ASTM B810-01a(2011)

(Test Method)Standard Test Method for Calibration of Atmospheric Corrosion Test Chambers by Change in Mass of Copper Coupons

Standard Test Method for Calibration of Atmospheric Corrosion Test Chambers by Change in Mass of Copper Coupons

SIGNIFICANCE AND USE

Electrical devices that contain electrical contacts generally contain some copper-based materials. Atmospheric corrosion of copper parts in such devices often occurs in service environments. A quantitative measure of the effect of a laboratory corrosion test on copper permits assessment of the severity of the test. In addition, corrosion tests may be defined in terms of their effect on copper; this test method provides a way of comparing one test against a standard defined elsewhere, or allows a comparison of the performance of a test over a period of time. Although this test method provides for a relatively simple check of a test, the user is advised that additional analysis of the test chamber ambient is generally required to reproduce test conditions.

Atmospheric corrosion tests are used on a variety of materials besides copper. Care should be exercised in drawing conclusions about the effects on such materials of apparently equivalent tests if the composition of gases or experimental conditions are different. The primary use of this calibration test method is to assure correlation among nominally identical tests.

SCOPE

1.1 This test method covers the calibration of atmospheric corrosion test chambers for electrical contacts that produce an adherent film of corrosion product on copper, such as a test comprised of a mixture of flowing gases that react with copper.

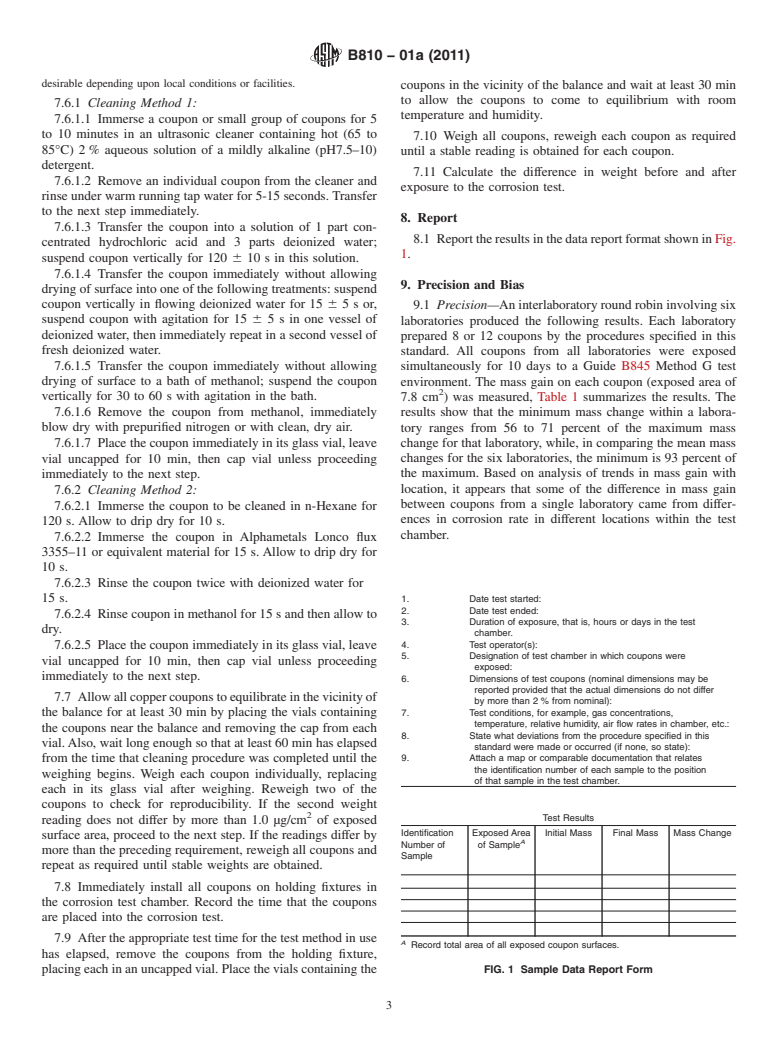

1.2 This test method is not applicable to tests where corrosion products may be removed from a copper surface during the test by fluids.

1.3 This test method is not applicable to tests where airborne solid or liquid material may be deposited on a copper surface during the test, as in a test which includes particulates suspended in the atmosphere.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B810 − 01a (Reapproved 2011)

Standard Test Method for

Calibration of Atmospheric Corrosion Test Chambers by

Change in Mass of Copper Coupons

This standard is issued under the fixed designation B810; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope coupons are cleaned by a standard process. Each coupon is

weighed and the value is recorded.All coupons are exposed to

1.1 This test method covers the calibration of atmospheric

the corrosion test for a specified time. The coupons are

corrosion test chambers for electrical contacts that produce an

removed from the test and weighed and the new values are

adherent film of corrosion product on copper, such as a test

recorded. The change in weight for each coupon is calculated.

comprisedofamixtureofflowinggasesthatreactwithcopper.

Thecouponsaresubjectedtoadditionalanalysisasappropriate

1.2 This test method is not applicable to tests where

to determine the composition and thickness of any films

corrosion products may be removed from a copper surface

present on the surface.

during the test by fluids.

1.3 This test method is not applicable to tests where 4. Significance and Use

airborne solid or liquid material may be deposited on a copper

4.1 Electrical devices that contain electrical contacts gener-

surface during the test, as in a test which includes particulates

ally contain some copper-based materials.Atmospheric corro-

suspended in the atmosphere.

sion of copper parts in such devices often occurs in service

1.4 The values stated in SI units are to be regarded as

environments. A quantitative measure of the effect of a

standard. No other units of measurement are included in this

laboratory corrosion test on copper permits assessment of the

standard.

severity of the test. In addition, corrosion tests may be defined

in terms of their effect on copper; this test method provides a

1.5 This standard does not purport to address all of the

way of comparing one test against a standard defined

safety concerns, if any, associated with its use. It is the

elsewhere, or allows a comparison of the performance of a test

responsibility of the user of this standard to become familiar

over a period of time.Although this test method provides for a

with all hazards including those identified in the appropriate

relatively simple check of a test, the user is advised that

Material Safety Data Sheet (MSDS) for this product/material

additional analysis of the test chamber ambient is generally

as provided by the manufacturer, to establish appropriate

required to reproduce test conditions.

safety and health practices, and determine the applicability of

regulatory limitations prior to use.

4.2 Atmospheric corrosion tests are used on a variety of

materials besides copper. Care should be exercised in drawing

2. Referenced Documents

conclusions about the effects on such materials of apparently

2.1 ASTM Standards:

equivalent tests if the composition of gases or experimental

B845Guide for Mixed Flowing Gas (MFG) Tests for Elec-

conditionsaredifferent.Theprimaryuseofthiscalibrationtest

trical Contacts

method is to assure correlation among nominally identical

tests.

3. Summary of Test Method

3.1 Copper coupon samples of a well-defined size are

5. Apparatus

prepared and each is labeled for identification. All such

5.1 Racks or Fixtures suitable for holding the copper

coupons in the test chamber are required. Make these fixtures

This test method is under the jurisdiction of ASTM Committee B02 on

from a material that is not attacked by the corrosion test. The

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.11 on Electrical Contact Test Methods.

fixtures shall be designed to:

Current edition approved Oct. 1, 2011. Published October 2011. Originally

5.1.1 Hold the coupons in a vertical orientation,

approved in 1991. Last previous edition approved in 2006 as B810–01a(2006).

DOI: 10.1520/B0810-01AR11. 5.1.2 Hold the coupons so that they do not show any

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

perceptiblemotionwhenobservedwiththeunaidedeyeduring

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the test,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 5.1.3 Cover less than 5% of the entire coupon surface area,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B810 − 01a (2011)

5.1.4 Touch the coupon only with electrically insulating appropriate guidelines applied to cubic chambers. Thus, if the

parts and, x and z axes are 1.5 m and the y axis is 0.8 m, four grid lines

5.1.5 Allow free circulation of the ambient on both sides of would be used for the x and z axes and 3 grid lines would be

the coupon. used for the y axis when determining the grid for coupon

location.

5.2 In general, design all parts of the fixture to permit

7.1.3 For chambers with working volumes of other shapes

maximum circulation of the ambient around the coupon

than those covered in the preceding sections, devise a logical

surfaces. The size and positioning of the holding fixtures

placement pattern with a coupon density roughly equal to that

depends on the chamber size. Section 7 of this test method

specified for rectangular chambers.

gives requirements on the number and spacing of coupons; the

holding fixtures must be designed to comply with these

7.2 Select an appropriate duration of exposure for the

requirements.

copper coupons. Base this selection primarily upon the time

required for the test ambient to produce a statistically signifi-

5.3 Balance, with a capacity of at least 2 g and a resolution

cantweightchange.Additionalexposuretimemaybeaddedto

of 5 µg is required. Maintain the ambient in the vicinity of the

comply with other applicable requirements, specifications,

balance between 20 and 50% relative humidity.

agreements,etc.,orfortheconvenienceofthetestoperators,or

5.4 Fume Hood,toconductthechemicalcleaningprocedure

both. Generally, the test time shall be one or more whole days

of the coupons is required.

with a tolerance of 61h.

6. Reagents and Materials 7.3 Prepare the test coupons from wrought, annealed,

oxygen-free copper (99.95% copper minimum, copper alloy

6.1 Purity of Reagents—Reagent grade chemicals shall be

C10200) sheet. Select a thickness of sheet sufficiently stiff to

used in all tests. Unless otherwise indicated, it is intended that

resist bending during handling during the test but not so thick

all reagents conform to the specifications of the Committee on

3 that the edges become a significant portion of the surface area.

Analytical Reagents of the American Chemical Society

In general, thicknesses between 0.1 and 0.6 mm are recom-

where such specifications are available. Other grades may be

mended. Obtain material with a surface roughness less than

used, provided it is first ascertained that the reagent is of

0.15 µm center line average and use the material with the

sufficiently high purity to permit its use without lessening the

as-rolled surface finish. Make the coupons, squares or rect-

accuracy of the determination.

angles preferably 12.5 6 1.2 mm wide. One or two holes 2.5

mm or less in diameter may be added to aid in mounting.

7. Procedure

Inspect the edges of the coupons at 10× magnification for the

7.1 Use the requirements listed in 7.1.1 through 7.1.3 to

presence of burrs or slivers. If such features are found, they

determine the number of copper coupon specimens to be

mustberemovedsincetheymaycorrodeatamuchhigherrate

prepared.

than the coupon surface.

7.1.1 For chambers with cubic working volumes, use the

length of an edge to determine the number and placement of 7.4 Mark all coupons with a code giving each coupon a

unique identification. Make the characters in the code marking

coupons in accordance with the following rules. For chambers

with an edge dimension of 0.9 m or less, construct a reference about 2 mm high by engraving or stamping without ink.

grid with three equally spaced lines in each direction with the

7.5 During the cleaning procedure and at all times after

outer lines 0.1 m from the chamber wall and the third line

cleaning, handle coupons only with clean tweezers grasping in

centered between the outer lines. Place a coupon at each

theregionaroundtheidentificationmarking.Placeeachcopper

intersection of grid lines (27 coupons required). For chambers

couponinaseparateclean,dryglassvialofanappropriatesize

withanedgedimensionof0.9mto1.4m,constructareference

such that only the edges and corners of the coupons touch the

gridwithfourequallyspacedlinesineachdirection.Theouter

glass surfaces.

lines are placed 0.1 m from the chamber wall. Place a coupon

7.6 Clean all coupons in accordance with either of the two

at each intersection of grid lines (64 coupons required). For

procedures given in 7.6.1 through 7.6.2.5. Where a liquid bath

chambers with a maximum edge dimension greater than 1.4 m

is required, fill an appropriate vessel to a depth equal to or

butlessthan2.0m,constructareferencegridwithfiveequally

greater than 25 mm plus the largest dimension of the coupon

spacedlinesineachdirection.Theouterlinesareplaced0.1m

sample to be cleaned. Unless otherwise directed, change the

from the chamber wall. Place a coupon at each intersection of

fluid in all baths after 50 coupons have been processed. Unless

grid lines (125 coupons required).

otherwise directed, use all baths at room temperature.

7.1.2 For rectangular chambers with non-cubic working

(Warning—Conduct all operations involving acids and sol-

volumes, the guidelines for each dimension of the chamber

vents in a fume hood. Please be careful of N-Hexane. It is

al

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.