ASTM D5967-99a

(Test Method)Standard Test Method for Evaluation of Diesel Engine Oils in T-8 Diesel Engine

Standard Test Method for Evaluation of Diesel Engine Oils in T-8 Diesel Engine

SCOPE

1.1 This test method is commonly referred to as the Mack T-8. This test method covers an engine test procedure for evaluating diesel engine oils for performance characteristics, including viscosity increase and soot concentrations (loading).

1.2 This test method also provides the procedure for running an extended length T-8 test, which is commonly referred to as the T-8E. The procedure for the T-8E is identical to the T-8 with the exception of the items specifically listed in Annex A8. Additionally, the procedure modifications listed in Annex A8 refer to the corresponding section of the T-8 procedure.

1.3 The values stated in either SI or inch-pound units are to be regarded separately as the standard. Within the text, the inch-pound units are shown in parentheses.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Annex A5 for specific safety precautions.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 5967 – 99a

Standard Test Method for

Evaluation of Diesel Engine Oils in T-8 Diesel Engine

This standard is issued under the fixed designation D 5967; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

General Description 6.1

The Test Engine 6.2

1.1 This test method is commonly referred to as the Mack

Mack T Test Engine 6.2.1

T-8. This test method covers an engine test procedure for

Engine Cooling System 6.2.2

Engine Oil System 6.2.3

evaluating diesel engine oils for performance characteristics,

Auxiliary Oil System 6.2.4

including viscosity increase and soot concentrations (loading).

Crankcase Aspiration 6.2.5

1.2 This test method also provides the procedure for running Blowby Meter 6.2.6

Air Supply and Filtration 6.2.7

an extended length T-8 test, which is commonly referred to as

Fuel Supply 6.2.8

the T-8E and an abbreviated length test, which is commonly

Intake Manifold Temperature Control 6.2.9

referred to as T-8A. The procedures for the T-8E and the T-8A

Engine Fluids 7

Test Oils 7.1

are identical to the T-8 with the exception of the items

Test Fuel 7.2

specifically listed in Annex A8 and Annex A9 respectively.

Engine Coolant 7.3

Additionally, the procedure modifications listed in Annex A8 Cleaning Materials 7.4

Preparation of Apparatus at Rebuild 8

and Annex A9 refer to the corresponding section of the T-8

Parts Cleaning 8.1

procedure.

Cylinder Head Preparation 8.2

1.3 The values stated in either SI or inch-pound units are to Cylinder Liner, Piston, and Piston Ring Assembly 8.3

Injectors and Injection Pump 8.4

be regarded separately as the standard. Within the text, the

Assembly Instructions 8.5

inch-pound units are shown in parentheses when combined

Measurements 8.6

with SI units, and vice versa. Laboratory and Engine Test Stand Calibration/Non-Reference 9

Requirements

1.4 This standard does not purport to address all of the

Calibration Frequency 9.1

safety concerns, if any, associated with its use. It is the

Calibration Reference Oils 9.2

Test Numbering 9.3

responsibility of the user of this standard to establish appro-

New Laboratories and New Test Stands 9.4

priate safety and health practices and determine the applica-

Calibrated Laboratories and Test Stands 9.5

bility of regulatory limitations prior to use. See Annex A5 for

Calibrated Test Acceptance 9.6

specific safety precautions. Failing Calibration Tests 9.7

Non-Reference Oil Test Requirements 9.8

1.5 A Table of Contents follows:

Procedure 10

Scope 1

Pretest Procedure 10.1

Referenced Documents 2

Engine Start Up 10.2

Terminology 3

Engine Shutdown 10.3

Summary of Test Method 4

Test Cycle 10.4

Significance and Use 5

Oil Addition/Drain Procedure 10.5

Apparatus 6

Oil Samples 10.6

Oil Consumption Calculations 10.7

Fuel Samples 10.8

Periodic Measurements 10.9

Blowby 10.10

This test method is under the jurisdiction of ASTM Committee D02 on

Centrifugal Oil Filter Mass Gain 10.11

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

Oil Filter DP Calculation 10.12

D02.B on Automotive Lubricants.

Post Test 10.13

Current edition approved Dec. 10, 1999. Published February 2000.

Inspection of Fuel and Oil During Test 11

Originally published as D 5967-96. Last previous edition D 5967-99.

Oil Inspection 11.1

The American Society for Testing and Materials takes no position respecting

Fuel Inspections 11.2

the validity of any patent rights asserted in connection with any item mentioned in Oil Consumption 11.3

this standard. Users of this standard are expressly advised that determination of the Report 12

Reporting Reference Test Results 12.1

validity of any such patent rights, and the risk of infringement of such rights, are

Deviations from Test Operational Limits 12.2

entirely their own responsibility.

Electronic Transmission of Test Results 12.3

The ASTM Test Monitoring Center will update changes in this test method by

Plots of Operational Data 12.4

means of Information Letters. This edition incorporates revisions contained in all

Precision and Bias 13

information letters through 98-5. Information letters may be obtained from the

Precision 13.1

ASTM Test Monitoring Center, 6555 Penn Avenue, Pittsburgh, PA 15206-4489,

Bias 13.2

Attention: Administrator.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5967 – 99a

D 6278 Test Method for Shear Stability of Polymer-

Keywords 14

Annexes

Containing Fluids Using European Diesel Injector Appa-

Report Forms A1

ratus

Sensor Locations A2

E 29 Practice for Using Significant Digits in Test Data to

Kinematic Viscosity at 100°C Procedure A3

Enhanced Thermal Gravimetric Analysis (TGA) Procedure A4

Determine Conformance With Specifications

Procurement of Test Materials A5

E 344 Terminology Relating to Thermometry and Hydro-

Safety Precautions A6

Data Dictionary A7 mometry

T-8E Extended Length Test Requirements A8

2.2 SAE Standard:

T-8A Abbreviated Length Test Requirements A9

SAE J1995 Engine Power Test Code—Spark Ignition and

Compression Ignition—Gross Power Rating

2. Referenced Documents

2.1 ASTM Standards:

3. Terminology

D 86 Test Method for Distillation of Petroleum Products

3.1 Definitions:

D 93 Test Methods for Flash Point by Pensky-Martens

3.1.1 blind reference oil, n—a reference oil, the identity of

Closed Tester

which is unknown by the test facility. Sub. B Glossary

D 97 Test Method for Pour Point of Petroleum Products

3.1.2 blowby, n—in internal combustion engines, the com-

D 129 Test Method for Sulfur in Petroleum Products (Gen-

bustion products and unburned air-and-fuel mixture that enter

eral Bomb Method)

the crankcase. D 5302

D 130 Test Method for Detection of Copper Corrosion from

3.1.3 calibrate, v—to determine the indication or output of

Petroleum Products by the Copper Strip Tarnish Test

a measuring device with respect to that of a standard. E 344

D 287 Test Method for API Gravity of Crude Petroleum and

3.1.4 heavy-duty, adj—in internal combustion engine opera-

Petroleum Products (Hydrometer Method)

tion, characterized by average speeds, power output, and

D 445 Test Method for Kinematic Viscosity of Transparent

internal temperatures that are close to the potential maximums.

and Opaque Liquids (the Calculation of Dynamic Viscos-

D 4485

ity)

3.1.5 heavy-duty engine, n—in internal combustion engines,

D 446 Specifications and Operating Instructions for Glass

one that is designed to allow operation continuously at or close

Capillary Kinematic Viscometers

to its peak output. D 4485

D 482 Test Method for Ash from Petroleum Products

3.1.6 non-reference oil, n—any oil other than a reference

D 524 Test Method for Ramsbottom Carbon Residue of

oil; such as a research formulation, commercial oil, or candi-

Petroleum Products

date oil. Sub. B Glossary

D 613 Test Method for Cetane Number of Diesel Fuel Oil

3.1.7 non-standard test, n—a test that is not conducted in

D 1319 Test Method for Hydrocarbon Types in Liquid

conformance with the requirements in the standard test

Petroleum Products by Fluorescent Indicator Adsorption

method, such as running on an uncalibrated test stand, using

D 2500 Test Method for Cloud Point of Petroleum Prod-

different test equipment, applying different equipment assem-

ucts

bly procedures, or using modified operating conditions.

D 2622 Test Method for Sulfur in Petroleum Products by

Sub. B Glossary

X-Ray Spectrometry

3.1.8 oxidation, n—of engine oil, the reaction of the oil with

D 2709 Test Method for Water and Sediment in Middle

an electron acceptor, generally oxygen, which can produce

Distillate Fuels by Centrifuge

deleterious acidic or resinous materials often manifested as

D 4052 Test Method for Density and Relative Density of

sludge formation, varnish formation, viscosity increase, or

Liquids by Digital Density Meter

corrosion, or a combination thereof. Sub. B. Glossary

D 4485 Specification for Performance of Engine Oils

3.1.9 reference oil, n—an oil of known performance char-

D 4737 Test Method for Calculated Cetane Index by Four

acteristics, used as a basis for comparison. Sub. B Glossary

Variable Equation

3.1.9.1 Discussion—Reference oils are used to calibrate

D 5185 Test Method for Determination of Additive Ele-

testing facilities, to compare the performance of other oils, or

ments, Wear Metals, and Contaminants in Used Lubricat-

to evaluate other materials (such as seals) that interact with

ing Oils and Determination of Selected Elements in Base

oils.

Oils by Inductively Coupled Plasma Atomic Emission

3.1.10 sludge, n—in internal combustion engines, a deposit,

Spectrometry (ICP-AES)

principally composed of insoluble resins and oxidation prod-

D 5302 Test Method for Evaluation of Automotive Engine

ucts from fuel combustion and the lubricant, that does not drain

Oils for Inhibition of Deposit Formation and Wear in a

from engine parts but can be removed by wiping with a cloth.

Spark-Ignition Internal Composition Engine Fueled with

D 5302

Gasoline and Operated Under Low-Temperature, Light-

Duty Conditions

Annual Book of ASTM Standards, Vol 05.03.

Annual Book of ASTM Standards, Vol 14.02.

4 9

Annual Book of ASTM Standards, Vol 05.01. Annual Book of ASTM Standards, Vol 14.03.

5 10

Annual Book of ASTM Standards, Vol 05.04. Available from Society of Automotive Engineers, 400 Commonwealth Drive,

Annual Book of ASTM Standards, Vol 05.02. Warrendale, PA 15096-0001.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5967 – 99a

3.1.11 standard test, n—a test on a calibrated test stand, good laboratory standards. Additionally, it is recommended

using the prescribed equipment in accordance with the require- that the atmosphere in the engine buildup area be filtered and

ments in the test method, and conducted in accordance with the controlled for temperature and humidity to prevent accumula-

specified operating conditions. Sub. B Glossary tion of dirt or dust on engine parts. Uniform temperature

3.1.11.1 Discussion—The specified operating conditions in control will also aid in measuring and selecting parts for

some test methods include requirements for determining a assembly.

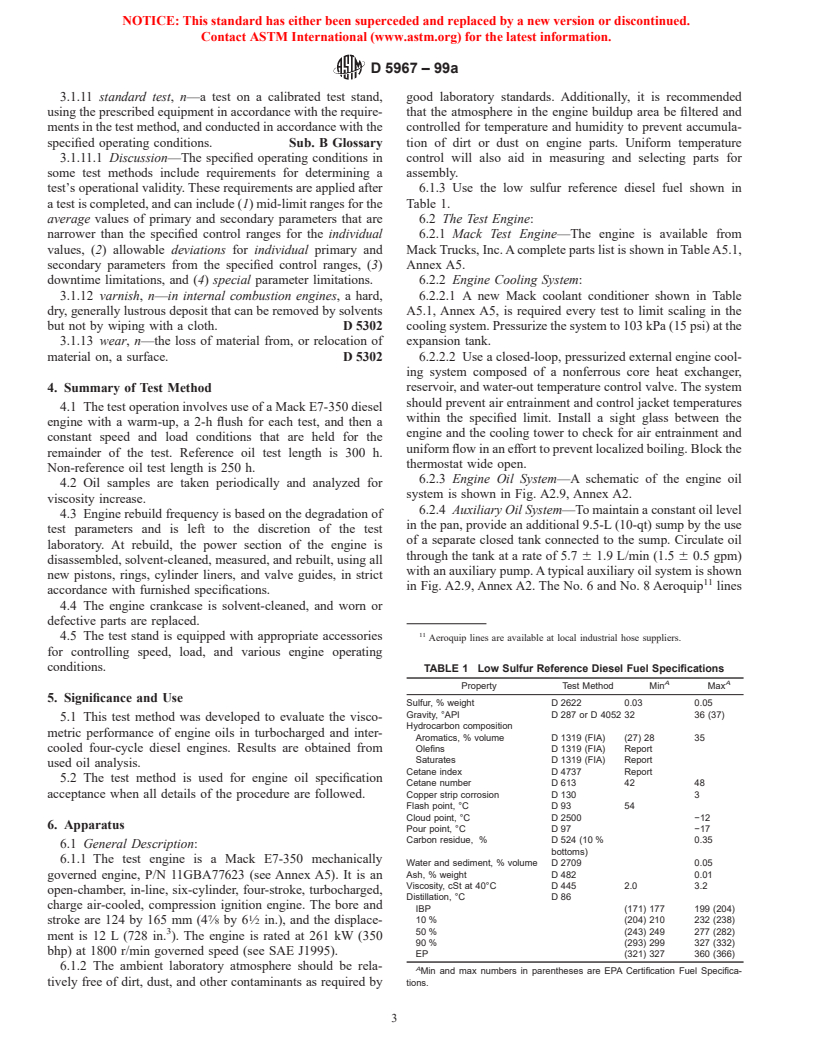

test’s operational validity. These requirements are applied after 6.1.3 Use the low sulfur reference diesel fuel shown in

a test is completed, and can include (1) mid-limit ranges for the Table 1.

average values of primary and secondary parameters that are 6.2 The Test Engine:

narrower than the specified control ranges for the individual 6.2.1 Mack Test Engine—The engine is available from

values, (2) allowable deviations for individual primary and Mack Trucks, Inc. A complete parts list is shown in Table A5.1,

secondary parameters from the specified control ranges, (3) Annex A5.

downtime limitations, and (4) special parameter limitations. 6.2.2 Engine Cooling System:

3.1.12 varnish, n—in internal combustion engines, a hard, 6.2.2.1 A new Mack coolant conditioner shown in Table

dry, generally lustrous deposit that can be removed by solvents A5.1, Annex A5, is required every test to limit scaling in the

but not by wiping with a cloth. D 5302 cooling system. Pressurize the system to 103 kPa (15 psi) at the

3.1.13 wear, n—the loss of material from, or relocation of expansion tank.

material on, a surface. D 5302 6.2.2.2 Use a closed-loop, pressurized external engine cool-

ing system composed of a nonferrous core heat exchanger,

4. Summary of Test Method reservoir, and water-out temperature control valve. The system

should prevent air entrainment and control jacket temperatures

4.1 The test operation involves use of a Mack E7-350 diesel

within the specified limit. Install a sight glass between the

engine with a warm-up, a 2-h flush for each test, and then a

engine and the cooling tower to check for air entrainment and

constant speed and load conditions that are held for the

uniform flow in an effort to prevent localized boiling. Block the

remainder of the test. Reference oil test length is 300 h.

thermostat wide open.

Non-reference oil test length is 250 h.

6.2.3 Engine Oil System—A schematic of the engine oil

4.2 Oil samples are taken periodically and analyzed for

system is shown in Fig. A2.9, Annex A2.

viscosity increase.

6.2.4 Auxiliary Oil System—To maintain a constant oil level

4.3 Engine rebuild frequency is based on the degradation of

in the pan, provide an additional 9.5-L (10-qt) sump by the use

test parameters and is left to the discretion of the test

of a separate closed tank connected to the sump. Circulate oil

laboratory. At rebuild, the power section of the engine is

through the tank at a rate of 5.7 6 1.9 L/min (1.5 6 0.5 gpm)

disassembled, solvent-cleaned, measured, and rebuilt, using all

with an auxiliary pump. A typical auxiliary oil system is shown

new pistons, rings, cylinder liners, and valve guides, in strict

in Fig. A2.9, Annex A2. The No. 6 and No. 8 Aeroquip lines

accordance with furnished specifications.

4.4 The engine crankcase is solvent-cleaned, and worn or

defective parts are replaced.

4.5 The test stand is equipped with appropriate accessories Aeroquip lines are available at local industrial hose suppliers.

for controlling speed, load, and various engine operating

conditions. TABLE 1 Low Sulfur Reference Diesel Fuel Specifications

A A

Property Test Method Min Max

5. Significance and Use

Sulfur, % weight D 2622 0.03 0.05

Gravity, °API D 287 or D 4052 32 36 (37)

5.1 This test method was developed to evaluate the visco-

Hydrocarbon composition

metric performance of engine oils in turbocharged and inter-

Aromatics, % volume D 1319 (FIA) (27) 28 35

cooled four-cycle diesel engines. Results are obtained from

Olefins D 1319 (FIA) Report

Saturates D 1319 (FIA) Report

used oil analysis.

Cetane index D 4737 Report

5.2 The test method is used for engine oil specification

Cetane number D 613 42 48

acceptance when all details of the procedure are followed. Copper strip corrosion D 130 3

Flash point, °C D 93 54

Cloud point, °C D 2500 −12

6. Apparatus

Pour point, °C D 97 −17

Carbon residue, % D 524 (10 % 0.35

6.1 General Description:

bottoms)

6.1.1 The test engine is a Mack E7-350 mechanically

Water and sediment, % vo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.