ASTM G187-05

(Test Method)Standard Test Method for Measurement of Soil Resistivity Using the Two-Electrode Soil Box Method

Standard Test Method for Measurement of Soil Resistivity Using the Two-Electrode Soil Box Method

SIGNIFICANCE AND USE

The resistivity of the surrounding soil environment is a factor in the corrosion of underground structures. High resistivity soils are generally not as corrosive as low resistivity soils. The resistivity of the soil is one of many factors that influence the service life of a buried structure. Soil resistivity may affect the material selection and the location of a structure.5

Soil resistivity is of particular importance and interest in the corrosion process because it is basic in the analysis of corrosion problems and the design of corrective measures.

The test method is focused to provide an accurate, expeditious measurement of soil resistivity to assist in the determination of a soil’s corrosive nature. Test Method G 57 emphasizes an in situ measurement commonly utilized in the design of a buried structures’ corrosion control (cathodic protection systems’ ground bed design, and so forth). The two-electrode soil box method often compliments the four-pin, in situ soil resistivity method.

The saturated soil resistivity determined by this test method does not necessarily indicate the minimum soil resistivity

SCOPE

1.1 This test method covers the equipment and a procedure for the measurement of soil resistivity, for samples removed from the ground, for use in the control of corrosion of buried structures.

1.2 Procedures allow for this test method to be used n the field or in the laboratory.

1.3 The test method procedures are for the resistivity measurement of soil samples in the saturated condition and in the as-received condition.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. Soil resistivity values are reported in ohm-centimeter.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G187–05

Standard Test Method for

Measurement of Soil Resistivity Using the Two-Electrode

Soil Box Method

This standard is issued under the fixed designation G187; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the equipment and a procedure 3.1 Definitions:

for the measurement of soil resistivity, for samples removed 3.1.1 Ohm’s law—The relationship between the electromo-

from the ground, for use in the control of corrosion of buried tive force, the current, and the resistance. Mathematically:

structures. current = electromotive force/resistance or I = E/R; where “I”

1.2 Procedures allow for this test method to be used n the is measured in amperes, “E” in volts, and “R” in ohms.

field or in the laboratory. 3.1.2 Resistivity (soil)—The electrical resistance between

1.3 The test method procedures are for the resistivity opposite faces of a unit cube of material; the reciprocal of

measurement of soil samples in the saturated condition and in conductivity.

the as-received condition. 3.1.3 Saturated soil—soil whose entire soil porosity is filled

1.4 The values stated in SI units are to be regarded as the with water.

standard. The values given in parentheses are for information 3.1.4 Soil box factor—A factor which is determined by a

only. Soil resistivity values are reported in ohm-centimeter. two-electrode soil box’s internal dimensions (cross sectional

1.5 This standard does not purport to address all of the area/distance between electrode plates). The soil box factor is

safety concerns, if any, associated with its use. It is the multiplied by the measured resistance of a substance in the soil

responsibility of the user of this standard to establish appro- box to obtain that substance’s resistivity.

priate safety and health practices and to determine the 3.1.5 Soil resistance meter—An instrument capable of mea-

applicability of regulatory limitations prior to use. suring soil resistance.

3.1.6 Two-electrode soil box—A non-conductive container

2. Referenced Documents

of known internal dimensions with two end plate electrodes for

2.1 ASTM Standards: measuring a substance’s resistivity.

G15 Terminology Relating to Corrosion and Corrosion

3.2 The terminology used herein, if not specifically defined

Testing otherwise, shall be in accordance with Terminology G15.

G57 Test Method for Field Measurement of Soil Resistivity

Definitions provided herein and not given in Terminology G15

Using the Wenner Four-Electrode Method are limited only to this standard.

D1193 Specification for Reagent Water

4. Summary of Test Method

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method 4.1 The two-electrode soil box method is predicated on

2.2 AISI Specifications: measuring the resistance between two opposite faces of a box

AISI Designation Type 304 containing a substance or solution. That resistance measure-

AISI Designation Type 316 ment through the substance being tested is then converted to

resistivity based on the conversion formula of Eq 1.

4.2 A voltage is impressed between the two opposite face

This test method is under the jurisdiction of ASTM Committee G01 on

electrodes, causing current to flow, and the voltage drop

Corrosion of Metals and is the direct responsibility of Subcommittee G01.10 on

between them is measured. Ohm’s law reveals the resistance.

Corrosion in Soils.

Current edition approved Oct. 1, 2005. Published November 2005. DOI:

The resistivity, ρ, is then:

10.1520/G0187-05.

r ~ohm2cm! 5 AR/d (1)

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

where:

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

A = cross-sectional area, cm ,

Available from American Iron and Steel Institute (AISI), 1140 Connecticut

R = resistance, ohms, and

Ave., Suite 705, Washington, DC 20036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G187–05

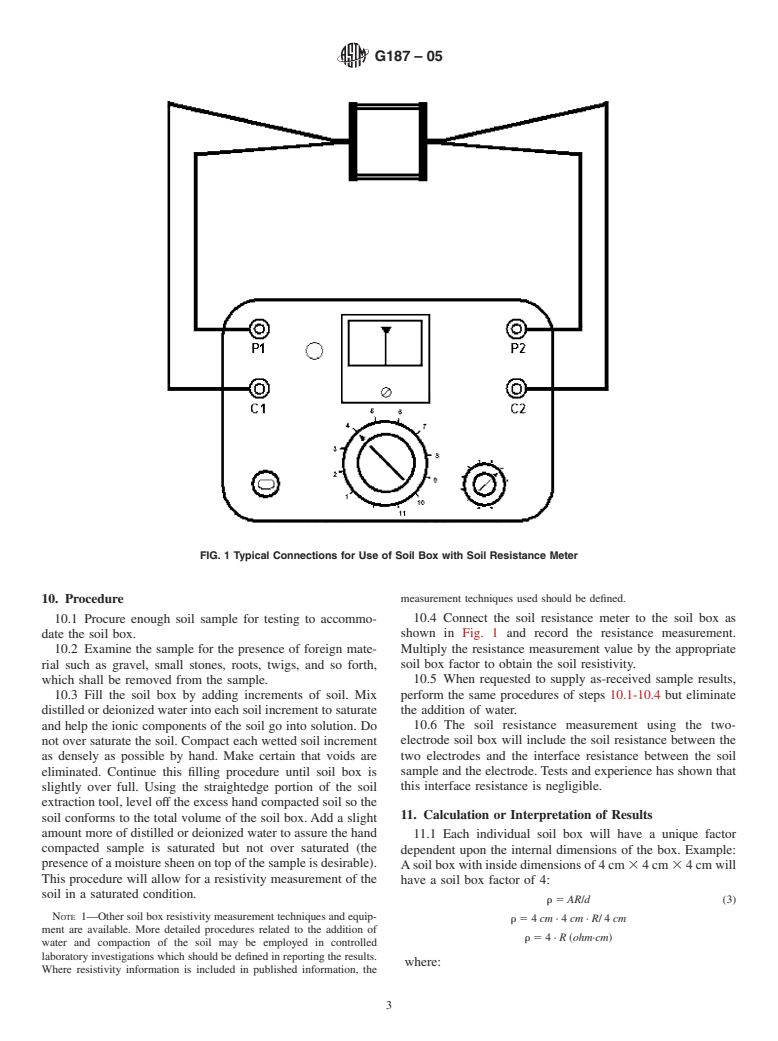

lent, which utilize a low voltage 97 Hz square wave current).

d = distance between electrodes, cm.

They offer convenience, ease of use, and repeatability. Soil

5. Significance and Use resistance meters yield direct readings in ohms, which are

multiplied by the appropriate factor for the specific two-

5.1 The resistivity of the surrounding soil environment is a

electrodesoilbox.Themeterutilizedmaylimittheupperrange

factor in the corrosion of underground structures. High resis-

of resistivity, which can be measured. In such cases the

tivity soils are generally not as corrosive as low resistivity

resistivity should be reported as greater than the meter’s upper

soils. The resistivity of the soil is one of many factors that

limit.

influence the service life of a buried structure. Soil resistivity

6.4 Wiring—18 to 22AWG insulated stranded copper wire.

may affect the material selection and the location of a struc-

Terminals and connections must be low-resistance.

ture.

5.2 Soil resistivity is of particular importance and interest in

7. Reagents and Materials

the corrosion process because it is basic in the analysis of

7.1 Distilled or deionized water (Type IV grade as refer-

corrosion problems and the design of corrective measures.

enced in Specification D1193) to saturate samples.

5.3 The test method is focused to provide an accurate,

expeditious measurement of soil resistivity to assist in the

8. Sampling Test Specimens, and Test Units

determination of a soil’s corrosive nature. Test Method G57

8.1 Generally, collected soil samples that are to be tested in

emphasizes an in situ measurement commonly utilized in the

the laboratory shall be placed in an appropriate sealable

design of a buried structures’ corrosion control (cathodic

container or polyethylene type bag. This allows containers to

protection systems’ ground bed design, and so forth). The

be identified for location and will facilitate a request for

two-electrode soil box method often compliments the four-pin,

as-received test results.

in situ soil resistivity method.

8.2 Soil samples shall be representative of the area of

5.4 The saturated soil resistivity determined by this test

interest.Where the stratum of interest contains a variety of soil

method does not necessarily indicate the minimum soil resis-

types, it is desirable to sample each type separately.

tivity

8.3 The collected soil sample size is dependent on the

6. Apparatus volume of the soil box used.

8.4 Soil resistivity measurements shall not be conducted on

6.1 The equipment required for the measurement of the

frozen or partially frozen soil samples. Soil samples to be

resistivity of soil samples, either in the field or in the

tested in the laboratory shall be allowed to reach room

laboratory, consists of a two-electrode soil box, a soil resis-

temperature (approximately 20°C (68°F)) prior to the resistiv-

tance meter, wiring to make the necessary connections and a

ity measurement. Field measurements shall reflect the soils

soil extraction tool with straightedge.Atwo-electrode soil box,

temperature during testing. Soil temperatures that are above

soilresistancemeteranditselectricalconnectionsareshownin

freezing can be corrected for a uniform temperature of 15.5°C

Fig. 1.

(60°F) by use of the following equation :

6.2 Two-electrode soil box—Two-electrode soil boxes can

R 5 R 24.5 1 t!/ 40 (2)

be constructed in various sizes provided the inside dimensions ~

15.5 t

are known. Design and construction shall incorporate materials

Where R is the resistance at 15.5°C (60°F) and R is the

15.5 t

that are durable and machinable. The two end plate electrodes

observed resistance at temperature t°C.

shall be constructed of a clean, polished corrosion-resistant

metal or alloy (that is, AISI Designation Type 304 or 316

9. Calibration and Standardization

stainless steel) that will not form a heavy oxide film or

9.1 The accuracy of the soil resistance meter shall be

otherwise add significant resistance. The body of the box shall

periodically checked with a commercial resistance decade box

be constructed of a material that is non-conductive and able to

or several appropriate known value resistors. Meter error shall

main

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.