ASTM D4290-07(2012)

(Test Method)Standard Test Method for Determining the Leakage Tendencies of Automotive Wheel Bearing Grease Under Accelerated Conditions

Standard Test Method for Determining the Leakage Tendencies of Automotive Wheel Bearing Grease Under Accelerated Conditions

SIGNIFICANCE AND USE

This test method differentiates among wheel bearing greases having distinctly different high-temperature leakage characteristics. It is not the equivalent of longtime service tests.

This test method has proven to be helpful in screening greases with respect to leakage tendencies for automotive wheel bearing applications.

Note 1—It is possible for skilled operators to observe changes in grease characteristics that can occur during the test, such as grease condition. Leakage is reported as a quantitative value, whereas the evaluation of grease condition is subject to differences in personal judgment among operators and cannot be used effectively for quantitative measurements.

SCOPE

1.1 This test method covers a laboratory procedure for evaluating leakage tendencies of wheel bearing greases when tested under prescribed conditions.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. The exception is apparatus dimensions, in inches, which are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4290 − 07(Reapproved 2012)

Standard Test Method for

Determining the Leakage Tendencies of Automotive Wheel

Bearing Grease Under Accelerated Conditions

This standard is issued under the fixed designation D4290; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3.1 Discussion—The solid thickener can be fibers (such

as various metallic soaps) or plates or spheres (such as certain

1.1 This test method covers a laboratory procedure for

non-soap thickeners) which are insoluble or, at the most, only

evaluating leakage tendencies of wheel bearing greases when

very slightly soluble in the liquid lubricant. The general

tested under prescribed conditions.

requirements are that the solid particles be extremely small,

1.2 The values stated in SI units are to be regarded as

uniformlydispersed,andcapableofformingarelativelystable,

standard. No other units of measurement are included in this

gel-like structure with the liquid lubricant.

standard. The exception is apparatus dimensions, in inches,

3.2 Definitions of Terms Specific to This Standard:

which are to be regarded as the standard.

3.2.1 automotive wheel bearing grease, n—a lubricating

1.3 This standard does not purport to address all of the

grease specifically formulated to lubricate automotive wheel

safety concerns, if any, associated with its use. It is the

bearings at relatively high grease temperatures and bearing

responsibility of the user of this standard to establish appro-

speeds.

priate safety and health practices and determine the applica-

3.2.2 leakage, n—of wheel bearing grease, separation and

bility of regulatory limitations prior to use. For specific

overflow of grease or oil from the bulk grease charge, induced

warning statements, see Section 8.

by high temperatures and bearing rotation.

2. Referenced Documents

4. Summary of Test Method

2.1 AFBMA Standard:

4.1 The test grease is distributed in a modified, automobile

AFBMA Standard 19 1974 (ANSI B.3.19-1975)

front wheel hub-spindle-bearings assembly.While the bearings

are thrust-loaded to 111 N, the hub is rotated at 1000 rpm and

3. Terminology

the spindle temperature maintained at 160°C for 20 h. Leakage

3.1 Definitions:

of grease or oil, or both, is measured, and the condition of the

3.1.1 lubricant, n—any material interposed between two

bearing surface is noted at the end of the test.

surfaces that reduces the friction or wear between them.

3.1.2 lubricating grease, n—a semifluid to solid product of 5. Significance and Use

a dispersion of a thickener in a liquid lubricant.

5.1 This test method differentiates among wheel bearing

3.1.2.1 Discussion—The dispersion of the thickener forms a

greases having distinctly different high-temperature leakage

two-phase system and immobilizes the liquid lubricant by

characteristics.Itisnottheequivalentoflongtimeservicetests.

surface tension and other physical forces. Other ingredients are

5.2 This test method has proven to be helpful in screening

commonly included to impart special properties.

greases with respect to leakage tendencies for automotive

3.1.3 thickener, n—in lubricating grease, a substance com-

wheel bearing applications.

posed of finely-divided particles dispersed in a liquid lubricant

to form the product’s structure. NOTE1—Itispossibleforskilledoperatorstoobservechangesingrease

characteristics that can occur during the test, such as grease condition.

Leakage is reported as a quantitative value, whereas the evaluation of

grease condition is subject to differences in personal judgment among

This test method is under the jurisdiction of ASTM Committee D02 on

operators and cannot be used effectively for quantitative measurements.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.G0.05 on Functional Tests - Temperature.

6. Apparatus

Current edition approved April 15, 2012. Published May 2012. Originally

approved in 1983. Last previous edition approved in 2007 as D4290–07. DOI:

6.1 Test Assembly (Figs. 1 and 2).

10.1520/D4290-07R12.

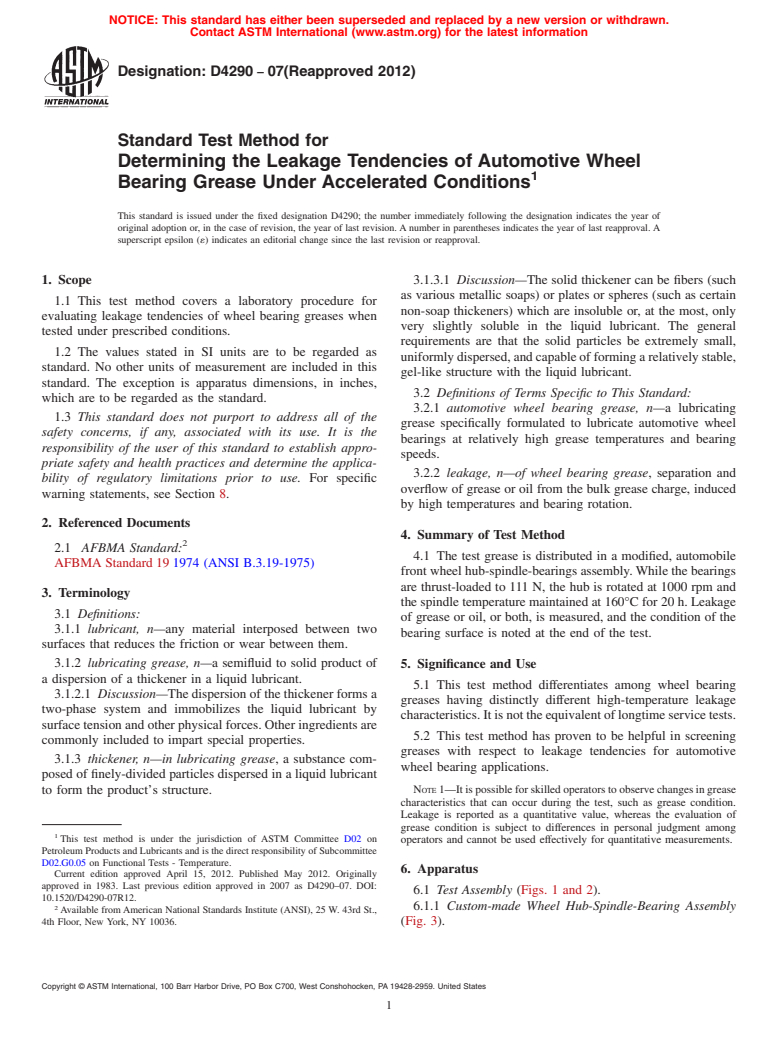

6.1.1 Custom-made Wheel Hub-Spindle-Bearing Assembly

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036. (Fig. 3).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4290 − 07 (2012)

NOTE 1—Caution should be taken when modifying older units since some may still contain asbestos insulation leading to a possible inhalation hazard.

FIG. 1 Wheel Bearing Lubricant Tester (Elevation View)

FIG. 2 Wheel Bearing Lubricant Tester (Top View)

6.1.2 Oven, electrically heated by 1800 watt heater, thermo- 6.4 Balance, having a minimum capacity of 100 g and

statically controlled to maintain spindle temperature at 160 6 minimum sensitivity of 0.1 g.

1.5°C.

7. Test Bearings

6.1.3 Spindle Drive Motor, ⁄4 hp, 120 volts dc with 1725

7.1 Use LM67048-LM67010 and LM11949-LM11910 (AF-

rpm speed control for the hub; motor torque is indicated by a

meter equipped with an adjustable, automatic cutoff. BMA Standard 19) inboard and outboard bearings, respec-

tively.

6.1.4 Fan Drive Motor, ⁄30 hp, 120 v dc, 1550 rpm.

6.2 Motor speed, oven temperature, spindle temperature,

8. Reagents and Materials

time cycles and torque are controlled or monitored, or both, by

8.1 Penmul L460 (previously called Penetone-ECS) —

accessory equipment.

(Warning—Combustible. Vapors can be harmful.)

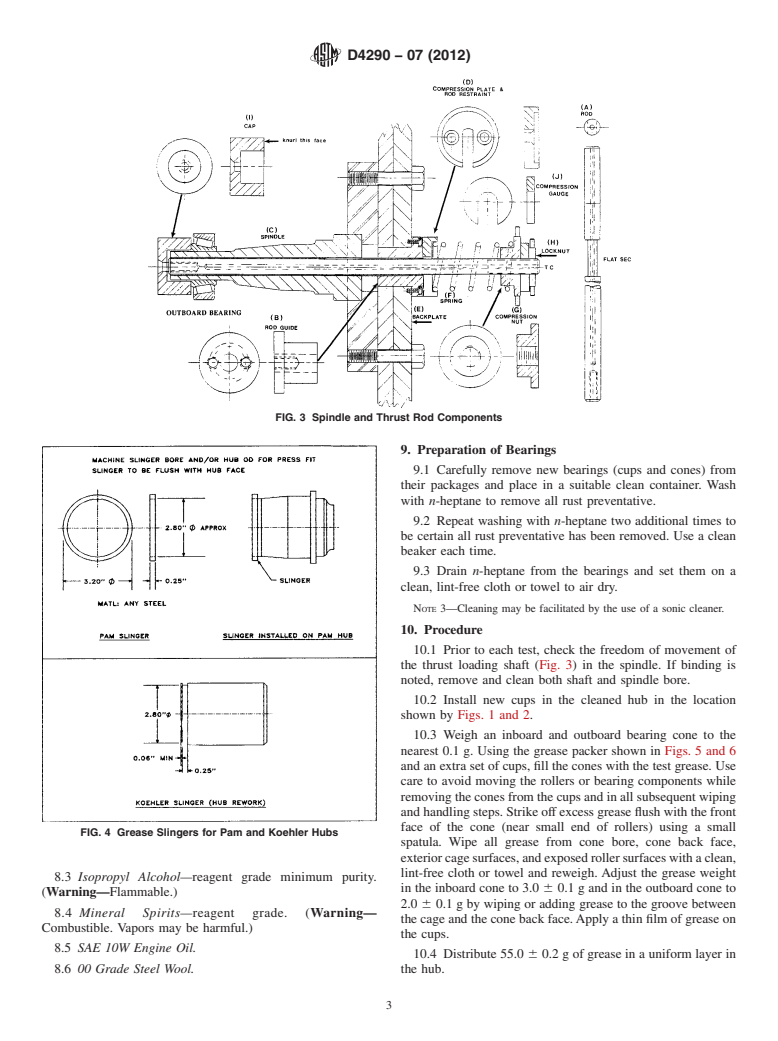

6.3 A grease slinger has been added since the original

8.2 n-heptane—reagent grade minimum purity.

design of the apparatus. Fig. 4 shows the slinger used for the

(Warning—Flammable. Harmful if inhaled.)

hub of Koehler and Pam apparatus.

NOTE 2—The slinger was developed to prevent grease from creeping 3

The sole source of supply of Penmul L460 (previously called Penetone-ECS)

along the hub and being slung off past the grease collector. Greases that

knowntothecommitteeatthistimeisPenetoneCorp.,74HudsonAve.,Tenaply,NJ

crept during the test can lead to erroneously low results. Addition of the

07670. If you are aware of alternative suppliers, please provide this information to

slinger will not affect the precision data in Section 13 because none of the ASTM International Headquarters. Your comments will receive careful consider-

round-robin greases exhibited grease creepage. ation at a meeting of the responsible technical committee, which you may attend.

D4290 − 07 (2012)

FIG. 3 Spindle and Thrust Rod Components

9. Preparation of Bearings

9.1 Carefully remove new bearings (cups and cones) from

their packages and place in a suitable clean container. Wash

with n-heptane to remove all rust preventative.

9.2 Repeat washing with n-heptane two additional times to

be certain all rust preventative has been removed. Use a clean

beaker each time.

9.3 Drain n-heptane from the bearings and set them on a

clean, lint-free cloth or towel to air dry.

NOTE 3—Cleaning may be facilitated by the use of a sonic cleaner.

10. Procedure

10.1 Prior to each test, check the freedom of movement of

the thrust loading shaft (Fig. 3) in the spindle. If binding is

noted, remove and clean both shaft and spindle bore.

10.2 Install new cups in the cleaned hub in the location

shown by Figs. 1 and 2.

10.3 Weigh an inboard and outboard bearing cone to the

nearest 0.1 g. Using the grease packer shown in Figs. 5 and 6

and an extra set of cups, fill the cones with the test grease. Use

care to avoid moving the rollers or bearing components while

removing the cones from the cups and in all subsequent wiping

and handling steps. Strike off excess grease flush with the front

face of the cone (near small end of rollers) using a small

FIG. 4 Grease Slingers for Pam and Koehler Hubs

spatula. Wipe all grease from cone bore, cone back face,

exteriorcagesurfaces,andexposedrollersurfaceswithaclean,

lint-free cloth or towel and reweigh. Adjust the grease weight

8.3 Isopropyl Alcohol—reagent grade minimum purity.

in the inboard cone to 3.0 6 0.1 g and in the outboard cone to

(Warning—Flammable.)

2.0 6 0.1 g by wiping or adding grease to the groove between

8.4 Mineral Spirits—reagent grade. (Warning—

the cage and the cone back face.Apply a thin film of grease on

Combustible. Vapors may be harmful.)

the cups.

8.5 SAE 10W Engine Oil.

10.4 Distribute 55.0 6 0.2 g of grease in a uniform layer in

8.6 00 Grade Steel Wool. the hub.

D4290 − 07 (2012)

temperature has stabilized at the test temperature, make no

further adjustment of the oven temperature for the duration of

the test.

10.10 Asteady-state running torque will develop in the first

2 h of operation as indicated by a stabilized value on the meter.

R

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.