ASTM D5301-92(1997)

(Practice)Standard Practice for Physical Characterization of Paint Brushes

Standard Practice for Physical Characterization of Paint Brushes

SCOPE

1.1 This practice covers the dimensions, terminology, materials and characteristics generally considered of importance to those within, or dealing with paint brushes, and describes methods of determining these parameters. This practice is not meant to be a definitive analytical method to deformulate brushes.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: D 5301 – 92 (Reapproved l997)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

Physical Characterization of Paint Brushes

This standard is issued under the fixed designation D 5301; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the dimensions, terminology, ma-

terials and characteristics generally considered of importance

to those within, or dealing with paint brushes, and describes

methods of determining these parameters. This practice is not

meant to be a definitive analytical method to deformulate

brushes.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Terminology

2.1 Definitions:

2.1.1 chisel (or chiseled)—a description of the configura-

tion of the tip of the brush as being of a more or less convex

shape across the thickness dimension.

2.1.2 flat tip—a description of the configuration of the tip of

the brush as being flat or of uniform length across the thickness

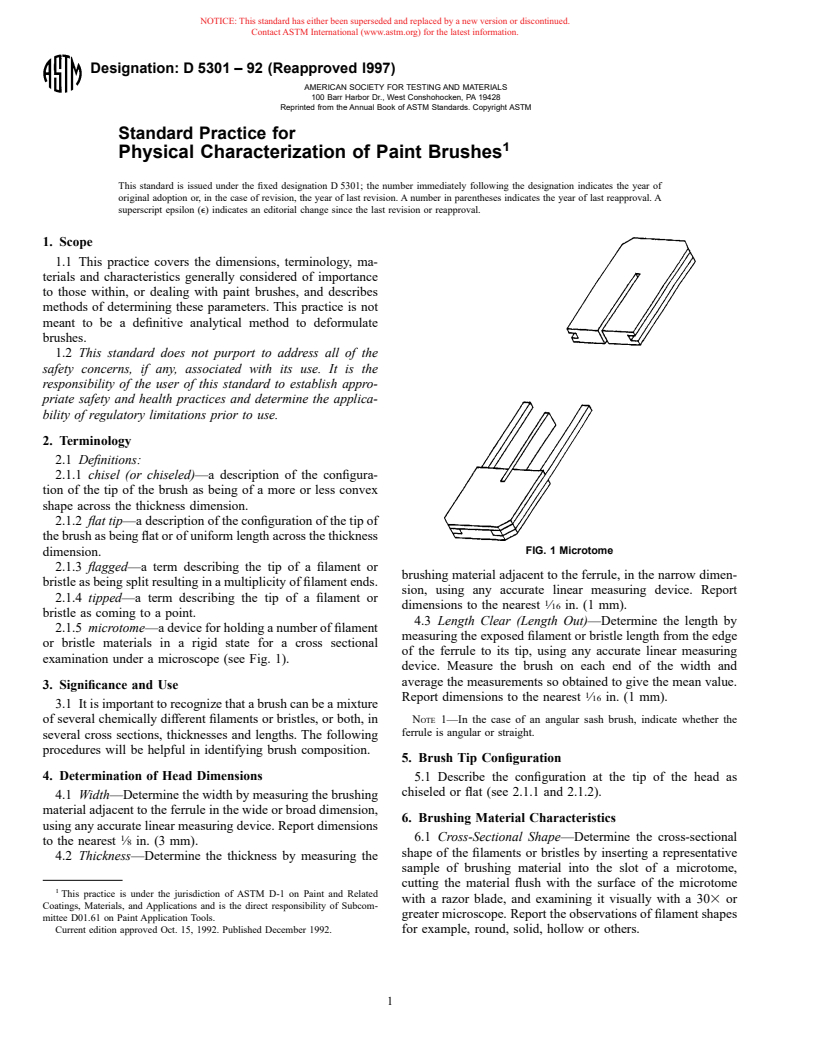

FIG. 1 Microtome

dimension.

2.1.3 flagged—a term describing the tip of a filament or

brushing material adjacent to the ferrule, in the narrow dimen-

bristle as being split resulting in a multiplicity of filament ends.

sion, using any accurate linear measuring device. Report

2.1.4 tipped—a term describing the tip of a filament or

dimensions to the nearest ⁄16 in. (1 mm).

bristle as coming to a point.

4.3 Length Clear (Length Out)—Determine the length by

2.1.5 microtome—a device for holding a number of filament

measuring the exposed filament or bristle length from the edge

or bristle materials in a rigid state for a cross sectional

of the ferrule to its tip, using any accurate linear measuring

examination under a microscope (see Fig. 1).

device. Measure the brush on each end of the width and

average the measurements so obtained to give the mean value.

3. Significance and Use

Report dimensions to the nearest ⁄16 in. (1 mm).

3.1 It is important to recognize that a brush can be a mixture

of several chemically different filaments or bristles, or both, in NOTE 1—In the case of an angular sash brush, indicate whether the

ferrule is angular or straight.

several cross sections, thicknesses and lengths. The following

procedures will be helpful in identifying brush composition.

5. Brush Tip Configuration

4. Determination of Head Dimensions

5.1 Describe the configuration at the tip of the head as

chiseled or flat (see 2.1.1 and 2.1.2).

4.1 Width—Determine the width by measuring the brushing

material adjacent to the ferrule in the wide or broad dimension,

6. Brushing Material Characteristics

using any accurate linear measuring device. Report dimensions

1 6.1 Cross-Sectional Shape—Determine the cross-sectional

to the nearest ⁄8 in. (3 mm).

shape of the filaments or bristles by inserting a representative

4.2 Thickness—Determine the thickness by measuring the

sample of brushing material into the slot of a microtome,

cutting the material flush with the surface of the microtome

This practice is under the jurisdiction of ASTM D-1 on Paint and Related

with a razor blade, and examining it visually with a 303 or

Coatings, Materials, and Applications and is the direct responsibility of Subcom-

greater microscope. Report the observations of filament shapes

mittee D01.61 on Paint Application Tools.

Current edition approved Oct. 15, 1992. Published December 1992. for example, round, solid, hollow or others.

D 5301

6.2 Filament or Bristle Length—Determine the lengths of 7.1.3 Measure dimension across the closed part of the

the filaments or bristles used in a brush by opening the ferrule ferrule (height) to the nearest ⁄16in. (1 mm).

and removing the filaments from that portion of the brush 7.2 Ferrule Material:

unaffect

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.