.1°Candlimitingthenumberoftimestheasphaltsampleis

thecomplexshearmodulus(G*)andphaseangle(d)ofasphalt heated prior to testing (only one heating is recommended) is

binders using dynamic shear rheometer and parallel plate essential in order to obtain repeatable test results within a

geometry. laboratory as well as to reproduce results between laboratories.

D7175–05

NOTE 2—Acirculatingbathunit,separatefromtheDSRthatpumpsthe

7. Apparatus

water through the test chamber may be required if a fluid medium is used.

7.1 Dynamic Shear Rheometer (DSR) Test System—A dy-

7.1.2.1 Temperature Controller—A temperature controller

namic shear rheometer test system consisting of parallel metal

capable of maintaining the temperature of the test specimen at

plates, a means for controlling the temperature of the test

the test temperature 6 0.1°C for test temperatures ranging

specimen, a loading device, and a control and data acquisition

from 4 to 88°C.

system.

7.1.3 Internal DSR Thermometer—A platinum resistance

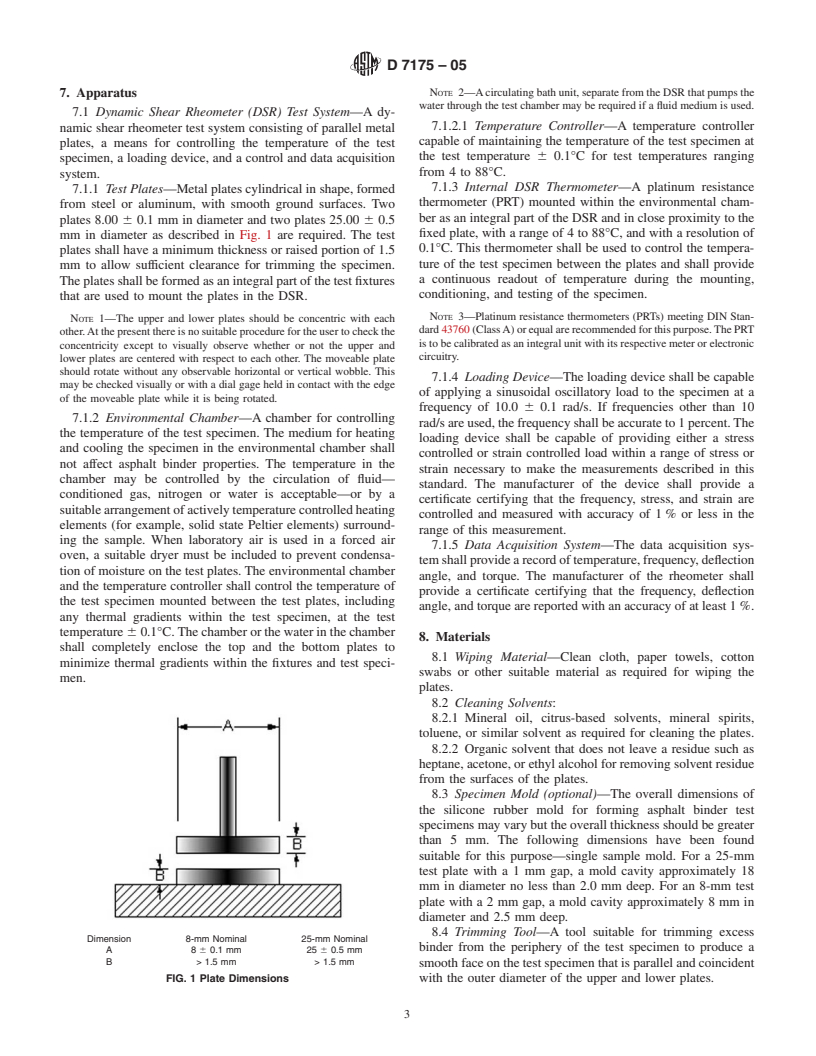

7.1.1 Test Plates—Metal plates cylindrical in shape, formed

thermometer (PRT) mounted within the environmental cham-

from steel or aluminum, with smooth ground surfaces. Two

ber as an integral part of the DSR and in close proximity to the

plates 8.00 6 0.1 mm in diameter and two plates 25.00 6 0.5

fixed plate, with a range of 4 to 88°C, and with a resolution of

mm in diameter as described in Fig. 1 are required. The test

0.1°C. This thermometer shall be used to control the tempera-

plates shall have a minimum thickness or raised portion of 1.5

ture of the test specimen between the plates and shall provide

mm to allow sufficient clearance for trimming the specimen.

a continuous readout of temperature during the mounting,

Theplatesshallbeformedasanintegralpartofthetestfixtures

conditioning, and testing of the specimen.

that are used to mount the plates in the DSR.

NOTE 3—Platinum resistance thermometers (PRTs) meeting DIN Stan-

NOTE 1—The upper and lower plates should be concentric with each

dard43760(ClassA)orequalarerecommendedforthispurpose.ThePRT

other.Atthepresentthereisnosuitableprocedurefortheusertocheckthe

istobecalibratedasanintegralunitwithitsrespectivemeterorelectronic

concentricity except to visually observe whether or not the upper and

circuitry.

lower plates are centered with respect to each other. The moveable plate

should rotate without any observable horizontal or vertical wobble. This

7.1.4 Loading Device—The loading device shall be capable

may be checked visually or with a dial gage held in contact with the edge

of applying a sinusoidal oscillatory load to the specimen at a

of the moveable plate while it is being rotated.

frequency of 10.0 6 0.1 rad/s. If frequencies other than 10

7.1.2 Environmental Chamber—A chamber for controlling

rad/sareused,thefrequencyshallbeaccurateto1percent.The

the temperature of the test specimen. The medium for heating

loading device shall be capable of providing either a stress

and cooling the specimen in the environmental chamber shall

controlled or strain controlled load within a range of stress or

not affect asphalt binder properties. The temperature in the

strain necessary to make the measurements described in this

chamber may be controlled by the circulation of fluid—

standard. The manufacturer of the device shall provide a

conditioned gas, nitrogen or water is acceptable—or by a

certificate certifying that the frequency, stress, and strain are

suitablearrangementofactivelytemperaturecontrolledheating

controlled and measured with accuracy of 1 % or less in the

elements (for example, solid state Peltier elements) surround-

range of this measurement.

ing the sample. When laboratory air is used in a forced air

7.1.5 Data Acquisition System—The data acquisition sys-

oven, a suitable dryer must be included to prevent condensa-

temshallprovidearecordoftemperature,frequency,deflection

tion of moisture on the test plates. The environmental chamber

angle, and torque. The manufacturer of the rheometer shall

and the temperature controller shall control the temperature of

provide a certificate certifying that the frequency, deflection

the test specimen mounted between the test plate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.