ASTM D6193-97

(Practice)Standard Practice for Stitches and Seams

Standard Practice for Stitches and Seams

SCOPE

1.1 This practice covers the requirements and characteristics of stitches and seams used in the fabrication of sewn items.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6193 – 97

Standard Practice for

Stitches and Seams

This standard is issued under the fixed designation D 6193; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

TABLE 1 Stitch and Seam Defects

1. Scope

Stitch Defects Seam Assembly Defects

1.1 This practice covers the requirements and characteristics

Loose stitches Puckers

of stitches and seams used in the fabrication of sewn items.

Poorly formed stitches Twists

1.2 This practice identifies the category, formation, and

Crowded stitches Plaits

general purpose for stitch types and seam types used in the

Tight stitches Undulations

Crooked stitches Run-off (raised seams)

fabrication of sewn items.

Skipped stitches Raw edges exposed

1.3 Subsequent to a general discussion of stitches and seams

(felled seams)

that include schematic indices, this practice is comprised of the

following sections that are listed in the order in which they

D 4034 Test Method for Resistance to Yarn Slippage at the

appear:

Sewn Seam in Woven Upholstery Fabrics – Plain, Tufted,

1.3.1 Section 5—Classification of Stitch Types for which

or Flocked

drawings are shown in Stitch Figs. 1- 62,

1.3.2 Section 6—Classification of Seam Types for which

3. Terminology

drawings are shown in Seam Figs. 63- 281, and

3.1 Definitions:

1.3.3 Annex A1—Seam Assembly Recommendations.

3.1.1 needle damage, n—in sewn fabrics, the partial or

1.4 This standard does not purport to address all of the

complete yarn severance or fiber fusing caused by a needle

safety concerns, if any, associated with its use. It is the

passing through a fabric during sewing.

responsibility of the user of this standard to establish appro-

3.1.1.1 Discussion—This can also be referred to as needle

priate safety and health practices and determine the applica-

cuts.

bility of regulatory limitations prior to use.

3.1.2 seam, n—a line where two or more fabrics are joined,

usually near the edge. See also sewn seam, glued seam, stapled

2. Referenced Documents

seam, thermally bonded seam.)

2.1 ASTM Standards:

3.1.3 seam allowance, n—in sewn fabrics, the distance from

D 123 Terminology Relating to Textiles

the edge of a fabric to the parallel stitch line furthest from that

D 204 Test Methods for Sewing Threads

edge.

D 434 Test Method for Resistance to Slippage of Yarns in

3.1.4 seam assembly, n—the composite structure obtained

Woven Fabrics Using a Standard Seam

when fabric(s) are joined by means of a seam.

D 1683 Test Method for Failure in Sewn Seam of Woven

3.1.5 seam damage, n—in sewn fabrics, an adverse change

Fabrics

in the physical condition of one or more of the components in

D 1908 Test Method for Needle Related Damage Due to

a seam which would reduce the seam acceptability such as yarn

Sewing in Woven Fabrics

slippage, needle damage, or fabric rupture.

D 3940 Test Method for Bursting Strength (Load) and

3.1.6 seam effıciency, n—in sewn fabrics, the ratio of seam

Elongation of Sewn Seams of Knit and Woven Stretch

strength to fabric strength.

Textile Fabrics

3.1.6.1 Discussion—For some constructions, yarn strength

and stitch type can contribute to a higher seam efficiency value.

1 3.1.7 seam slippage, n—in sewn fabrics, the displacement

This practice is under the jurisdiction of ASTM Committee D-13 on Textiles

of the fabric yarn parallel and adjacent to the stitch line.

and is the direct responsibility of Subcommittee D13.54 on Subassemblies.

Current edition approved Nov. 10, 1997. Published March 1998.

Annual Book of ASTM Standards, Vol 07.01.

3 4

Discontinued; See 1984 Annual Book of ASTM Standards, Vol 07.02. Annual Book of ASTM Standards, Vol 07.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6193

NOTE 1—This type of stitch shall be formed with one needle thread that shall be passed through the material and interlooped with itself on the

undersurface of the material.

FIG. 1 Stitch Type 101

NOTE 1—This type of stitch shall be formed with two needle threads A and A8. Both threads shall be passed through the material and thread A8 shall

be interlooped with itself and with thread A.

FIG. 2 Stitch Type 102

NOTE 1—This type of stitch shall be formed with one needle thread, which shall interloop with itself on the top surface of the material. The thread

shall be passed through the top ply and horizontally through portions of the bottom ply without penetrating it the full depth.

FIG. 3 Stitch Type 103

3.1.8 seam type, n—in sewn fabrics, an alphanumeric des-

ignation relating to the essential characteristics of fabric

positioning and rows of stitching in a specified sewn fabric

seam.

3.1.9 sew, v—to unite or fasten with stitches.

3.1.10 sewing thread, n—a flexible, small-diameter yarn or

strand, usually treated with a surface coating, lubricant, or

both, intended to be used to stitch one or more pieces of

NOTE 1—This type of stitch shall be formed with one needle thread

material or an object to a material.

which shall interloop with itself on the undersurface of the material.

3.1.11 sewn seam, n—in sewn fabrics, a juncture at which

FIG. 4 Stitch Type 104

two or more planar structures such as textile fabrics, are joined

by sewing, usually near the edge.

D 6193

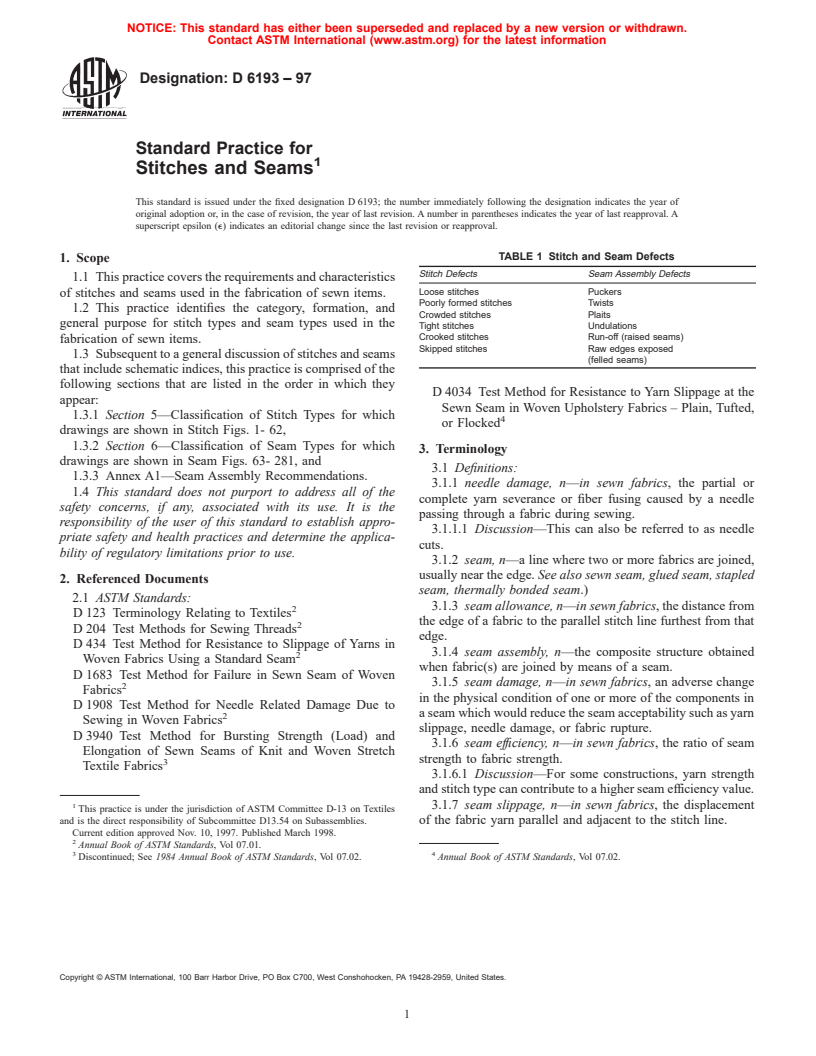

NOTE 1—This type of stitch shall be formed with one needle thread which shall be passed through the top ply of material and through portions of the

bottom ply without penetrating it the full depth, on either side of a center line. The thread shall interloop with itself on the surface of the material at the

center line.

FIG. 5 Stitch Type 105

NOTE 1—This type of stitch shall be formed with two needle threads, A and A8, which shall be passed through the material in the same perforations

from opposite directions without interlacing or interlooping.

FIG. 6 Stitch Type 201

NOTE 1—This type of stitch shall be formed with one needle thread, which shall be passed through the material brought forward two stitch lengths,

passed back through the material and brought back one stitch length before being passed through the material a third time.

FIG. 7 Stitch Type 202

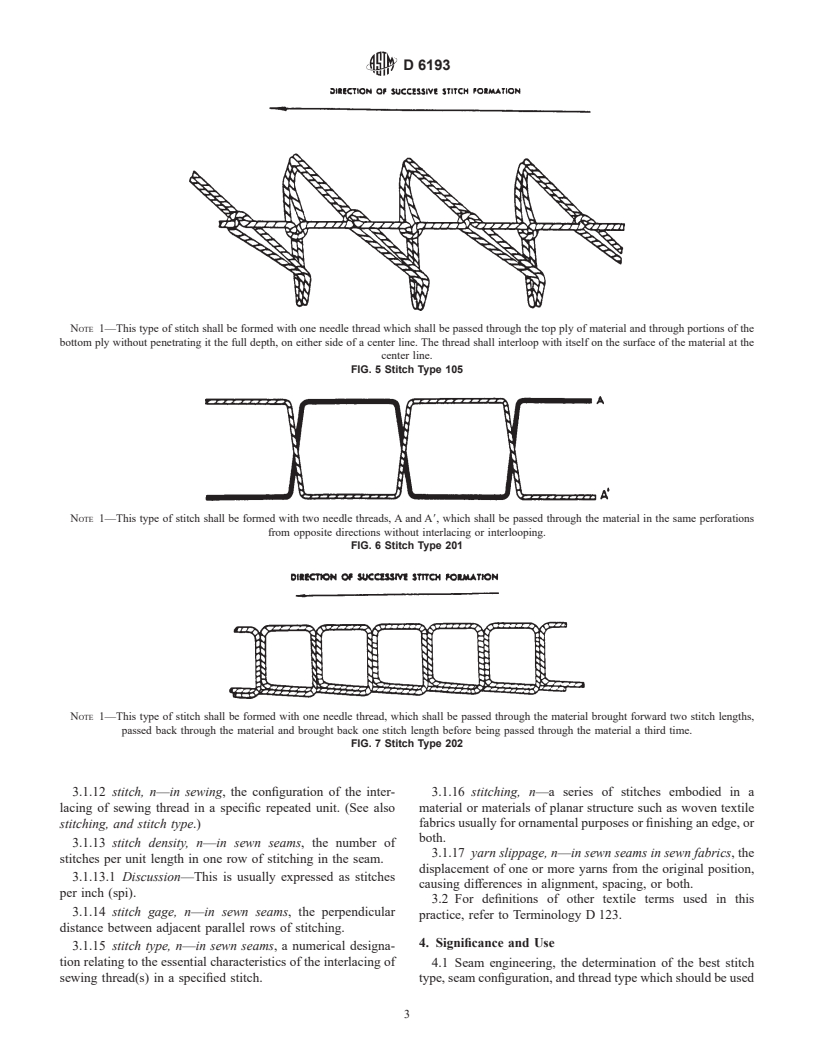

3.1.12 stitch, n—in sewing, the configuration of the inter- 3.1.16 stitching, n—a series of stitches embodied in a

material or materials of planar structure such as woven textile

lacing of sewing thread in a specific repeated unit. (See also

fabrics usually for ornamental purposes or finishing an edge, or

stitching, and stitch type.)

both.

3.1.13 stitch density, n—in sewn seams, the number of

3.1.17 yarn slippage, n—in sewn seams in sewn fabrics, the

stitches per unit length in one row of stitching in the seam.

displacement of one or more yarns from the original position,

3.1.13.1 Discussion—This is usually expressed as stitches

causing differences in alignment, spacing, or both.

per inch (spi).

3.2 For definitions of other textile terms used in this

3.1.14 stitch gage, n—in sewn seams, the perpendicular

practice, refer to Terminology D 123.

distance between adjacent parallel rows of stitching.

4. Significance and Use

3.1.15 stitch type, n—in sewn seams, a numerical designa-

tion relating to the essential characteristics of the interlacing of

4.1 Seam engineering, the determination of the best stitch

sewing thread(s) in a specified stitch. type, seam configuration, and thread type which should be used

D 6193

chosen. The stitch density also needs to be carefully deter-

mined for the material so as not to cause excess tension which

will unbalance the elasticity and cause puckering. It is also

important to minimize abrasion and wear by contact with

outside agencies to promote durability.

4.2.4 Security—The security of a sewn seam depends

chiefly upon the stitch type, spi, and its susceptibility to

become unraveled. The stitch must be well set to the material

to prevent snagging that can cause rupture of the thread and

unraveling of certain stitch types.

NOTE 1—This type of stitch shall be formed with one needle thread, 4.2.5 Appearance—The appearance of a sewn seam gener-

which shall be passed through the material from the underside and

ally is governed by the proper relationship between the size and

immediately passed back through the same perforation to form a loop on

type of thread, the stitch density, and the texture and weight of

the surface of the material. The needle shall be advanced one stitch length,

the fabric.

passed through the material and the loop and immediately passed back

4.2.5.1 In addition to these general characteristics, the

through the loop and the same needle perforation, and a new loop shall be

technique and skill of the sewing machine operators also

formed to receive the succeeding stitch.

govern the appearance of the sewn seams. Some of the factors

FIG. 8 Stitch Type 203

which will adversely affect the appearance are shown in Table

1.

for a particular assembly, requires a thorough knowledge of

5. Classification of Stitch Types

many variables. The improper selection of any one component

can result in failure of the sewn junction, and ultimately failure 5.1 Function—Because all stitch types require that a needle

of the product manufactured. penetrate a fabric while transporting a sewing thread, it is

4.2 General Characteristics—The characteristics of a prop-

important to understand how the unique characteristics of

erly constructed sewn seam are strength, elasticity, durability, every stitch type are dependent upon the mechanical actions of

security, and appearance. These characteristics must be bal-

the sewing machine. See Stitch Type Figs. 1-62.

anced with the properties of the material to be joined to form 5.2 Stitch Requirements:

the optimum sewn seam. The end use of the item will govern 5.2.1 Stitches are divided into six classes which are identi-

the relative importance of these characteristics. The selection fied by the first digit of three digit numerals. Each class is

of the seam type and stitch type should be based upon these divided into several types which are identified by the second

considerations. and third digit. All stitch types shall conform to the drawings

4.2.1 Strength—The seam efficiency of the sewn seam unless otherwise specified.

should be as high as possible. This will produce sewn seam 5.2.1.1 Stitch Class 100—This class of stitch (Types 101

strength with a balanced construction that will withstand the through 105) is formed with one or more needle threads and

forces encountered in the use of the sewn item. The elements requires interlooping. A loop (or loops) of thread(s) shall be

affecting the strength of a sewn seam are: passed through the material and be secured by interlooping

4.2.1.1 Fabric type and strength, with succeeding loop or loops, after they are passed through

4.2.1.2 Seam type, the material, to form a stitch.

4.2.1.3 Stitch type, 5.2.1.2 Stitch Class 200—This class of stitch (Types 201

4.2.1.4 Stitch density (spi), through 205) is formed by hand with one or more needle

4.2.1.5 Thread tension, and threads and requires that each thread passes through the

4.2.1.6 Thread strength. material as a single line of thread. Each stitch is secured by the

4.2.2 Elasticity—The elasticity of a sewn seam should be single line of thread passing in and out of the material or the

slightly greater than that of the material which it joins. This interlooping of the threads with themselves. When more than

will enable the material to support its share of the forces

one thread is used, the threads pass through the same perfora-

encountered for the intended end use of the sewn item. The tions in the material.

elasticity of a sewn seam depends upon: 5.2.1.3 Stitch Class 300—This class of stitch (Types 301

4.2.2.1 Fabric type and strength, through 316) is formed with two or more groups of threads and

4.2.2.2 Seam type, requires the interlacing of the two groups. Loops of the first

4.2.2.3 Stitch type, group are passed through the material where they are secured

4.2.2.4 Stitch density (spi), by the thread(s) of the second group to form a stitch.

4.2.2.5 Thread tension, and 5.2.1.4 Stitch Class 400—This class of stitch (Types 401

4.2.2.6 Thread elasticity. through 407) shall be formed with two or more groups of

4.2.3 Durability—The durability of a sewn seam depends threads and requires the interlacing and interlooping of the

largely upon its strength relative to the elasticity of the seam loops of the two groups. Loops of the first group of threads are

and the elasticity of the material. However, in less elastic, passed through the material and are secured by interlacing and

tightly woven or dense materials, there is a tendency for the interlooping with loops of the second group to form a stitch.

plies to “work” or slide on each other. To form a durable sewn 5.2.1.5 Stitch Class 500—This class of stitch (Types 501

seam in these types of fabrics, the thread size must be carefully through 522) is formed with one or more groups of thread, and

D 6193

NOTE 1—This type of stitch shall be formed with one needle thread, which shall be passed through the material and brought back one stitch length

and then passed back up through the material. The needle shall be moved diagonally across the material and forward one stitch length, passed through

the material, brought back one stitch length and again passed to the surface of the material. This process shall be repeated to form a crisscross pattern

of stitches on the surface and parallel rows of separated and off-set stitches on the underside of the material.

FIG. 9 Stitch Type 204

NOTE 1—This type of stitch shall be formed with one or more needle threads and has for a general characteristic that the thread does not interloop with

itself or any other thread or threads. The thread is passed completely through the material by means of a double pointed center eye needle and returned

by another path. This class of stitch simulates hand stitching.

FIG. 10 Stitch Type 205

NOTE 1—This type of stitch shall be formed with two threads: one needle thread, A, and one bobbin thread, B. A loop of thread A shall be passed

through the material and interlaced with thread B. Thread A shall be pulled back so that the interlacing shall be midway between surfaces of the material

or materials being sewn.

FIG. 11 Stitch Type 301

NOTE 1—This type of stitch shall be formed with three threads: two needle threads, A and A8, and one bobbin thread, B. Loops of threads A and A8

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.