ASTM D711-10

(Test Method)Standard Test Method for No-Pick-Up Time of Traffic Paint

Standard Test Method for No-Pick-Up Time of Traffic Paint

SIGNIFICANCE AND USE

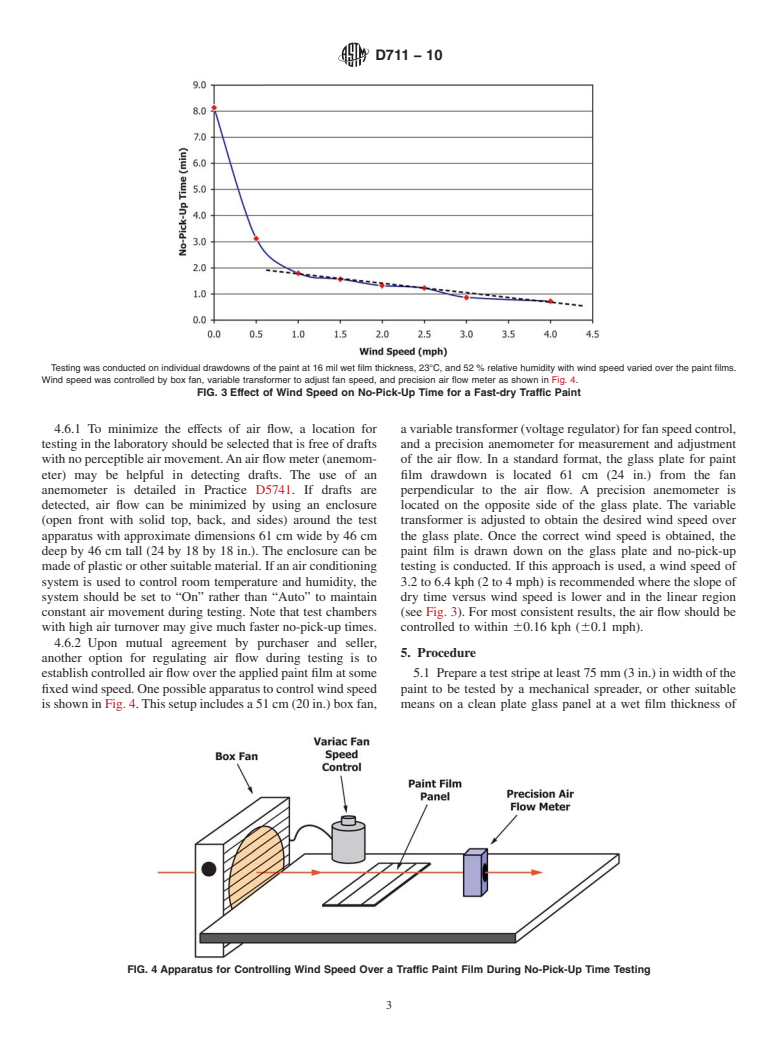

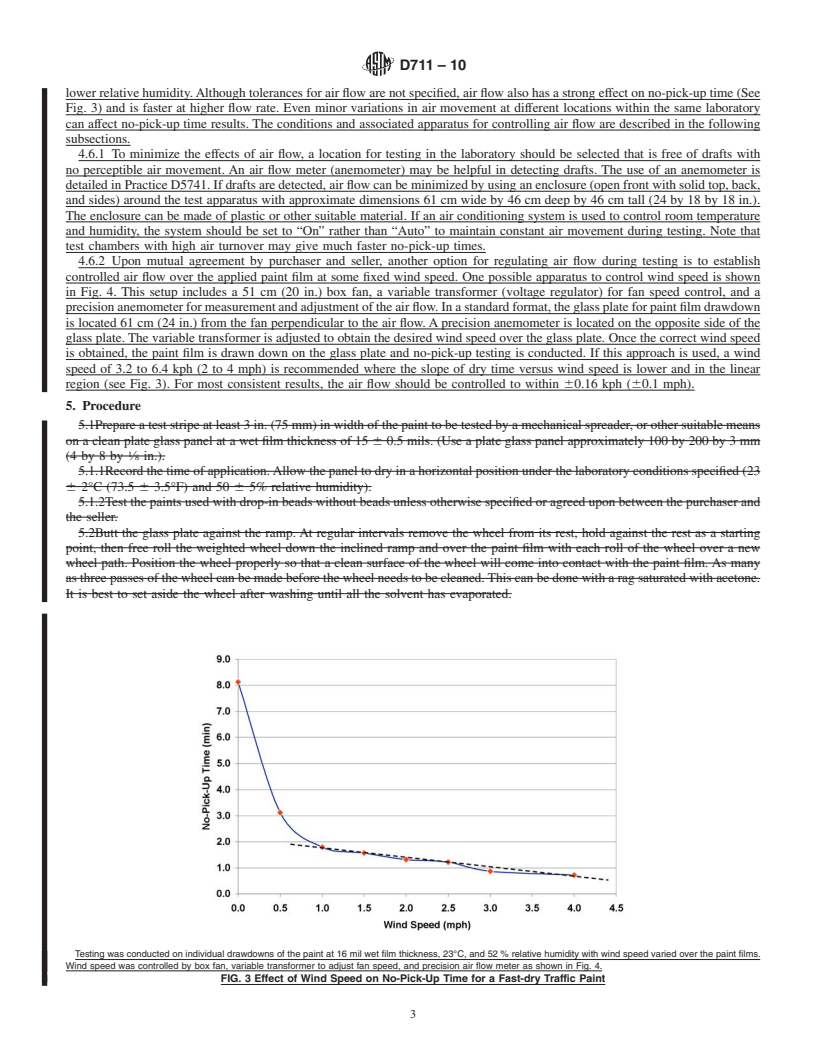

This test method serves as a laboratory control test. Types of traffic paints that can be tested with this method are waterborne, solventborne, and some 100 % solids liquid traffic paints. This test is most commonly used with fast-dry waterborne traffic paints. If wet film thickness, temperature, and humidity are controlled within the tolerances specified herein, this method can be useful for relative testing of traffic paints and potentially for qualification of traffic paints for field application in approved specifications. For improved repeatability and meaningful comparison of paint samples being tested, consistent air flow over the paint films during testing is important. Although a no-air-flow (static) test environment is standard, the buyer and seller should agree upon the air flow conditions, whether it be static or carefully regulated air flow (see 4.6.1 and 4.6.2). No-pick-up times for fast-dry waterborne traffic paints are typically less than 10 min in a static air flow condition. Because of the many variables operative in the field application of traffic paint (for example, film thickness, air temperature, humidity, wind speed, pavement type (asphalt or concrete), film profile over pavement, pavement temperature, pavement porosity, pavement moisture content, and the presence or absence of direct sunlight during striping), a direct correlation between the results of this test and field applications is difficult to obtain. However, relative field performance can be predicted using this method if the testing protocol is adhered to.

SCOPE

1.1 This test method covers a laboratory procedure for determining the no-pick-up time of a traffic paint. The method uses a wheel consisting of a metal cylinder with rubber O-rings. The wheel is rolled down a ramp over a freshly applied traffic paint film repeatedly until there is no transfer of paint to the rubber rings. The elapsed time from paint film application to point of no paint transfer is the no-pick-up time. Key variables to be controlled during testing are film thickness, temperature, humidity, and air flow.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D711 − 10

StandardTest Method for

1

No-Pick-Up Time of Traffic Paint

This standard is issued under the fixed designation D711; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D1414 Test Methods for Rubber O-Rings

D2000 Classification System for Rubber Products in Auto-

1.1 This test method covers a laboratory procedure for

motive Applications

determining the no-pick-up time of a traffic paint. The method

D4414 Practice for Measurement of Wet Film Thickness by

uses a wheel consisting of a metal cylinder with rubber

Notch Gages

O-rings. The wheel is rolled down a ramp over a freshly

D5741 Practice for Characterizing Surface Wind Using a

applied traffic paint film repeatedly until there is no transfer of

Wind Vane and Rotating Anemometer

paint to the rubber rings. The elapsed time from paint film

application to point of no paint transfer is the no-pick-up time.

3. Significance and Use

Keyvariablestobecontrolledduringtestingarefilmthickness,

temperature, humidity, and air flow.

3.1 This test method serves as a laboratory control test.

Types of traffic paints that can be tested with this method are

1.2 The values stated in SI units are to be regarded as the

waterborne, solventborne, and some 100 % solids liquid traffic

standard. The values given in parentheses are for information

paints. This test is most commonly used with fast-dry water-

only.

borne traffic paints. If wet film thickness, temperature, and

1.3 This standard does not purport to address all of the

humidity are controlled within the tolerances specified herein,

safety concerns, if any, associated with its use. It is the

this method can be useful for relative testing of traffic paints

responsibility of the user of this standard to establish appro-

and potentially for qualification of traffic paints for field

priate safety and health practices and determine the applica-

application in approved specifications. For improved repeat-

bility of regulatory limitations prior to use.

ability and meaningful comparison of paint samples being

tested, consistent air flow over the paint films during testing is

2. Referenced Documents

important. Although a no-air-flow (static) test environment is

2

2.1 ASTM Standards:

standard, the buyer and seller should agree upon the air flow

D823 Practices for Producing Films of Uniform Thickness

conditions, whether it be static or carefully regulated air flow

of Paint, Varnish, and Related Products on Test Panels

(see 4.6.1 and 4.6.2). No-pick-up times for fast-dry waterborne

D1212 Test Methods for Measurement of Wet Film Thick-

traffic paints are typically less than 10 min in a static air flow

ness of Organic Coatings

condition. Because of the many variables operative in the field

application of traffic paint (for example, film thickness, air

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint temperature, humidity, wind speed, pavement type (asphalt or

and Related Coatings, Materials, andApplications and is the direct responsibility of

concrete), film profile over pavement, pavement temperature,

Subcommittee D01.44 on Traffic Coatings.

pavement porosity, pavement moisture content, and the pres-

Current edition approved Dec. 1, 2010. Published January 2011. Originally

ence or absence of direct sunlight during striping), a direct

approved in 1943. Last previous edition approved in 2004 as D711 – 89 (2004).

DOI: 10.1520/D0711-10.

correlationbetweentheresultsofthistestandfieldapplications

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

is difficult to obtain. However, relative field performance can

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

bepredictedusingthismethodifthetestingprotocolisadhered

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. to.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D711 − 10

FIG. 1 Traffic Paint Drying Time Wheel and Ramp—Dual Model

Each pass of wheel over the paint film should be at least 2.5 mm (1 in.) from each end of the paint film.

FIG. 2 Picture of Apparatus and Traffic Paint Film Being Tested

4. Apparatus 715 of Classification D2000. Standards for O-rings and rubber

3 products are also found in Test Methods D1414 and Classifi-

4.1 The apparatus as shown in Fig. 1 shall consist of a steel

cation D2000.

cylinder of the shape and dimensions as indicate

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D711–89(Reapproved2004) Designation: D711 – 10

Standard Test Method for

1

No-Pick-Up Time of Traffic Paint

This standard is issued under the fixed designation D711; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1This test method covers a laboratory test for determining the no-pick-up time of a traffic paint by a rubber wheel.

1.1 This test method covers a laboratory procedure for determining the no-pick-up time of a traffic paint. The method uses a

wheel consisting of a metal cylinder with rubber O-rings. The wheel is rolled down a ramp over a freshly applied traffic paint film

repeatedly until there is no transfer of paint to the rubber rings. The elapsed time from paint film application to point of no paint

transferistheno-pick-uptime.Keyvariablestobecontrolledduringtestingarefilmthickness,temperature,humidity,andairflow.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards: ASTM Standards:

D823 Practices for Producing Films of Uniform Thickness of Paint, Varnish, and Related Products on Test Panels

D1212 Test Methods for Measurement of Wet Film Thickness of Organic Coatings

D1414 Test Methods for Rubber O-Rings

D2000 Classification System for Rubber Products in Automotive Applications Classification System for Rubber Products in

Automotive Applications

D4414 Practice for Measurement of Wet Film Thickness by Notch Gages

D5741 Practice for Characterizing Surface Wind Using a Wind Vane and Rotating Anemometer

3. Significance and Use

3.1This test method serves as a control test and should be used only as such. There is no direct correlation between the results

of this test and field applications.

3.1 Thistestmethodservesasalaboratorycontroltest.Typesoftrafficpaintsthatcanbetestedwiththismethodarewaterborne,

solventborne, and some 100 % solids liquid traffic paints. This test is most commonly used with fast-dry waterborne traffic paints.

If wet film thickness, temperature, and humidity are controlled within the tolerances specified herein, this method can be useful

for relative testing of traffic paints and potentially for qualification of traffic paints for field application in approved specifications.

Forimprovedrepeatabilityandmeaningfulcomparisonofpaintsamplesbeingtested,consistentairflowoverthepaintfilmsduring

testingisimportant.Althoughano-air-flow(static)testenvironmentisstandard,thebuyerandsellershouldagreeupontheairflow

conditions,whetheritbestaticorcarefullyregulatedairflow(see4.6.1and4.6.2).No-pick-uptimesforfast-drywaterbornetraffic

paints are typically less than 10 min in a static air flow condition. Because of the many variables operative in the field application

oftrafficpaint(forexample,filmthickness,airtemperature,humidity,windspeed,pavementtype(asphaltorconcrete),filmprofile

over pavement, pavement temperature, pavement porosity, pavement moisture content, and the presence or absence of direct

sunlight during striping), a direct correlation between the results of this test and field applications is difficult to obtain. However,

relative field performance can be predicted using this method if the testing protocol is adhered to.

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.44 on Traffic Coatings.

Current edition approved JuneDec. 1, 2004.2010. Published June 2004.January 2011. Originally approved in 1943. Last previous edition approved in 19982004 as

D711–89(1998).D711 – 89 (2004). DOI: 10.1520/D0711-89R04.10.1520/D0711-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr H

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.