ASTM B988-18(2022)

(Specification)Standard Specification for Powder Metallurgy (PM) Titanium and Titanium Alloy Structural Components

Standard Specification for Powder Metallurgy (PM) Titanium and Titanium Alloy Structural Components

ABSTRACT

This specification covers powder metallurgy (PM) structural components fabricated from commercially pure (CP) (that is, unalloyed) titanium powder, pre-alloyed powders, and mixtures of elemental powders or mixtures of elemental powders and pre-alloyed powders. It addresses ordering information, materials and manufacture, chemical composition requirements, tensile requirements, physical properties, mechanical properties, dimensions, mass, permissible variations, sampling, inspection, and certification.

SCOPE

1.1 This specification covers powder metallurgy (PM) structural components fabricated from:

1.1.1 Commercially pure (CP) (that is, unalloyed) titanium powder,

1.1.2 Pre-alloyed powders.

1.1.3 Mixtures of elemental powders or mixtures of elemental powders and pre-alloyed powders.

1.2 This specification covers:

1.2.1 Grade 1 PM—Unalloyed titanium,

1.2.2 Grade 2 PM—Unalloyed titanium,

1.2.3 Grade 3 PM—Unalloyed titanium,

1.2.4 Grade 4 PM—Unalloyed titanium,

1.2.5 Grade 5 PM—Titanium alloy (6 % aluminum, 4 % vanadium),

1.2.6 Grade 9 PM—Titanium alloy (3 % aluminum, 2.5 % vanadium),

1.2.7 Ti-6Al-4V PM Low Interstitial (LI),

1.2.8 Ti-6Al-6V-2Sn PM.

1.3 The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B988 −18 (Reapproved 2022)

Standard Specification for

Powder Metallurgy (PM) Titanium and Titanium Alloy

Structural Components

This standard is issued under the fixed designation B988; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 Thisspecificationcoverspowdermetallurgy(PM)struc-

tural components fabricated from:

2. Referenced Documents

1.1.1 Commercially pure (CP) (that is, unalloyed) titanium

powder, 2.1 ASTM Standards:

1.1.2 Pre-alloyed powders. B243 Terminology of Powder Metallurgy

B311 Test Method for Density of Powder Metallurgy (PM)

1.1.3 Mixturesofelementalpowdersormixturesofelemen-

tal powders and pre-alloyed powders. Materials Containing Less Than Two Percent Porosity

B348 Specification for Titanium and Titanium Alloy Bars

1.2 This specification covers:

and Billets

1.2.1 Grade 1 PM—Unalloyed titanium,

B923 Test Method for Metal Powder Skeletal Density by

1.2.2 Grade 2 PM—Unalloyed titanium,

Helium or Nitrogen Pycnometry

1.2.3 Grade 3 PM—Unalloyed titanium,

B962 Test Methods for Density of Compacted or Sintered

1.2.4 Grade 4 PM—Unalloyed titanium,

Powder Metallurgy (PM) Products Using Archimedes’

1.2.5 Grade 5 PM—Titanium alloy (6 % aluminum, 4 %

Principle

vanadium),

E8/E8M Test Methods for Tension Testing of Metallic Ma-

1.2.6 Grade 9 PM—Titanium alloy (3 % aluminum, 2.5 %

terials

vanadium),

E29 Practice for Using Significant Digits in Test Data to

1.2.7 Ti-6Al-4V PM Low Interstitial (LI),

Determine Conformance with Specifications

1.2.8 Ti-6Al-6V-2Sn PM.

E539 Test Method for Analysis of Titanium Alloys by

WavelengthDispersiveX-RayFluorescenceSpectrometry

1.3 The values stated in SI units are to be regarded as the

E1409 Test Method for Determination of Oxygen and Nitro-

standard. No other units of measurement are included in this

gen in Titanium and TitaniumAlloys by Inert Gas Fusion

standard.

E1447 Test Method for Determination of Hydrogen in Re-

1.4 This standard does not purport to address all of the

active Metals and Reactive Metal Alloys by Inert Gas

safety concerns, if any, associated with its use. It is the

Fusion with Detection by Thermal Conductivity or Infra-

responsibility of the user of this standard to establish appro-

red Spectrometry

priate safety, health, and environmental practices and deter-

E1941 Test Method for Determination of Carbon in Refrac-

mine the applicability of regulatory limitations prior to use.

tory andReactive Metals andTheirAlloys byCombustion

1.5 This international standard was developed in accor-

Analysis

dance with internationally recognized principles on standard-

E2371 Test Method for Analysis of Titanium and Titanium

ization established in the Decision on Principles for the

Alloys by Direct Current Plasma and Inductively Coupled

Development of International Standards, Guides and Recom-

Plasma Atomic Emission Spectrometry (Performance-

Based Test Methodology)

This specification is under the jurisdiction ofASTM Committee B09 on Metal

Powders and Metal Powder Products and is the direct responsibility of Subcom-

mittee B09.11 on Near Full Density Powder Metallurgy Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2022. Published September 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2013. Last previous edition approved in 2018 as B988 – 18. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/B988-18R22. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B988−18 (2022)

E2626 Guide for Spectrometric Analysis of Reactive and 6. Chemical Composition

Refractory Metals (Withdrawn 2017)

6.1 Chemical composition shall conform to the require-

ments of Table 1. The purchaser may negotiate with the

3. Terminology

producer for other chemical requirements.

3.1 Definitions—Definitions of powder metallurgy terms

6.2 ChemicalanalysisshallbemadeinaccordancewithTest

can be found in Terminology B243.

Methods E2371, E1409, E1447, E1941; alternatively, Test

Method E539, or any other standard method mutually agreed

4. Ordering Information

upon between the purchaser and producer. Alternative tech-

4.1 Orders for components under this specification should

niques are discussed in Guide E2626.

include the following information, or portions of it, as agreed

to between purchaser and producer:

7. Physical Properties

4.2 Grade or alloy composition (see Section 6 and Table 1).

7.1 Density—Thisspecificationcovershigh-andfull-density

parts with no interconnected porosity.

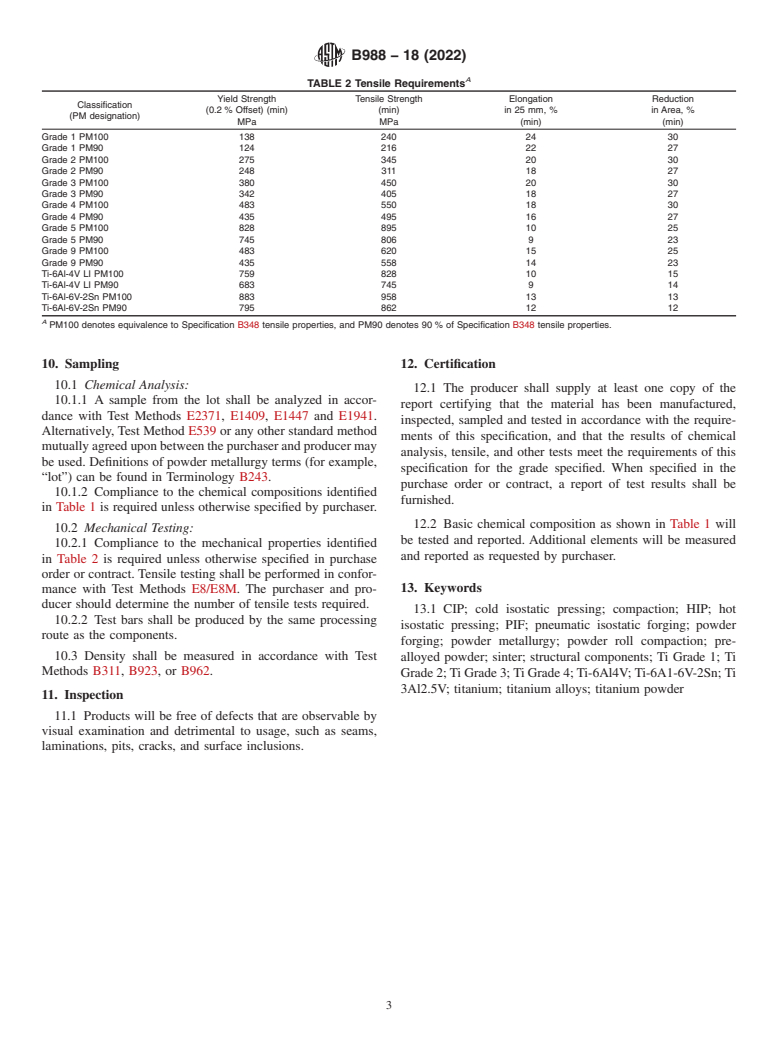

4.3 Mechanical properties (see Section 8 and Table 2).

7.2 Minimum density shall be sufficient to meet the me-

4.4 Density (see 7.1).

chanical properties of Table 2 or as specified in the purchase

4.5 Component description (see Section 9).

order or contract.

4.6 Processing route (see Section 5).

7.3 Density shall be determined in accordance with Test

4.7 Certification (see Section 12).

Methods B311, B923,or B962.

NOTE 1—Refer to Refs (1-11) for supplemental material property

4.8 Sampling—Sample size for determining chemical com-

information.

position will be decided by purchaser and producer. Methods

for chemical analysis are referenced in 10.1.1.

8. Mechanical Properties

4.9 Number of tensile tests required as mutually agreed

8.1 Tensile tests shall be performed using standardized test

upon by purchaser and producer.

bars in accordance with Test Methods E8/E8M produced from

the same powder lot as the components.

5. Materials and Manufacture

8.2 Alternatively, when standardized test bars are not

5.1 Structural components may be fabricated from powders

available, or when specified by the purchaser, testing may be

by processing to a near-net or net shape with final machining

performedonmaterialextractedfromactualcomponentsofthe

performed if required. Powders may include titanium, pre-

same lot.

alloyed titanium alloys, master alloys, and other elemental

NOTE 2—Test specimens may be machined from PM parts or blanks.

powders. The consolidation method shall be sufficient to

The test results, however, may differ from compacted test specimens.

achieve the final mechanical properties specified. The process-

ing method may include any combination of cold compaction

9. Dimensions, Mass, and Permissible Variations

(for example, cold isostatic pressing, uniaxial pressing), pow-

9.1 Dimensions and tolerances of the structural components

der roll compaction, hot compaction (for example, hot isostatic

shall be indicated on drawings accompanying the purchase

pressing, powder forging, and pneumatic isostatic forging),

order or contract.

sintering, and heat treatment.

The boldface numbers in parentheses refer to the list of references at the end of

this standard.

The last approved version of this historical standard is referenced on

www.astm.org.

A

TABLE 1 Chemical Composition Requirements

NOTE 1—Additional compositions may be added with future revisions.

Residual

Composition, Weight % N, max C, max H, max Fe O, max Al V Sn Cu Cr Nb

max ea.

Grade 1 PM 0.03 0.08 0.0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.