ASTM D2281-68(1997)

(Test Method)Standard Test Method for Evaluation of Wetting Agents by the Skein Test

Standard Test Method for Evaluation of Wetting Agents by the Skein Test

SCOPE

1.1 This method 2,3 covers the determination of the efficiency of ordinary commercial wetting agents as defined in Definitions D459. This method is applicable under limited and controlled conditions, but does not necessarily yield information correlating with specific end uses.

1.2 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.>

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2281–68 (Reapproved 1997)

Standard Test Method for

Evaluation of Wetting Agents by the Skein Test

This standard is issued under the fixed designation D 2281; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

,

2 3

1.1 This test method covers the determination of the

efficiency of ordinary commercial wetting agents as defined in

Terminology D 459. This test method is applicable under

limited and controlled conditions, but does not necessarily

yield information correlating with specific end uses.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

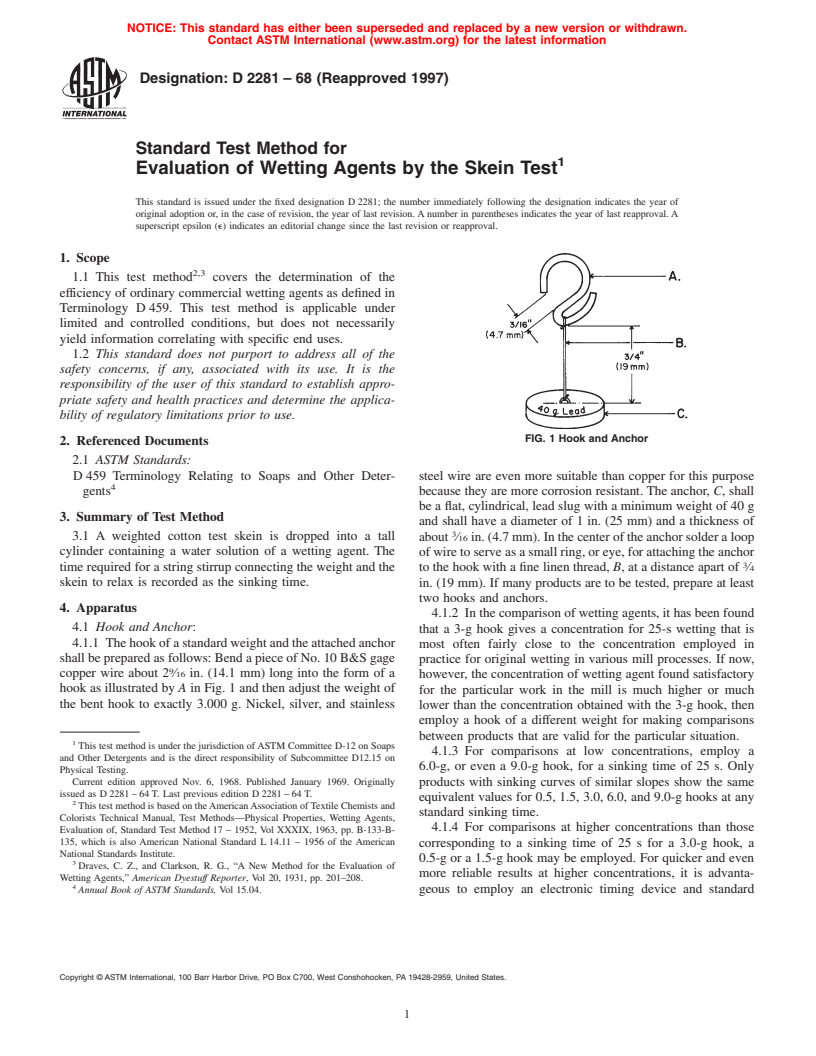

FIG. 1 Hook and Anchor

2. Referenced Documents

2.1 ASTM Standards:

D 459 Terminology Relating to Soaps and Other Deter- steel wire are even more suitable than copper for this purpose

gents because they are more corrosion resistant. The anchor, C, shall

be a flat, cylindrical, lead slug with a minimum weight of 40 g

3. Summary of Test Method

and shall have a diameter of 1 in. (25 mm) and a thickness of

3.1 A weighted cotton test skein is dropped into a tall about ⁄16in.(4.7mm).Inthecenteroftheanchorsolderaloop

cylinder containing a water solution of a wetting agent. The

of wire to serve as a small ring, or eye, for attaching the anchor

time required for a string stirrup connecting the weight and the to the hook with a fine linen thread, B, at a distance apart of ⁄4

skein to relax is recorded as the sinking time. in. (19 mm). If many products are to be tested, prepare at least

two hooks and anchors.

4. Apparatus

4.1.2 In the comparison of wetting agents, it has been found

4.1 Hook and Anchor:

that a 3-g hook gives a concentration for 25-s wetting that is

4.1.1 Thehookofastandardweightandtheattachedanchor

most often fairly close to the concentration employed in

shall be prepared as follows: Bend a piece of No. 10 B&S gage

practice for original wetting in various mill processes. If now,

copper wire about 2 ⁄16 in. (14.1 mm) long into the form of a

however, the concentration of wetting agent found satisfactory

hook as illustrated by A in Fig. 1 and then adjust the weight of

for the particular work in the mill is much higher or much

the bent hook to exactly 3.000 g. Nickel, silver, and stainless

lower than the concentration obtained with the 3-g hook, then

employ a hook of a different weight for making comparisons

between products that are valid for the particular situation.

This test method is under the jurisdiction ofASTM Committee D-12 on Soaps

4.1.3 For comparisons at low concentrations, employ a

and Other Detergents and is the direct responsibility of Subcommittee D12.15 on

6.0-g, or even a 9.0-g hook, for a sinking time of 25 s. Only

Physical Testing.

Current edition approved Nov. 6, 1968. Published January 1969. Originally

products with sinking curves of similar slopes show the same

issued as D 2281 – 64 T. Last previous edition D 2281 – 64 T.

equivalent values for 0.5, 1.5, 3.0, 6.0, and 9.0-g hooks at any

This test method is based on theAmericanAssociation of Textile Chemists and

standard sinking time.

Colorists Technical Manual, Test Methods—Physical Properties, Wetting Agents,

4.1.4 For comparisons at higher concentrations than those

Evaluation of, Standard Test Method 17 – 1952, Vol XXXIX, 1963, pp. B-133-B-

135, which is also American National Standard L 14.11 – 1956 of the American

corresponding to a sinking time of 25 s for a 3.0-g hook, a

National Standards Institute.

0.5-g or a 1.5-g hook may be employed. For quicker and even

Draves, C. Z., and Clarkson, R. G., “A New Method for the Evaluation of

more reliable results at higher concentrations, it is advanta-

Wetting Agents,” American Dyestuff Reporter, Vol 20, 1931, pp. 201–208.

Annual Book of ASTM Standards, Vol 15.04. geous to employ an electronic timing device and standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

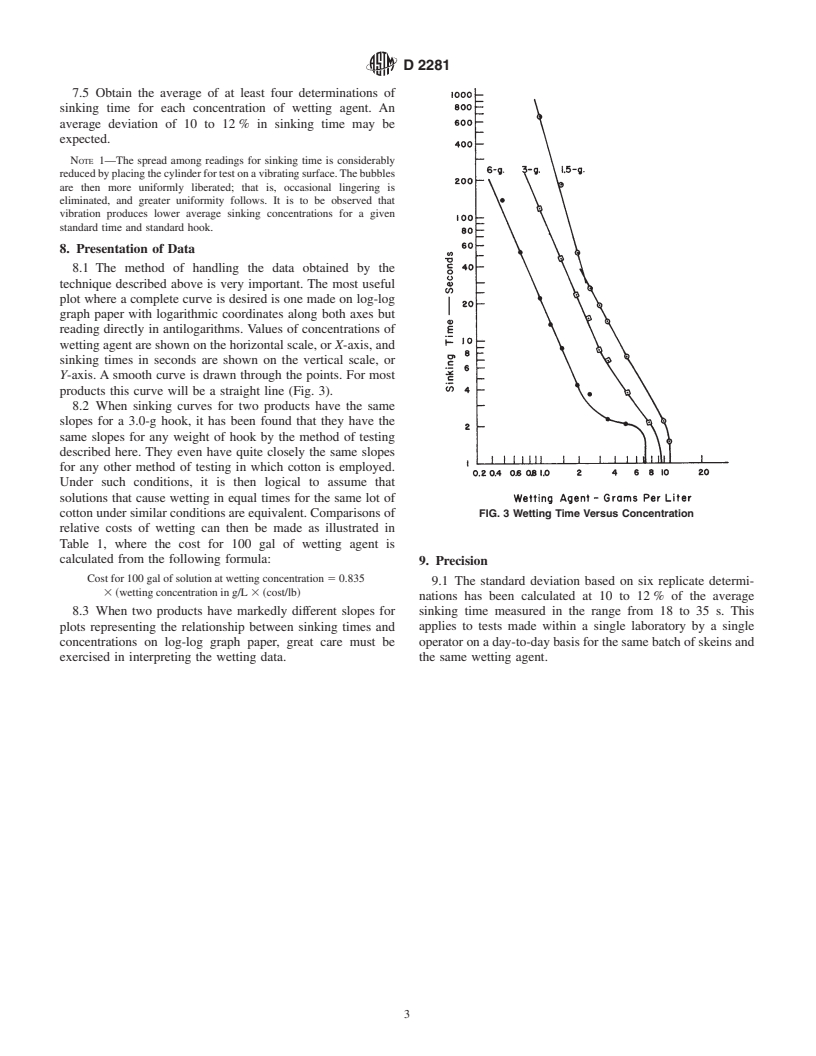

D2281

sinking times of 10 s and 4 s. The procedure, otherwise, is test solution. This corresponds, respectively, to concentrations

exactly the same as with the 3-g hook at 25 s. of 0.25, 0.35, 0.50, 0.75, 1.25, 1.75, 2.50, 3.75 and 5.00 g of

wetting agent/L. This range of concentrations is sufficient for

5. Test Skein

the study of any commercial product.

5.1 40s/2 combed Peeler yarn with a lisle twist of 18 to 20

7. Procedure

turns in. and a balanced construction is suitable. All the tubes

of grey cotton yarn used for making 5-g skeins for a given

7.1 Pourthedilutedtestsolutionfroma1-Lvolumetricflask

series of wetting tests shall be from the same lot of cotton. To

into a 1.5-Lbeaker to ensure mixing. Divide the solution in the

average out the slight differences still remaining between

beakerequallybetweentwo500-mLgraduatedcylinders.Ifthe

different tubes of the same lot and to increase the number of

more dilute solutions are tested first, the mixing beaker and

skeins that are closely alike in wetting properties for the series,

cylinders need not be rinsed out and dried each time.Wait after

it is urged that each skein be reeled simultaneously from 4 to

the cylinders have been filled until all bubbles below the

12 tubes of yarn. In the case of purchased skeins, the weights

surface of the solution have risen to the top before making the

of the skeins shall be corrected individually to within 10 mg of

sinking tests. Remove foam on the surface of the solution

5 g or to within 1 grain of 77 grains.

either with a 100-mL bulb pipet or with an aspirator. Where

5.2 For a determination, fold a 5.00-g (77 61-grain) skein

there is little tendency for exhaustion of the wetting agent on

of yarn enough times to form a loop 18 in. (460 mm) around.

the test skeins, practically always true for cotton, it is permis-

A36-in.(910-mm)skeinismostconvenientandcanbeformed

sible to use the same diluted solution over again several times

into an 18-in. loop with only two folds; a 54-in. (1370-mm)

rather than to make a new diluted solution for each new skein.

skein requires three folds; a 72-in. (1830-mm) skein, four

In this case only one 500-mLcylinder may be filled repeatedly

folds; and a 90-in. (2290-mm) skein requires five folds.

from the solutions of a certain concentration.

7.2 Since temperature often markedly affects wetting, stan-

6. Reagents

dard temperatures of 77, 122, 158, and 194°F (25, 50, 70, and

6.1 Water—The quality of the water used in the testing of

90°C) have been chosen for testing so as to include the

wetting agents must be given careful consideration. The stock

complete commercially useful range. It is most convenient to

solution is best prepared with distilled water. When it is not

attain a temperature of 77°F merely by using water that has

known under what

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.