ASTM F302-09

(Practice)Standard Practice for Field Sampling of Aerospace Fluids in Containers

Standard Practice for Field Sampling of Aerospace Fluids in Containers

SIGNIFICANCE AND USE

Samples obtained by use of this practice are intended for processing in accordance with Practice F311, Test Method D4898, and Test Method , and other chemical or physical methods of analysis.

SCOPE

1.1 This practice covers field sampling of fluids from hermetically sealed containers and other fluid containers of 208-L volume maximum. It may be utilized at manufacturing, storage, or use levels for obtaining representative fluid samples for chemical, physical, or particulate matter determinations.

1.2 Use of this practice depends upon variables such as fluid toxicity, restrictive fluid odors, fluid flammability, and so forth. It is suitable for most hydraulic fluids; however, care should be exercised in determining compatibility before use.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For hazard statement, see 6.5.1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F302 − 09

StandardPractice for

1

Field Sampling of Aerospace Fluids in Containers

ThisstandardisissuedunderthefixeddesignationF302;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F311 Practice for Processing Aerospace Liquid Samples for

Particulate ContaminationAnalysis Using Membrane Fil-

1.1 This practice covers field sampling of fluids from

ters

hermetically sealed containers and other fluid containers of

F314 Methods of Test for Identification of Metallic and

208-L volume maximum. It may be utilized at manufacturing,

Fibrous Contaminants in Aerospace Fluids (Withdrawn

storage, or use levels for obtaining representative fluid samples

4

1990)

for chemical, physical, or particulate matter determinations.

1.2 Useofthispracticedependsuponvariablessuchasfluid

3. Summary of Practice

toxicity, restrictive fluid odors, fluid flammability, and so forth.

3.1 The minimum requirements for container agitation,

It is suitable for most hydraulic fluids; however, care should be

2

sample withdrawal, and sample transfer are given in this

exercised in determining compatibility before use.

practice. Precautions to ensure sampling reliability are in-

1.3 The values stated in SI units are to be regarded as

cluded in the procedure to the extent required by normal

standard. No other units of measurement are included in this

processing conditions. The procedure involves agitating the

standard.

container, withdrawing with a suitable instrument capable of

1.4 This standard does not purport to address all of the

creating a vacuum, a predetermined quantity of fluid, and

safety concerns, if any, associated with its use. It is the

immediately transferring it to a vessel, properly identified, to

responsibility of the user of this standard to establish appro-

hold for analysis by a stipulated method.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For hazard

4. Significance and Use

statement, see 6.5.1.

4.1 Samplesobtainedbyuseofthispracticeareintendedfor

processing in accordance with Practice F311, Test Method

2. Referenced Documents

D4898, and Test Method F314, and other chemical or physical

3

2.1 ASTM Standards:

methods of analysis.

D1193 Specification for Reagent Water

D1836 Specification for Commercial Hexanes

5. Apparatus

D2021 SpecificationforNeutralDetergent,40PercentAlky-

4

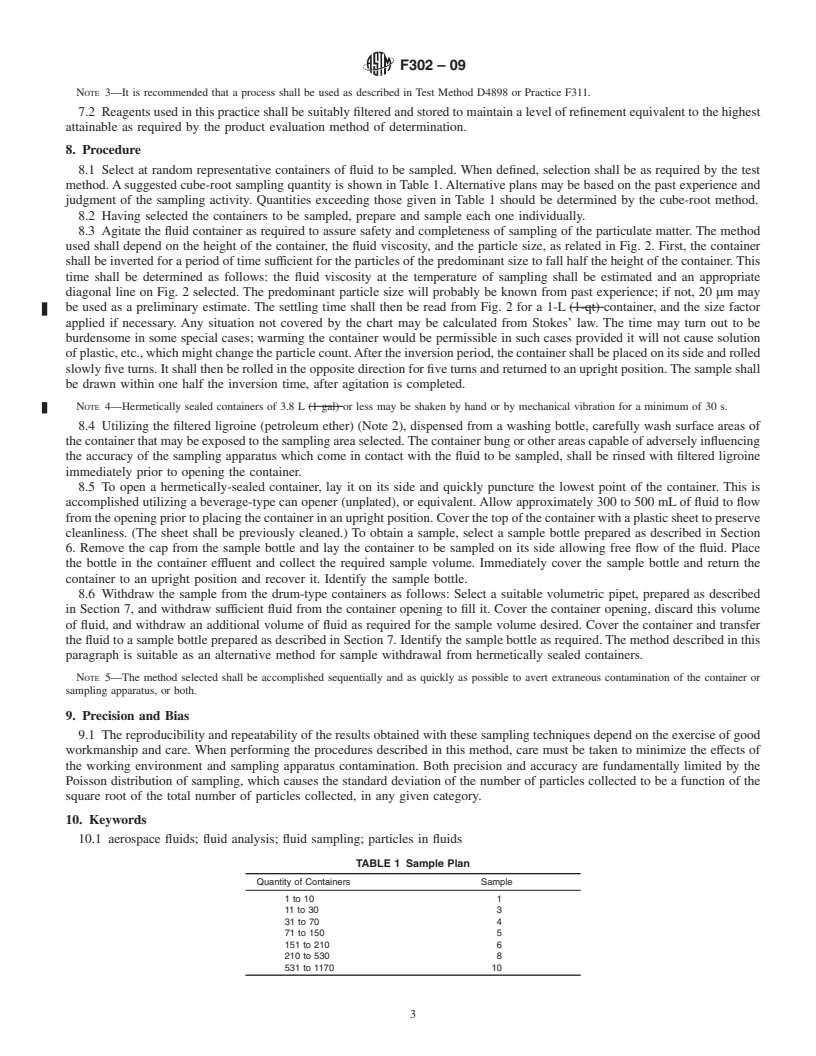

5.1 Pipet, volumetric transfer or equivalent rubber-bulb

lbenzene Sulfonate Type (Withdrawn 2000)

type. A taper-jointed type, as shown in Fig. 1, 560 mm long,

D4898 Test Method for Insoluble Contamination of Hydrau-

calibrated to deliver 100 mL at 20°C, is also acceptable. This

lic Fluids by Gravimetric Analysis

typeprovidesforeaseofmaintenancebybeingseparableatthe

midpoint of the bulb.

1

This practice is under the jurisdiction of ASTM Committee E21 on Space

NOTE 1—The volume capacities selected for the pipet and sample

Simulation andApplications of Space Technology and is the direct responsibility of

bottlesshallbeasrequiredforthesamplevolumedesired.Normallya100

Subcommittee E21.05 on Contamination.

6 5-mL sample is standard, which would require a capacity of approxi-

Current edition approved Nov. 1, 2009. Published December 2009. Originally

mately 125 mL. Unless otherwise indicated, it is intended that a sample

approved in 1965. Last previous edition approved in 2004 as F302 – 2004. DOI:

volume of 100 6 5 mL be used for accomplishing the methods defined

10.1520/F0302-09.

herein.

2

Where a special environment is required, a Proposed Laboratory Method for

Sampling Aerospace Fluids in Containers is under development in the committee.

5.2 Bottles, sample, wide-mouth type (Note 1).

For further information write to B. R. Hall, American Petroleum Institute, 1220 L

5.3 Solvent Filtering Dispenser—Anapparatustodispensea

St., N.W., Washington, D. C. 20005.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

stream of 2.0 µm or finer membrane-filtered fluid.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 5.4 Vinylidene Chloride, Polyethylene Terephthalate, or

the ASTM website.

Polyamide Sheet, 0.1 mm (4-mil) min.

4

The last approved version of this historical standard is referenced on

www.astm.org. 5.5 Beverage Can Opener (Unplated), sharpened, deburred.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F302 − 09

7. Preparations of Apparatus and Reagents

7.1 A

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F302–04 Designation:F302–09

Standard Practice for

1

Field Sampling of Aerospace Fluids in Containers

ThisstandardisissuedunderthefixeddesignationF302;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thispracticecoversfieldsamplingoffluidsfromhermeticallysealedcontainersandotherfluidcontainersof208-L(55-gal)

volume maximum. It may be utilized at manufacturing, storage, or use levels for obtaining representative fluid samples for

chemical, physical, or particulate matter determinations.

1.2 Use of this practice depends upon variables such as fluid toxicity, restrictive fluid odors, fluid flammability, and so forth.

2

It is suitable for most hydraulic fluids; however, care should be exercised in determining compatibility before use.

1.3The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For hazard statement, see 6.5.1.

2. Referenced Documents

3

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D1836 Specification for Commercial Hexanes

4

D2021 Specification for Neutral Detergent, 40 Percent Alkylbenzene Sulfonate Type

D4898 Test Method for Insoluble Contamination of Hydraulic Fluids by Gravimetric Analysis

F311 Practice for Processing Aerospace Liquid Samples for Particulate Contamination Analysis Using Membrane Filters

4

F314 Test Method for Identification of Metallic and Fibrous Contaminants in Aerospace Fluids

2.2 DoD Standard:

MIL-C-81302Cleaning Compound Solvent Trichlorotrifluoroethane

3. Summary of Practice

3.1 The minimum requirements for container agitation, sample withdrawal, and sample transfer are given in this practice.

Precautions to ensure sampling reliability are included in the procedure to the extent required by normal processing conditions.

The procedure involves agitating the container, withdrawing with a suitable instrument capable of creating a vacuum, a

predetermined quantity of fluid, and immediately transferring it to a vessel, properly identified, to hold for analysis by a stipulated

method.

4. Significance and Use

4.1 Samples obtained by use of this practice are intended for processing in accordance with Practice F311,Test Method D4898,

and Test Method F314, and other chemical or physical methods of analysis.

5. Apparatus

5.1 Pipet, volumetric transfer or equivalent rubber-bulb type. A taper-jointed type, as shown in Fig. 1, 560 mm (22 in.) long,

1

This practice is under the jurisdiction of ASTM Committee E21 on Space Simulation and Applications of Space Technology and is the direct responsibility of

Subcommittee E21.05 on Contamination.

Current edition approved Sept. 1, 2004. Published September 2004. Originally approved in 1965. Last previous edition approved in 2000 as F302–78 (2000). DOI:

10.1520/F0302-04.

Current edition approved Nov. 1, 2009. Published December 2009. Originally approved in 1965. Last previous edition approved in 2004 as F302 – 2004. DOI:

10.1520/F0302-09.

2

Whereaspecialenvironmentisrequired,aProposedLaboratoryMethodforSamplingAerospaceFluidsinContainersisunderdevelopmentinthecommittee.Forfurther

information write to B. R. Hall, American Petroleum Institute, 1220 L St., N.W., Washington, D. C. 20005.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F302–09

FIG. 1 Separable Pipet

calibrated to deliver 100 mL at 20°C, is also acceptable. This type provides for ease of maintenance by being separable at the

midpoint of the bulb.

NOTE 1—The volume capacities selected for the pipet and sample bottles shall be as required for the samp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.