ASTM E2558-07

(Test Method)Standard Test Method for Determining Particulate Matter Emissions from Fires in Low Mass Wood-Burning Fireplaces

Standard Test Method for Determining Particulate Matter Emissions from Fires in Low Mass Wood-Burning Fireplaces

SCOPE

1.1 This test method covers the fueling and operating protocol for determining particulate matter emissions from wood fires in low mass wood-burning fireplaces.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2558–07

Standard Test Method for

Determining Particulate Matter Emissions from Fires in Low

Mass Wood-Burning Fireplaces

This standard is issued under the fixed designation E 2558; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1 1

1. Scope The actual dimensions are 38 mm 3 89 mm (1 ⁄2 in. 3 3 ⁄2

1 1

in.) and 89 mm 3 89 mm (3 ⁄2 in. 3 3 ⁄2 in.).

1.1 This test method covers the fueling and operating

3.2.5 grate, n—any device included with the fireplace or

protocol for determining particulate matter emissions from

specified by the fireplace manufacturer, for the purpose of

wood fires in low mass wood-burning fireplaces.

elevating the fuel load above the hearth or for constraining fuel

1.2 The values stated in SI units are to be regarded as the

pieces from falling outside the intended burning area, or both.

standard. The values given in parentheses are for information

This includes basket grates and andirons.

only.

3.2.6 hearth, n—the footprint of the fireplace firebox.

1.3 This standard does not purport to address all of the

3.2.7 kindling brands, n—the initial fuel load or loads

safety concerns, if any, associated with its use. It is the

placed above crumpled newspaper to initiate combustion in the

responsibility of the user of this standard to establish appro-

fireplace and to establish a charcoal bed that will become the

priate safety and health practices and determine the applica-

ignition source for subsequent fuel loads. These are comprised

bility of regulatory limitations prior to use.

offuelstripsseparatedbyairspaces.Thespecificconfiguration

2. Referenced Documents is described in 9.3.4.

3.2.8 low mass fireplace, n—any fireplace and attached

2.1 ASTM Standards:

chimney that can be weighed (including the weight of the test

E 2515 TestMethodforDeterminationofParticulateMatter

fuel) on a platform scale that meets the requirements as

Emissions Collected in a Dilution Tunnel

specified in 8.2.

E 631 Terminology of Building Constructions

3.2.9 nominal fuel length, n—the Nominal Fuel Length

3. Terminology

(NFL) is one of five incremental nominal fuel piece lengths

that simulates real-world firewood five piece lengths. These

3.1 Definitions—Terms used in this test method are defined

lengths are 406 mm (16 in.), 457 mm (18 in.), 508 mm (20 in.),

in Terminology E 631.

559 mm (22 in.), and 610 mm (24 in.). The NFL is used for

3.2 Definitions of Terms Specific to This Standard:

both the kindling brands and fuel cribs.

3.2.1 douglas fir, n—untreated, standard, or better grade

3.2.10 particulate matter (PM), n—all gas-borne matter

Douglas fir lumber with agency grade stamp: D. Fir or Douglas

resulting from combustion of solid fuel, as specified in this test

Fir.

method, which is collected in accordance with Test Method

3.2.2 firebox, n—the volume within the fireplace where logs

E 2515.

are burned.

3.2.11 second fuel crib, n—the second fuel load (including

3.2.3 first fuel crib, n—the first fuel load (including fuel

fuel pieces and spacers to create air spaces) placed on the

pieces and spacers to create air spaces) placed on the residual

residual fuel from the first fuel crib. The specific configuration

fuel from the kindling brands. The specific configuration is

is described in 9.3.4.5.

described in 9.3.1.4.

3.2.12 spacers, n—wood pieces used to hold individual fuel

3.2.4 fuel piece, n—2 34or4 3 4 wood pieces used to

pieces together when constructing the three fuel cribs. Their

construct fuel cribs and referring to the nominal width and

function is to provide reproducible fuel crib geometry and air

depth dimensions for commonly available dimensional lumber.

spaces between fuel pieces, as well as to hold the fuel cribs

together (with nails).

This test method is under the jurisdiction of ASTM Committee E06 on

3.2.13 standardized fuel retainer, n—any fireplace that

Performance of Buildings and is the direct responsibility of Subcommittee E06.54

doesn’t include or specify a grate as defined in 3.2.11 shall use

on Solid Fuel Burning Appliances.

a standardized fuel retainer during testing.These retainers shall

Current edition approved April 1, 2007. Published May 2007.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or include vertical fuel retainer bars that are made from 19 mm 3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

19 mm (0.75 in. 3 0.75 in.) steel square bar or 19 mm (0.75

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2558–07

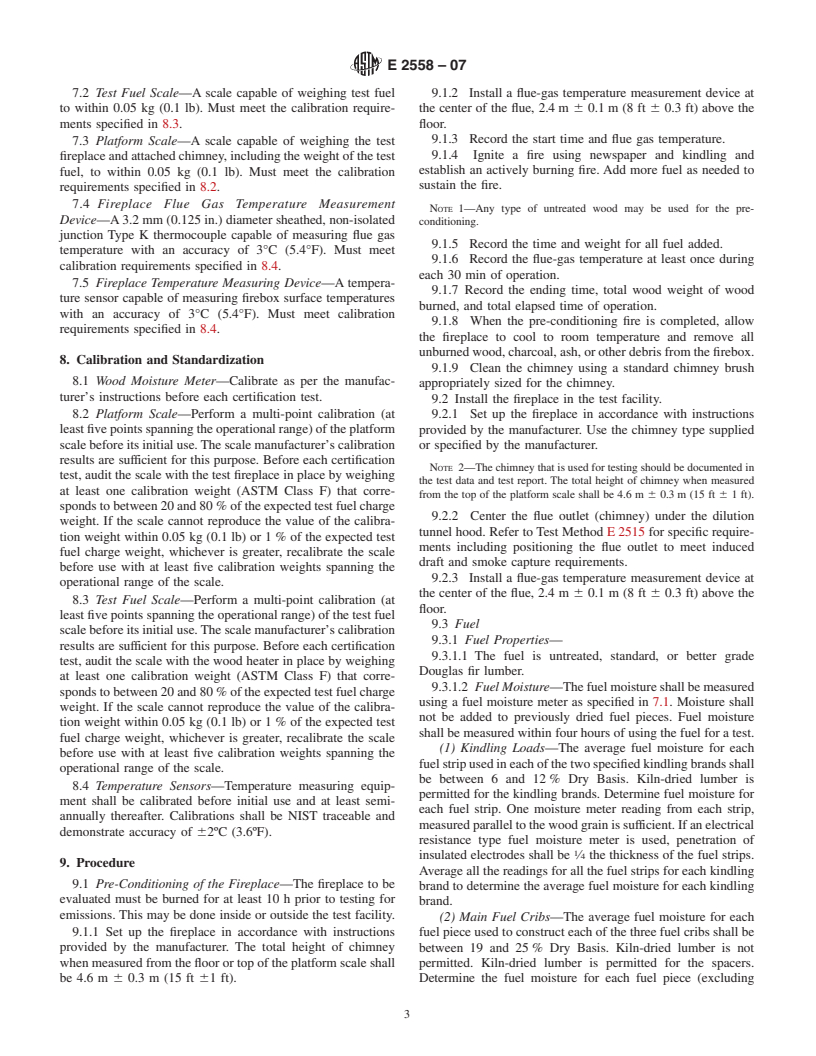

in.) diameter round steel bar and shall be 200 mm 6 50 mm (8 separateemissionstestsmayberequiredforeachofthevarious

in. 6 2 in.) high. They shall be attached to a steel plate that positions or conditions that are allowed in the manual. This

projects toward the front of the fireplace and shall not interfere might include things like door open and door closed operation,

with any fireplace function. They shall be spaced so they are for example. See 9.4.11-9.4.13.

300 mm 6 13 mm (12 in. 6 ⁄2 in.) apart. Their purpose is to

prevent fuel from rolling or falling forward during testing, thus 5. Significance and Use

helping to prevent an aborted test. See Fig. 1.

5.1 This test method is used for determining emission

3.2.14 test facility, n—the area in which the tested fireplace

factors and emission rates for low mass wood-burning fire-

is installed, operated, and sampled for emissions.

places.

3.2.15 third fuel crib, n—the third and final fuel load

5.1.1 The emission factor is useful for determining emission

(including fuel pieces and spacers to create air spaces) placed

performance during product development.

on the residual fuel from the second fuel crib. The specific

5.1.2 The emission factor is useful for the air quality

configuration is described in 9.3.4.6.

regulatory community for determining compliance with emis-

sion performance limits.

4. Summary of Test Method

5.1.3 The emission rate may be useful for the air quality

4.1 This test method is used in conjunction with Test

regulatory community for determining impacts on air quality

Method E 2515. The fireplace under evaluation is fueled with

from fireplaces, but must be used with caution as use patterns

kindlingandcribsinawaythatsimulatesfireplaceoperationin

must be factored into any prediction of atmospheric particulate

the home. An algorithm that uses the specific configuration of

matter impacts from fireplaces based on results from this

the test fireplace, including hearth and grate dimensions, is

method.

used to determine the kindling and fuel crib geometry and

5.2 The reporting units are grams of particulate per kilo-

dimensions. Kindling brands are placed in the fireplace above

gram of dry fuel and grams of particulate per hour.

crumpled newspaper and ignited. When the kindling brands

5.2.1 Appropriate reporting units for comparing emissions

haveburnedtoacertainpoint,thefirstfuelcribisplacedonthe

from non-heating appliances: g/kg.

remains of the kindling. When the first crib is substantially

5.2.2 Appropriate reporting units for predicting atmospheric

burned, the remaining material is adjusted as needed to form a

emission impacts only if hours of fireplace use are factored in:

base for the second crib. This process is repeated again before

g/hour.

addition of the third crib.The third crib is allowed to burn until

all flaming from volatile material in the fuel ceases, at which

6. Safety

point the test is terminated. Burn rate is determined based on

6.1 Disclaimer—This test method may involve hazardous

the amount of fuel added less the amount remaining at the end

materials,operations,andequipment.Thistestmethodmaynot

of the test divided by the length of test and corrected to a dry

address all of the safety problems associated with its use. It is

fuel basis. Particulate sampling begins at the time of ignition of

the responsibility of the user of this test method to establish

the newspaper and stops when the test terminates. The total

appropriate safety and health practices and to determine the

particulate emissions are determined over the test period. The

applicability of regulatory limitations prior to performing this

particulate emissions factor is then determined from the total

test method.

emissions and the total amount of fuel burned and is reported

in grams of particulate per dry kilogram of fuel or grams of

7. Equipment and Supplies

particulate per hour.

4.2 If the test fireplace includes standard (or offers optional) 7.1 Wood Moisture Meter—Calibrated electrical resistance

components that affect particulate emission performance and meter capable of measuring test fuel moisture to within 1 %

that have more than one operating position or condition moisture content. Must meet the calibration requirements

allowed in the owner’s manual that accompanies the fireplace, specified in 8.1.

FIG. 1 Example, Standardized Fuel Retainer

E2558–07

7.2 Test Fuel Scale—A scale capable of weighing test fuel 9.1.2 Install a flue-gas temperature measurement device at

to within 0.05 kg (0.1 lb). Must meet the calibration require- the center of the flue, 2.4 m 60.1m(8ft 6 0.3 ft) above the

ments specified in 8.3. floor.

9.1.3 Record the start time and flue gas temperature.

7.3 Platform Scale—A scale capable of weighing the test

9.1.4 Ignite a fire using newspaper and kindling and

fireplace and attached chimney, including the weight of the test

establish an actively burning fire. Add more fuel as needed to

fuel, to within 0.05 kg (0.1 lb). Must meet the calibration

sustain the fire.

requirements specified in 8.2.

7.4 Fireplace Flue Gas Temperature Measurement

NOTE 1—Any type of untreated wood may be used for the pre-

Device—A3.2 mm (0.125 in.) diameter sheathed, non-isolated

conditioning.

junction Type K thermocouple capable of measuring flue gas

9.1.5 Record the time and weight for all fuel added.

temperature with an accuracy of 3°C (5.4°F). Must meet

9.1.6 Record the flue-gas temperature at least once during

calibration requirements specified in 8.4.

each 30 min of operation.

7.5 Fireplace Temperature Measuring Device—A tempera-

9.1.7 Record the ending time, total wood weight of wood

ture sensor capable of measuring firebox surface temperatures

burned, and total elapsed time of operation.

with an accuracy of 3°C (5.4°F). Must meet calibration

9.1.8 When the pre-conditioning fire is completed, allow

requirements specified in 8.4.

the fireplace to cool to room temperature and remove all

unburned wood, charcoal, ash, or other debris from the firebox.

8. Calibration and Standardization

9.1.9 Clean the chimney using a standard chimney brush

8.1 Wood Moisture Meter—Calibrate as per the manufac-

appropriately sized for the chimney.

turer’s instructions before each certification test.

9.2 Install the fireplace in the test facility.

8.2 Platform Scale—Perform a multi-point calibration (at 9.2.1 Set up the fireplace in accordance with instructions

leastfivepointsspanningtheoperationalrange)oftheplatform provided by the manufacturer. Use the chimney type supplied

scale before its initial use.The scale manufacturer’s calibration or specified by the manufacturer.

results are sufficient for this purpose. Before each certification

NOTE 2—The chimney that is used for testing should be documented in

test, audit the scale with the test fireplace in place by weighing

the test data and test report. The total height of chimney when measured

at least one calibration weight (ASTM Class F) that corre-

from the top of the platform scale shall be 4.6 m 6 0.3 m (15 ft 6 1 ft).

sponds to between 20 and 80 % of the expected test fuel charge

9.2.2 Center the flue outlet (chimney) under the dilution

weight. If the scale cannot reproduce the value of the calibra-

tunnel hood. Refer to Test Method E 2515 for specific require-

tion weight within 0.05 kg (0.1 lb) or1%ofthe expected test

ments including positioning the flue outlet to meet induced

fuel charge weight, whichever is greater, recalibrate the scale

draft and smoke capture requirements.

before use with at least five calibration weights spanning the

9.2.3 Install a flue-gas temperature measurement device at

operational range of the scale.

the center of the flue, 2.4 m 60.1m(8ft 6 0.3 ft) above the

8.3 Test Fuel Scale—Perform a multi-point calibration (at

floor.

least five points spanning the operational range) of the test fuel

9.3 Fuel

scale before its initial use.The scale manufacturer’s calibration

9.3.1 Fuel Properties—

results are sufficient for this purpose. Before each certification

9.3.1.1 The fuel is untreated, standard, or better grade

test, audit the scale with the wood heater in place by weighing

Douglas fir lumber.

at least one calibration weight (ASTM Class F) that corre-

9.3.1.2 FuelMoisture—Thefuelmoistureshallbemeasured

sponds to between 20 and 80 % of the expected test fuel charge

using a fuel moisture meter as specified in 7.1. Moisture shall

weight. If the scale cannot reproduce the value of the calibra-

not be added to previously dried fuel pieces. Fuel moisture

tion weight within 0.05 kg (0.1 lb) or1%ofthe expected test

shall be measured within four hours of using the fuel for a test.

fuel charge weight, whichever is greater, recalibrate the scale

(1) Kindling Loads—The average fuel moisture for each

before use with at least five calibration weights spanning the

fuelstripusedineachofthetwospecifiedkindlingbrandsshall

operational range of the scale.

be between 6 and 12 % Dry Basis. Kiln-dried lumber is

8.4 Temperature Sensors—Temperature measuring equip-

permitted for the kindling brands. Determine fuel moisture for

ment shall be calibrated before initial use and at least semi-

each fuel strip. One moisture meter reading from each strip,

annually thereafter. Calibrations shall be NIST traceable and

measuredparalleltothewoodgrainissufficient.Ifanelectrical

demonstrate accuracy of 62ºC (3.6ºF).

resistance type fuel moisture meter is used, penetration of

insulated electrodes shall be ⁄4 the thickness of the fuel strips.

9. Procedure

Average all the readings for all the fuel strips for each kindling

9.1 Pre-Conditioning of the Fireplace—The fireplace to be

brand to determine the average fuel moisture for each kindling

evaluated must be burned for at least 10 h prior to testing for

brand.

emissions. This may be done inside or outside the test facility.

(2) Main Fuel Cribs—The average fuel moisture for each

9.1.1 Set up the fireplace in accordanc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.