ASTM D4169-22

(Practice)Standard Practice for Performance Testing of Shipping Containers and Systems

Standard Practice for Performance Testing of Shipping Containers and Systems

SIGNIFICANCE AND USE

4.1 This practice provides a guide for the evaluation of shipping units in accordance with a uniform system, using established test methods at levels representative of those occurring in actual distribution. The recommended test levels are based on available information on the shipping and handling environment, and current industry/government practice and experience (1-13).6 The tests should be performed sequentially on the same containers in the order given. For use as a performance test, this practice requires that the shipping unit tested remain unopened until the sequence of tests are completed. If used for other purposes, such as package development, it may be useful to open and inspect shipping units at various times throughout the sequence. This may, however, prohibit evaluating the influence of the container closure on container performance.

4.2 For Distribution Cycle 18, as referred to in MIL-STD-2073–1, the use of this practice is defined in subsequent sections identified as DC-18.

SCOPE

1.1 This practice provides a uniform basis of evaluating, in a laboratory, the ability of shipping units to withstand the distribution environment. This is accomplished by subjecting them to a test plan consisting of a sequence of anticipated hazard elements encountered in various distribution cycles. This practice is not intended to supplant material specifications or existing preshipment test procedures.

1.2 Consider the use of Practice D7386 for testing of packages for single parcel shipments.

1.3 The suitability of this practice for use with hazardous materials has not been determined.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

- Status

- Historical

- Publication Date

- 31-Dec-2021

- Technical Committee

- D10 - Packaging

- Current Stage

Relations

- Replaced By

ASTM D4169-23 - Standard Practice for Performance Testing of Shipping Containers and Systems - Effective Date

- 01-Dec-2023

- Effective Date

- 01-Dec-2023

- Effective Date

- 01-Oct-2023

- Effective Date

- 01-Aug-2019

- Effective Date

- 01-Aug-2019

- Effective Date

- 01-Sep-2017

- Refers

ASTM D951-17 - Standard Test Method for Water Resistance of Shipping Containers by Spray Method - Effective Date

- 01-Sep-2017

- Effective Date

- 01-May-2017

- Effective Date

- 01-Apr-2016

- Effective Date

- 01-Oct-2015

- Effective Date

- 01-Oct-2015

- Effective Date

- 01-Apr-2014

- Effective Date

- 15-Mar-2013

- Effective Date

- 01-Apr-2012

- Refers

ASTM D4728-06(2012) - Standard Test Method for Random Vibration Testing of Shipping Containers - Effective Date

- 01-Apr-2012

ASTM D4169-22 - Standard Practice for Performance Testing of Shipping Containers and Systems

REDLINE ASTM D4169-22 - Standard Practice for Performance Testing of Shipping Containers and Systems

ASTM D4169-22 - Standard Practice for Performance Testing of Shipping Containers and Systems

Frequently Asked Questions

ASTM D4169-22 is a standard published by ASTM International. Its full title is "Standard Practice for Performance Testing of Shipping Containers and Systems". This standard covers: SIGNIFICANCE AND USE 4.1 This practice provides a guide for the evaluation of shipping units in accordance with a uniform system, using established test methods at levels representative of those occurring in actual distribution. The recommended test levels are based on available information on the shipping and handling environment, and current industry/government practice and experience (1-13).6 The tests should be performed sequentially on the same containers in the order given. For use as a performance test, this practice requires that the shipping unit tested remain unopened until the sequence of tests are completed. If used for other purposes, such as package development, it may be useful to open and inspect shipping units at various times throughout the sequence. This may, however, prohibit evaluating the influence of the container closure on container performance. 4.2 For Distribution Cycle 18, as referred to in MIL-STD-2073–1, the use of this practice is defined in subsequent sections identified as DC-18. SCOPE 1.1 This practice provides a uniform basis of evaluating, in a laboratory, the ability of shipping units to withstand the distribution environment. This is accomplished by subjecting them to a test plan consisting of a sequence of anticipated hazard elements encountered in various distribution cycles. This practice is not intended to supplant material specifications or existing preshipment test procedures. 1.2 Consider the use of Practice D7386 for testing of packages for single parcel shipments. 1.3 The suitability of this practice for use with hazardous materials has not been determined. 1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. 1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SIGNIFICANCE AND USE 4.1 This practice provides a guide for the evaluation of shipping units in accordance with a uniform system, using established test methods at levels representative of those occurring in actual distribution. The recommended test levels are based on available information on the shipping and handling environment, and current industry/government practice and experience (1-13).6 The tests should be performed sequentially on the same containers in the order given. For use as a performance test, this practice requires that the shipping unit tested remain unopened until the sequence of tests are completed. If used for other purposes, such as package development, it may be useful to open and inspect shipping units at various times throughout the sequence. This may, however, prohibit evaluating the influence of the container closure on container performance. 4.2 For Distribution Cycle 18, as referred to in MIL-STD-2073–1, the use of this practice is defined in subsequent sections identified as DC-18. SCOPE 1.1 This practice provides a uniform basis of evaluating, in a laboratory, the ability of shipping units to withstand the distribution environment. This is accomplished by subjecting them to a test plan consisting of a sequence of anticipated hazard elements encountered in various distribution cycles. This practice is not intended to supplant material specifications or existing preshipment test procedures. 1.2 Consider the use of Practice D7386 for testing of packages for single parcel shipments. 1.3 The suitability of this practice for use with hazardous materials has not been determined. 1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. 1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM D4169-22 is classified under the following ICS (International Classification for Standards) categories: 55.040 - Packaging materials and accessories. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM D4169-22 has the following relationships with other standards: It is inter standard links to ASTM D4169-23, ASTM D999-08(2023), ASTM D5276-19(2023), ASTM D6055-96(2019), ASTM D4003-98(2019)e1, ASTM D5276-98(2017), ASTM D951-17, ASTM D6344-04(2017), ASTM D7386-16, ASTM D999-08(2015), ASTM D4003-98(2015), ASTM D6055-96(2014), ASTM D4332-13, ASTM D7386-12, ASTM D4728-06(2012). Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ASTM D4169-22 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4169 − 22

Standard Practice for

Performance Testing of Shipping Containers and Systems

This standard is issued under the fixed designation D4169; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This practice provides a uniform basis of evaluating, in

a laboratory, the ability of shipping units to withstand the D642TestMethodforDeterminingCompressiveResistance

distribution environment. This is accomplished by subjecting of Shipping Containers, Components, and Unit Loads

them to a test plan consisting of a sequence of anticipated D880Test Method for ImpactTesting for Shipping Contain-

hazard elements encountered in various distribution cycles. ers and Systems

Thispracticeisnotintendedtosupplantmaterialspecifications D951Test Method for Water Resistance of Shipping Con-

or existing preshipment test procedures. tainers by Spray Method

D996Terminology of Packaging and Distribution Environ-

1.2 Consider the use of Practice D7386 for testing of

ments

packages for single parcel shipments.

D999Test Methods for Vibration Testing of Shipping Con-

1.3 The suitability of this practice for use with hazardous

tainers

materials has not been determined.

D4003Test Methods for Programmable Horizontal Impact

Test for Shipping Containers and Systems

1.4 Thevaluesstatedininch-poundunitsaretoberegarded

D4332Practice for Conditioning Containers, Packages, or

as standard. The values given in parentheses are mathematical

Packaging Components for Testing

conversions to SI units that are provided for information only

D4728Test Method for Random Vibration Testing of Ship-

and are not considered standard.

ping Containers

1.5 This standard does not purport to address all of the

D5265Test Method for Bridge Impact Testing

safety concerns, if any, associated with its use. It is the

D5276Test Method for Drop Test of Loaded Containers by

responsibility of the user of this standard to establish appro-

Free Fall

priate safety, health, and environmental practices and deter-

D5277Test Method for Performing Programmed Horizontal

mine the applicability of regulatory limitations prior to use.

Impacts Using an Inclined Impact Tester

1.6 This international standard was developed in accor-

D5487Test Method for Simulated Drop of Loaded Contain-

dance with internationally recognized principles on standard-

ers by Shock Machines

ization established in the Decision on Principles for the

D6055Test Methods for Mechanical Handling of Unitized

Development of International Standards, Guides and Recom-

Loads and Large Shipping Cases and Crates

mendations issued by the World Trade Organization Technical

D6179Test Methods for Rough Handling of Unitized Loads

Barriers to Trade (TBT) Committee.

and Large Shipping Cases and Crates

D6344Test Method for Concentrated Impacts to Transport

Packages

This practice is under the jurisdiction ofASTM Committee D10 on Packaging

andisthedirectresponsibilityofSubcommitteeD10.21onShippingContainersand

Systems - Application of Performance Test Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 1, 2022. Published February 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2004. Last previous edition approved in 2016 as D4169–16. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D4169-22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4169 − 22

D6653Test Methods for Determining the Effects of High 3.2.7.2 large shipping unit, n—for DC-18, a large shipping

Altitude on Packaging Systems by Vacuum Method unit is defined as one having at least one edge dimension or

D7386Practice for Performance Testing of Packages for diameterover60in.(1.52m)oragrossweightinexcessof100

Single Parcel Delivery Systems lb(45kg),oritisonethathasagrossweightexceeding100lb

F1327Terminology Relating to Barrier Materials for Medi- (45 kg) and is secured to a base or to the base of a shipping

cal Packaging (Withdrawn 2007) unit.

2.2 Military Standards: 3.2.8 test plan, n—a specific listing of the test sequence to

MIL-STD-810FEnvironmental Test Methods

be followed to simulate the hazards anticipated during the

MIL-STD-2073–1 DOD Standard Practice for Military distribution cycle of a shipping unit. Included will be the test

Packaging

intensity and number of sequential tests to be conducted. See

8.5.

2.3 Association of American Railroads Standards:

General Information Bulletin No. 2Rules and Procedures

3.2.9 test schedule, n—the specific procedure to be used,

for Testing of New Loading and Bracing Methods or

including the three assurance level intensities, and a reference

Materials to the test method that is the basis of the schedule.

3.2.9.1 Discussion—Thepurposeofthescheduleistosimu-

3. Terminology

late the forces occurring during any hazard element of the

distribution cycle. See Section 9.

3.1 Definitions—General definitions for the packaging and

distribution environments are found in Terminology D996. 3.2.10 total velocity change, (∆V), n—thesumoftheimpact

and rebound velocities.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 acceptance criteria, n—the acceptable quality level 3.3 Abbreviations:

that must be met after the shipping unit has been subjected to

3.3.1 TOFC—trailer on flatcar.

the test plan. See Section 7.

3.3.2 COFC—container on flatcar.

3.2.2 assurance level, n—theleveloftestintensitybasedon

3.3.3 TL—truckload.

its probability of occurring in a typical distribution cycle.

3.3.4 CL—carload.

3.2.2.1 Discussion—Level I is a high level of test intensity

3.3.5 LTL—less than truckload.

andhasalowprobabilityofoccurrence.LevelIIIisalowlevel

of test intensity, but has a correspondingly high probability of

4. Significance and Use

occurrence. Level II is between these extremes. For Distribu-

4.1 This practice provides a guide for the evaluation of

tion Cycle 18 (DC–18), see MIL-STD-2073–1 for definitions

shipping units in accordance with a uniform system, using

of military levels of protection.

established test methods at levels representative of those

3.2.3 coeffıcient of restitution, n—the ratio of the rebound

occurring in actual distribution. The recommended test levels

velocity to the impact velocity.

are based on available information on the shipping and

3.2.4 distribution cycle (DC), n—the sequential listing of

handling environment, and current industry/government prac-

the test schedules employed to simulate the hazard elements 6

tice and experience (1-13). The tests should be performed

expectedtooccurforaspecificroutingofashippingunitfrom

sequentially on the same containers in the order given. For use

production to consumption. See Table 1.

as a performance test, this practice requires that the shipping

3.2.5 feeder aircraft, n—small, potentially non-pressurized

unit tested remain unopened until the sequence of tests are

aircraft used to transport express packages.

completed. If used for other purposes, such as package

development, it may be useful to open and inspect shipping

3.2.6 hazard element, n—a specific event that occurs in a

units at various times throughout the sequence. This may,

distribution cycle that may pose a hazard to a shipping unit.

however, prohibit evaluating the influence of the container

Theelementwillusuallybesimulatedbyasingletestschedule.

closure on container performance.

See Section 9.

3.2.7 shipping unit, n—the smallest complete unit that will 4.2 For Distribution Cycle 18, as referred to in MIL-STD-

2073–1, the use of this practice is defined in subsequent

be subjected to the distribution environment, for example, a

shipping container and its contents. sections identified as DC-18.

3.2.7.1 small shipping unit, n—for DC-18, a small shipping

5. Test Specimen

unit is defined as one having no edge dimension or diameter

5.1 Test specimens consist of representative samples of

over 60 in. (1.52 m) and a gross weight of 100 lb (45 kg) or

complete shipping units, including actual contents. Products

less.

with blemishes or minor defects may be used if the defective

component is not to be studied by the test and if the defect is

3 documented in the report. Dummy test loads are acceptable if

The last approved version of this historical standard is referenced on

testingtheactualproductmightbehazardous.Ifadummyload

www.astm.org.

Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

5 6

Available fromAssociation ofAmerican Railroads (AAR), 425 Third St., SW, The boldface numbers in parentheses refer to a list of references at the end of

Washington, DC 20024, http://www.aar.org. this standard.

D4169 − 22

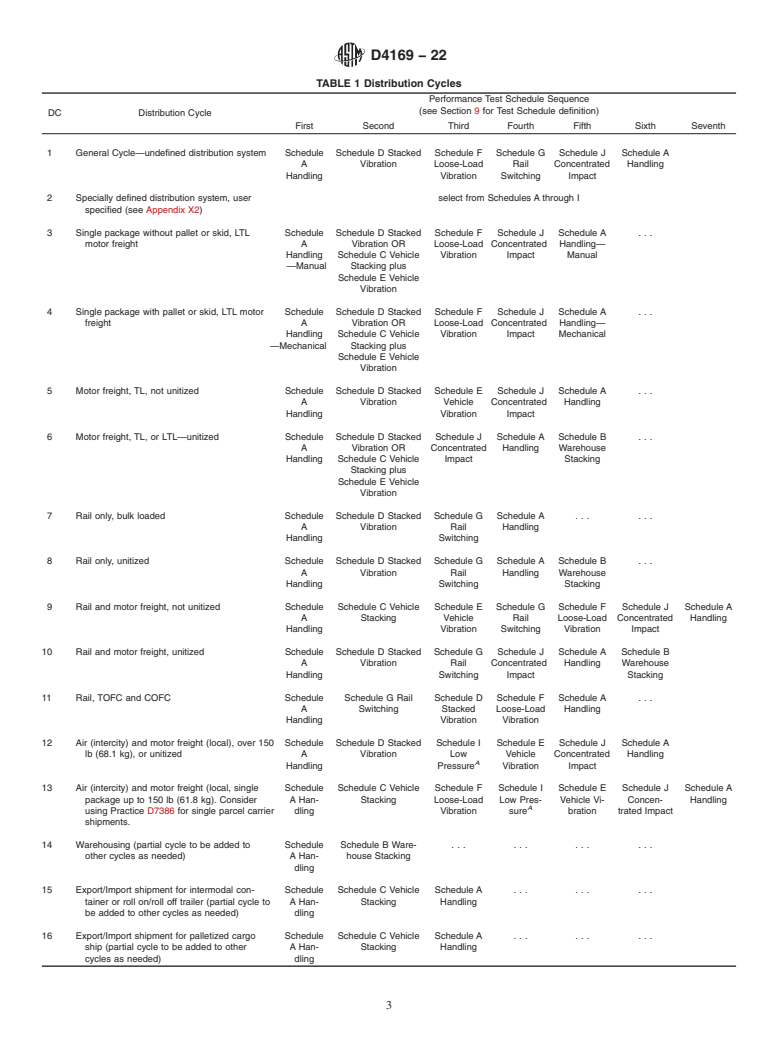

TABLE 1 Distribution Cycles

Performance Test Schedule Sequence

(see Section 9 for Test Schedule definition)

DC Distribution Cycle

First Second Third Fourth Fifth Sixth Seventh

1 General Cycle—undefined distribution system Schedule Schedule D Stacked Schedule F Schedule G Schedule J Schedule A

A Vibration Loose-Load Rail Concentrated Handling

Handling Vibration Switching Impact

2 Specially defined distribution system, user select from Schedules A through I

specified (see Appendix X2)

3 Single package without pallet or skid, LTL Schedule Schedule D Stacked Schedule F Schedule J Schedule A .

motor freight A Vibration OR Loose-Load Concentrated Handling—

Handling Schedule C Vehicle Vibration Impact Manual

—Manual Stacking plus

Schedule E Vehicle

Vibration

4 Single package with pallet or skid, LTL motor Schedule Schedule D Stacked Schedule F Schedule J Schedule A .

freight A Vibration OR Loose-Load Concentrated Handling—

Handling Schedule C Vehicle Vibration Impact Mechanical

—Mechanical Stacking plus

Schedule E Vehicle

Vibration

5 Motor freight, TL, not unitized Schedule Schedule D Stacked Schedule E Schedule J Schedule A .

A Vibration Vehicle Concentrated Handling

Handling Vibration Impact

6 Motor freight, TL, or LTL—unitized Schedule Schedule D Stacked Schedule J Schedule A Schedule B .

A Vibration OR Concentrated Handling Warehouse

Handling Schedule C Vehicle Impact Stacking

Stacking plus

Schedule E Vehicle

Vibration

7 Rail only, bulk loaded Schedule Schedule D Stacked Schedule G Schedule A . .

A Vibration Rail Handling

Handling Switching

8 Rail only, unitized Schedule Schedule D Stacked Schedule G Schedule A Schedule B .

A Vibration Rail Handling Warehouse

Handling Switching Stacking

9 Rail and motor freight, not unitized Schedule Schedule C Vehicle Schedule E Schedule G Schedule F Schedule J Schedule A

A Stacking Vehicle Rail Loose-Load Concentrated Handling

Handling Vibration Switching Vibration Impact

10 Rail and motor freight, unitized Schedule Schedule D Stacked Schedule G Schedule J Schedule A Schedule B

A Vibration Rail Concentrated Handling Warehouse

Handling Switching Impact Stacking

11 Rail, TOFC and COFC Schedule Schedule G Rail Schedule D Schedule F Schedule A .

A Switching Stacked Loose-Load Handling

Handling Vibration Vibration

12 Air (intercity) and motor freight (local), over 150 Schedule Schedule D Stacked Schedule I Schedule E Schedule J Schedule A

lb (68.1 kg), or unitized A Vibration Low Vehicle Concentrated Handling

A

Handling Pressure Vibration Impact

13 Air (intercity) and motor freight (local, single Schedule Schedule C Vehicle Schedule F Schedule I Schedule E Schedule J Schedule A

package up to 150 lb (61.8 kg). Consider A Han- Stacking Loose-Load Low Pres- Vehicle Vi- Concen- Handling

A

using Practice D7386 for single parcel carrier dling Vibration sure bration trated Impact

shipments.

14 Warehousing (partial cycle to be added to Schedule Schedule B Ware- . . . .

other cycles as needed) A Han- house Stacking

dling

15 Export/Import shipment for intermodal con- Schedule Schedule C Vehicle Schedule A . . .

tainer or roll on/roll off trailer (partial cycle to A Han- Stacking Handling

be added to other cycles as needed) dling

16 Export/Import shipment for palletized cargo Schedule Schedule C Vehicle Schedule A . . .

ship (partial cycle to be added to other A Han- Stacking Handling

cycles as needed) dling

D4169 − 22

TABLE 1 Continued

Performance Test Schedule Sequence

(see Section 9 for Test Schedule definition)

DC Distribution Cycle

First Second Third Fourth Fifth Sixth Seventh

17 Export/Import shipment for break bulk cargo Schedule Schedule C Vehicle Schedule A . . .

ship (partial cycle to be added to other A Stacking Handling

cycles as needed) Handling

Non-Commercial Government shipments in

18 Refer to Annex A1 for Test Schedules applying to DC-18.

accordance with MIL-STD-2073–1

A

This high altitude, non-pressurized transport simulation test may be deleted from this distribution cycle when testing shipping units that contain primary packages that

have a porous material.

is used, it should be instrumented to determine if the fragility atmosphere whenever possible. If not possible, conduct the

level of the actual product has been exceeded. Take care to tests as soon after removal from the conditioning atmosphere

duplicate the load characteristics of the actual product, and as practicable. Recondition the shipping units as necessary

avoid unnecessary prehandling. during the test plan. For atmospheres other than the standard

conditioning atmosphere, the user must determine the appro-

5.2 Care must be taken to ensure that no degradation has

priate compressive load factor for warehouse and vehicle

occurred to either the product or the package if the test

stacking,asthefactorsgivenin11.2arebasedontestingunder

packages have been shipped to the test site. If any doubt exists

the standard test atmosphere.

as to the condition of the package, repack the product in new

packaging material before testing.

7. Acceptance Criteria

5.3 The number of test replications depends on the desired

7.1 Acceptance criteria must be established prior to testing

objectives of the testing and the availability of duplicate

and should consider the required condition of the product at

products and shipping containers. Replicate testing is recom-

receipt. The organizations conducting the test may choose any

mended to improve the reliability of the test results.

acceptance criteria suitable for their purpose. It is advisable to

compare the type and quantity of damage that occurred to the

6. Conditioning

test specimens with the damage that occurs during actual

6.1 Ifthedistributioncyclecontainsclimaticconditionsthat

distribution and handling or with test results of similar con-

have an effect on the performance characteristics of the

tainers whose shipping history is known.

product,shippingcontainer,orcomponentssuchascushioning,

7.2 In many cases, the acceptance criteria can be the

use one of the following procedures. (It should be noted that

following:

differentatmosphericconditionsarelikelytoexistbetweenthe

Criterion 1—Product is damage-free.

origin and destination points of a distribution cycle, particu-

Criterion 2—Package is intact.

larly for export/import cycles.)

Criterion 3—Both criteria 1 and 2.

6.1.1 Conduct the test at standard conditions and compen-

Often,thismeansthattheshippingcontaineranditscontents

sate for the effects of any climatic condition. Condition the

aresuitablefornormalsaleanduseatthecompletionofthetest

shipping units to a standard atmosphere of 73.4 6 2°F (23 6

cycle. Detailed acceptance criteria may allow for accepting

1°C) and 50 6 2% relative humidity. Condition fiberboard

specified damage to a product or its package. The form and

containers in accordance with Practice D4332. The same

content of acceptance criteria may vary widely, in accordance

atmospheric condition should be used for any assurance level.

with the particular situation. Methods may range from simple

A conditioning period of 72 h, or sufficient time to reach

pass-fail judgments to highly quantitative scoring or analysis

equilibrium of all parts of the package and product is recom-

systems.

mended. Tests should be conducted in the conditioned atmo-

sphere whenever possible. If not possible, conduct the tests as

8. Procedure

soon after removal from the conditioning atmosphere as

8.1 Define Shipping Unit—Describe shipping unit in terms

practicable. Recondition the shipping units to the standard

ofsize,weight,andformofconstruction.See3.2.7.Determine

atmosphere as necessary during the test plan.

whether the container will be manually or mechanically

6.1.2 Insomecircumstances,itmaybenecessarytoconduct

handled.

some or all of the tests at special climatic conditions, such as

thosegiveninPracticeD4332,orTestMethodD951,orothers 8.2 Establish Assurance Level—Specify a level of test

(salt, spray, water immersion, humidity, or temperature). The intensity. The level should be one of three pre-established

sameclimaticconditionshouldbeusedforanyassurancelevel. assurance levels. This must be pre-established based on the

A conditioning period should be provided which will allow product value, the desired level of anticipated damage that can

sufficient time to reach equilibrium of all parts of the package be tolerated, the number of units to be shipped, knowledge of

and product. Tests should be conducted in the conditioned the shipping environment, or other criteria.Assurance Level II

D4169 − 22

is suggested unless conditions dictate otherwise. Assurance

A Handling—manual and drop, impact, 10

LevelIprovidesamoreseveretestthanII.AssuranceLevelIII

mechanical stability

provides a less severe test than II. The assurance level may be

B Warehouse Stacking compression 11

varied between schedules (see Sections 10–15) if such

C Vehicle Stacking compression 11

D Stacked Vibration vibration 12

variations are known to occur. The test levels used should be

E Vehicle Vibration vibration 12

reported. See Section 18.

F Loose Load Vibration repetitive shock 13

G Rail Switching longitudinal shock 14

8.3 Determine Acceptance Criteria—Acceptance criteria

H Environmental Hazard cyclic exposure 15

are related to the desired condition of the product and package

I Low Pressure Hazard vacuum 16

J Concentrated Impact impact 17

at the end of the distribution cycle. See Section 7.

8.4 Select Distribution Cycle—Select a Distribution Cycle

10. Schedule A—Handling—Manual and Mechanical

from the available standard distribution cycles compiled in

10.1 There are two types of handling hazard element,

Table 1. Use the DC that most closely correlates with the

manual and mechanical. The manual handling test should be

projected distribution. When the distribution is undefined, the

general distribution cycle DC-1 should be selected. When the used for single containers, smaller packages, and any shipping

container that can be handled manually, up to a weight of 200

anticipated distribution is well understood, a special distribu-

tion cycle DC-2 may be specified. In using DC-2, the user lb (90.7 kg). Mechanical handling should be used for unitized

loads, large cases and crates, and any shipping container or

selects test schedules from Section 9 and specifies the test

sequence (see Appendix X2 for more details). For purposes of system that will be handled by mechanical means. Manual and

mechanical handling are described further in 10.2 and 10.3.

DC-3andDC-13,thebottomofasinglepackageisthesurface

on which the package rests in its most stable orientation. The

10.2 Manual Handling—The test levels and the test method

identified bottom should be utilized for purposes of determin-

for this schedule of the distribution cycle are intended to

ing the starting orientation of each test schedule within the

determine the ability of the shipping unit to withstand the

above stated distribution cycles.

hazards occurring during manual handlings, such as loading,

8.5 Write Test Plan—Prepare a test plan by using the

unloading, stacking, sorting, or palletizing. The main hazards

sequence presented in Table 1 for the distribution cycle

from these operations are the impacts caused by dropping or

selected. Obtain the test intensities from the referenced sched-

throwing. Size, weight, and shape of the shipping unit will

ules. The test plan intensity details must take into account the affect the intensity of these hazards. Several test method

assurance levels selected as well as the physical description of

options are permitted, including free fall and simulated drop

the shipping unit. Table 1 thus leads to a detailed test plan test using shock machines. While these test methods produce

consistingoftheexactsequenceinwhichtheshippingunitwill

similar results, the shock machine method produces more

be subjected to the test inputs. The test schedules associated control of orientations of impact; see Test Method D5487 for

with each element reference the existing ASTM test methods

limitations of the shock machine method.

for clarification of the equipment and techniques to be used to

10.2.1 For long narrow packages that are mechanically

conduct the test.

sorted, another hazard to be simulated is bridge impact

8.5.1 Sample test plans are provided in Appendix X1.

(10.2.4).

8.6 Select Samples for Test—See Section 5. 10.2.2 Mechanical handling (10.3) may be used when it is

anticipated that handling will be by mechanical means only.

8.7 Condition Samples—See Section 6.

10.2.3 For the free-fall and shock machine tests, recom-

8.8 Perform Tests—Perform tests as directed in reference

mended drop heights, the number of drops, the sequence of

ASTM standards and as further modified in the special

drops, and the shipping unit orientation at impact are as

instructions for each test schedule.

follows:

8.9 Evaluate Results—Evaluate results to determine if the

Test Methods—D5276, D5487.

shipping units meet the acceptance criteria. See Section 7. Conditioning—See Section 6.

Drop Height, in. (mm)

8.10 Document Test Results—Document test results by re-

Shipping Weight, lb (kg) Assurance Level

porting each step. See Section 18.

I II III

8.11 Monitor Shipments—When possible, obtain feedback

0 to 20 (0 to 9.1) 24 (610) 15 (381) 9 (229)

by monitoring shipments of the container that was tested to

20 to 40 (9.1 to 18.1) 21 (533) 13 (330) 8 (203)

ensure that the type and quantity of damage obtained by the 40 to 60 (18.1 to 27.2) 18 (457) 12 (305) 7 (178)

60 to 80 (27.2 to 36.3) 15 (381) 10 (254) 6 (152)

laboratorytestingcorrelateswiththedamagethatoccursinthe

80 to 100 (36.3 to 45.4) 12 (305) 9 (229) 5 (127)

distribution cycle. This information is very useful for the

100 to 200 (45.4 to 90.7) 10 (254) 7 (178) 4 (102)

planning of subsequent tests of similar shipping containers.

Number of

Impacts at Impact Orientation

Specified First Sequence of Distribution Cycle

9. Hazard Elements and Test Schedules

Height

Box Bag or Sack Cylindrical Container

9.1 Hazard Elements and Test Schedules are categorized as

follows:

One top face top

Schedule Hazard Element Test Section Two adjacent bottom edges two sides two sides 90° apart

D4169 − 22

10.3.1.2 Crane Handling—(Conduct this test only if cranes

Two diagonally opposite both ends bottom edges 90°

bottom corners apart

areusedforhandlinginthedistributionprocess.)Onedropflat

One bottom opposite face bottom

on bottom and one drop on base edge in accordance with

Method D of Test Methods D6179. Use the same drop heights

Number of

versus shipping unit weight as in 10.3.1.1.

Impacts at Impact Orientation

10.3.1.3 Side Impact Test—Impact all four sides of the

Specified Second Sequence of Distribution Cycle

shippingunitinaccordancewithTestMethodD880,Procedure

Height

Box Bag or Sack Cylindrical Container

B.Alternately,useTestMethodD4003MethodBusingashort

duration programmer, assuming the coefficient of restitution is

One vertical edge face top

Two adjacent side faces two sides two sides 90° apart 0.0 and the total velocity change is equivalent to the specified

Two one top corner and one both ends bottom edges 90°

impact velocity.

adjacent top edge apart

One see Note 1 see Note 1 see Note 1 Assurance Level Impact Velocity ft/s(m/s)

NOTE 1—On the last impact of the last manual handling sequence in a I 5.75(1.75)

II 4.0(1.22)

distributioncycle,theimpactshouldbemadeat twicethespecifiedheight

III 3.0(0.91)

or equivalent velocity change. (This is the final (sixth) drop in the

sequence, not an additional drop.) The drop should be in the impact

10.3.1.4 Tip Test—In accordance with Method F of Test

orientation most likely for a drop to occur, usually the largest face or the

Methods D6179.

bottom.Fordistributioncycleswhereanydroporientationispossible(that

10.3.1.5 TipoverTest—InaccordancewithMethodGofTest

is, shipments by means of carriers that mechanically sort packages), this

Methods D6179 if shipping unit fails Tip Test above.

dropshouldbeinthemostcriticalordamage-proneorientation,asdefined

10.3.2 Unitized Loads—Perform the following tests se-

in Test Method D5276.

NOTE2—Theequivalentvelocitychangecorrespondingtothespecified quences as appropriate for the method of truck handling:

drop height used for the shock machine method shall be calculated as

Test Methods—D880, D4003, D6055, D6179.

specified in Test Method D5487.

Conditioning—See Section 6.

10.3.2.1 All Methods of Truck Handling—Pick up, transport

10.2.4 Bridge Impact Test:

around test course, and set down in accordance with Test

Test Method—D5265.

Methods D6055, Method A for fork lift, Method B for spade

Conditioning—See Section 6.

lift, Method C for clamp, and Method D for pull pack.

10.2.4.1 Conduct bridge impacts on long, narrow shipping

Assurance Level Cycles (Round Trips)

units which have a length of at least 36 in. (915 mm) and each

of the other two dimensions are 20% or less of the longest

I8

dimension.

II 5

III 3

10.2.4.2 These tests are required only once in any test

schedule sequence.

(1) For shipments by means of less-than-truckload (LTL),

simulate transfer terminal handling by performing fork lift

10.3 Mechanical Handling—The test levels and the test

truck transport over a floor hazard described as follows: a

method for this schedule of the distribution cycle are intended

modified nominal 2 by 6 in. board with one edge beveled full

to determine the ability of large and heavy shipping units,

height at 45° (see Fig. 1) shall be placed on the course in a

single packages with pallet or skid, and unitized loads to

position where both lift truck wheels on one side must pass

withstand the mechanical handling hazards that occur during

over it during each handling sequence, and a second modified

loading, unloading, sorting, or stacking. For large shipping

nominal2by6in.boardshallbeplacedonthecourseafterthe

cases and crates and any single package with pallet or skid,

90° turn in such a position that both lift truck wheels on the

different test methods are used versus unit loads. For various

oppositesidemustpassoveritduringeachhandlingsequence.

types of unit loads, test methods also vary, depending on the

10.3.2.2 All Methods of Truck Handling—Impact all four

method of truck handling: fork, clamp, spade, or pull/pack.

sides of the shipping unit in accordance with Test Method

10.3.1 Large Shipping Cases and Crates and Single Pack-

D880 Procedure B. Alternately, use Test Method D4003,

ages with Pallet or Skid—Perform the following test se-

Method B using a short duration programmer, assuming the

quences:

coefficient of restitution is 0.0 and the total velocity change is

Test Methods—D6179, D880, D4003.

equivalent to the specified impact velocity.

Conditioning—See Section 6.

10.3.1.1 Fork Lift Truck Handling—One rotational flat drop

from each opposite base edge in accordance with Method C of

Test Methods D6179 and one rotational drop on each of two

diagonallyoppositebasecornersinaccordancewithMethodB

of Test Methods D6179.

Drop Height, in. (mm)

Assurance Level

Gross Weight, lb (kg) I II III

0 to 500 (0 to 226.8) 12 (305) 9 (229) 6 (152)

Over 500 (226.8) 9 (229) 6 (152) 3 (076)

FIG. 1 Floor Hazard

D4169 − 22

where:

Assurance Level Impact Velocity ft/s(m/s)

F = factor given above for compression package (construc-

p

I 5.75 (1.75)

tion Type 3),

II 4.0 (1.22)

III 3.0 (0.91) P = fraction of load supported by product,

F = factor given above for appropriate container

10.3.2.3 Fork Lift Truck Handling—One rotational flat drop c

construction, and

from each opposite base edge in accordance with Method C of

C = fraction of load supported by container.

Test Methods D6179.

If a full pallet load is tested, F factors may be reduced by

Drop Height, in. (mm)

Assurance Level

30%.

Gross Weight, lb (kg) I II III

11.3 For warehouse stacking and vehicle stacking made up

0 to 500 (0 to 226.8) 12 (305) 9 (229) 6 (152)

of identical shipping units, load the shipping unit to the

Over 500 (226.8) 9 (229) 6 (152) 3 (76)

computed load value, as calculated below. Remove the load

11. Schedule B—Warehouse Stacking and Schedule

within 3 s after reaching the specified value.

C—Vehicle Stacking

H 2 h

L 5 M 3J 3F (2)

11.1 Thetestlevelsandthetestmethodsfortheseschedules

h

of a distribution cycle are intended to determine the ability of

where:

theshippingunittowithstandthecompressiveloadsthatoccur

L = computed load, lbf or N,

during warehouse storage or vehicle transport. The required

M = mass of one shipping unit or individual container, lb or

loading must consider the effects of length of time in storage,

kg,

thealignmentorstackingpatternofthecontainer,variabilityin

J = 1 lbf/lb or 9.8 N/kg,

container strength, moisture content, temperature, previous

H = maximumheightofstackinstorageortransitvehicle(if

handling and transportation, method of load support, and

vehicle stack height is unknown, use 108 in. (2.7 m)),

vibration. The minimum required loads for typical shipping

in. or m,

units which include the combined effects of the above factors

h = heightofshippingunitorindividualcontainer,in.orm,

arerecommendedbelowforScheduleB—WarehouseStacking

and

and Schedule C—Vehicle Stacking (select test levels for either

F = a factor to account for the combined effect of the

warehouse or vehicle stacking as defined in the distribution

individual factors described above.

cycle):

11.4 For vehicle stacking made up of mixed commodities

Test Method—D642.

and shipped in an LTLor small package delivery environment,

Conditioning—73.4 6 2°F (23 6 1°C), 50 6 2% relative

loadtheshippingunittothecomputedloadvalue,ascalculated

humidity in accordance with Practice D4332.

below. Remove the load within 3 s after reaching the specified

11.2 Use the following test levels:

value. If the average shipping density factor (M) for the

f

F Factors Assurance Level

specific distribution system is not known, use a value of 10

Schedule Schedule

3 3

lb/ft (160 kg/m ).

B—Warehouse C—Vehicle

Shipping Unit Construction I II III I II III

l 3w 3h H 2 h

L 5 M 3J 3 3F (3)

f

1. Corrugated, fiberboard, or plastic 8.0 4.5 3.0 10.0 7.0 5.0 K h

container that may or may not

have stress–bearing interior where:

packaging using these materials,

L = computed load, lbf or N,

and where the product does not

M = shipping density factor, lb/ft or kg/m3,

support any of the load.

f

J = 1 lbf/lb or 9.8 N/kg,

2. Corrugated, fiberboard, or plastic 4.5 3.0 2.0 6.0 4.5 3.0

H = maximum height of stack in transit vehicle (if vehicle

container that has stress-bearing

stack height is unknown, use 108 in.(2.7 m)), in. or m,

interior packaging with rigid

inserts such as wood.

see Note 3,

h = height of shipping unit or individual container, in. or

3. Containers constructed of materials 3.0 2.0 1.5 4.0 3.0 2.0

m,

other than corrugated, fiberboard,

or plastic that are not l = length of shipping unit or individual container, in. or

temperature or humidity sensitive

m,

or where the product supports

w = widthofshippingunitorindividualcontainer,in.orm,

the load directly, for example,

3 3 3 3

K = 1728 in. /ft or1m /m , and

compression package.

F = a factor to account for the combined effect of the

4. If the product supports a known

individual factors described above.

portion of the load, the F factor is

NOTE 3—The value for H, when unknown, is reduced to 54 in. (1.4 m)

calculated in the following

from108in.(2.7m)forpackagesunder30lb(13.6kg)and2.0ft (0.056

manner:

m ) or less in size when applied to a vehicle stacking hazard element in

F 5 P F 1C F (1)

~ !

~ ! LTL shipments.

p c

D4169 − 22

12. Schedule D—Stacked Vibration and Schedule Recommended intensities and durations for the random tests

E—Vehicle Vibration are given in 12.4, and those for sine tests are given in 12.5.

12.1 The test levels and test methods for these distribution 12.3 Schedule E—Vehicle Vibration—Perform the test for

cycles are intended to determine the shipping units ability to each possible shipping orientation (up to three axes). Recom-

withstand the vertical vibration environment during transport mendedintensitiesanddurationsfortherandomtestsaregiven

and the dynamic compression forces resulting from vehicle in 12.4, and those for sine tests are given in 12.5.

stacking. The test levels and methods account for the

12.4 Random Test Option:

magnitude, frequency range, duration and direction of vibra-

Test Method—D4728.

tion. Select the Schedule D—Stacked Vibration or Schedule

Conditioning—See Section 6.

E—Vehicle Vibration (no stacking) test as defined by the

12.4.1 ThepowerspectraldensitiesinTables2-4,asdefined

distribution cycle. Test methods for sine and random vibration

by their mode of transport, frequency and amplitude

are permitted testing options.The two methods are not equiva-

breakpoints, and test durations are recommended.

lent and will not necessarily produce the same results. The

12.4.1.1 Conducting the Truck Profile test is recommended

random test method results in a better simulation of actual

for Distribution Cycles 1, 3, 4, 5 and 6.

transport vibration environments, and is the preferred method

12.4.1.2 Conducting the Rail Profile test is recommended

forqualification.Thesinetestmethodisoftenusedasameans

for Distribution Cycles 7, 8 and 11.

of determining and observing system resonances and can be

12.4.1.3 A 60 min test using the Truck Profile followed by

used in conjunction with the random method.

a 120 min test using the Rail Profile is recommended for

12.2 Schedule D—Stacked Vibration—Perform the test Distribution Cycles 9 and 10.

along the vertical axis with the load in the normal shipping 12.4.1.4 A 60 min test using the Truck Profile followed by

orientation or with the predetermined bottom orientation (as a 120 min test using the Air Profile is recommended for

specified in DC-3) facing down. It is permissible to use a Distribution Cycles 12 and 13.

concentrateddeadloadtosimulateanupperunitloadormixed 12.4.2 If more detailed information is available on the

commodities. The concentrated load may be calculated from transport vibration environment or the shipping unit damage

the formulas in 11.3 and 11.4, with the F factor set equal to 1. history, it is recommended that the procedure be modified to

TABLE 2 TRUCK—Power Spectral Density Levels

Power Spectral Density Level, G /Hz

Frequency

High Level Medium Level Low Level

1 0.00072 0.00072 0.0004

3 0.030 0.018 0.010

4 0.030 0.018 0.010

6 0.0012 0.00072 0.00040

12 0.0012 0.00072 0.00040

16 0.0060 0.0036 0.0020

25 0.0060 0.0036 0.0020

30 0.0012 0.00072 0.00040

40 0.0060 0.0036 0.0020

80 0.0060 0.0036 0.0020

100 0.00060 0.00036 0.00020

200 0.000030 0.000018 0.000010

Overall G 0.70 0.54 0.40

rms

D4169 − 22

TABLE 3 RAIL—Power Spectral Density Levels

Power Spectral Density Level G /Hz

Frequency Assurance Level

I II III

1 0.00002 0.00001 0.000005

2 0.002 0.001 0.0005

50 0.002 0.001 0.0005

90 0.0008 0.0004 0.0002

200 0.00002 0.00001 0.000005

Overall G 0.41 0.29 0.2

rms

use such information. The test time required to reproduce Low Level Time = 0.67 × 60 = 40 minutes

shipping damage is dependent on the mode of failure, as well Medium Level Time = 0.25 × 60 = 15 minutes

as the vibration level. Test durations ranging from 30 min to 6 High Level Time = 0.08 × 60 = 5 minutes

h have been used successfully for different product or package (2)Rounding rule will be in effect. Any duration value

types. A 3 h (180 min) duration is reasonable to use in the equal to or less than 0.5 round down; equal to or greater than

absence of specific shipping or testing experience. 0.6 round up.

12.4.2.1 FortheTruckProfiletest,itisrecommendedtouse (3) For a 3 hour (180 minutes) duration, a total of 120

acombinationofallthreeTestLevels(low,medium,andhigh) minutes of Low Level, 45 minutes of Medium Level, and 15

for a better simulation of actual truck vibration environments. minutes of High Level vibration will be required in one

TheTruck test should be performed ina1h(60 min) loop that orientation.Thesedurationvaluesarenotdirectcorrelationsto

can be repeated for longer duration simulations. The recom- the flight time of the aircraft.

mendedtestdurationsfortherandomvibrationtruckprofileare

(4)The air vibration profile is not compressed and uses

as follows: actualactivevibrationdatausingconstructedprobabilitybased

Low Level for 40 minutes. on CL of 99, 95, and 90 % respectively.

Medium Level for 15 minutes.

12.4.2.3 For vibration tests when more than one shipping

High Level for 5 minutes.

orientation is possible, the total duration should be distributed

12.4.2.2 For theAir Profile test, it is recommended to use a

evenly between the orientations tested.

combination of all three Test Levels (low, medium, and high)

NOTE 4—When conducting the Truck and Air Profiles, Assurance

for a better simulation of actual air vibration environments.

Levels I, II, and III are not used.

The air test should be performed ina2h (120 min) duration,

in three 40 minute loops that can be adjusted for other time 12.5 Sine Test Option:

duration simulations. The recommended test durations for the Test Method—D999, Method B or C.

random air profile are as follows: Conditioning—See Section 6.

Low Level for 27 minutes. Special Instructions—Dwelltimeisforeachnotedproduct

Medium Level for 10 minutes. or package resonance up to four discrete resonances. If more

High Level for 3 minutes. than four resonances are noted, test at the four frequencies

(1)If duration varies from 120 minutes use the following where the greatest response is noted. In frequency sweeps it is

formula to calculate duration loop: advisable to consider the frequency ranges normally encoun-

Example—CalculatingVibration duration loop for 3 hour tered in the type of transportation being considered. The

duration (180 minutes): resonant frequency(ies) may shift during test due to changing

D4169 − 22

TABLE 4 AIR—Power Spectral Density Levels

Power Spectral Density Level (G /Hz)

Frequency (Hz)

High Level Medium Level Low Level

1 0.001 0.0006 0.0003

2 0.01 0.006 0.003

42 0.0001 0.00006 0.00003

50 0.0005 0.0003 0.00015

120 0.0005 0.0003 0.00015

200 0.000025 0.000015 0.0000075

Overall G 0.29 0.22 0.16

rms

characteristics of the container system. It is suggested that the Special Instructions—Dwell time distributed 50% along

dwell frequency be varied slightly during the test to detect any normalverticalshippingaxisorwiththepredeterminedbottom

shift and to continue testing at the frequency of maximum

orientation (as specified in DC-3 and DC-13) facing down and

response. Use the following test levels:

remaining 50% evenly along all other possible shipping

Amplitude orientations:

Dwell

Assurance Frequency Range, (O-Peak), g

Time,

Assurance Level Dwell Time, min

Level Hz

min

Rail Truck

I60

II 40

I 3 to 100 0.25 0.5 15

III 30

II 3 to 100 0.25 0.5 10

III 3 to 100 0.25 0.5 5

14. Schedule G—Simulated Rail Switching

13. Schedule F—Loose Load Vibration

14.1 The test levels and test methods for this schedule are

13.1 The test levels and the test method for this schedule of

intended to determine the ability of the shipping unit to

the distribution cycle are intended to determine the ability of

withstand the acceleration levels and compressive forces that

the shipping unit to withstand the repetitive shocks occurring

might occur during rail switching operations.

duringtransportationofbulkorlooseloads.Thetestlevelsand

Test Methods—D4003, Test Method A; or D5277.

test method account for amplitude, direction, and duration of

Conditioning—See Section 6.

the repetitive shocks.

Special Instructions—Four impacts shall be performed.

13.2 Use the following test levels:

For railcars with standard draft gear, shock durations of 40 6

Test Method—D999, Method A1 or A2.

10 ms shall be used, as measured on the floor of the carriage.

Conditioning—See Section 6.

D4169 − 22

Forrailcarswithlong–traveldraftgear,shockdurationsof300

Assurance Level Temperature, °F (°C) Water Spray Duration, h

6 50 ms shall be used. Reference Association of American

I 160±5(71±2) 16

Railroads, General Information Bulletin No. 2.

55±5(13±2) X 2

Note that Test Method D5277 is used for standard draft

–5±5(–21±2) 2

125±5(52±2) X 2

gear only.

55±5(13±2) X 2

Refer to Test Methods D4003 or D5277 for specific

32±5(0±2) 16

instructions on how to instrument and conduct the test.

160±5(71±2) 4

55±5(13±2) X 2

14.2 Procedure—Load shipping unit on carriage against

–65±5(–54±2) 2

160±5(71±2) 16

bulkhead. Use a backload equivalent to a minimum of 3 ft

55±5(13±2) X 2

lineal (0.9 m) of cargo. The package used as backload in

–65±5(–54±2) 2

contact with the test package must be identical to the test 40±5(4±2) 3

160±5(71±2) 16

package.

II 160±5(71±2) 14

14.3 Test Levels—Allow the carriage to impact a cushioned

55±5(13±2) X 2

barrierinaccordancewiththefollowingtable.AssuranceLevel

160±5(71±2) 4

Ishallbeusedforopen-toprailcarloadtests.AssuranceLevel

32±5(0±2) 2

55±5(13±2) X 2

II shall be used for boxcar load tests for non-hazardous

The cyclic sequence shall be repeated on three

materials and for TOFC/COFC load tests for non-hazardous

consecutive days. At the end of the three day period, the

materials. There is no Assurance Level III for this Test unit pack being tested shall then set overnight

160±5(71±2) 16

Schedule.

14.3.1 If known, container impact surfaces should be the

III Not applicable

same as occur in actual shipment. If the shipping orientation is

15.3 Durationtimeshallbemeasuredstartingthemomentat

not known, or if more than one orientation is possible, the first

which temperature setting is changed to next condition.

three impacts should be on that test specimen surface which is

15.4 When specified in the contract, this test should be

deemed to be most sensitive to damage. For the fourth impact,

performed as part of the complete distribution cycle for the

rotate the specimen 180° on the carriage.

smallest complete shipping unit, as part of the contract.

Assurance Impact Velocity

Level Number

mph (m/s)

16. Schedule I—Low Pressure (High Altitude) Hazard

I 1 4(±0.5) 1.79(±0.22)

16.1 Thisscheduleisintendedtoprovidefortheanticipated

2 6 (± 0.5) 2.68 (± 0.22)

3 8 (± 0.5) 3.58 (± 0.22)

reduction in pressure when packaged products are transported

4 (rotate 180°) 8 (± 0.5) 3.58 (± 0.22)

by means of certain modes of transport, such as feeder aircraft

or by ground over mountain passes. This test shall be con-

II 1 4 (± 0.5) 1.79 (± 0.22)

2 6 (± 0.5) 2.68 (± 0.22)

ducted in accordance with levels described in Test Method

3 6 (± 0.5) 2.68 (± 0.22)

D6653.Thistestshouldbeincludedforproductsandpackages

4 (rotate 180°) 6 (± 0.5) 2.68 (± 0.22)

that could be sensitive to a low pressure environment, for

14.4 Procedure Modification—If more detailed information

example, sealed flexible non-porous packages, liquid

is available on backload or shock characteristics it is recom-

containers, or porous packages that may be packed in such a

mended that the above procedure be modified to use such

manner as to be adversely affected by low pressure environ-

information.

ments. This test may be del

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4169 − 16 D4169 − 22

Standard Practice for

Performance Testing of Shipping Containers and Systems

This standard is issued under the fixed designation D4169; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*Scope

1.1 This practice provides a uniform basis of evaluating, in a laboratory, the ability of shipping units to withstand the distribution

environment. This is accomplished by subjecting them to a test plan consisting of a sequence of anticipated hazard elements

encountered in various distribution cycles. This practice is not intended to supplant material specifications or existing preshipment

test procedures.

1.2 Consider the use of Practice D7386 for testing of packages for single parcel shipments.

1.3 The suitability of this practice for use with hazardous materials has not been determined.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

This practice is under the jurisdiction of ASTM Committee D10 on Packaging and is the direct responsibility of Subcommittee D10.21 on Shipping Containers and

Systems - Application of Performance Test Methods.

Current edition approved April 1, 2016Jan. 1, 2022. Published June 2016February 2022. Originally approved in 2004. Last previous edition approved in 20142016 as

D4169 – 14.D4169 – 16. DOI: 10.1520/D4169-16.10.1520/D4169-22.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4169 − 22

2. Referenced Documents

2.1 ASTM Standards:

D642 Test Method for Determining Compressive Resistance of Shipping Containers, Components, and Unit Loads

D880 Test Method for Impact Testing for Shipping Containers and Systems

D951 Test Method for Water Resistance of Shipping Containers by Spray Method

D996 Terminology of Packaging and Distribution Environments

D999 Test Methods for Vibration Testing of Shipping Containers

D4003 Test Methods for Programmable Horizontal Impact Test for Shipping Containers and Systems

D4332 Practice for Conditioning Containers, Packages, or Packaging Components for Testing

D4728 Test Method for Random Vibration Testing of Shipping Containers

D5265 Test Method for Bridge Impact Testing

D5276 Test Method for Drop Test of Loaded Containers by Free Fall

D5277 Test Method for Performing Programmed Horizontal Impacts Using an Inclined Impact Tester

D5487 Test Method for Simulated Drop of Loaded Containers by Shock Machines

D6055 Test Methods for Mechanical Handling of Unitized Loads and Large Shipping Cases and Crates

D6179 Test Methods for Rough Handling of Unitized Loads and Large Shipping Cases and Crates

D6344 Test Method for Concentrated Impacts to Transport Packages

D6653 Test Methods for Determining the Effects of High Altitude on Packaging Systems by Vacuum Method

D7386 Practice for Performance Testing of Packages for Single Parcel Delivery Systems

F1327 Terminology Relating to Barrier Materials for Medical Packaging (Withdrawn 2007)

2.2 Military Standards:

MIL-STD-810F Environmental Test Methods

MIL-STD-2073–1 DOD Standard Practice for Military Packaging

2.3 Association of American Railroads Standards:

General Information Bulletin No. 2 Rules and Procedures for Testing of New Loading and Bracing Methods or Materials

3. Terminology

3.1 Definitions—General definitions for the packaging and distribution environments are found in Terminology D996.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 acceptance criteria—criteria, n—the acceptable quality level that must be met after the shipping unit has been subjected to

the test plan. See Section 7.

3.2.2 assurance level—level, n—the level of test intensity based on its probability of occurring in a typical distribution cycle.

3.2.2.1 Discussion—

Level I is a high level of test intensity and has a low probability of occurrence. Level III is a low level of test intensity, but has

a correspondingly high probability of occurrence. Level II is between these extremes. For Distribution Cycle 18 (DC–18), see

MIL-STD-2073–1 for definitions of military levels of protection.

3.2.3 coeffıcient of restitution—restitution, n—the ratio of the rebound velocity to the impact velocity.

3.2.4 distribution cycle (DC)—(DC), n—the sequential listing of the test schedules employed to simulate the hazard elements

expected to occur for a specific routing of a shipping unit from production to consumption. See Table 1.

3.2.5 feeder aircraft—aircraft, n—small, potentially non-pressurized aircraft used to transport express packages.

3.2.6 hazard element—element, n—a specific event that occurs in a distribution cycle that may pose a hazard to a shipping unit.

The element will usually be simulated by a single test schedule. See Section 9.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, DLA Document Services, Building 4/D, 700 Robbins Ave., Philadelphia, PA

19111-5098, http://dodssp.daps.dla.mil.19111-5094, http://quicksearch.dla.mil.

Available from Association of American Railroads (AAR), 425 Third St., SW, Washington, DC 20024, http://www.aar.org.

D4169 − 22

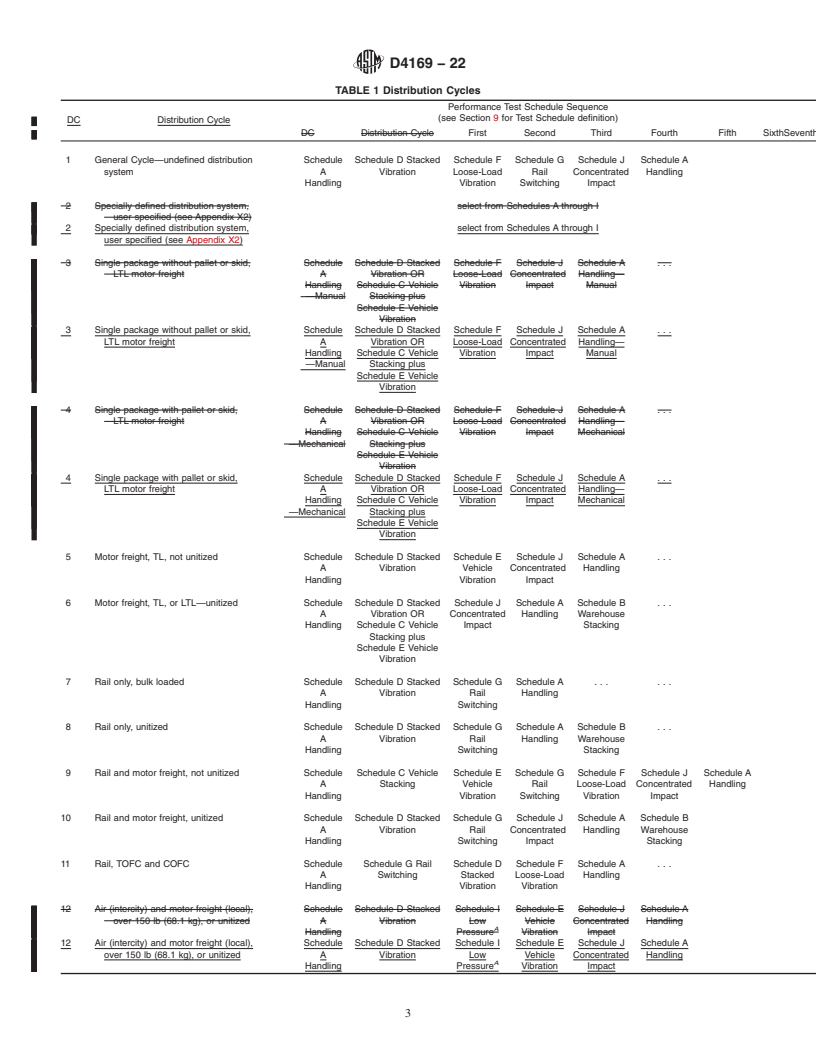

TABLE 1 Distribution Cycles

Performance Test Schedule Sequence

(see Section 9 for Test Schedule definition)

DC Distribution Cycle

DC Distribution Cycle First Second Third Fourth Fifth SixthSeventh

1 General Cycle—undefined distribution Schedule Schedule D Stacked Schedule F Schedule G Schedule J Schedule A

system A Vibration Loose-Load Rail Concentrated Handling

Handling Vibration Switching Impact

2 Specially defined distribution system, select from Schedules A through I

user specified (see Appendix X2)

2 Specially defined distribution system, select from Schedules A through I

user specified (see Appendix X2)

3 Single package without pallet or skid, Schedule Schedule D Stacked Schedule F Schedule J Schedule A . . .

LTL motor freight A Vibration OR Loose-Load Concentrated Handling—

Handling Schedule C Vehicle Vibration Impact Manual

—Manual Stacking plus

Schedule E Vehicle

Vibration

3 Single package without pallet or skid, Schedule Schedule D Stacked Schedule F Schedule J Schedule A . . .

LTL motor freight A Vibration OR Loose-Load Concentrated Handling—

Handling Schedule C Vehicle Vibration Impact Manual

—Manual Stacking plus

Schedule E Vehicle

Vibration

4 Single package with pallet or skid, Schedule Schedule D Stacked Schedule F Schedule J Schedule A . . .

LTL motor freight A Vibration OR Loose-Load Concentrated Handling—

Handling Schedule C Vehicle Vibration Impact Mechanical

—Mechanical Stacking plus

Schedule E Vehicle

Vibration

4 Single package with pallet or skid, Schedule Schedule D Stacked Schedule F Schedule J Schedule A . . .

LTL motor freight A Vibration OR Loose-Load Concentrated Handling—

Handling Schedule C Vehicle Vibration Impact Mechanical

—Mechanical Stacking plus

Schedule E Vehicle

Vibration

5 Motor freight, TL, not unitized Schedule Schedule D Stacked Schedule E Schedule J Schedule A . . .

A Vibration Vehicle Concentrated Handling

Handling Vibration Impact

6 Motor freight, TL, or LTL—unitized Schedule Schedule D Stacked Schedule J Schedule A Schedule B . . .

A Vibration OR Concentrated Handling Warehouse

Handling Schedule C Vehicle Impact Stacking

Stacking plus

Schedule E Vehicle

Vibration

7 Rail only, bulk loaded Schedule Schedule D Stacked Schedule G Schedule A . . . . . .

A Vibration Rail Handling

Handling Switching

8 Rail only, unitized Schedule Schedule D Stacked Schedule G Schedule A Schedule B . . .

A Vibration Rail Handling Warehouse

Handling Switching Stacking

9 Rail and motor freight, not unitized Schedule Schedule C Vehicle Schedule E Schedule G Schedule F Schedule J Schedule A

A Stacking Vehicle Rail Loose-Load Concentrated Handling

Handling Vibration Switching Vibration Impact

10 Rail and motor freight, unitized Schedule Schedule D Stacked Schedule G Schedule J Schedule A Schedule B

A Vibration Rail Concentrated Handling Warehouse

Handling Switching Impact Stacking

11 Rail, TOFC and COFC Schedule Schedule G Rail Schedule D Schedule F Schedule A . . .

A Switching Stacked Loose-Load Handling

Handling Vibration Vibration

12 Air (intercity) and motor freight (local), Schedule Schedule D Stacked Schedule I Schedule E Schedule J Schedule A

over 150 lb (68.1 kg), or unitized A Vibration Low Vehicle Concentrated Handling

A

Handling Pressure Vibration Impact

12 Air (intercity) and motor freight (local), Schedule Schedule D Stacked Schedule I Schedule E Schedule J Schedule A

over 150 lb (68.1 kg), or unitized A Vibration Low Vehicle Concentrated Handling

A

Handling Pressure Vibration Impact

D4169 − 22

TABLE 1 Continued

Performance Test Schedule Sequence

(see Section 9 for Test Schedule definition)

DC Distribution Cycle

DC Distribution Cycle First Second Third Fourth Fifth SixthSeventh

13 Air (intercity) and motor freight (local, Schedule Schedule C Vehicle Schedule F Schedule I Schedule E Schedule J Schedule A

single package up to 150 lb (61.8 kg). A Han- Stacking Loose-Load Low Pres- Vehicle Vi- Concen- Handling

A

Consider using Practice D7386 dling Vibration sure bration trated Impact

for single parcel carrier shipments.

13 Air (intercity) and motor freight (local, Schedule Schedule C Vehicle Schedule F Schedule I Schedule E Schedule J Schedule A

single package up to 150 lb (61.8 kg). A Han- Stacking Loose-Load Low Pres- Vehicle Vi- Concen- Handling

A

Consider using Practice D7386 dling Vibration sure bration trated Impact

for single parcel carrier shipments.

14 Warehousing (partial cycle to be added to Schedule Schedule B Ware- . . . . . . . . . . . .

other cycles as needed) A Han- house Stacking

dling

15 Export/Import shipment for intermodal Schedule Schedule C Vehicle Schedule A . . . . . . . . .

container or roll on/roll off trailer (partial A Han- Stacking Handling

cycle to be added to other cycles as dling

needed)

15 Export/Import shipment for intermodal Schedule Schedule C Vehicle Schedule A . . . . . . . . .

container or roll on/roll off trailer (partial A Han- Stacking Handling

cycle to be added to other cycles as dling

needed)

16 Export/Import shipment for palletized cargo Schedule Schedule C Vehicle Schedule A . . . . . . . . .

ship (partial cycle to be added to A Han- Stacking Handling

other cycles as needed) dling

16 Export/Import shipment for palletized cargo Schedule Schedule C Vehicle Schedule A . . . . . . . . .

ship (partial cycle to be added to A Han- Stacking Handling

other cycles as needed) dling

17 Export/Import shipment for break bulk Schedule Schedule C Vehicle Schedule A . . . . . . . . .

cargo ship (partial cycle to be added A Han- Stacking Handling

to other cycles as needed) dling

17 Export/Import shipment for break bulk Schedule Schedule C Vehicle Schedule A . . . . . . . . .

cargo ship (partial cycle to be added A Han- Stacking Handling

to other cycles as needed) dling

Non-Commercial Government shipments

18 Refer to Annex A1 for Test Schedules applying to DC-18.

per MIL-STD-2073-1

Non-Commercial Government shipments

18 Refer to Annex A1 for Test Schedules applying to DC-18.

in accordance with MIL-STD-2073–1

A

This high altitude, non-pressurized transport simulation test may be deleted from this distribution cycle when testing shipping units that contain primary packages that

have a porous material.

3.2.7 shipping unit—unit, n—the smallest complete unit that will be subjected to the distribution environment, for example, a

shipping container and its contents.

3.2.7.1 small shipping unit—unit, n—for DC-18, a small shipping unit is defined as one having no edge dimension or diameter

over 60 in. (1.52 m) and a gross weight of 100 lb (45 kg) or less.

3.2.7.2 large shipping unit—unit, n—for DC-18, a large shipping unit is defined as one having at least one edge dimension or

diameter over 60 in. (1.52 m) or a gross weight in excess of 100 lb (45 kg), or it is one that has a gross weight exceeding 100 lb

(45 kg) and is secured to a base or to the base of a shipping unit.

3.2.8 test plan—plan, n—a specific listing of the test sequence to be followed to simulate the hazards anticipated during the

distribution cycle of a shipping unit. Included will be the test intensity and number of sequential tests to be conducted. See 8.5.

3.2.9 test schedule—schedule, n—the specific procedure to be used, including the three assurance level intensities, and a reference

to the test method that is the basis of the schedule.

3.2.9.1 Discussion—

The purpose of the schedule is to simulate the forces occurring during any hazard element of the distribution cycle. See Section

9.

D4169 − 22

3.2.10 total velocity change, (ΔV)—), n—the sum of the impact and rebound velocities.

3.3 Abbreviations:

3.3.1 TOFC—trailer on flatcar.

3.3.2 COFC—container on flatcar.

3.3.3 TL—truckload.

3.3.4 CL—carload.

3.3.5 LTL—less than truckload.

4. Significance and Use

4.1 This practice provides a guide for the evaluation of shipping units in accordance with a uniform system, using established test

methods at levels representative of those occurring in actual distribution. The recommended test levels are based on available

information on the shipping and handling environment, and current industry/government practice and experience (1-13). The tests

should be performed sequentially on the same containers in the order given. For use as a performance test, this practice requires

that the shipping unit tested remain unopened until the sequence of tests are completed. If used for other purposes, such as package

development, it may be useful to open and inspect shipping units at various times throughout the sequence. This may, however,

prohibit evaluating the influence of the container closure on container performance.

4.2 For Distribution Cycle 18, as referred to in MIL-STD-2073–1, the use of this practice is defined in subsequent sections

identified as DC-18.

5. Test Specimen

5.1 Test specimens consist of representative samples of complete shipping units, including actual contents. Products with

blemishes or minor defects may be used if the defective component is not to be studied by the test and if the defect is documented

in the report. Dummy test loads are acceptable if testing the actual product might be hazardous. If a dummy load is used, it should

be instrumented to determine if the fragility level of the actual product has been exceeded. Take care to duplicate the load

characteristics of the actual product, and avoid unnecessary prehandling.

5.2 Care must be taken to ensure that no degradation has occurred to either the product or the package if the test packages have

been shipped to the test site. If any doubt exists as to the condition of the package, repack the product in new packaging material

before testing.

5.3 The number of test replications depends on the desired objectives of the testing and the availability of duplicate products and

shipping containers. Replicate testing is recommended to improve the reliability of the test results.

6. Conditioning

6.1 If the distribution cycle contains climatic conditions that have an effect on the performance characteristics of the product,

shipping container, or components such as cushioning, use one of the following procedures. (It should be noted that different

atmospheric conditions are likely to exist between the origin and destination points of a distribution cycle, particularly for

export/import cycles.)

6.1.1 Conduct the test at standard conditions and compensate for the effects of any climatic condition. Condition the shipping units

to a standard atmosphere of 73.4 6 2°F (23 6 1°C) and 50 6 2 % relative humidity. Condition fiberboard containers in accordance

with Practice D4332. The same atmospheric condition should be used for any assurance level. A conditioning period of 72 h, or

sufficient time to reach equilibrium of all parts of the package and product is recommended. Tests should be conducted in the

The boldface numbers in parentheses refer to a list of references at the end of this practice.standard.

D4169 − 22

conditioned atmosphere whenever possible. If not possible, conduct the tests as soon after removal from the conditioning

atmosphere as practicable. Recondition the shipping units to the standard atmosphere as necessary during the test plan.