ASTM F2968/F2968M-14

(Specification)Standard Specification for Black Crosslinked Polyethylene (PEX) Pipe, Fittings and Joints For Gas Distribution Applications

Standard Specification for Black Crosslinked Polyethylene (PEX) Pipe, Fittings and Joints For Gas Distribution Applications

ABSTRACT

This specification covers the requirements and corresponding test methods for outside diameter controlled, black metric-sized and IPS-sized crosslinked polyethylene (PEX) pipe, fittings and joints, made in pipe dimension ratios ranging from 6 to 17, and pressure rated for gas distribution. Included are requirements and test methods for material, workmanship, dimensions, burst pressure, hydrostatic sustained pressure, stabilizer functionality, bent-pipe hydrostatic pressure, degree of crosslinking, chemical resistance, and squeeze-off. Requirements for pipe and fittings markings are also provided, along with quality assurance. The pipe, fittings and joints covered by this specification are intended for buried gas distribution pressure piping applications. Several tables list the PEX pipe material designation codes; metric-sized outside diameters and tolerances for PEX pipe; inch-sized outside diameters and tolerances for PEX pipe; metric-sized wall thickness and tolerances for PEX plastic pipe; inch-sized wall thickness and tolerances for PEX plastic pipe; and pipe category.

SCOPE

1.1 This specification covers outside diameter controlled, black metric-sized and IPS-sized crosslinked polyethylene (PEX) pipe, fittings and joints, made in pipe dimension ratios ranging from 6 to 17, and pressure rated for gas distribution. Included are requirements and test methods for material, workmanship, dimensions, burst pressure, hydrostatic sustained pressure, stabilizer functionality, bent-pipe hydrostatic pressure, degree of crosslinking, chemical resistance, and squeeze-off. Requirements for pipe and fittings markings are also given. The pipe, fittings and joints covered by this specification are intended for buried gas distribution pressure piping applications.

1.2 The text of this specification references notes, footnotes, and appendixes, which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.Note 1—Metric sized (SI units) pipe should only be joined with corresponding metric sized fittings, and inch sized pipe should only be joined with corresponding inch sized fittings. Inch sized fittings should not be used for metric sized pipe, and metric sized fittings should not be used for inch sized pipe.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2968/F2968M −14 AnAmerican National Standard

Standard Specification for

Black Crosslinked Polyethylene (PEX) Pipe, Fittings and

Joints For Gas Distribution Applications

ThisstandardisissuedunderthefixeddesignationF2968/F2968M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers outside diameter controlled, 2.1 ASTM Standards:

black metric-sized and IPS-sized crosslinked polyethylene D543 Practices for Evaluating the Resistance of Plastics to

(PEX) pipe, fittings and joints, made in pipe dimension ratios Chemical Reagents

ranging from 6 to 17, and pressure rated for gas distribution. D618 Practice for Conditioning Plastics for Testing

Included are requirements and test methods for material, D792 Test Methods for Density and Specific Gravity (Rela-

workmanship, dimensions, burst pressure, hydrostatic sus- tive Density) of Plastics by Displacement

tained pressure, stabilizer functionality, bent-pipe hydrostatic D1505 Test Method for Density of Plastics by the Density-

pressure, degree of crosslinking, chemical resistance, and Gradient Technique

squeeze-off. Requirements for pipe and fittings markings are D1598 Test Method for Time-to-Failure of Plastic Pipe

also given. The pipe, fittings and joints covered by this Under Constant Internal Pressure

specification are intended for buried gas distribution pressure D1599 Test Method for Resistance to Short-Time Hydraulic

piping applications. Pressure of Plastic Pipe, Tubing, and Fittings

D1600 Terminology forAbbreviatedTerms Relating to Plas-

1.2 The text of this specification references notes, footnotes,

tics

and appendixes, which provide explanatory material. These

D1603 Test Method for Carbon Black Content in Olefin

notesandfootnotes(excludingthoseintablesandfigures)shall

Plastics

not be considered as requirements of the specification.

D2122 Test Method for Determining Dimensions of Ther-

1.3 Units—The values stated in either SI units or inch-

moplastic Pipe and Fittings

pound units are to be regarded separately as standard. The

D2290 Test Method for Apparent Hoop Tensile Strength of

values stated in each system may not be exact equivalents;

Plastic or Reinforced Plastic Pipe

therefore,eachsystemshallbeusedindependentlyoftheother.

D2765 Test Methods for Determination of Gel Content and

Combining values from the two systems may result in non-

Swell Ratio of Crosslinked Ethylene Plastics

conformance with the standard.

D2837 Test Method for Obtaining Hydrostatic Design Basis

forThermoplasticPipeMaterialsorPressureDesignBasis

NOTE 1—Metric sized (SI units) pipe should only be joined with

corresponding metric sized fittings, and inch sized pipe should only be

for Thermoplastic Pipe Products

joinedwithcorrespondinginchsizedfittings.Inchsizedfittingsshouldnot

D4218 Test Method for Determination of Carbon Black

be used for metric sized pipe, and metric sized fittings should not be used

Content in Polyethylene Compounds By the Muffle-

for inch sized pipe.

Furnace Technique

1.4 This standard does not purport to address all of the

F412 Terminology Relating to Plastic Piping Systems

safety concerns, if any, associated with its use. It is the

F1041 Guide for Squeeze-Off of Polyolefin Gas Pressure

responsibility of the user of this standard to establish appro-

Pipe and Tubing

priate safety and health practices and determine the applica-

F1055 Specification for Electrofusion Type Polyethylene

bility of regulatory limitations prior to use.

Fittings for Outside Diameter Controlled Polyethylene

1 2

This specification is under the jurisdiction ofASTM Committee F17 on Plastic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Piping Systems and is the direct responsibility of Subcommittee F17.60 on Gas. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved April 15, 2014. Published June 2014. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

F2968–14. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2968/F2968M−14

and Crosslinked Polyethylene (PEX) Pipe and Tubing crosslinked polyethylene (PEX) followed by fourArabic digits

F1563 Specification for Tools to Squeeze-off Polyethylene as shown in Table 1, and as defined in Terminology F412 for

(PE) Gas Pipe or Tubing PEX pipe materials.

F1948 Specification for Metallic Mechanical Fittings for

4. Pipe Classification

Use on Outside Diameter Controlled Thermoplastic Gas

Distribution Pipe and Tubing

4.1 General—This standard covers black PEX pipe that is

F2897 Specification for Tracking and Traceability Encoding

pressure rated based on HDB at 73ºF [23ºC] and 200ºF [93ºC].

System of Natural Gas Distribution Components (Pipe,

Pressure ratings for temperatures between 73ºF [23ºC] and

Tubing, Fittings, Valves, and Appurtenances)

200ºF [93ºC] are determined by temperature interpolation in

accordance with PPI TR-3.

2.2 Federal Standard:

FED-STD-123 Marking for Shipment (Civil Agencies)

4.2 Classification—PEX pipes are classified by their PEX

2.3 Military Standard: pipe material designation codes as shown in Table 1.

MIL-STD-129 Marking for Shipment and Storage

5. Materials

2.4 ISO Standards:

ISO 1167 Thermoplastics pipes, fittings and assemblies for 5.1 General—PEX pipes, meeting the requirements of this

specification, are defined by means of (1) degree of crosslink-

the conveyance of fluids — Determination of the resis-

tance to internal pressure — Part 1: General method ing per 6.7, and (2) long-term strength tests per Test Method

D2837 to determine HDB per Table 1. The HDB is a property

ISO 14531-2 Plastics pipes and fittings — Crosslinked

of the PEX compound, which is used to make the PEX pipe.

polyethylene (PE-X) pipe systems for the conveyance of

gaseous fuels — Metric series — Specifications — Part 2:

5.2 Basic Materials—PEX pipe and fittings shall be made

Fittings for heat-fusion jointing

from PE compounds, which have been crosslinked by

ISO 14531-3 Plastics pipes and fittings — Crosslinked

peroxides, azo compounds, or silane compounds in extrusion,

polyethylene (PE-X) pipe systems for the conveyance of

or by electron beam after extrusion, such that the pipe meets

gaseous fuels — Metric series — Specifications — Part 3:

the performance requirements of Section 6. The materials,

Fittings for mechanical jointing (including PE-X/metal

procedure for mixing, and the process for crosslinking shall

transitions)

result in a product with Hydrostatic Design Basis ratings equal

2.5 PPI Standards: to or better than those shown in Table 1, when determined in

PPI TR-3 Policies and Procedures for Developing Hydro-

accordance with procedures no less restrictive than those of

static Design Basis (HDB), Pressure Design Basis (PDB), Test Method D2837, and the PEX material shall have a Plastics

Strength Design Basis (SDB), and Minimum Required

Pipe Institute (PPI) long-term hydrostatic design stress and

Strength (MRS) Ratings for Thermoplastic Piping Mate- hydrostatic design basis rating per PPITR-3. See Appendix X1

rials or Pipe

for additional information on PPI hydrostatic stress ratings.

PPI TR-4 PPI Listing of Hydrostatic Design Basis (HDB),

5.3 Pipe Material Designation Code—The PEX material

Strength Design Basis (SDB), Pressure Design Basis

meeting the requirements of this specification shall be desig-

(PDB) and Minimum Required Strength (MRS) Ratings

nated PEX 0006, PEX 0008 or PEX 0009.

for Thermoplastic Piping Materials or Pipe

NOTE 2—The first two digits in the pipe material designation code are

for chlorine resistance and UV resistance. A “0” indicates “not tested”. If

3. Terminology

either of these properties has been tested, then the “0” is replaced by the

3.1 Definitions—Definitions are in accordance with Termi- appropriate digit.

nology F412, and abbreviations are in accordance with Termi-

5.4 Density—When determined in accordance with 7.5, the

nologyD1600,unlessotherwisespecified.Theabbreviationfor

PE base resin used for PEX pipe, without carbon black, used

crosslinked polyethylene is PEX. Plastic pipe denotes a par-

for PEX pipe shall have a minimum average density of 0.926

ticular diameter schedule of plastic pipe that is outside diam-

g/cm .

eter controlled.

5.5 Carbon Black—PE compounds used to make PEX pipe

3.2 Definitions of Terms Specific to This Standard:

shall contain 2.0 to 3.0 percent well dispersed carbon black as

3.2.1 crosslinked polyethylene, n—molecular chains chemi-

measured in the PEX pipe by Test Methods D1603 or D4218.

cally connected through irradiation with high-energy electron

5.6 Rework Material—PEX rework shall not be used in the

beams,orchemicalagentssuchasorganicperoxidesorsilanes.

manufacture of PEX pipes and fittings made in accordance to

3.2.2 PEX pipe material designation code—The PEX pipe

this specification.

material designation code shall consist of the abbreviation for

TABLE 1 PEX Pipe Material Designation Codes

DLA Document Services Building 4/D 700 Robbins Avenue Philadelphia, PA

PEX Pipe Material 73ºF [23ºC] HDB 200ºF [93ºC] HDB

19111-5094 http://quicksearch.dla.mil/

Designation Code Psi [MPa] Psi [MPa]

Available from International Organization for Standardization (ISO), 1, ch. de

PEX 0006 1250 [8.62] 630 [4.34]

la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

PEX 0008 1600 [11.03] 630 [4.34]

Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825, PEX 0009 1800 [12.41] 630 [4.34]

Irving, TX 75062, http://www.plasticpipe.org.

F2968/F2968M−14

TABLE 3 Inch-sized Outside Diameters and Tolerances for PEX

5.7 Chemical Resistance—The PEX material shall not in-

Pipe

crease in weight more than 0.5 % (1.0 % for toluene in

Pipe Size Outside Diameter Tolerances for Outside

methanol). Where the test specimen is a pipe ring, the material

Diameter (±)

shall not change more than 612 % in apparent tensile yield

in. in. in.

strength when measured in accordance with 7.11.

3 3.500 0.016

4 4.500 0.020

NOTE 3—This test is only an indication of what will happen as a result

5 5.563 0.025

of short-term exposure to these chemicals. For long-term results, addi-

6 6.625 0.030

8 8.625 0.039

tional testing is required.

10 10.750 0.048

12 12.750 0.057

6. Requirements

14 14.000 0.063

16 16.000 0.072

6.1 Workmanship—The pipe shall be homogeneous

18 18.000 0.081

throughout and free of visible cracks, holes, foreign inclusions,

20 20.000 0.090

or other defects. The pipe shall be as uniform as commercially 22 22.000 0.099

24 24.000 0.108

practicable in color, opacity, density, and other physical prop-

26 26.000 0.117

erties.

28 28.000 0.126

30 30.000 0.135

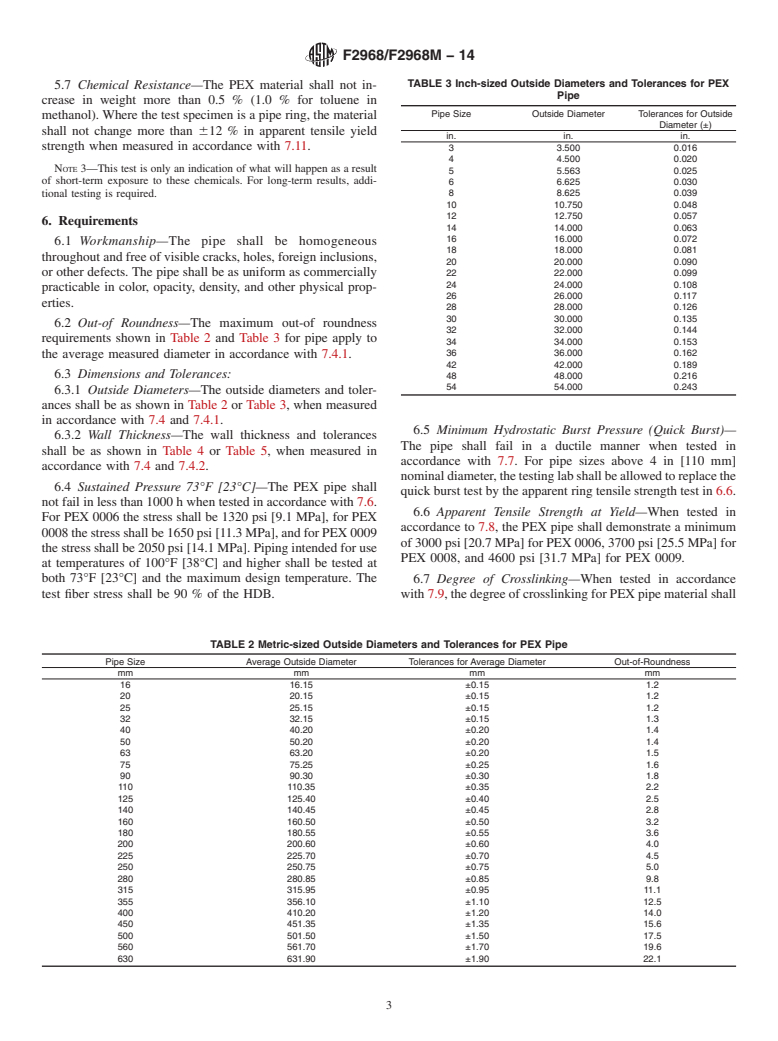

6.2 Out-of Roundness—The maximum out-of roundness

32 32.000 0.144

requirements shown in Table 2 and Table 3 for pipe apply to

34 34.000 0.153

36 36.000 0.162

the average measured diameter in accordance with 7.4.1.

42 42.000 0.189

6.3 Dimensions and Tolerances: 48 48.000 0.216

54 54.000 0.243

6.3.1 Outside Diameters—The outside diameters and toler-

ances shall be as shown in Table 2 or Table 3, when measured

in accordance with 7.4 and 7.4.1.

6.5 Minimum Hydrostatic Burst Pressure (Quick Burst)—

6.3.2 Wall Thickness—The wall thickness and tolerances

The pipe shall fail in a ductile manner when tested in

shall be as shown in Table 4 or Table 5, when measured in

accordance with 7.7. For pipe sizes above 4 in [110 mm]

accordance with 7.4 and 7.4.2.

nominaldiameter,thetestinglabshallbeallowedtoreplacethe

6.4 Sustained Pressure 73°F [23°C]—The PEX pipe shall

quick burst test by the apparent ring tensile strength test in 6.6.

not fail in less than 1000 h when tested in accordance with 7.6.

6.6 Apparent Tensile Strength at Yield—When tested in

For PEX 0006 the stress shall be 1320 psi [9.1 MPa], for PEX

accordance to 7.8, the PEX pipe shall demonstrate a minimum

0008thestressshallbe1650psi[11.3MPa],andforPEX0009

of 3000 psi [20.7 MPa] for PEX 0006, 3700 psi [25.5 MPa] for

the stress shall be 2050 psi [14.1 MPa]. Piping intended for use

PEX 0008, and 4600 psi [31.7 MPa] for PEX 0009.

at temperatures of 100°F [38°C] and higher shall be tested at

both 73°F [23°C] and the maximum design temperature. The 6.7 Degree of Crosslinking—When tested in accordance

test fiber stress shall be 90 % of the HDB. with 7.9, the degree of crosslinking for PEX pipe material shall

TABLE 2 Metric-sized Outside Diameters and Tolerances for PEX Pipe

Pipe Size Average Outside Diameter Tolerances for Average Diameter Out-of-Roundness

mm mm mm mm

16 16.15 ±0.15 1.2

20 20.15 ±0.15 1.2

25 25.15 ±0.15 1.2

32 32.15 ±0.15 1.3

40 40.20 ±0.20 1.4

50 50.20 ±0.20 1.4

63 63.20 ±0.20 1.5

75 75.25 ±0.25 1.6

90 90.30 ±0.30 1.8

110 110.35 ±0.35 2.2

125 125.40 ±0.40 2.5

140 140.45 ±0.45 2.8

160 160.50 ±0.50 3.2

180 180.55 ±0.55 3.6

200 200.60 ±0.60 4.0

225 225.70 ±0.70 4.5

250 250.75 ±0.75 5.0

280 280.85 ±0.85 9.8

315 315.95 ±0.95 11.1

355 356.10 ±1.10 12.5

400 410.20 ±1.20 14.0

450 451.35 ±1.35 15.6

500 501.50 ±1.50 17.5

560 561.70 ±1.70 19.6

630 631.90 ±1.90 22.1

F2968/F2968M−14

TABLE 4 Metric-sized Wall Thickness and Tolerances for PEX Plastic Pipe

Minimum Wall Thickness (t), mm (tolerance is plus 12%)

Pipe Size [mm] DR 6 DR 7.4 DR 9 DR 11 DR 13.6 DR 16.2 DR 17 DR 21

16 3.0 2.3 2.0 . . . . .

20 3.4 3.0 2.3 2.0 . . . .

25 5.4 3.5 3.0 2.3 2.0 . . .

32 5.4 4.4 3.6 3.0 2.4 2.0 2.0 2.3

40 6.7 5.5 4.5 3.7 3.0 2.5 2.4 2.8

50 8.3 6.9 5.6 4.6 3.7 3.1 3.0 3.4

63 10.5 8.6 7.1 5.8 4.7 3.9 3.8 4.3

75 12.5 10.3 8.4 6.8 5.6 4.6 4.5 5.1

90 15.0 12.3 10.1 8.2 6.7 5.6 5.4 6.1

110 18.3 15.1 12.3 10.0 8.1 7.7 6.6 7.4

125 20.8 17.1 14.0 11.4 9.2 7.7 7.4 8.3

140 23.3 19.2 15.7 12.7 10.3 8.7 8.3 9.3

160 26.6 21.9 17.9 14.6 11.8 9.9 9.5 10.6

180 29.9 24.6 20.1 16.4 13.3 11.1 10.7 11.9

200 33.2 27.4 22.4 18.2 14.7 12.4 11.9 13.2

225 37.4 30.8 25.2 20.5 16.6 13.9 13.4 14.9

250 41.5 34.2 27.9 22.7 18.4 15.5 14.8 16.4

280 46.5 38.3 31.3 25.4 20.6 17.3 16.6 18.4

315 52.3 43.1 35.2 28.6 23.2 19.5 18.7 20.7

355 59.0 48.5 39.7 32.2 26.1 21.9 21.1 23.4

400 . 54.7 44.7 36.3 29.4 24.7 26.2 23.7

450 . 61.5 50.3 40.9 33.1 27.8 26.7 29.5

500 . . 55.8 45.4 36.8 30.9 29.7 32.8

560 . . 62.5 50.8 41.2 34.6 33.2 36.7

630 . . 70.3 57.2 46.3 38.9 37.4 41.3

710 . . 79.3 64.5 52.2 43.9 42.1 46.5

800 . . 89.3 72.6 58.8 49.4 47.4 52.3

900 . . . 81.7 66.2 56.6 53.3 58.8

1000 .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.