ASTM E1001-99a

(Practice)Standard Practice for Detection and Evaluation of Discontinuities by the Immersed Pulse-Echo Ultrasonic Method Using Longitudinal Waves

Standard Practice for Detection and Evaluation of Discontinuities by the Immersed Pulse-Echo Ultrasonic Method Using Longitudinal Waves

SCOPE

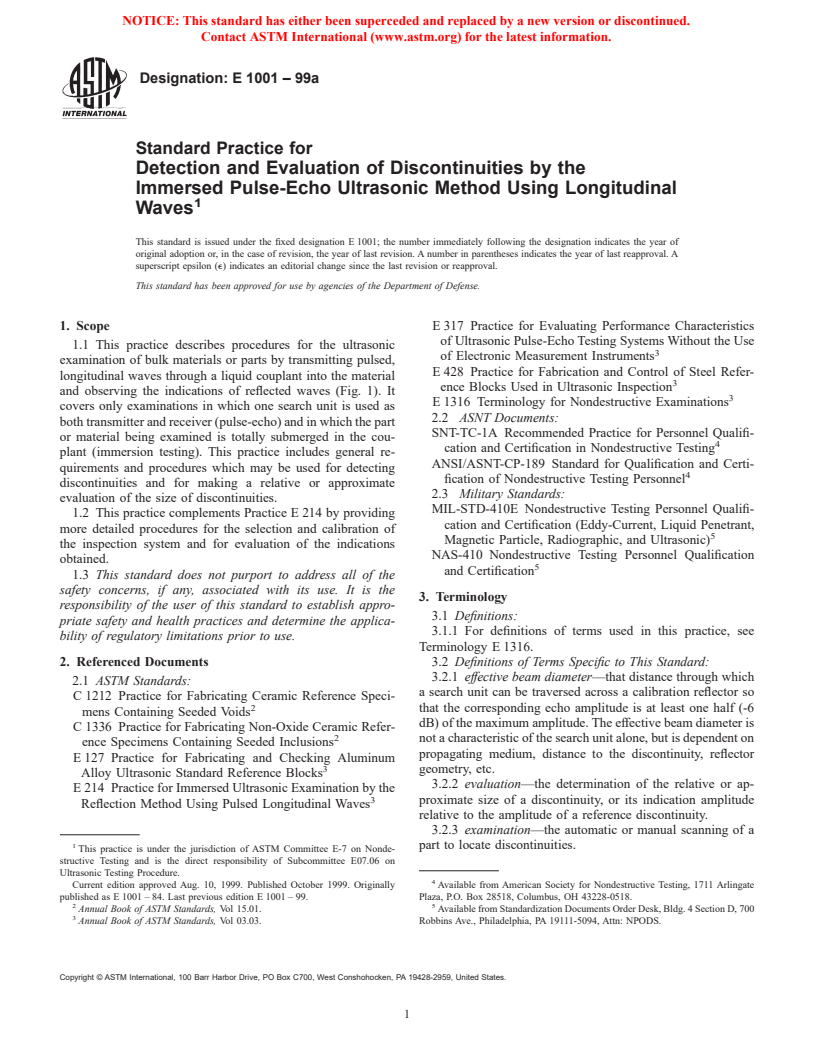

1.1 This practice describes procedures for the ultrasonic examination of bulk materials or parts by transmitting pulsed, longitudinal waves through a liquid couplant into the material and observing the indications of reflected waves (Fig. 1). It covers only examinations in which one search unit is used as both transmitter and receiver (pulse-echo) and in which the part or material being examined is totally submerged in the couplant (immersion testing). This practice includes general requirements and procedures which may be used for detecting discontinuities and for making a relative or approximate evaluation of the size of discontinuities.

1.2 This practice complements Practice E214 by providing more detailed procedures for the selection and calibration of the inspection system and for evaluation of the indications obtained.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1001 – 99a

Standard Practice for

Detection and Evaluation of Discontinuities by the

Immersed Pulse-Echo Ultrasonic Method Using Longitudinal

Waves

This standard is issued under the fixed designation E 1001; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E 317 Practice for Evaluating Performance Characteristics

of Ultrasonic Pulse-Echo Testing Systems Without the Use

1.1 This practice describes procedures for the ultrasonic

of Electronic Measurement Instruments

examination of bulk materials or parts by transmitting pulsed,

E 428 Practice for Fabrication and Control of Steel Refer-

longitudinal waves through a liquid couplant into the material

ence Blocks Used in Ultrasonic Inspection

and observing the indications of reflected waves (Fig. 1). It

E 1316 Terminology for Nondestructive Examinations

covers only examinations in which one search unit is used as

2.2 ASNT Documents:

both transmitter and receiver (pulse-echo) and in which the part

SNT-TC-1A Recommended Practice for Personnel Qualifi-

or material being examined is totally submerged in the cou-

cation and Certification in Nondestructive Testing

plant (immersion testing). This practice includes general re-

ANSI/ASNT-CP-189 Standard for Qualification and Certi-

quirements and procedures which may be used for detecting

fication of Nondestructive Testing Personnel

discontinuities and for making a relative or approximate

2.3 Military Standards:

evaluation of the size of discontinuities.

MIL-STD-410E Nondestructive Testing Personnel Qualifi-

1.2 This practice complements Practice E 214 by providing

cation and Certification (Eddy-Current, Liquid Penetrant,

more detailed procedures for the selection and calibration of

Magnetic Particle, Radiographic, and Ultrasonic)

the inspection system and for evaluation of the indications

NAS-410 Nondestructive Testing Personnel Qualification

obtained.

and Certification

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Definitions:

priate safety and health practices and determine the applica-

3.1.1 For definitions of terms used in this practice, see

bility of regulatory limitations prior to use.

Terminology E 1316.

2. Referenced Documents 3.2 Definitions of Terms Specific to This Standard:

3.2.1 effective beam diameter—that distance through which

2.1 ASTM Standards:

a search unit can be traversed across a calibration reflector so

C 1212 Practice for Fabricating Ceramic Reference Speci-

2 that the corresponding echo amplitude is at least one half (-6

mens Containing Seeded Voids

dB) of the maximum amplitude. The effective beam diameter is

C 1336 Practice for Fabricating Non-Oxide Ceramic Refer-

2 not a characteristic of the search unit alone, but is dependent on

ence Specimens Containing Seeded Inclusions

propagating medium, distance to the discontinuity, reflector

E 127 Practice for Fabricating and Checking Aluminum

geometry, etc.

Alloy Ultrasonic Standard Reference Blocks

3.2.2 evaluation—the determination of the relative or ap-

E 214 Practice for Immersed Ultrasonic Examination by the

proximate size of a discontinuity, or its indication amplitude

Reflection Method Using Pulsed Longitudinal Waves

relative to the amplitude of a reference discontinuity.

3.2.3 examination—the automatic or manual scanning of a

part to locate discontinuities.

This practice is under the jurisdiction of ASTM Committee E-7 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.06 on

Ultrasonic Testing Procedure.

Current edition approved Aug. 10, 1999. Published October 1999. Originally Available from American Society for Nondestructive Testing, 1711 Arlingate

published as E 1001 – 84. Last previous edition E 1001 – 99. Plaza, P.O. Box 28518, Columbus, OH 43228-0518.

2 5

Annual Book of ASTM Standards, Vol 15.01. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 03.03. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1001 – 99a

FIG. 1 Basic Immersion Setup

3.2.4 gain—the amount of amplification or attenuation, or signals at frequencies in the range of search unit frequencies

both, applied to an electrical signal that dictates its amplitude being used. The equipment and its display should be capable of

as displayed on the cathode-ray tube (CRT). meeting the requirements to be completed in Table 1, as agreed

3.2.5 scan index—the length of the step created by rastering upon between the supplier and the purchaser, and as measured

the search unit over the part, that is continuously scanning in in accordance with procedures described in Practice E 317 or

one direction, then stepping in the direction perpendicular to equivalent procedures (see Note 1). These requirements are

the scan. The allowable scan index should be correlated with applicable only for the frequencies required for the inspection.

the search unit effective beam diameter to ensure full coverage Also, the equipment, including the search unit, should be

of the part. capable of producing echo amplitudes of at least 60 %, of full

3.2.6 standardize—to adjust the gain of an ultrasonic instru- scale, with the noise level no greater than 20 %, from the

ment so that the amplitude of the echo from a specified appropriate reference reflector at a material distance equal to

reference reflector is a specified value. the thickness of the part to be inspected. Alternatively, if these

3.2.7 transfer—a change in scanning gain to compensate for conditions can be met at one half the part thickness, the part

differences in attenuation of the reference blocks and the part may be inspected from both sides.

or material being inspected.

NOTE 1—Significantly higher frequencies than those shown in Table 1

(for example, 50 MHz) may be necessary for the smaller critical flaw size

4. Summary of Practice

of advanced ceramics.

4.1 This practice describes a means for obtaining an evalu-

6.2 Voltage Regulator—If fluctuations in line voltage cause

ation of discontinuities in materials by immersed examination

variations exceeding 65 % of the vertical limit in an indication

with longitudinal ultrasonic waves. Equipment, reference stan-

with an amplitude of one half the vertical limit, a voltage

dards, examination and evaluation procedures, and documen-

regulator should be required on the power source. This

tation are described in detail.

requirement is not applicable to battery-operated units.

6.3 Search Units—The search unit selected should be com-

5. Significance and Use

patible with the electronic equipment being used and with the

5.1 This practice provides guidelines for the application of

material to be inspected. The search units should be of the

immersed longitudinal wave examination to the detection and

quantitative evaluation of discontinuities in materials.

TABLE 1 Minimum Equipment Requirements (Longitudinal Wave)

5.2 Although not all requirements of this practice can be

Ultrasonic Test

applied universally to all inspection situations and materials, it

Frequency, MHz

Instrument Characteristics

does provide a basis for establishing contractual criteria

2.25 5.0 10.0 15.0

between suppliers and purchasers of materials for performing

Vertical limit, in. (mm), trace to peak or percent of full

immersed pulse-echo examination, and may be used as a

screen height

general guide for writing detailed specifications for particular

Upper linearity limit, in. (mm), trace to peak or percent

of full screen height

applications.

Lower linearity limit, in. (mm), trace to peak or percent

5.3 This practice is directed towards the evaluation of

of full screen height

discontinuities detectable at normal beam incidence. If discon-

Ultrasonic sensitivity, reflector size, material distance,

in. (mm)

tinuities at other orientations are of concern, alternate scanning

Signal-to-noise ratio

techniques are required.

Entry surface resolution, in. (mm)

Back surface resolution, in. (mm)

6. Apparatus Horizontal limit, in. (mm) or percent of full screen width

Horizontal linearity range, in. (mm) or percent of full

6.1 Electronic Equipment—The electronic equipment

screen width

should be capable of producing and processing electronic

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1001 – 99a

immersion type. Only straight-beam (longitudinal) search 6.7.1 Flat Blocks—The three most commonly used sets of

units, with flat or focused acoustic lenses, should be used. reference blocks are (1) area-amplitude blocks, containing

Focused or dual element search units may provide better blocks with the same material path and various sizes of

near-surface resolution and detection of small discontinuities. reference reflectors; (2) distance-amplitude blocks containing

Generally, round or rectangular search units are used for blocks with one-size reference reflector at various material

examination whereas round search units with symmetrical paths; and (3) a combination including both area-amplitude and

sound beam patterns are used for evaluation. distance-amplitude blocks in one set. These sets are described

6.4 Alarm—For the examination of parts or material with in Practice E 127. However, other types of reference blocks

regular shape and parallel surfaces, such as plate, machined bar may be used when mutually agreed upon between the supplier

stock, and forgings, an audible alarm should be used in and the purchaser, for example, those given in Practice E 428.

preference to a visual alarm, since the examination process can Practices C 1212 and C 1336 containing seeded voids and

be accomplished at a speed which prevents reliable visual seeded inclusions may be used for advanced ceramics.

monitoring of the instrument screen. As a matter of practicality, 6.7.2 Curved Surfaces—Reference blocks with flat surfaces

an audible alarm should be used in conjunction with visual may be used for establishing gain settings for examinations on

monitoring wherever possible. The alarm should be adjustable test surfaces with radii of curvature 5 in. (130 mm) or greater.

For test surfaces with radii of curvature less than 5 in.,

to allow triggering at any commonly required level of indica-

tion amplitude and depth of material. During operation the reference blocks with the same nominal curvature should be

used, unless otherwise agreed upon between the supplier and

audible or visible signal produced by the alarm should be easily

detectable by the operator. the purchaser.

6.8 Reference Reflectors—Flat-bottom holes, (FBH), or

NOTE 2—This requirement may not be applicable if recording equip-

other artificial discontinuities, located either directly in the test

ment is used.

part or material, in a representative sample of the part or

6.4.1 Alarm Gate Synchronization—To ensure that the

material, or in reference blocks, should be used to establish the

alarm gate tracks the inspection area, the gate should lock on

reference echo amplitude or to perform distance-amplitude

the first interface pulse from the test piece rather than on the

correction, or both. For most examinations, the bottom surface

initial pulse from the system. Gating from the initial pulse can

of a suitable diameter flat-bottom hole is the common reference

result in either partial loss of the inspection area from the gate,

reflector. However, other types of artificial discontinuities

or the inclusion of the back reflection and interface signal in the

(notches, side-drilled holes, etc.) may be used when mutually

gated area. This will trigger the gate as would an imperfection.

agreed upon between the supplier and the purchaser. Seeded

6.5 Manipulating Equipment should be provided to ad-

voids (Practice C 1212), seeded inclusions (Practice C 1336),

equately support a search tube, containing the search unit, and

and laser-drilled holes are common reflectors for advanced

to allow angular adjustment in two mutually perpendicular,

ceramics.

vertical planes. A manipulator may be attached between the

7. General Examination Requirements

search tube and search unit to provide the necessary angular

adjustments. The scanning and indexing apparatus should have

7.1 Material Condition—Perform ultrasonic examination of

sufficient structural rigidity to provide support for the manipu- parts or material before machining if surface roughness and

lator and should allow smooth, accurate positioning of the

part geometry are within the tolerance specified in the contrac-

search unit. This apparatus should permit control of the scan in tual agreement. Surfaces may already be sufficiently free of

accordance with 8.3.1 and control of the index in accordance

roughness and waviness to permit a uniform examination over

with 8.2.1. Also, the scanning apparatus should be sufficiently the required areas. When it is determined that surface rough-

rigid to keep search unit backlash to within tolerances as

ness precludes adequate detection and evaluation of subsurface

specified in the contractual agreement. Water-path distances discontinuities, smooth the areas in question by machining,

should be continuously adjustable.

grinding, or other means before the examination is performed.

6.6 Tank—The container or tank should permit accurate For advanced ceramics, care should be taken to avoid gener-

positioning of the search unit, reference blocks, and part or

ating surface or near-surface cracks by the smoothing opera-

material to be examined in accordance with the requirements of tion. During examination and evaluation, ensure that the entry

Section 7. surface and back surface are free of loose scale, machining, or

6.7 Reference Artifacts—Ultrasonic reference blocks, often grinding particles or other loose foreign matter.

called test blocks or reference specimens, are used to standard- 7.2 Coverage—In all examinations, perform scanning to

ize the ultrasonic equipment and to evaluate the indications locate disc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.