ASTM D4772-09

(Test Method)Standard Test Method for Surface Water Absorption of Terry Fabrics (Water Flow)

Standard Test Method for Surface Water Absorption of Terry Fabrics (Water Flow)

SIGNIFICANCE AND USE

This test method may be used to test the surface water absorption of terry fabrics for bath towels, bath sheets, hand towels, kitchen towels, dishcloths, washcloths, beachwear, bathrobes, and the like. Different specifications may be needed for each of these fabrics because of different applications.

It is recognized that surface water absorption is only one of the characteristics that the ultimate consumer may use in determining which terry fabric is acceptable. Consult Specification D 5433 for other characteristics that may be applicable to terry fabrics.

This test method is recommended for quality control testing of terry fabrics during manufacturing and product comparisons of different terry fabrics by manufacturers, retailers, and users.

This test method may be used for the acceptance testing of commercial shipments of terry fabrics, but caution is advised since interlaboratory precision is known to be poor. Comparative tests as directed in 5.4.1 may be advisable.

In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of laboratory sampling units (such as towels) that are as homogeneous as possible and that are from a lot of material of the type in question. The laboratory sampling units should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using appropriate statistical analysis for unpaired data and an acceptable probability level chosen by the two parties before the testing is begun. If a bias is found, either its cause must be found and corrected or the purchaser and supplier must agree to interpret future t...

SCOPE

1.1 This test method determines the ability of a terry fabric to rapidly absorb and retain liquid water from surfaces such as human skin, dishes, and furniture.

1.2 This test method is not applicable to non-terry fabrics such as huck towels, waffle-weave towels, crash towels, flour-sack towels, and nonwoven wipes. The steep angle of the specimen on the apparatus may cause a large amount of water to runoff these non-pile fabrics, or the lightweight/open structure of these fabrics may allow a large amount of water to completely pass through the specimen; thus the test result may not be a valid measure of a non-terry fabric's ability to absorb water.

1.3 This test method is not applicable to decorative terry fabrics that will not be used to absorb water from surfaces.

1.4 This test method is written in SI units. The inch-pound units that are provided are not necessarily exact equivalents of the SI units. Either system of units may be used in this test method. In case of referee decisions the SI units will prevail.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4772–09

Standard Test Method for

1

Surface Water Absorption of Terry Fabrics (Water Flow)

This standard is issued under the fixed designation D4772; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3136 Terminology Relating to Care Labeling forApparel,

Textile, Home Furnishing, and Leather Products

1.1 This test method determines the ability of a terry fabric

D5433 Performance Specification for Towel Products for

to rapidly absorb and retain liquid water from surfaces such as

3

Institutional and Household Use

human skin, dishes, and furniture.

2.2 AATCC Standard:

1.2 This test method is not applicable to non-terry fabrics

Test Method 135 Dimensional Changes inAutomatic Home

such as huck towels, waffle-weave towels, crash towels,

4

Laundering of Woven and Knit Fabrics

flour-sack towels, and nonwoven wipes. The steep angle of the

specimen on the apparatus may cause a large amount of water

3. Terminology

to runoff these non-pile fabrics, or the lightweight/open struc-

3.1 Definitions:

ture of these fabrics may allow a large amount of water to

3.1.1 absorption, n—a process in which one material (the

completely pass through the specimen; thus the test result may

absorbent) takes in or absorbs another (the absorbate); as the

not be a valid measure of a non-terry fabric’s ability to absorb

absorption of moisture by fibers.

water.

3.1.2 pile, n—in pile fabric, the raised loops or tufts (cut

1.3 This test method is not applicable to decorative terry

loops) that form all or part of the surface.

fabrics that will not be used to absorb water from surfaces.

3.1.3 surface water absorption, n—by a fabric, the process

1.4 This test method is written in SI units. The inch-pound

of removing liquid water from a surface such as human skin,

units that are provided are not necessarily exact equivalents of

dishes, or furniture.

the SI units. Either system of units may be used in this test

3.1.4 terry fabric, n—a material with a woven warp pile or

method. In case of referee decisions the SI units will prevail.

a knitted pile, with uncut loops on a single side or uncut loops

1.5 This standard does not purport to address all of the

on both sides, and which is used for such products as toweling,

safety concerns, if any, associated with its use. It is the

beachwear, and bathrobes.

responsibility of the user of this standard to establish appro-

3.1.5 For definitions of other textile terms used in this test

priate safety and health practices and determine the applica-

method, refer to Terminologies D123 and D3136.

bility of regulatory limitations prior to use.

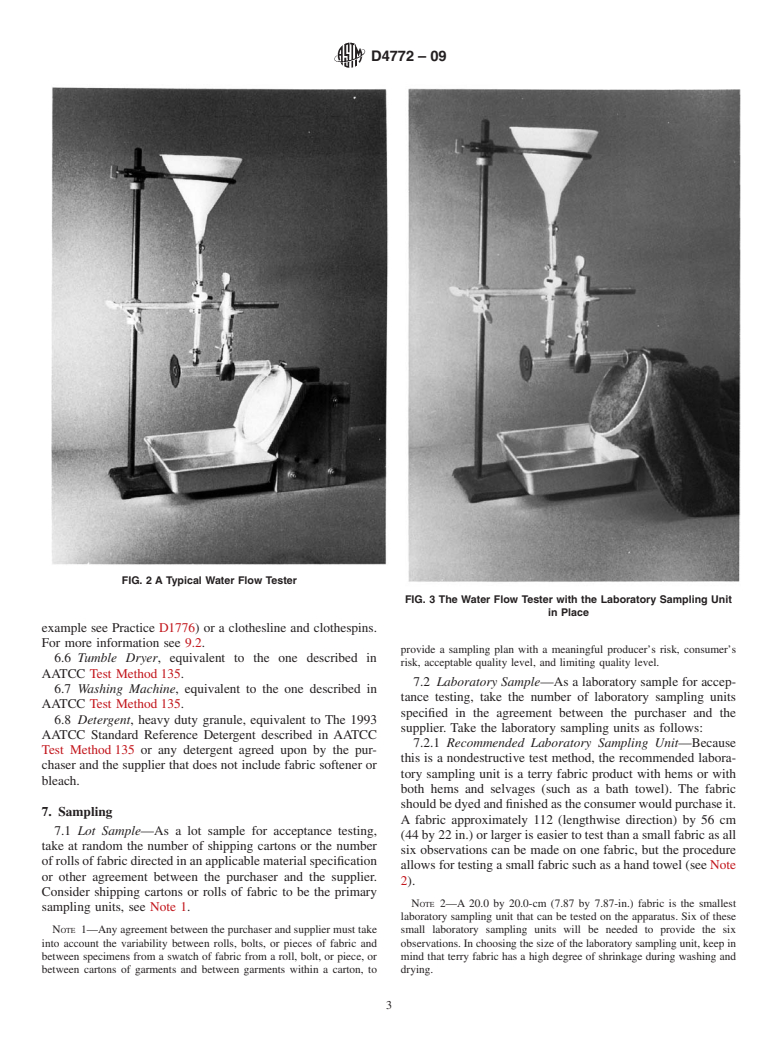

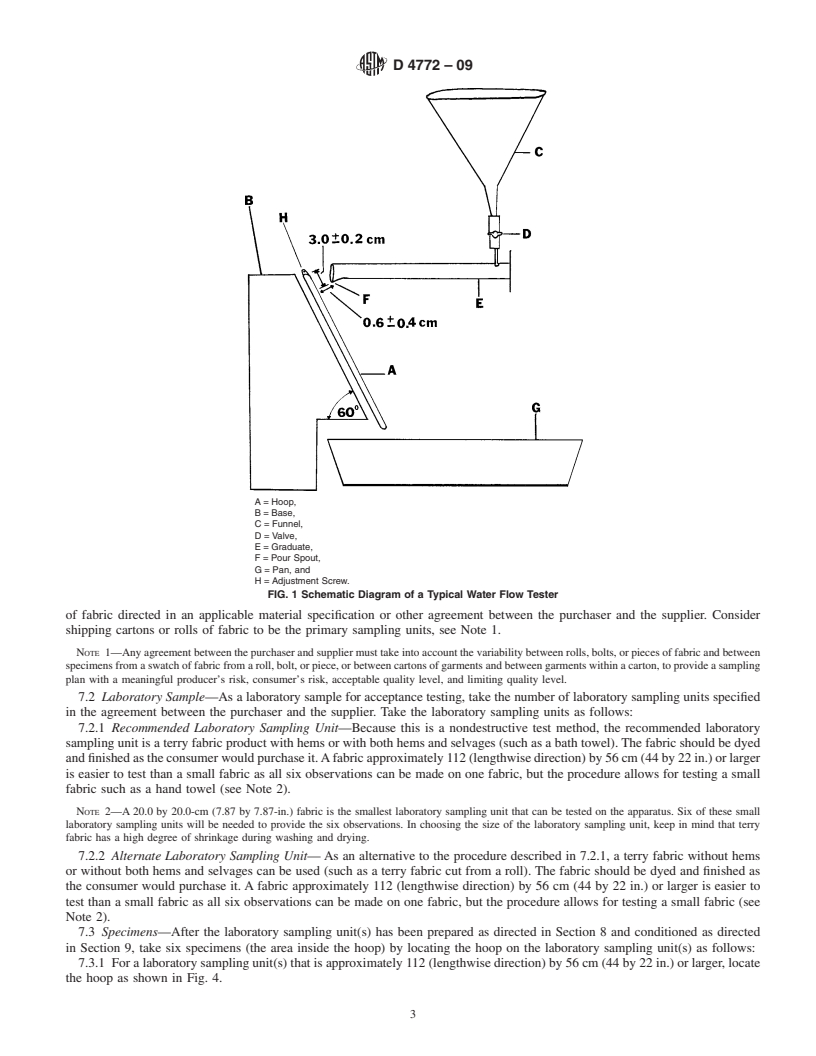

4. Summary of Test Method

2. Referenced Documents

2 4.1 Aterry fabric product with hems or with both hems and

2.1 ASTM Standards:

selvages (such as a bath towel), or a terry fabric without hems

D123 Terminology Relating to Textiles

or without both hems and selvages (such as a terry fabric cut

D1776 Practice for Conditioning and Testing Textiles

from a roll) is prepared for testing by preconditioning and

D2904 Practice for Interlaboratory Testing of a Textile Test

conditioning. Specimens are placed one at a time in an

Method that Produces Normally Distributed Data

embroidery hoop and then the hoop/specimen assembly is

D2906 Practice for Statements on Precision and Bias for

3 placed at an angle on the base of the apparatus. After water

Textiles

flows down the surface of each specimen, the amount of water

retained by each specimen is measured. Six specimens are

1

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

tested, three on the face of the fabric and three on the back of

and is the direct responsibility of Subcommittee D13.59 on Fabric Test Methods,

the fabric. The six observations are averaged to determine the

General

surface water absorption of the fabric.

Current edition approved Jan. 15, 2009. Published February 2009. Originally

´1

approved in 1988. Last previous edition approved in 2008 as D4772 – 97(2008) .

DOI: 10.1520/D4772-09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4

the ASTM website Available from American Association of Textile Chemists and Colorists

3

Withdrawn. The last approved version of this historical standard is referenced (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709, http://

on www.astm.org. www.aatcc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D4772–97 (Reapproved 2008) Designation:D4772–09

Standard Test Method for

1

Surface Water Absorption of Terry Fabrics (Water Flow)

This standard is issued under the fixed designation D 4772; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Minor editorial corrections were made throughout in October 2008.

1. Scope

1.1 This test method determines the ability of a terry fabric to rapidly absorb and retain liquid water from surfaces such as

human skin, dishes, and furniture.

1.2 This test method is not applicable to non-terry fabrics such as huck towels, waffle-weave towels, crash towels, flour-sack

towels, and nonwoven wipes. The steep angle of the specimen on the apparatus may cause a large amount of water to runoff these

non-pile fabrics, or the lightweight/open structure of these fabrics may allow a large amount of water to completely pass through

the specimen; thus the test result may not be a valid measure of a non-terry fabric’s ability to absorb water.

1.3 This test method is not applicable to decorative terry fabrics that will not be used to absorb water from surfaces.

1.4 This test method is written in SI units. The inch-pound units that are provided are not necessarily exact equivalents of the

SI units. Either system of units may be used in this test method. In case of referee decisions the SI units will prevail.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 123 Terminology Relating to Textiles

D 1776 Practice for Conditioning and Testing Textiles

D 2904 Practice for Interlaboratory Testing of a Textile Test Method that Produces Normally Distributed Data

D 2906 Practice for Statements on Precision and Bias for Textiles

D 3136 Terminology Relating to Care Labeling for Apparel, Textile, Home Furnishing, and Leather Products

D 5433 Performance Specification for Towel Products for Institutional and Household Use

2.2 AATCC Standard:

3

Test Method 135 Dimensional Changes in Automatic Home Laundering of Woven and Knit Fabrics

3. Terminology

3.1 Definitions:

3.1.1 absorption, n—a process in which one material (the absorbent) takes in or absorbs another (the absorbate); as the

absorption of moisture by fibers.

3.1.2 pile, n—in pile fabric, the raised loops or tufts (cut loops) that form all or part of the surface.

3.1.3 surface water absorption, n—by a fabric, the process of removing liquid water from a surface such as human skin, dishes,

or furniture.

3.1.4 terry fabric, n—a material with a woven warp pile or a knitted pile, with uncut loops on a single side or uncut loops on

both sides, and which is used for such products as toweling, beachwear, and bathrobes.

3.1.5 For definitions of other textile terms used in this test method, refer to Terminologies D 123 and D 3136.

4. Summary of Test Method

4.1 A terry fabric product with hems or with both hems and selvages (such as a bath towel), or a terry fabric without hems or

1

This test method is under the jurisdiction ofASTM Committee D13 onTextiles and is the direct responsibility of Subcommittee D13.59 on FabricTest Methods, General

Current edition approved July 1, 2008. Published October 2008. Originally approved in 1988. Last previous edition approved in 2004 as D4772–88(2004).

´1

Current edition approved Jan. 15, 2009. Published February 2009. Originally approved in 1988. Last previous edition approved in 2008 as D 4772 – 97(2008) .

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website

3

Available from American Association of Textile Chemists and Colorists (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709, http://www.aatcc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4772–09

without both hems and selvages (such as a terry fabric cut from a roll) is p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.