ASTM F1911-05

(Practice)Standard Practice for Installation of Barbed Tape

Standard Practice for Installation of Barbed Tape

SIGNIFICANCE AND USE

This practice is intended to provide standard requirements utilizing specialized equipment and hand tools.

Ensure that the barbed tape is fabricated from acceptable material and well constructed. Field verification of the barbed tape’acceptability shall be in accordance with the project’specifications and this specification.

SCOPE

1.1 This practice covers the installation procedure for barbed tape.

1.2 The primary purpose of this practice is to guide those responsible for, or concerned with, the installation of barbed tape on chain link fences, masonry walls, roofs or used as ground barriers. This practice is not intended to cover aspects of perimeter security for establishing levels of product performance or give analysis relating to various design comparisons.

1.3 This practice involves the use of material, that may cause injury, including exposure to hazardous materials, and operation of specialized equipment.

1.4 This standard does not purport to address all of the safety concerns, if any associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1911–05

Standard Practice for

1

Installation of Barbed Tape

This standard is issued under the fixed designation F1911; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Site Preparation

1.1 This practice covers the installation procedure for 5.1 Theownershallspecifythelocationinwhichthebarbed

barbed tape. tape shall be installed by furnishing drawings or personal

1.2 The primary purpose of this practice is to guide those instruction.

responsible for, or concerned with, the installation of barbed 5.2 Barbed tape obstacles shall be in accordance with

tape on chain link fences, masonry walls, roofs or used as Specification F1910 barbed tape specifications.

ground barriers. This practice is not intended to cover aspects

NOTE 1—Refer to Terminology F1379 for barb configuration and cross

of perimeter security for establishing levels of product perfor-

sections.

mance or give analysis relating to various design comparisons.

1.3 This practice involves the use of material, that may 6. Installation

cause injury, including exposure to hazardous materials, and

6.1 When the specifications are unclear, refer to these

operation of specialized equipment.

instructions or contact the owner for information pertaining to

1.4 This standard does not purport to address all of the

placement, coil attachment, splicing, and so forth.

safety concerns, if any associated with its use. It is the

6.2 Non-Reinforced (Concertina):

responsibility of the user of this standard to establish appro-

6.2.1 Description—Barbed obstacle capable of being per-

priate safety and health practices and determine the applica-

manently or temporarily installed. Barbed tape used for some

bility of regulatory limitations prior to use.

temporary installations shall have the ability of being recov-

ered and used repeatedly.

2. Referenced Documents

6.2.2 Top of the Fence Installation—Barb arms are recom-

2

2.1 ASTM Standards:

mended for top of the fence installations. Single 45° barb arms

F1379 Terminology Relating to Barbed Tape

with a single strand of barbed wire or tension wire located in

F1910 Specification for Long Barbed Tape Obstacles

the outer position of the arm will support coils deployed at the

F2200 Specification for Automated Vehicular Gate Con-

top of the fence. Barb arms are positioned so that arms are out

struction

of reach from the approach side. “V” arms are not recom-

mended for security applications where climbing is a threat or

3. Terminology

where only one row of barbed tape is specified. Two rows of

3.1 Refers to Terminology F1379.

barbed tape are recommended where “V” arms are specified.

See Fig. 1.

4. Significance and Use

6.2.2.1 Deployment—Stretch the coils out and allow them

4.1 This practice is intended to provide standard require-

to rotate (spiral) naturally around their central axis. Allowing

ments utilizing specialized equipment and hand tools.

the coil to rotate will ensure that there is no mechanical stress

4.2 Ensurethatthebarbedtapeisfabricatedfromacceptable

within the obstacle before tying. Locate the coil loops uni-

material and well constructed. Field verification of the barbed

formly at the specified coil spacing. The coil spacing is

tape’s acceptability shall be in accordance with the project’s

predetermined by one or more permanently attached cables

specifications and this specification.

running the entire length of the roll. The number of cables

depends largely on the diameter and application. Coil loop

1

This practice is under the jurisdiction ofASTM Committee F14 on Fences and spacing for non-reinforced products are generally 12.0 inches.

is the direct responsibility of Subcommittee F14.40 on Chain Link Fence and Wire

See Fig. 2.

Accessories.

6.2.2.2 Tie Points—Before making the final attachment to

Current edition approved July 1, 2005. Published August 2005. Originally

the fence, inspect the coils for tangles and proper coil spacing.

approved in 1998. Last previous edition approved in 1998 as F1911 - 98. DOI:

10.1520/F1911-05. Attach the first ties to the single strand of barbed wire, cable or

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tension wire located in the barb arm. Tie parallel coil loops at

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the desired spacing, determined by the spacer cable.Attach the

Standards volume information, refer to the standard’s Document Summary page on

second tie points to the top of the chain link at the desired

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshoh

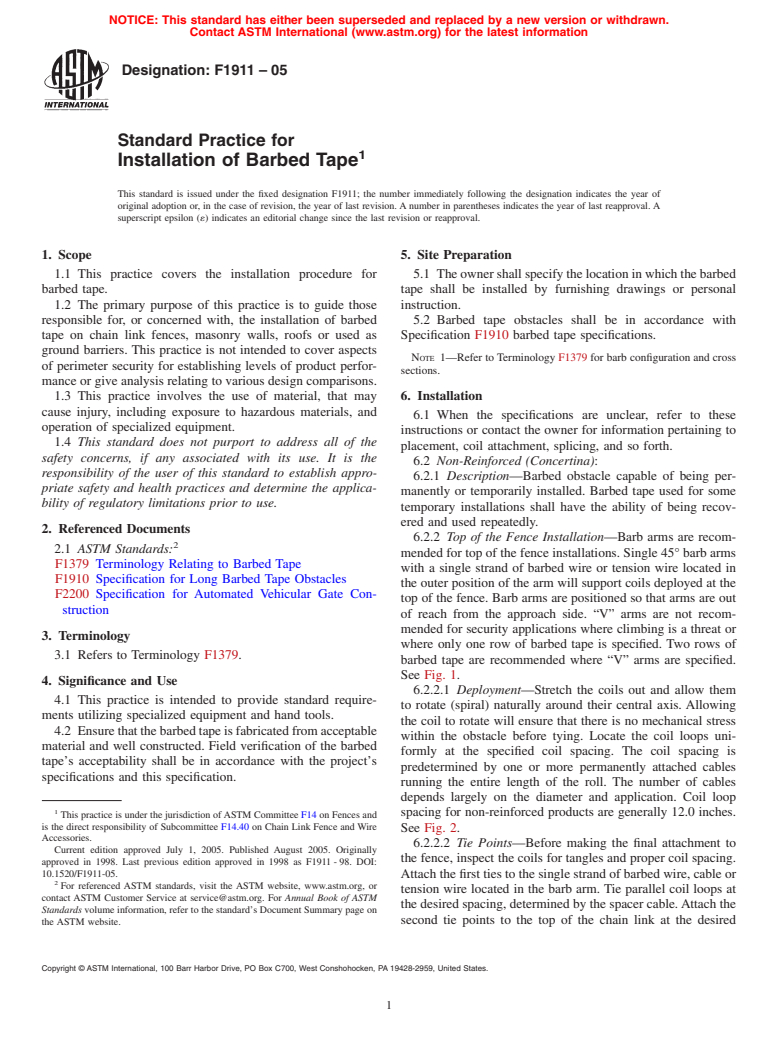

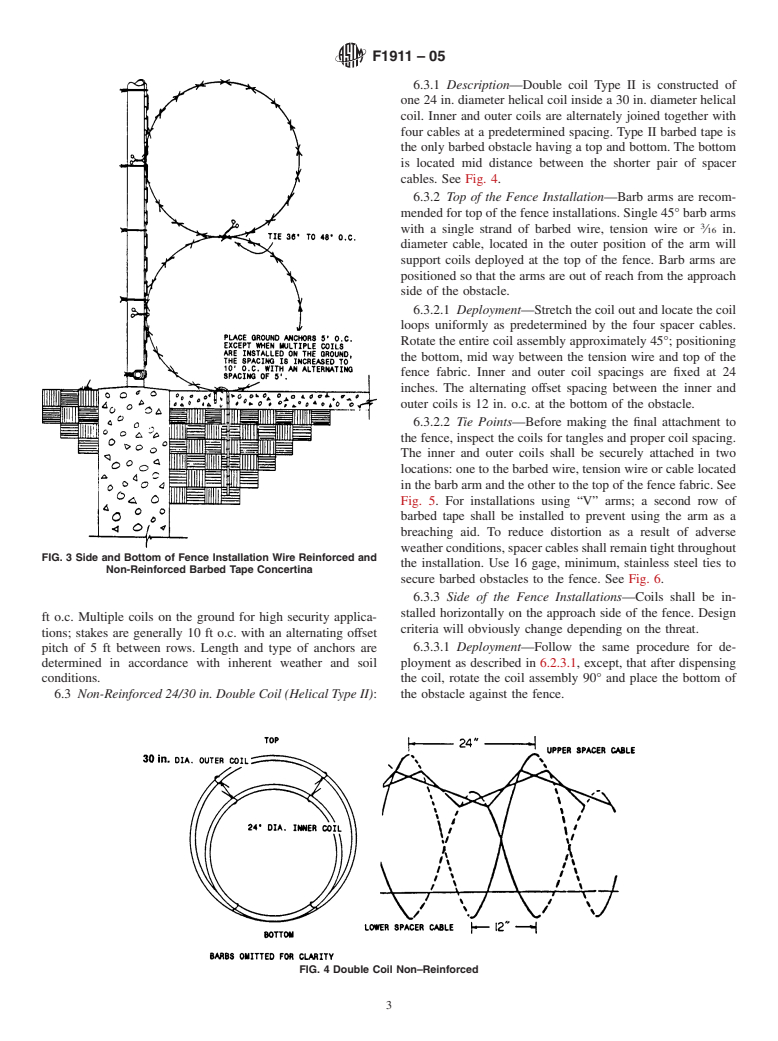

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.