ASTM E2244-11e1

(Test Method)Standard Test Method for In-Plane Length Measurements of Thin, Reflecting Films Using an Optical Interferometer

Standard Test Method for In-Plane Length Measurements of Thin, Reflecting Films Using an Optical Interferometer

SIGNIFICANCE AND USE

5.1 In-plane length measurements can be used in calculations of parameters, such as residual strain and Young's modulus.

5.2 In-plane deflection measurements are required for specific test structures. Parameters, including residual strain, are calculated given the in-plane deflection measurements.

SCOPE

1.1 This test method covers a procedure for measuring in-plane lengths (including deflections) of patterned thin films. It applies only to films, such as found in microelectromechanical systems (MEMS) materials, which can be imaged using an optical interferometer, also called an interferometric microscope.

1.2 There are other ways to determine in-plane lengths. Using the design dimensions typically provides more precise in-plane length values than using measurements taken with an optical interferometric microscope. (Interferometric measurements are typically more precise than measurements taken with an optical microscope.) This test method is intended for use when interferometric measurements are preferred over using the design dimensions (for example, when measuring in-plane deflections and when measuring lengths in an unproven fabrication process).

1.3 This test method uses a non-contact optical interferometric microscope with the capability of obtaining topographical 3-D data sets. It is performed in the laboratory.

1.4 The maximum in-plane length measured is determined by the maximum field of view of the interferometric microscope at the lowest magnification. The minimum deflection measured is determined by the interferometric microscope’s pixel-to-pixel spacing at the highest magnification.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:E2244 −11

Standard Test Method for

In-Plane Length Measurements of Thin, Reflecting Films

1

Using an Optical Interferometer

This standard is issued under the fixed designation E2244; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Reference (1) was editorially revised in September 2013.

1. Scope 2. Referenced Documents

2

1.1 This test method covers a procedure for measuring 2.1 ASTM Standards:

E2245Test Method for Residual Strain Measurements of

in-plane lengths (including deflections) of patterned thin films.

It applies only to films, such as found in microelectromechani- Thin, Reflecting Films Using an Optical Interferometer

E2246Test Method for Strain Gradient Measurements of

cal systems (MEMS) materials, which can be imaged using an

optical interferometer, also called an interferometric micro- Thin, Reflecting Films Using an Optical Interferometer

E2444Terminology Relating to Measurements Taken on

scope.

Thin, Reflecting Films

1.2 There are other ways to determine in-plane lengths.

E2530Practice for Calibrating the Z-Magnification of an

Using the design dimensions typically provides more precise

Atomic Force Microscope at Subnanometer Displacement

in-plane length values than using measurements taken with an

Levels Using Si(111) Monatomic Steps (Withdrawn

optical interferometric microscope. (Interferometric measure-

3

2015)

mentsaretypicallymoreprecisethanmeasurementstakenwith

4

2.2 SEMI Standard:

an optical microscope.) This test method is intended for use

MS2Test Method for Step Height Measurements of Thin

when interferometric measurements are preferred over using

Films

the design dimensions (for example, when measuring in-plane

deflections and when measuring lengths in an unproven fabri-

3. Terminology

cation process).

3.1 Definitions:

1.3 This test method uses a non-contact optical interfero-

3.1.1 The following terms can be found in Terminology

metricmicroscopewiththecapabilityofobtainingtopographi-

E2444.

cal 3-D data sets. It is performed in the laboratory.

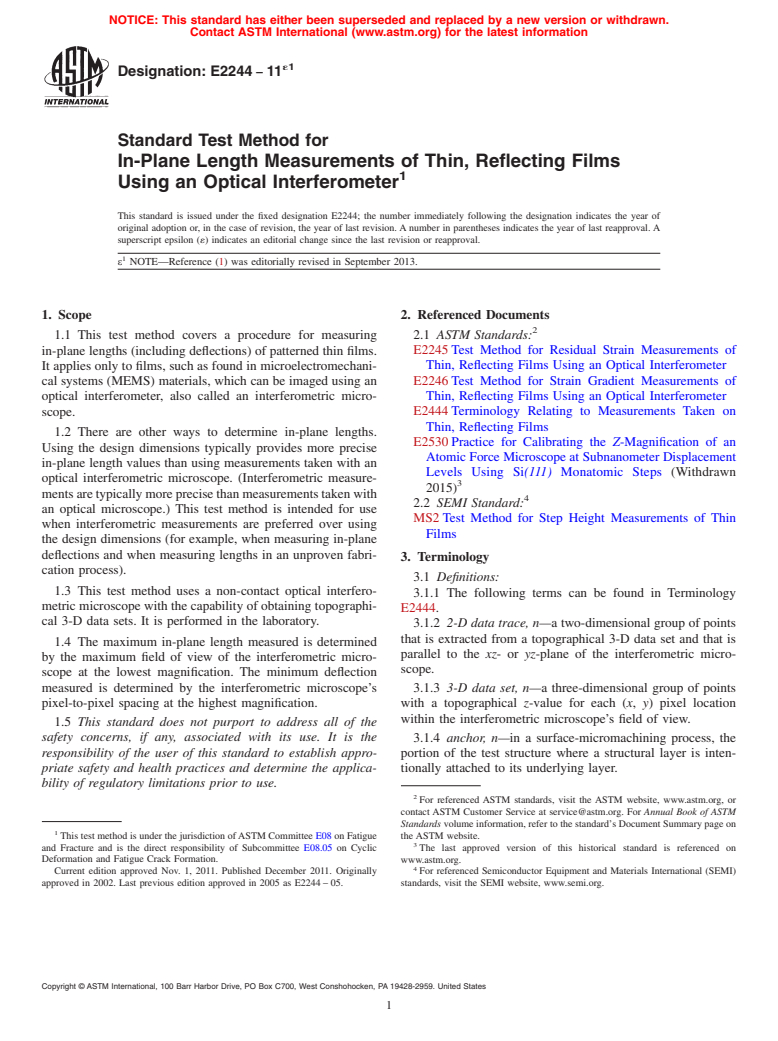

3.1.2 2-D data trace, n—a two-dimensional group of points

that is extracted from a topographical 3-D data set and that is

1.4 The maximum in-plane length measured is determined

parallel to the xz-or yz-plane of the interferometric micro-

by the maximum field of view of the interferometric micro-

scope.

scope at the lowest magnification. The minimum deflection

measured is determined by the interferometric microscope’s 3.1.3 3-D data set, n—a three-dimensional group of points

pixel-to-pixel spacing at the highest magnification.

with a topographical z-value for each (x, y) pixel location

within the interferometric microscope’s field of view.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.1.4 anchor, n—in a surface-micromachining process, the

responsibility of the user of this standard to establish appro- portion of the test structure where a structural layer is inten-

priate safety and health practices and determine the applica- tionally attached to its underlying layer.

bility of regulatory limitations prior to use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This test method is under the jurisdiction ofASTM Committee E08 on Fatigue the ASTM website.

3

and Fracture and is the direct responsibility of Subcommittee E08.05 on Cyclic The last approved version of this historical standard is referenced on

Deformation and Fatigue Crack Formation. www.astm.org.

4

Current edition approved Nov. 1, 2011. Published December 2011. Originally For referenced Semiconductor Equipment and Materials International (SEMI)

approved in 2002. Last previous edition approved in 2005 as E2244–05. standards, visit the SEMI website, www.semi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

E2244−11

3.1.5 anchor lip, n—in a surface-micromachining process, 3.2.1 For Calibration:

the freestanding extension of the structural layer of interest σ =the standard deviation in a ruler measurement in the

xcal

around the edges of the anchor to its underlying layer. interferometric microscope’s x-direction for the given combi-

3.1.5.1 Discussion—In some processes, the width of the nation of lenses

anchor lip may be zero. σ =the standard deviation in a ruler measurement in the

ycal

interf

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.