ASTM F1157-90(1994)e1

(Practice)Standard Practice for Classifying the Relative Performance of the Physical Properties of Security Seals

Standard Practice for Classifying the Relative Performance of the Physical Properties of Security Seals

SCOPE

1.1 This practice presents methods for testing the physical properties of security seals. Where appropriate, the various tests include particular apparatus or procedural specifications required for different types of security seals.

1.2 This practice will serve as a basis for comparing the response of various security seals under different modes of attack. The security seal to be evaluated shall first be placed in an appropriate classification, and then tested in the manner designated as most suitable for that class of seal, in accordance with Classification F832.

Note 1--See Guide F1158 for procedures on the inspection and evaluation of tampering of security seals.

1.3 A security seal is a device intended to detect tampering or entry. Single use locking devices are to be evaluated under this specification. Therefore, the following procedures are to reflect the relative performance of security seals when subject to various physical attacks.

1.4 This practice is not intended to be fully comprehensive, since certain types of security seals, such as labels, are not addressed. Further, it is the responsibility of users of this practice to interpret their specific security needs concerning the application of seals, and to determine the grade of seal appropriate for their particular application. ASTM assumes no responsibility for losses occurring as a result of a defeated seal whether the defeat is apparent or the seal is not suited for its application.

1.5 The values as stated in inch-pound units are to be regarded as the standard. The values in parentheses are given for information only.

1.6 The following safety hazards caveat pertains only to the test procedures portion, Section 6, of this practice. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: F 1157 – 90 (Reapproved 1994)

Standard Practice for

Classifying the Relative Performance of the Physical

Properties of Security Seals

This standard is issued under the fixed designation F 1157; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Section 8, Keywords, was added in November 1994.

1. Scope practices and determine the applicability of regulatory limita-

tions prior to use.

1.1 This practice presents methods for testing the physical

properties of security seals. Where appropriate, the various

2. Referenced Documents

tests include particular apparatus or procedural specifications

2.1 ASTM Standards:

required for different types of security seals.

F 832 Classification for Security Seals

1.2 This practice will serve as a basis for comparing the

F 883 Performance Specification for Padlocks

response of various security seals under different modes of

F 946 Guide for Establishing Security Seal Control and

attack. The security seal to be evaluated shall first be placed in

Accountability Procedures

an appropriate classification, and then tested in the manner

F 1158 Guide for Inspection and Evaluation of Tampering

designated as most suitable for that class of seal, in accordance

of Security Seals

with Classification F 832.

NOTE 1—See Guide F 1158 for procedures on the inspection and 3. Terminology

evaluation of tampering of security seals.

3.1 Definition:

1.3 A security seal is a device intended to detect tampering

3.1.1 seal—a passive, one-time locking device which is

or entry. Single use locking devices are to be evaluated under used to indicate tampering or entry, afford limited resistance (to

this specification. Therefore, the following procedures are to

entry) or provide a combination of both functional aspects.

reflect the relative performance of security seals when subject

4. Summary of Practice

to various physical attacks.

1.4 This practice is not intended to be fully comprehensive, 4.1 A security seals shall be evaluated in accordance with its

since certain types of security seals, such as labels, are not classification into one of five general groups and its perfor-

addressed. Further, it is the responsibility of users of this mance in the following: a test to determine pull strength, a

practice to interpret their specific security needs concerning the shear cutting test, a bending test, an impact test, a low-

application of seals, and to determine the grade of seal temperature impact test, and a high-temperature pull test. A

appropriate for their particular application. ASTM assumes no total of 18 seals shall be used to complete minimum testing.

responsibility for losses occurring as a result of a defeated seal 4.2 A security seal shall receive a rating designation which

whether the defeat is apparent or the seal is not suited for its denotes its general classification and its performance in each of

application. the required tests. This rating shall be obtained by testing three

1.5 The values as stated in inch-pound units are to be individual seals in each specific test, and by taking the average

regarded as the standard. The values in parentheses are given of the data points.

for information only.

5. Seal Classification

1.6 The following safety hazards caveat pertains only to the

5.1 General—For the purpose of defining the most appro-

test procedures portion, Section 6, of this practice. This

standard does not purport to address all of the safety concerns, priate configuration by which to evaluate a security seal in

subsequent tests, a seal shall be classified as an initial step.

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health 5.2 For the purpose of comparing the physical properties of

security seals, seals are grouped in accordance with the

following description of application seals:

5.2.1 Groups:

This practice is under the jurisdiction of ASTM Committee F-12 on Security

5.2.1.1 Group 1—Flexible cable and wire seals.

Systems and Equipmentand is the direct responsibility of Subcommittee F 12.50on

Locking Devices.

Current edition approved Jan. 26, 1990. Published March 1990. Originally

published as F 1157 – 88. Last previous edition F 1157 – 88. Annual Book of ASTM Standards, Vol 15.07.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 1157

5.2.1.2 Group 2—Strap and cinch seals.

5.2.1.3 Group 3—Rigid bolt and rod seals, including heavy

duty metal padlock type.

5.2.1.4 Group 4—Twisted rod or wire seals (pigtail).

5.2.1.5 Group 5—Padlock type seals, scored seals, metal or

plastic base.

5.3 If a particular security seal does not appear to fall into

any of these general classifications, the closest description shall

be chosen by the user, keeping in mind that effectiveness of the

testing procedures may be jeopardized by a faulty classification

choice. These general groupings shall be assigned the arbitrary

numerical listing of one through five, respectively, as shown in

5.2.1. This listing shall then be designated in the security seal’s

overall evaluation to serve as a reference indicating the

particular test configurations with which it was tested.

5.4 The required performance levels in any test category

(see Section 11) shall not be affected by this general classifi-

cation (see 5.2.1); only the manner in which the seal is

physically manipulated during subsequent testing shall be

affected by this portion of the evaluation. All seals will be

tested in a locked position.

5.5 Seals often have unique identification to prevent dupli-

cation and reapplication. Evaluation of this uniqueness is not

required.

6. Test Procedures

6.1 Pull (Tensile) Test:

6.1.1 Conduct a pull test to determine the strength of a

security seal’s locking mechanism. Apply a tensile load to the

locked seal in a manner that simulates a reversal of the motion

needed to lock the seal. Hardware necessary to perform this

test will be indicated by the configuration of the seal. See Fig.

1(a), (b), (c), and (d) for a schematic drawing of this test, as

applied to the various general classifications of seals.

(a) Groups 1 and 2,

6.1.2 Record the load required to forcibly open (or destroy

(b) Group 3,

or damage) the security seal and compare it to the rating

(c) Group 4, and

(d) Group 5.

requirements listed in Table 1. Assign the appropriate letter

FIG. 1 Schematic Drawings of Pull (Tensile) Test as Applied to

designation to that security seal for performance in the pull

Security Seals:

test.

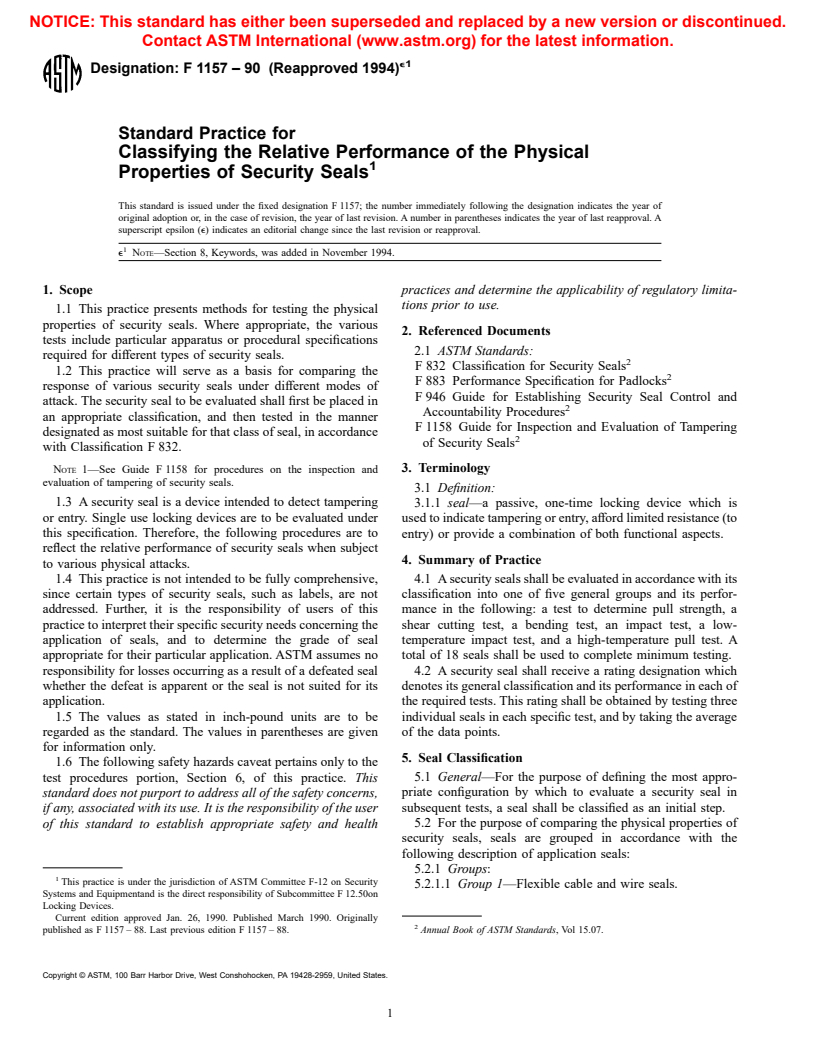

6.2 Shear Test:

TABLE 1 Pull (Tensile) Test Requirements for Grade

6.2.1 Test security seals for ability to withstand cutting with

Classification of Security Seals at Room Temperature

shearing blades, as might be implemented with bolt cutters. To

65°F (18°C), and at 180°F (82.2°C)

perform this test, use hardware that is the same as the apparatus

Load to Failure (lbf (N)) Seal Grade Level Awarded

used in the Padlock Shackle Cutting Test in Performance

5001 or more F

Specification F 833. (See Fig. 2 for a drawing of this equip-

3001 to 5000 E

1001 to 3000 D

ment.) This equipment may suffice for testing all classifications

201 to 1000 C

of security seals, with the possible exception of thin metal or

51 to 200 B

plastic bands, such as strap or cinch seals. In such cases, it is

1to50 A

conceivable that a slight misalignment in the cutting blades

would not sever the seal, only deform it. In this instance, use a NOTE 1—1 lbf 5 4.448222 N 5 0.4536 kg.

more precise cutting apparatus which incorporates sharp,

well-aligned cutting blades. flexible or rigid, test configurations to make appropriate

6.2.2 Record the compressive load required to sever the selections for bending resistance rating must first be made. Test

security seal and compare it to the rating levels given in Table flexible seals for ability to withstand repeated bending loads,

2. Assign an appropriate rating in the shear test. and test rigid seals for resistance to deformation by bending to

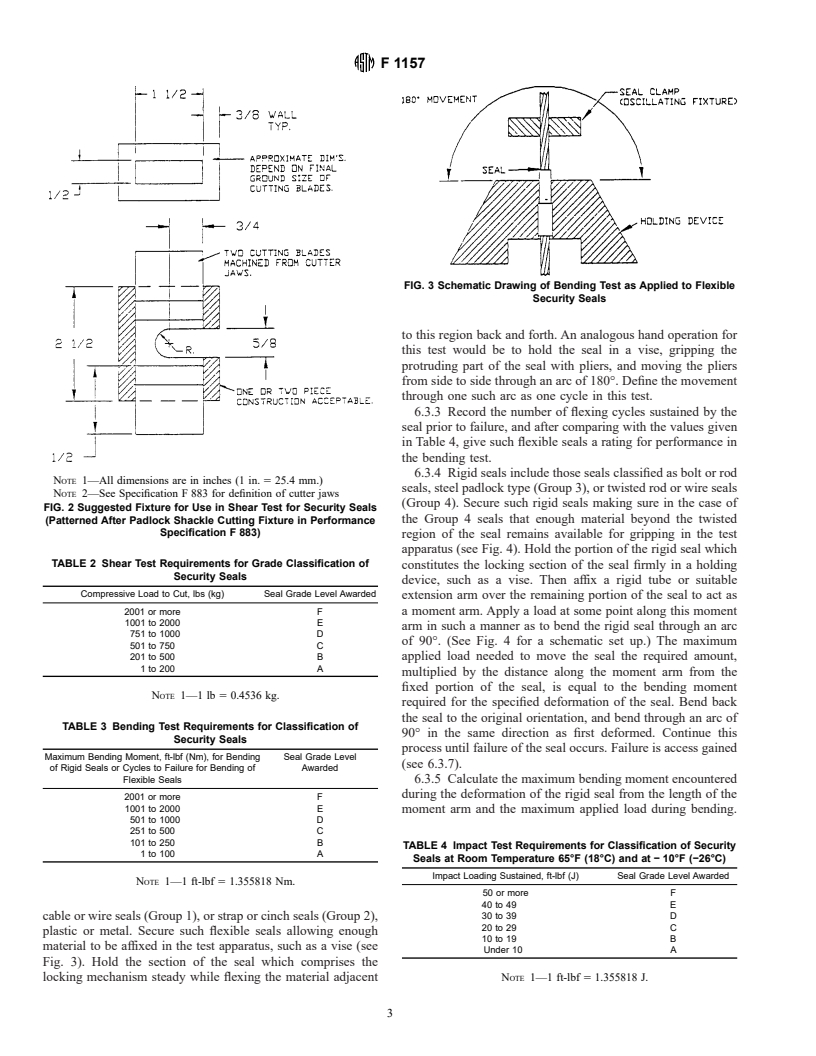

6.3 Bending Test: a specified degree. Test padlock type seals (Groups 3 or 5)

6.3.1 Conduct a bending test to determine the resistance of using particular methods appropriate for those seals, as out-

a security seal to fail under bending loads in this test. Because lined in 6.3.6 and 6.3.7. Failure is access gained (see Table 3).

various designs allow for seals to be categorized as either 6.3.2 Flexible seals include those seals classified as being

F 1157

FIG. 3 Schematic Drawing of Bending Test as Applied to Flexible

Security Seals

to this region back and forth. An analogous hand operation for

this test would be to hold the seal in a vise, gripping the

protruding part of the seal with pliers, and moving the pliers

from side to side through an arc of 180°. Define the movement

through one such arc as one cycle in this test.

6.3.3 Record the number of flexing cycles sustained by the

seal prior to failure, and after comparing with the values given

in Table 4, give such flexible seals a rating for performance in

the bending test.

6.3.4 Rigid seals include those seals classified as bolt or rod

NOTE 1—All dimensions are in inches (1 in. 5 25.4 mm.)

seals, steel padlock type (Group 3), or twisted rod or wire sea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.