ASTM D6546-23

(Test Method)Standard Test Methods for and Suggested Limits for Determining Compatibility of Elastomer Seals for Industrial Hydraulic Fluid Applications

Standard Test Methods for and Suggested Limits for Determining Compatibility of Elastomer Seals for Industrial Hydraulic Fluid Applications

SIGNIFICANCE AND USE

4.1 When more than one elastomer seal material is tested, the test methods yield comparative data on which to base judgements as to expected service quality. Suggested in-service property change limits are provided. Property changes beyond these limits will indicate limited service life of the elastomer seal.

4.2 These test methods attempt to simulate service conditions through controlled aging and evaluation of property changes but may not give any direct correlations with actual part performance since actual service conditions vary widely. These test methods yield comparative data and indications of property changes of the elastomeric seal material under ideal service conditions. These test methods can be used for quality control purposes, for engineering assessments, for service evaluation, and for manufacturing control. The information from these test methods can be used to anticipate expected service quality.

SCOPE

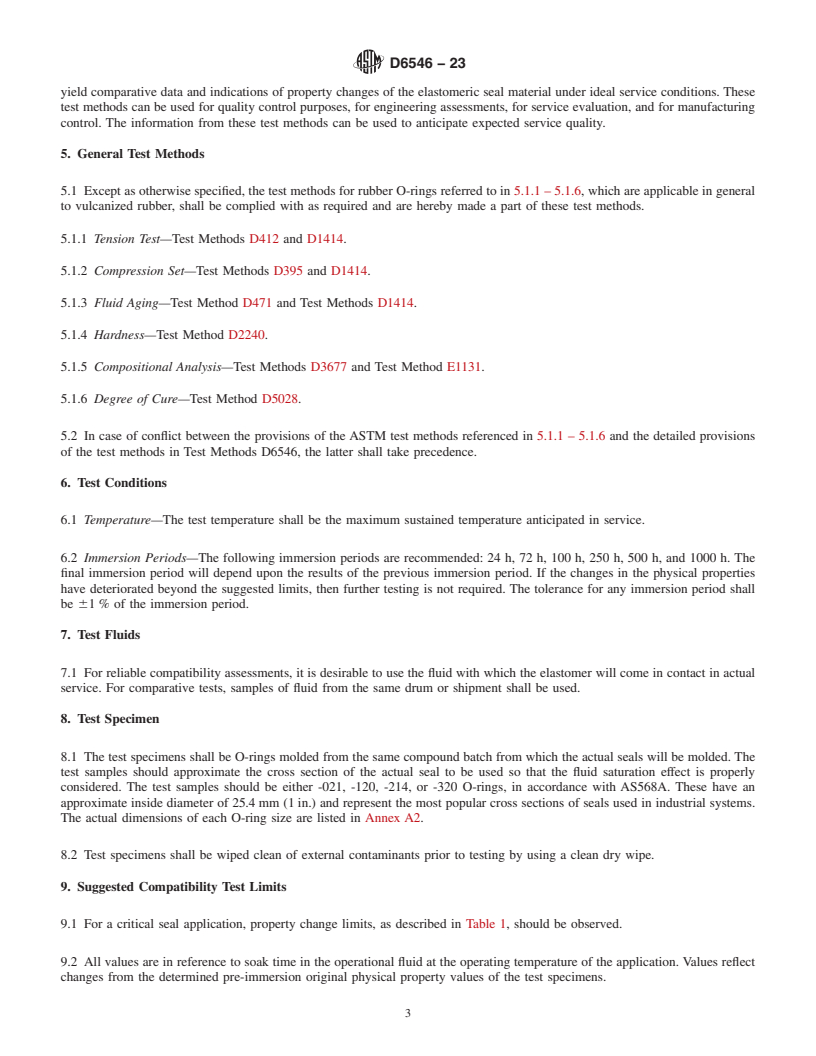

1.1 These test methods cover the procedure for measuring physical properties of elastomer seals in the form of O-rings after exposure to industrial hydraulic fluids and thermal aging. The measured properties are then compared to the physical properties of elastomer seals that have not been exposed to the industrial hydraulic fluids and thermal aging. The changes in these properties form a basis for assessing compatibility when these changes are compared against the suggested limits in Table 1.

1.2 While these test methods involve the use of O-rings, they can also be used to evaluate the compatibility of the elastomeric compounds of specialty seals with industrial hydraulic fluids and their resistance to thermal aging. The compounds can be molded into O-rings for evaluation purposes.

1.3 These test methods provide procedures for exposing O-ring test specimens to industrial hydraulic fluids under definite conditions of temperature and time. The resulting deterioration of the O-ring material is determined by comparing the changes in work function, hardness, physical properties, compression set, and seal volume after immersion in the test fluid to the pre-immersion values.

1.4 The values stated in SI units are to be regarded as the standard.

1.4.1 Exception—The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6546 − 23

Standard Test Methods for

and Suggested Limits for Determining Compatibility of

1

Elastomer Seals for Industrial Hydraulic Fluid Applications

This standard is issued under the fixed designation D6546; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

1.1 These test methods cover the procedure for measuring

Barriers to Trade (TBT) Committee.

physical properties of elastomer seals in the form of O-rings

after exposure to industrial hydraulic fluids and thermal aging.

2. Referenced Documents

The measured properties are then compared to the physical

2

2.1 ASTM Standards:

properties of elastomer seals that have not been exposed to the

D395 Test Methods for Rubber Property—Compression Set

industrial hydraulic fluids and thermal aging. The changes in

D412 Test Methods for Vulcanized Rubber and Thermoplas-

these properties form a basis for assessing compatibility when

tic Elastomers—Tension

these changes are compared against the suggested limits in

D471 Test Method for Rubber Property—Effect of Liquids

Table 1.

D1414 Test Methods for Rubber O-Rings

1.2 While these test methods involve the use of O-rings,

D2000 Classification System for Rubber Products in Auto-

they can also be used to evaluate the compatibility of the

motive Applications

elastomeric compounds of specialty seals with industrial hy-

D2240 Test Method for Rubber Property—Durometer Hard-

draulic fluids and their resistance to thermal aging. The

ness

compounds can be molded into O-rings for evaluation pur-

D3677 Test Methods for Rubber—Identification by Infrared

poses.

Spectrophotometry

1.3 These test methods provide procedures for exposing D3767 Practice for Rubber—Measurement of Dimensions

O-ring test specimens to industrial hydraulic fluids under

D4175 Terminology Relating to Petroleum Products, Liquid

definite conditions of temperature and time. The resulting Fuels, and Lubricants

deterioration of the O-ring material is determined by compar-

D5028 Test Method for Curing Properties of Pultrusion

ing the changes in work function, hardness, physical

Resins by Thermal Analysis

properties, compression set, and seal volume after immersion

E1131 Test Method for Compositional Analysis by Thermo-

in the test fluid to the pre-immersion values.

gravimetry

3

2.2 SAE Standard:

1.4 The values stated in SI units are to be regarded as the

AS568A O-ring Sizes

standard.

1.4.1 Exception—The values given in parentheses are for

3. Terminology

information only.

3.1 Definitions:

1.5 This standard does not purport to address all of the

3.1.1 For definitions of terms used in this test method, refer

safety concerns, if any, associated with its use. It is the

to Terminology D4175.

responsibility of the user of this standard to establish appro-

3.2 Definitions of Terms Specific to This Standard:

priate safety, health, and environmental practices and deter-

3.2.1 batch, n—all the O-rings molded from the same lot of

mine the applicability of regulatory limitations prior to use.

material and presented for inspection at one time.

1.6 This international standard was developed in accor-

3.2.2 compound, n—a fully formulated elastomer material

dance with internationally recognized principles on standard-

containing all fillers and cross-linking agents.

ization established in the Decision on Principles for the

1 2

These test methods are under the jurisdiction of ASTM Committee D02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D02.N0 on Hydraulic Fluids. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2023. Published July 2023. Originally approved the ASTM website.

3

in 2000. Last previous edition approved in 2015 as D6546 – 15. DOI: 10.1520/ Available from Society of Automotive Engineers, 400 Commonwealth Drive,

D6546-23. Warrendale, PA 15096.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6546 − 23

TABLE 1 Property Change Limits

Time,

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6546 − 15 D6546 − 23

Standard Test Methods for

and Suggested Limits for Determining Compatibility of

1

Elastomer Seals for Industrial Hydraulic Fluid Applications

This standard is issued under the fixed designation D6546; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 These test methods cover the procedure for measuring physical properties of elastomer seals in the form of O-rings after

exposure to industrial hydraulic fluids and thermal aging. The measured properties are then compared to the physical properties

of elastomer seals that have not been exposed to the industrial hydraulic fluids and thermal aging. The changes in these properties

form a basis for assessing compatibility when these changes are compared against the suggested limits in Table 1.

1.2 While these test methods involve the use of O-rings, they can also be used to evaluate the compatibility of the elastomeric

compounds of specialty seals with industrial hydraulic fluids and their resistance to thermal aging. The compounds can be molded

into O-rings for evaluation purposes.

1.3 These test methods provide procedures for exposing O-ring test specimens to industrial hydraulic fluids under definite

conditions of temperature and time. The resulting deterioration of the O-ring material is determined by comparing the changes in

work function, hardness, physical properties, compression set, and seal volume after immersion in the test fluid to the

pre-immersion values.

1.4 The values stated in SI units are to be regarded as the standard.

1.4.1 Exception—The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D395 Test Methods for Rubber Property—Compression Set

D412 Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

1

These test methods are under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.N0 on Hydraulic Fluids.

Current edition approved Dec. 1, 2015July 1, 2023. Published February 2016July 2023. Originally approved in 2000. Last previous edition approved in 20102015 as

D6546 – 00 (2010).D6546 – 15. DOI: 10.1520/D6546-15.10.1520/D6546-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6546 − 23

TABLE 1 Property Change Limits

Time, h Maximum Maximum Hardness Maximum Maximum Maximum Maximum

Volume Volume Change, Tensile Elongation Work Compression

Swell, Shrinkage, Shore A Strength Change, Function Set, %

% % Points Change, % Change,

% %

24 15 −3 ±7 −20 −20 ±12 . . .

70 15 −3 ±7 −20 −20 ±12 20

100 15 −3 ±8 −20 −20 ±12 20

250 15 −4 ±8 −20 −20 ±12 25

500 20 −4 ±10 −25 −25 ±17 30

1000 20 −5 ±10 −30 −30 ±20 35

D471 Test Method for Rubber Property—Effect of Liquids

D1414 Test Methods for Rubber O-Rings

D2000 Classification System for Rubber Products in Automotive Applications

D2240 Test Method for Rubber Property—Durometer Hardness

D3677 Test Methods for Rubber—Identification by Infrared Spectrophotometry

D3767 Practice for Rubber—Measurement of Dimensions

D4175 Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants

D5028 Test Method for Curing Properties of Pultrusion Resins by Thermal Analysis

E1131 Tes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.