ASTM B215-20

(Practice)Standard Practices for Sampling Metal Powders

Standard Practices for Sampling Metal Powders

SIGNIFICANCE AND USE

4.1 Specifications and test methods for metal powders and metal powder products require the sampling, testing, and performance evaluation of small samples taken from large quantities of powder. The sampling procedure is equally as important as the testing and evaluation; the sampling methods used must include every precaution to ensure that the samples obtained will show the true nature and condition of the large powder quantity that they represent.

4.2 The primary objective of any sampling procedure is to obtain a small quantity of material that is truly representative of the larger amount from which it is taken, a condition that is readily comprehended but difficult to define, quantify, and prove. Certain criteria are desirable to meet this condition:3

4.2.1 Every sampling increment should have a non-zero probability of being selected.

4.2.2 All increments should have an equal probability of being selected.

4.2.3 The sampling procedure should not alter the material (for example, by changing the particle size or chemical composition).

4.3 Sampling a moving powder helps to satisfy these criteria; therefore, Practice 1A should be used whenever possible to obtain the composite sample. Similarly, Practice 2 should be used to obtain the test portions; use of a spinning riffler is preferred when possible and practicable.

4.4 Although not always meeting all the criteria of 4.2.1 – 4.2.3, the other sampling practices described in this standard are based on time-proven experience in the PM industry in sampling granular metal powders. These practices have been shown to produce samples that give reliable and representative evaluation data.

4.5 Since many tests are performed using very small amounts of powder meant to represent much larger quantities, it is most important that the test portions be obtained in a standardized manner. The practices described here take into account the possibility of segregation of the metal powder during and after filling of ...

SCOPE

1.1 These practices cover sampling methods used to collect a small quantity of metal powder that is as representative of the entire starting material as possible, and detail the procedures that are recommended for reducing this quantity into smaller test portions on which chemical, physical, and mechanical property data may be determined.

1.2 Several sampling practices are described, depending on their applicability to the conditions of storage and transport of the sampled powders:

1.2.1 Practice 1A (Described in Section 6)—Applicable to sampling moving powders, as when being transferred from one container to another or to a process stream; or when falling from a conveyor; or in a moving process stream. This is the preferred practice for obtaining the several increments that are combined to form the gross sample.

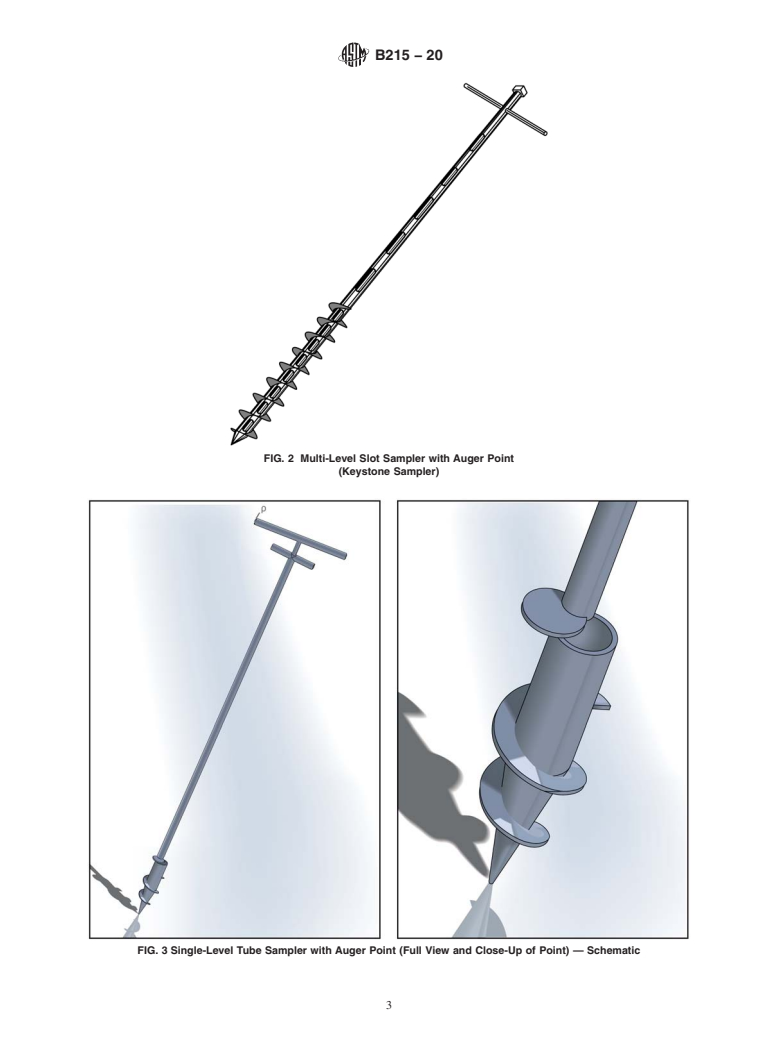

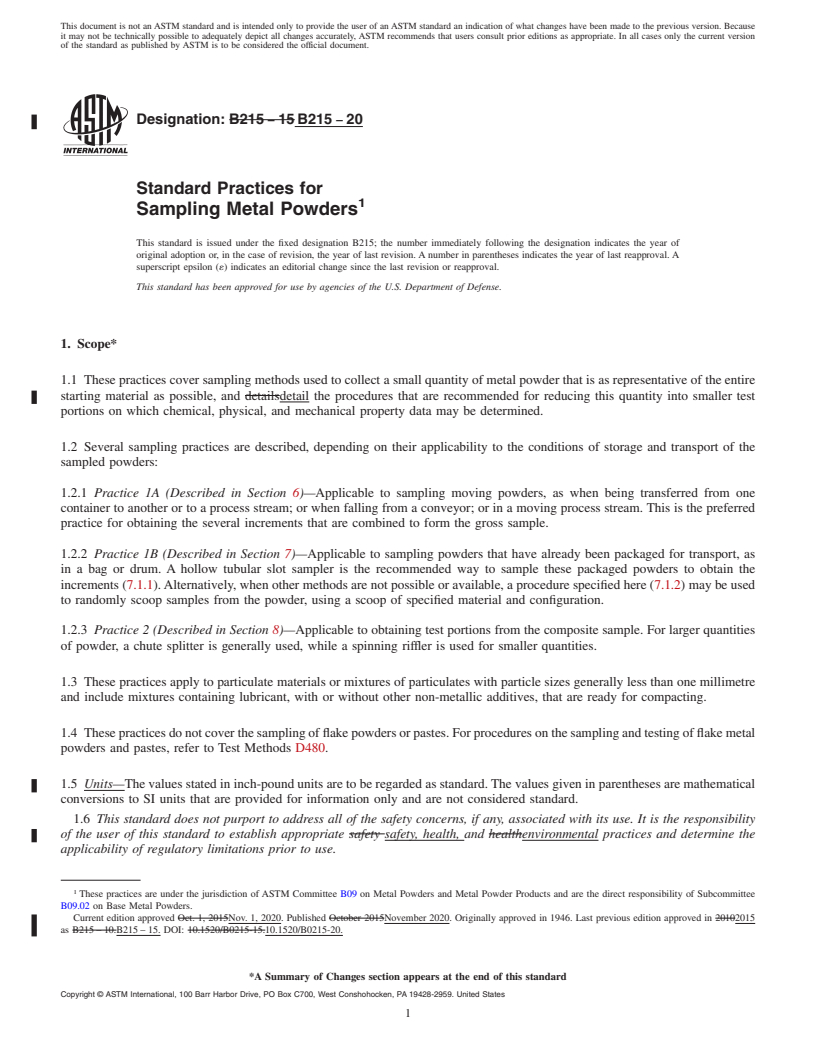

1.2.2 Practice 1B (Described in Section 7)—Applicable to sampling powders that have already been packaged for transport, as in a bag or drum. A hollow tubular slot sampler is the recommended way to sample these packaged powders to obtain the increments (7.1.1). Alternatively, when other methods are not possible or available, a procedure specified here (7.1.2) may be used to randomly scoop samples from the powder, using a scoop of specified material and configuration.

1.2.3 Practice 2 (Described in Section 8)—Applicable to obtaining test portions from the composite sample. For larger quantities of powder, a chute splitter is generally used, while a spinning riffler is used for smaller quantities.

1.3 These practices apply to particulate materials or mixtures of particulates with particle sizes generally less than one millimetre and include mixtures containing lubricant, with or without other non-metallic additives, that are ready for compacting.

1.4 These practices do not cover the sampling of flake powders or pastes. For procedures on the sampling and testing of flake metal powders and pastes, ...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B215 − 20

Standard Practices for

1

Sampling Metal Powders

This standard is issued under the fixed designation B215; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 1.5 Units—The values stated in inch-pound units are to be

regarded as standard. The values given in parentheses are

1.1 These practices cover sampling methods used to collect

mathematical conversions to SI units that are provided for

asmallquantityofmetalpowderthatisasrepresentativeofthe

information only and are not considered standard.

entire starting material as possible, and detail the procedures

that are recommended for reducing this quantity into smaller 1.6 This standard does not purport to address all of the

test portions on which chemical, physical, and mechanical safety concerns, if any, associated with its use. It is the

property data may be determined. responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

1.2 Several sampling practices are described, depending on

mine the applicability of regulatory limitations prior to use.

their applicability to the conditions of storage and transport of

1.7 This international standard was developed in accor-

the sampled powders:

dance with internationally recognized principles on standard-

1.2.1 Practice 1A (Described in Section 6)—Applicable to

ization established in the Decision on Principles for the

samplingmovingpowders,aswhenbeingtransferredfromone

Development of International Standards, Guides and Recom-

container to another or to a process stream; or when falling

mendations issued by the World Trade Organization Technical

from a conveyor; or in a moving process stream. This is the

Barriers to Trade (TBT) Committee.

preferred practice for obtaining the several increments that are

combined to form the gross sample.

2. Referenced Documents

1.2.2 Practice 1B (Described in Section 7)—Applicable to

2

sampling powders that have already been packaged for

2.1 ASTM Standards:

transport, as in a bag or drum.Ahollow tubular slot sampler is

B243 Terminology of Powder Metallurgy

the recommended way to sample these packaged powders to

D480 Test Methods for Sampling and Testing of Flaked

obtain the increments (7.1.1). Alternatively, when other meth-

Aluminum Powders and Pastes

ods are not possible or available, a procedure specified here

(7.1.2) may be used to randomly scoop samples from the

3. Terminology

powder, using a scoop of specified material and configuration.

3.1 Definitions—Definitions of powder metallurgy terms

1.2.3 Practice 2 (Described in Section 8)—Applicable to

can be found in Terminology B243. Additional descriptive

obtaining test portions from the composite sample. For larger

information is available in the Related Materials section of Vol

quantities of powder, a chute splitter is generally used, while a

02.05 of the Annual Book of ASTM Standards.

spinning riffler is used for smaller quantities.

3.2 Definitions of Terms Specific to This Standard:

1.3 These practices apply to particulate materials or mix-

3.2.1 See Fig. 1 for the terms hereinafter defined.

tures of particulates with particle sizes generally less than one

3.2.2 composite sample, n—blended entire gross sample.

millimetre and include mixtures containing lubricant, with or

without other non-metallic additives, that are ready for com-

3.2.3 increment, n—quantity of powder obtained by a sam-

pacting.

pling device at one time from a larger quantity of powder.

1.4 These practices do not cover the sampling of flake

3.2.4 gross sample, n—totalquantityofpowderadequatefor

powders or pastes. For procedures on the sampling and testing

the intended purpose(s), consisting of all the increments

of flake metal powders and pastes, refer toTest Methods D480.

combined.

1

These practices are under the jurisdiction of ASTM Committee B09 on Metal

Powders and Metal Powder Products and are the direct responsibility of Subcom-

2

mittee B09.02 on Base Metal Powders. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2020. Published November 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1946. Last previous edition approved in 2015 as B215 – 15. DOI: Standards volume information, refer to the standard’s Document

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B215 − 15 B215 − 20

Standard Practices for

1

Sampling Metal Powders

This standard is issued under the fixed designation B215; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 These practices cover sampling methods used to collect a small quantity of metal powder that is as representative of the entire

starting material as possible, and detailsdetail the procedures that are recommended for reducing this quantity into smaller test

portions on which chemical, physical, and mechanical property data may be determined.

1.2 Several sampling practices are described, depending on their applicability to the conditions of storage and transport of the

sampled powders:

1.2.1 Practice 1A (Described in Section 6)—Applicable to sampling moving powders, as when being transferred from one

container to another or to a process stream; or when falling from a conveyor; or in a moving process stream. This is the preferred

practice for obtaining the several increments that are combined to form the gross sample.

1.2.2 Practice 1B (Described in Section 7)—Applicable to sampling powders that have already been packaged for transport, as

in a bag or drum. A hollow tubular slot sampler is the recommended way to sample these packaged powders to obtain the

increments (7.1.1). Alternatively, when other methods are not possible or available, a procedure specified here (7.1.2) may be used

to randomly scoop samples from the powder, using a scoop of specified material and configuration.

1.2.3 Practice 2 (Described in Section 8)—Applicable to obtaining test portions from the composite sample. For larger quantities

of powder, a chute splitter is generally used, while a spinning riffler is used for smaller quantities.

1.3 These practices apply to particulate materials or mixtures of particulates with particle sizes generally less than one millimetre

and include mixtures containing lubricant, with or without other non-metallic additives, that are ready for compacting.

1.4 These practices do not cover the sampling of flake powders or pastes. For procedures on the sampling and testing of flake metal

powders and pastes, refer to Test Methods D480.

1.5 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1

These practices are under the jurisdiction of ASTM Committee B09 on Metal Powders and Metal Powder Products and are the direct responsibility of Subcommittee

B09.02 on Base Metal Powders.

Current edition approved Oct. 1, 2015Nov. 1, 2020. Published October 2015November 2020. Originally approved in 1946. Last previous edition approved in 20102015

as B215 – 10.B215 – 15. DOI: 10.1520/B0215-15.10.1520/B0215-20.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B215 − 20

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B243 Terminology of Powder Metallurgy

D480 Test Methods for Sampling and Testing of Flaked Aluminum Powders and Pastes

3. Terminology

3.1 Definitions—Definitions of powder metallurgy terms can be found in Terminology B243. Additional descriptive information

is available in the Related Materials section of Vol 02.05 of the Annual Book of ASTM Standards.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 See Fig. 1 for the terms hereinafter defined.

3.2.2 composite sample—sa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.