ASTM D4893-94(2004)

(Test Method)Standard Test Method for Determination of Pitch Volatility

Standard Test Method for Determination of Pitch Volatility

SIGNIFICANCE AND USE

This test is useful in evaluating and characterizing pitch physical properties in comparing the consistency of shipments and sources of supply.

SCOPE

1.1 This test method covers the determination of the percent of pitch volatility.

1.2 Since this test method is empirical, strict adherence of the procedure is necessary.

1.3 The values stated in the SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4893–94 (Reapproved 2004)

Standard Test Method for

Determination of Pitch Volatility

This standard is issued under the fixed designation D4893; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope inserted into the thermowell No. 1 near the center of the block.

A proportional temperature controller regulates the heat input.

1.1 This test method covers the determination of the percent

Two insulated handles are attached to this part for easy

of pitch volatility.

handling.An additional thermowell No. 2, located in the center

1.2 Since this test method is empirical, strict adherence to

of the block, accommodates another thermocouple used only

the procedure is necessary.

for the determination of the rate of temperature rise of the

1.3 The values stated in SI units are to be regarded as the

pitch. When the screw at the bottom of the No. 2 well is taken

standard.

out, the thermocouple can then be pushed down and inserted in

1.4 This standard does not purport to address all of the

pitch.

safety concerns, if any, associated with its use. It is the

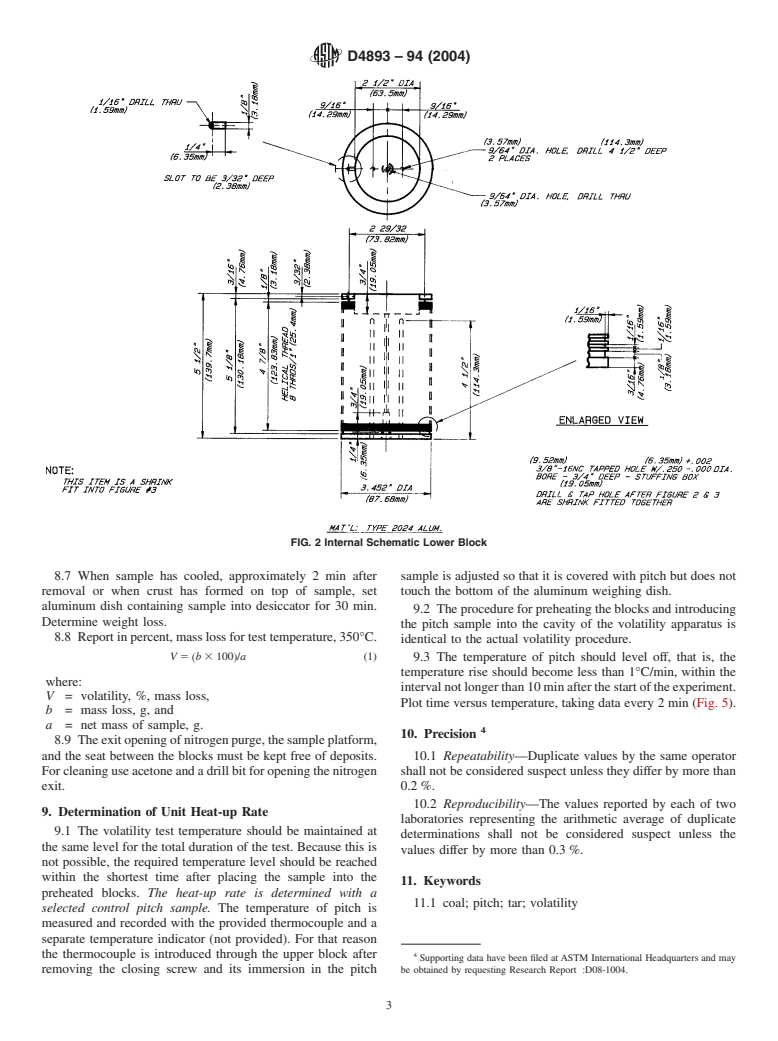

4.1.2 The bottom block has a cavity for the aluminum

responsibility of the user of this standard to establish appro-

weighingdish.Aspiralchannelcutaroundtheperipheryofthis

priate safety and health practices and determine the applica-

part serves for preheating the nitrogen introduced at the

bility of regulatory limitations prior to use.

measured rate (10 cm /min) into the block for purging vola-

2. Summary of Test Method tiles.

4.1.3 The test temperature, the same as that in the top block,

2.1 An aluminum weighing dish with about 15 g of speci-

is maintained by the second proportional temperature control-

men is introduced into the cavity of a metal block heated and

ler according to the signals of a thermocouple inserted in a

maintained at 350°C (662°F). After 30 min 6 10 s during

thermowell No. 3 of the bottom block. There is a hole in the

which the volatiles are swept away from the surface of the

center of the bottom cylinder to accommodate the sample

liquid pitch by preheated nitrogen, the sample is taken out and

platform, a rod with a stainless steel disk welded to its top.The

allowed to cool down in the desiccator. The pitch volatility is

aluminum sample dish containing the sample rests on top of

determined by the sample weight loss and reported as percent

this disk during the test. The aluminum sample dish can be

weight loss.

lifted out of the cavity by raising the disk up to the upper rim

3. Significance and Use

of the cavity.

4.2 Aluminum Weighing Dish.

3.1 This test is useful in evaluating and characterizing pitch

4.3 Flowmeter, 0 to 25-cm /min range.

physical properties in comparing the consistency of shipments

4.4 Nitrogen Cylinder, equipped with a pressure regulator.

and sources of supply.

4.5 Timer, with an alarm.

4. Apparatus

4.6 Aluminum Plate, 5-by-5-in., approximately 20-gage.

4.1 Aluminum Block, 4 ⁄2-in. outside diameter, composed

5. Dehydration of Sample

of two sections (Figs. 1-4).

5.1 Hard Pitch—If the solid bulk sample contains free

4.1.1 The top block is maintained at a chosen constant

water, air-dry a representative portion in a forced-draft oven at

temperature according to the signal from the thermocouple

50°C (122°F).

5.2 Soft Pitch (Softening Point <60°C (<140°F))—If the

This test method is under the jurisdiction of ASTM Committee D02 on

presence of water is indicated by surface foam on heating,

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

maintain a representative portion of the bulk sample at a

D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material.

Current edition approved Nov. 1, 2004. Published November 2004. Originally

temperature between 125 and 150°C (251 and 302°F) in an

approved in 1989. Last previous edition approved in 1999 as D4893 – 94 (1999).

open container until the surface is free of foam. Take care not

DOI: 10.1520/D4893-94R04.

2 to overheat, and remove heat source immediately when foam

An aluminum block that may be obtained on special order from Koppers

Company, Inc., 1005 Wm. Pitt Way, Pittsburgh, PA 15238, has been found subsides.

satisfactory for this purpose; or drawings of block will be furnished by Koppers

upon request. If you are aware of alternative suppliers, please provide this

information to ASTM International Headquarters. Your comments will receive

careful consideration at a meeting of the responsible technical committee , which Fisher Catalog Number 08-732 or VWR Scientific Catalog Number 25433-008

you may attend. has been found satisfactory for this purpose.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4893–94 (2004)

FIG. 1 Schematic of the Volatility Apparatus

6. Preparation of Working Sample 8.4 Remove top block. Raise the sample platform up

slightly above the rim of heating cavity and support with the

6.1 Crush sample to pass No. 4 mesh (4760 µm).

aluminum plate inserted between the sample platform and top

7. P

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.