ASTM D6193-09

(Practice)Standard Practice for Stitches and Seams

Standard Practice for Stitches and Seams

SIGNIFICANCE AND USE

Seam engineering, the determination of the best stitch type, seam configuration, and thread type which should be used for a particular assembly, requires a thorough knowledge of many variables. The improper selection of any one component can result in failure of the sewn junction, and ultimately failure of the product manufactured.

General Characteristics—The characteristics of a properly constructed sewn seam are strength, elasticity, durability, security, and appearance. These characteristics must be balanced with the properties of the material to be joined to form the optimum sewn seam. The end use of the item will govern the relative importance of these characteristics. The selection of the seam type and stitch type should be based upon these considerations.

Strength—The seam efficiency of the sewn seam should be as high as possible. This will produce sewn seam strength with a balanced construction that will withstand the forces encountered in the use of the sewn item. The elements affecting the strength of a sewn seam are:

Fabric type and strength,

Seam type,

Stitch type,

Stitch density (spi),

Thread tension, and

Thread strength.

Elasticity—The elasticity of a sewn seam should be slightly greater than that of the material which it joins. This will enable the material to support its share of the forces encountered for the intended end use of the sewn item. The elasticity of a sewn seam depends upon:

Fabric type and strength,

Seam type,

Stitch type,

Stitch density (spi),

Thread tension, and

Thread elasticity.

Durability—The durability of a sewn seam depends largely upon its strength relative to the elasticity of the seam and the elasticity of the material. However, in less elastic, tightly woven or dense materials, there is a tendency for the plies to “work” or slide on each other. To form a durable sewn seam in these types of fabrics, the thread size must be carefully chosen. The stitch density also needs to be carefully determine...

SCOPE

1.1 This practice covers the requirements and characteristics of stitches and seams used in the fabrication of sewn items.

1.2 This practice identifies the category, formation, and general purpose for stitch types and seam types used in the fabrication of sewn items.

1.3 Subsequent to a general discussion of stitches and seams that include schematic indices, this practice is comprised of the following sections that are listed in the order in which they appear:

1.3.1 Section Classification of Stitch Types for which drawings are shown in Stitch ,

1.3.2 Section Classification of Seam Types for which drawings are shown in Seam , and

1.3.3 Seam Assembly Recommendations.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6193 – 09

Standard Practice for

1

Stitches and Seams

This standard is issued under the fixed designation D6193; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

TABLE 1 Stitch and Seam Defects

1. Scope

Stitch Defects Seam Assembly Defects

1.1 Thispracticecoverstherequirementsandcharacteristics

Loose stitches Puckers

of stitches and seams used in the fabrication of sewn items.

Poorly formed stitches Twists

1.2 This practice identifies the category, formation, and

Crowded stitches Plaits

general purpose for stitch types and seam types used in the

Tight stitches Undulations

Crooked stitches Run-off (raised seams)

fabrication of sewn items.

Skipped stitches Raw edges exposed

1.3 Subsequenttoageneraldiscussionofstitchesandseams

(felled seams)

that include schematic indices, this practice is comprised of the

following sections that are listed in the order in which they

appear:

3.1.3 seam allowance, n—in sewn fabrics,thedistancefrom

1.3.1 Section 5—Classification of Stitch Types for which

the edge of a fabric to the parallel stitch line furthest from that

drawings are shown in Stitch Figs. 1-69,

edge.

1.3.2 Section 6—Classification of Seam Types for which

3.1.4 seam assembly, n—the composite structure obtained

drawings are shown in Seam Figs. 70-288, and

when fabric(s) are joined by means of a seam.

1.3.3 Annex A1—Seam Assembly Recommendations.

3.1.5 seam damage, n—in sewn fabrics, an adverse change

1.4 This standard does not purport to address all of the

in the physical condition of one or more of the components in

safety concerns, if any, associated with its use. It is the

aseamwhichwouldreducetheseamacceptabilitysuchasyarn

responsibility of the user of this standard to establish appro-

slippage, needle damage, or fabric rupture.

priate safety and health practices and determine the applica-

3.1.6 seam effıciency, n—in sewn fabrics, the ratio of seam

bility of regulatory limitations prior to use.

strength to fabric strength.

3.1.6.1 Discussion—For some constructions, yarn strength

2. Referenced Documents

andstitchtypecancontributetoahigherseamefficiencyvalue.

2

2.1 ASTM Standards:

3.1.7 seam slippage, n—in sewn fabrics, the displacement

D123 Terminology Relating to Textiles

of the fabric yarn parallel and adjacent to the stitch line.

3.1.8 seam type, n—in sewn fabrics, an alphanumeric des-

3. Terminology

ignation relating to the essential characteristics of fabric

3.1 Definitions:

positioning and rows of stitching in a specified sewn fabric

3.1.1 needle damage, n—in sewn fabrics, the partial or

seam.

complete yarn severance or fiber fusing caused by a needle

3.1.9 sew, v—to unite or fasten with stitches.

passing through a fabric during sewing.

3.1.10 sewing thread, n—a flexible, small-diameter yarn or

3.1.1.1 Discussion—This can also be referred to as needle

strand, usually treated with a surface coating, lubricant, or

cuts.

both, intended to be used to stitch one or more pieces of

3.1.2 seam, n—a line where two or more fabrics are joined,

material or an object to a material.

usually near the edge. See also sewn seam, glued seam, stapled

3.1.11 sewn seam, n—in sewn fabrics, a juncture at which

seam, thermally bonded seam.)

two or more planar structures such as textile fabrics, are joined

by sewing, usually near the edge.

1

ThispracticeisunderthejurisdictionofASTMCommitteeD13onTextilesand

3.1.12 stitch, n—in sewing, the configuration of the inter-

is the direct responsibility of Subcommittee D13.54 on Subassemblies.

lacing of sewing thread in a specific repeated unit. (See also

Current edition approved Jan. 15, 2009. Published March 2009. Originally

stitching, and stitch type.)

approved in 1997. Last previous edition approved in 2004 as D6193 – 97(2004).

DOI: 10.1520/D6193-09.

3.1.13 stitch density, n—in sewn seams, the number of

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

stitches per unit length in one row of stitching in the seam.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.13.1 Discussion—This is usually expressed as stitches

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. per inch (spi).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

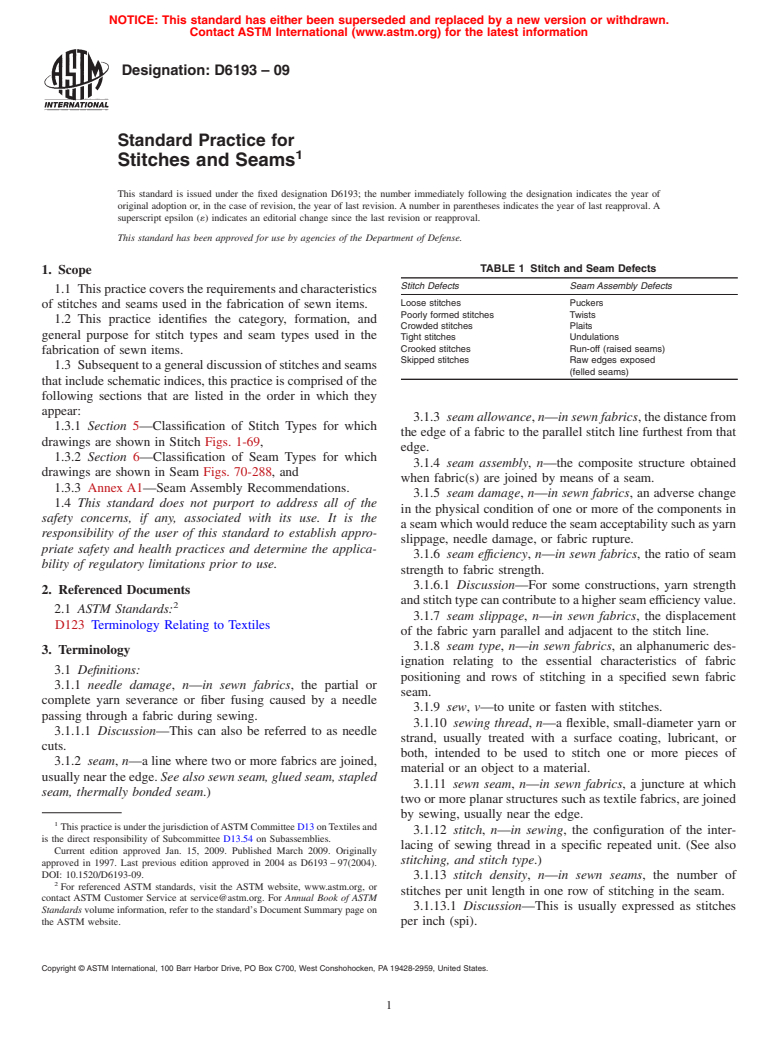

D6193 – 09

NOTE 1—This type of stitch shall be formed with one needle thread that shall be passed through the material and interlooped with itsel

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D6193–97 (Reapproved 2004) Designation: D 6193 – 09

Standard Practice for

1

Stitches and Seams

This standard is issued under the fixed designation D 6193; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This practice covers the requirements and characteristics of stitches and seams used in the fabrication of sewn items.

1.2 This practice identifies the category, formation, and general purpose for stitch types and seam types used in the fabrication

of sewn items.

1.3 Subsequent to a general discussion of stitches and seams that include schematic indices, this practice is comprised of the

following sections that are listed in the order in which they appear:

1.3.1 Section 5—Classification of Stitch Types for which drawings are shown in Stitch Figs. 1-62Figs. 1-69,

1.3.2 Section 6—Classification of Seam Types for which drawings are shown in Seam Figs. 63-281Figs. 70-288, and

1.3.3 Annex A1—Seam Assembly Recommendations.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 123 Terminology Relating to Textiles

D204Test Methods for Sewing Threads

D434Test Method for Resistance to Slippage of Yarns in Woven Fabrics Using a Standard Seam

D1683Test Method for Failure in Sewn Seam of Woven Fabrics

D1908Test Method for Needle Related Damage Due to Sewing in Woven Fabrics

D3940Test Method for Bursting Strength (Load) and Elongation of Sewn Seams of Knit and Woven Stretch Textile Fabrics

D4034Test Method for Resistance toYarn Slippage at the Sewn Seam in Woven Upholstery Fabrics – Plain, Tufted, or Flocked

3. Terminology

3.1 Definitions:

3.1.1 needle damage, n— in sewn fabrics, the partial or complete yarn severance or fiber fusing caused by a needle passing

through a fabric during sewing.

3.1.1.1 Discussion—This can also be referred to as needle cuts.

3.1.2 seam, n—a line where two or more fabrics are joined, usually near the edge. See also sewn seam, glued seam, stapled

seam, thermally bonded seam.)

3.1.3 seam allowance, n— in sewn fabrics, the distance from the edge of a fabric to the parallel stitch line furthest from that

edge.

3.1.4 seam assembly, n—the composite structure obtained when fabric(s) are joined by means of a seam.

3.1.5 seam damage, n— in sewn fabrics, an adverse change in the physical condition of one or more of the components in a

seam which would reduce the seam acceptability such as yarn slippage, needle damage, or fabric rupture.

3.1.6 seam effıciency, n— in sewn fabrics, the ratio of seam strength to fabric strength.

3.1.6.1 Discussion—For some constructions, yarn strength and stitch type can contribute to a higher seam efficiency value.

3.1.7 seam slippage, n— in sewn fabrics, the displacement of the fabric yarn parallel and adjacent to the stitch line.

3.1.8 seam type, n—in sewn fabrics, an alphanumeric designation relating to the essential characteristics of fabric positioning

1

This practice is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.54 on Subassemblies.

Current edition approved Oct. 1, 2004. Published November 2004. Originally approved in 1997. Last previous edition approved in 1997 as D6193–97.

Current edition approved Jan. 15, 2009. Published March 2009. Originally approved in 1997. Last previous edition approved in 2004 as D 6193 – 97(2004).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

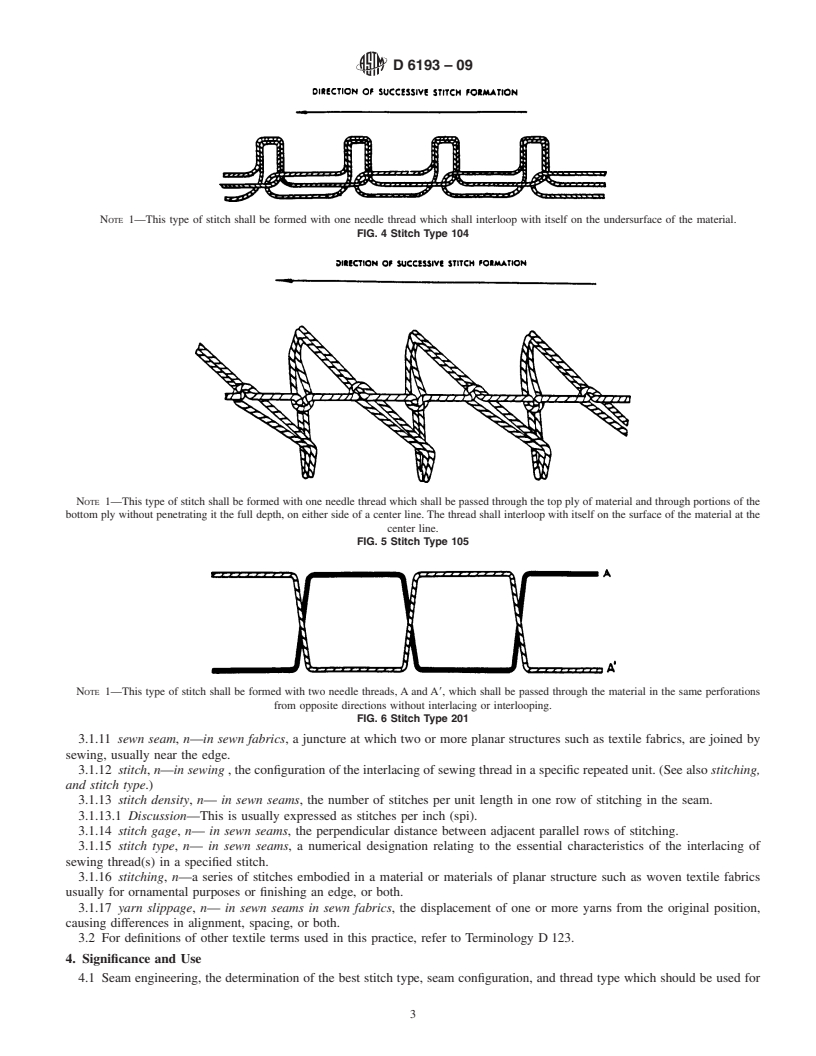

D6193–09

TABLE 1 Stitch and Seam Defects

Stitch Defects Seam Assembly Defects

Loose stitches Puckers

Poorly formed stitches Twists

Crowded stitches Plaits

Tight stitches Undulations

Crooked stitches Run-off (raised

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.