ASTM E1736-15(2022)

(Practice)Standard Practice for Acousto-Ultrasonic Assessment of Filament-Wound Pressure Vessels

Standard Practice for Acousto-Ultrasonic Assessment of Filament-Wound Pressure Vessels

SIGNIFICANCE AND USE

4.1 The AU method should be considered for vessels that are proven to be free of major flaws or discontinuities as determined by conventional techniques. The AU method may be used for detecting major flaws if other methods are deemed impractical. It is important to use methods such as immersion pulse-echo ultrasonics (Practice E1001) and acoustic emission (Practice E1067) to ascertain the presence of major flaws before proceeding with AU.

4.2 The AU method is intended almost exclusively for materials characterization by assessing the collective effects of dispersed defects and subcritical flaw populations. These are material aberrations that influence AU measurements and also underlie mechanical property variations, dynamic load response, and impact and fracture resistance.7

4.3 The AU method can be used to evaluate laminate quality using access to only one surface, the usual constraint imposed by closed pressure vessels. For best results, the AU probes must be fixtured to maintain the probe orientation at normal incidence to the curved surface of the vessel. Given these constraints, this practice describes a procedure for automated AU scanning using water squirters to assess the serviceability and reliability of filament-wound pressure vessels.8

SCOPE

1.1 This practice covers a procedure for acousto-ultrasonic (AU) assessment of filament-wound pressure vessels. Guidelines are given for the detection of defect states and flaw populations that arise during materials processing or manufacturing or upon exposure to aggressive service environments. Although this practice describes an automated scanning mode, similar results can be obtained with a manual scanning mode.

1.2 This procedure recommends technical details and rules for the reliable and reproducible AU detection of defect states and flaw populations. The AU procedure described herein can be a basis for assessing the serviceability of filament-wound pressure vessels.

1.3 The objective of the AU method is primarily the assessment of defect states and diffuse flaw populations that influence the mechanical strength and ultimate reliability of filament-wound pressure vessels. The AU approach and probe configuration are designed specifically to determine composite properties in lateral rather than through-the-thickness directions.2

1.4 The AU method is not for flaw detection in the conventional sense. The AU method is most useful for materials characterization, as explained in Guide E1495, which gives the rationale and basic technology for the AU method. Flaws and discontinuities such as large voids, disbonds, or extended lack of contact of interfaces can be found by other nondestructive examination (NDE) methods such as immersion pulse-echo ultrasonics.

1.5 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this practice.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1736 − 15 (Reapproved 2022)

Standard Practice for

Acousto-Ultrasonic Assessment of Filament-Wound

Pressure Vessels

This standard is issued under the fixed designation E1736; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice covers a procedure for acousto-ultrasonic

responsibility of the user of this standard to establish appro-

(AU) assessment of filament-wound pressure vessels. Guide-

priate safety, health, and environmental practices and deter-

lines are given for the detection of defect states and flaw

mine the applicability of regulatory limitations prior to use.

populations that arise during materials processing or manufac-

1.7 This international standard was developed in accor-

turing or upon exposure to aggressive service environments.

dance with internationally recognized principles on standard-

Although this practice describes an automated scanning mode,

ization established in the Decision on Principles for the

similar results can be obtained with a manual scanning mode.

Development of International Standards, Guides and Recom-

1.2 This procedure recommends technical details and rules

mendations issued by the World Trade Organization Technical

for the reliable and reproducible AU detection of defect states

Barriers to Trade (TBT) Committee.

and flaw populations. The AU procedure described herein can

be a basis for assessing the serviceability of filament-wound

2. Referenced Documents

pressure vessels.

2.1 ASTM Standards:

1.3 The objective of the AU method is primarily the

E543 Specification for Agencies Performing Nondestructive

assessment of defect states and diffuse flaw populations that

Testing

influence the mechanical strength and ultimate reliability of

E1001 Practice for Detection and Evaluation of Discontinui-

filament-wound pressure vessels. The AU approach and probe

ties by the Immersed Pulse-Echo Ultrasonic Method

configuration are designed specifically to determine composite

Using Longitudinal Waves

properties in lateral rather than through-the-thickness direc-

E1067 PracticeforAcousticEmissionExaminationofFiber-

tions.

glass Reinforced Plastic Resin (FRP) Tanks/Vessels

1.4 TheAU method is not for flaw detection in the conven-

E1316 Terminology for Nondestructive Examinations

tional sense. The AU method is most useful for materials

E1495 Guide for Acousto-Ultrasonic Assessment of

characterization, as explained in Guide E1495, which gives the

Composites, Laminates, and Bonded Joints

rationale and basic technology for the AU method. Flaws and

2.2 ASNT Standards:

discontinuities such as large voids, disbonds, or extended lack

ANSI/ASNT CP-189 Personnel Qualification and Certifica-

of contact of interfaces can be found by other nondestructive

tion in Nondestructive Testing

examination (NDE) methods such as immersion pulse-echo

ASNT SNT-TC-1A Personnel Qualification and Certifica-

ultrasonics.

tion in Nondestructive Testing

1.5 Units—The values stated in SI units are to be regarded

2.3 AIA Standard:

as standard. No other units of measurement are included in this

NAS-410 Certification and Qualification of Nondestructive

practice.

Test Personnel

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.04 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Acoustic Emission Method. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Dec. 1, 2022. Published December 2022. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1995. Last previous edition approved in 2015 as E1736 – 15. DOI: the ASTM website.

10.1520/E1736-15R22. AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

Vary, A., “Acousto-Ultrasonics,” Nondestructive Testing of Fibre-Reinforced 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

Plastics Composites, Vol 2, J. Summerscales, ed., Elsevier Science Publishers Ltd., Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1000

Barking, Essex, England, 1990, Chapter 1, pp. 1-54. WilsonBlvd.,Suite1700,Arlington,VA22209-3928,http://www.aia-aerospace.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1736 − 15 (2022)

2.4 ISO Standard:

ISO 9712 Non-destructive Testing—Qualification and Cer-

tification of NDT Personnel

3. Terminology

3.1 Definitions—Relevant terminology and nomenclature

are defined in Terminology E1316 and Guide E1495.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 composite shell—a multilayer filament-winding that

comprises a second shell that reinforces the inner shell. The

compositeshellconsistsofcontinuousfibers,impregnatedwith

a matrix material, wound around the inner shell, and cured in

place.An example is the Kevlar-epoxy filament-wound spheri-

cal shell shown in Fig. 1. The number of layers, fiber

orientation, and composite shell thickness may vary from point

to point (Fig. 2). The examination and assessment of the

composite shell are the objectives of this practice.

3.2.2 filament-wound pressure vessel—an inner shell over-

wrapped with composite layers that form a composite shell.

The inner shell or liner may consist of an impervious metallic

or nonmetallic material. The vessel may be cylindrical or

spheroidal and will have at least one penetration with valve

attachments for introducing and holding pressurized liquids or

FIG. 2 Representation of Filament-Wound Composite Shell Lay-

ers Showing Typical Thicknesses and Layering Variations

gases.

4. Significance and Use

(Practice E1067) to ascertain the presence of major flaws

4.1 The AU method should be considered for vessels that

before proceeding with AU.

are proven to be free of major flaws or discontinuities as

4.2 The AU method is intended almost exclusively for

determined by conventional techniques. The AU method may

materials characterization by assessing the collective effects of

be used for detecting major flaws if other methods are deemed

dispersed defects and subcritical flaw populations. These are

impractical. It is important to use methods such as immersion

material aberrations that influence AU measurements and also

pulse-echo ultrasonics (Practice E1001) and acoustic emission

underlie mechanical property variations, dynamic load

response, and impact and fracture resistance.

Available from International Organization for Standardization (ISO), 1, ch. de

4.3 TheAUmethodcanbeusedtoevaluatelaminatequality

la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

using access to only one surface, the usual constraint imposed

by closed pressure vessels. For best results, the AU probes

must be fixtured to maintain the probe orientation at normal

incidence to the curved surface of the vessel. Given these

constraints, this practice describes a procedure for automated

AU scanning using water squirters to assess the serviceability

and reliability of filament-wound pressure vessels.

5. Limitations

5.1 TheAU method possesses the limitations common to all

ultrasonic methods that attempt to measure either absolute or

relative attenuation. When instrument settings and probe con-

figurations are optimized for AU, they are unsuitable for

conventional ultrasonic flaw detection because the objective of

AU is not the detection and imaging of individual micro- or

macro-flaws.

Vary, A., “Material Property Characterization,” Nondestructive Testing

Handbook—Ultrasonic Testing, Vol 7,A. S. Birks, R. E. Green, Jr., and P. McIntire,

eds., American Society for Nondestructive Testing, Columbus, OH, 1991, Section

12, pp. 383–431.

Sundaresan, M. J., Henneke, E. G., and Brosey, W. D., “Acousto-Ultrasonic

Investigation of Filament-Wound Spherical Pressure Vessels,” Materials

FIG. 1 Kevlar-Epoxy Filament-Wound Shell Evaluation, Vol 49, No. 5, 1991, pp. 601–6012.

E1736 − 15 (2022)

5.2 The AU results may be affected adversely by the 6.7 Reexamination of Repaired/Reworked Items—

following factors: Reexamination of repaired/reworked items is not addressed in

(1) couplant (squirter or water jet) variations and bubbles, this standard and if required shall be specified in the contrac-

(2) vessel surface texture and roughness, tual agreement.

(3) improper selection of probe characteristics (center fre-

7. Apparatus

quency and bandwidth),

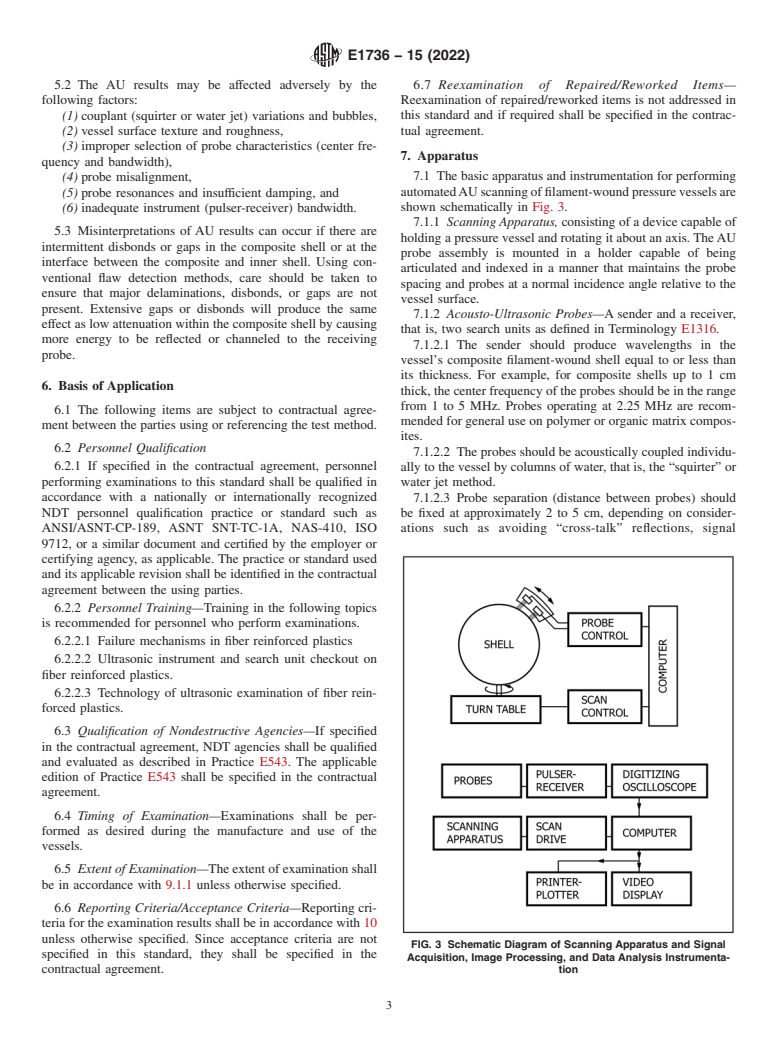

7.1 The basic apparatus and instrumentation for performing

(4) probe misalignment,

(5) probe resonances and insufficient damping, and automatedAUscanningoffilament-woundpressurevesselsare

shown schematically in Fig. 3.

(6) inadequate instrument (pulser-receiver) bandwidth.

7.1.1 Scanning Apparatus, consisting of a device capable of

5.3 Misinterpretations of AU results can occur if there are

holding a pressure vessel and rotating it about an axis. TheAU

intermittent disbonds or gaps in the composite shell or at the

probe assembly is mounted in a holder capable of being

interface between the composite and inner shell. Using con-

articulated and indexed in a manner that maintains the probe

ventional flaw detection methods, care should be taken to

spacing and probes at a normal incidence angle relative to the

ensure that major delaminations, disbonds, or gaps are not

vessel surface.

present. Extensive gaps or disbonds will produce the same

7.1.2 Acousto-Ultrasonic Probes—A sender and a receiver,

effect as low attenuation within the composite shell by causing

that is, two search units as defined in Terminology E1316.

more energy to be reflected or channeled to the receiving

7.1.2.1 The sender should produce wavelengths in the

probe.

vessel’s composite filament-wound shell equal to or less than

its thickness. For example, for composite shells up to 1 cm

6. Basis of Application

thick, the center frequency of the probes should be in the range

from 1 to 5 MHz. Probes operating at 2.25 MHz are recom-

6.1 The following items are subject to contractual agree-

mended for general use on polymer or organic matrix compos-

ment between the parties using or referencing the test method.

ites.

6.2 Personnel Qualification

7.1.2.2 The probes should be acoustically coupled individu-

6.2.1 If specified in the contractual agreement, personnel ally to the vessel by columns of water, that is, the “squirter” or

performing examinations to this standard shall be qualified in

water jet method.

accordance with a nationally or internationally recognized 7.1.2.3 Probe separation (distance between probes) should

NDT personnel qualification practice or standard such as be fixed at approximately 2 to 5 cm, depending on consider-

ANSI/ASNT-CP-189, ASNT SNT-TC-1A, NAS-410, ISO ations such as avoiding “cross-talk” reflections, signal

9712, or a similar document and certified by the employer or

certifying agency, as applicable. The practice or standard used

and its applicable revision shall be identified in the contractual

agreement between the using parties.

6.2.2 Personnel Training—Training in the following topics

is recommended for personnel who perform examinations.

6.2.2.1 Failure mechanisms in fiber reinforced plastics

6.2.2.2 Ultrasonic instrument and search unit checkout on

fiber reinforced plastics.

6.2.2.3 Technology of ultrasonic examination of fiber rein-

forced plastics.

6.3 Qualification of Nondestructive Agencies—If specified

in the contractual agreement, NDT agencies shall be qualified

and evaluated as described in Practice E543. The applicable

edition of Practice E543 shall be specified in the contractual

agreement.

6.4 Timing of Examination—Examinations shall be per-

formed as desired during the manufacture and use of the

vessels.

6.5 Extent of Examination—The extent of examination shall

be in accordance with 9.1.1 unless otherwise specified.

6.6 Reporting Criteria/Acceptance Criteria—Reporting cri-

teria for the examination results shall be in accordance with 10

unless otherwise specified. Since acceptance criteria are not

FIG. 3 Schematic Diagram of Scanning Apparatus and Signal

specified in this standard, they shall be specified in the

Acquisition, Image Processing, and Data Analysis Instrumenta-

contractual agreement. tion

E1736 − 15 (2022)

attenuation, and the need to include an adequate representative 9.1.1.2 Option 2—Refer all AU readings on the composite

volume of material between the sender and the receiver. The shell being examined to the highest reading on the same shell.

latter requirement is to ensure integrating the effects of diffuse Inthiscase,AUreadingsonthetestshellwilldemonstrateonly

flaw populations in the region being examined currently. nonuniformities in and peculiar to that shell.

7.1.2.4 Apreamplifierisrecommendedincloseproximityto 9.1.2 Using an optimized reference composite shell, adjust

the receiving probe to strengthen the signal it sends to the the probes with respect to each other and set the gate that

pulser-receiver. The need to strengthen the signal depends on acquires the signal of interest.

thesender-receiverprobespacing,waterjetcolumnlength,and 9.1.2.1 The signal reaching the receiving probe should

attenuation by the shell. resemble that illustrated in Fig. 4. In this case, the receivedAU

7.1.3 Instrumentation, for automated scanning and data signal is the result of propagation through three layers: the

acquisition and presentation. Essential components consist of a inner shell, composite shell, and water layer on the surface.

programmable scan drive module, signal digitizing oscillo- 9.1.2.2 Include only Parts A and B in the gate for signal

scope with time base and vertical (voltage) amplifier, computer acquisition and analysis. Part C contains only random fluctua-

with an appropriate bus interface, ultrasonic pulser-receiver, tions due to stress waves traveling through the water. Some

digital display, and printer/plotter. trials involving (finger) obstruction of the water layer will help

define the transition from Part B to Part C. PartAmay contain

8. Principles of Practice signals from the inner shell, but these constitute a constant

factor and need not be of concern.

8.1 The sending probe in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.