ASTM F1791-00(2006)

(Specification)Standard Specification for Filters Used in Air or Nitrogen Systems

Standard Specification for Filters Used in Air or Nitrogen Systems

ABSTRACT

This specification covers the design, construction, test, and performance requirements for air or nitrogen system filters, referred to hereinafter as filters. These filters are intended to be installed in-line to protect equipment from particular contamination. Filter element type: type 1 - disposable, and type 2 - cleanable. Filter element bypass composition - composition A - with bypass, and composition B - without bypass. Filter element differential indicator style: style I - with differential pressure indicator, and style II - without differential pressure indicator. Visual examination, hydrostatic shell test, external leakage test, and bubble point test shall be performed to meet the requirements prescribed.

SCOPE

1.1 This specification covers the design, construction, test, and performance requirements for air or nitrogen system filters, referred to hereinafter as filters. These filters are intended to be installed in-line to protect equipment from particular contamination.

1.2 The values stated in this specification in inch-pounds units are to be regarded as the standard. The SI equivalent shown in parentheses are provided for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1791 −00(Reapproved 2006) An American National Standard

Standard Specification for

Filters Used in Air or Nitrogen Systems

This standard is issued under the fixed designation F1791; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope MS16142 Boss, Gasket Seal Straight Thread Tube Fitting,

Standard Dimensions for

1.1 This specification covers the design, construction, test,

MIL-S-901 Shock Tests, H.I. (High-Impact); Shipboard

andperformancerequirementsforairornitrogensystemfilters,

Machinery, Equipment and Systems, Requirements for

referred to hereinafter as filters.These filters are intended to be

MIL-F-1183 Fittings, Pipe, Cast Bronze, Silver-Brazing,

installed in-line to protect equipment from particular contami-

General Specifications for

nation.

2.5 Naval SEA Systems Command (NAVSEA): Government

1.2 The values stated in this specification in inch-pounds

Drawings:

units are to be regarded as the standard. The SI equivalent

NAVSEA 803-1385884 Unions, Fittings and Adapters Butt

shown in parentheses are provided for information only.

and Socket Welding 6000 PSI, WOG, NPS

NAVSEA 803-1385943 Unions, Silver Brazing 3000 PSI,

2. Referenced Documents

WOG, NPS, for UT Inspection

2.1 ASTM Standards:

NAVSEA 803-1385946 Unions, Bronze Silver Brazing,

F992 Specification for Valve Label Plates

WOG for UT Inspection

2.2 American Society of Mechanical Engineers (ASME):

3 3. Terminology

B1.1 United Screw Threads (UN and UNR Thread Form)

B1.20.1 Pipe Threads, General Purpose (Inch) 3.1 Definitions:

B16.11 Forged Steel Fittings, Socket-Welding and 3.1.1 absolute contaminant removal rating—the smallest

Threaded size of contaminant as defined in ARP 901 that the filter will

B16.25 Buttwelding Ends retain with 100 % efficiency by weight.

B16.34 Flanged, Threaded, and Welded End

3.1.2 bubble point—the pressure differential across a sub-

2.3 Society of Automotive Engineers (SAE):

merged filter element required to produce a visible and steady

ARP 901 Aerospace Recommended Practice—Bubble-Point

stream of air bubbles. Correlation between bubble point and

Test Method

contaminant removal capability provides an economical means

2.4 Military Standards and Specifications:

to test for contaminant removal capability on a production

MIL-STD-167-1 Mechanical Vibrations of Shipboard basis.The bubble point indicates the maximum pore size of the

Equipment (Type I—Environmental and Type II—

filter media under static conditions.

Internally Excited)

3.1.3 bubble-tight—no visible leakage over a 3-min period

MIL-STD-740-1 Airborne Sound Measurements andAccep-

usingeitherwatersubmersionortheapplicationofbubblefluid

tance Criteria of Shipboard Equipment

for detection.

3.1.4 clean filter element pressure drop—the pressure drop

This specification is under the jurisdiction of ASTM Committee F25 on Ships across the filter element when it is new or uncontaminated.

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

3.1.5 cleanable filter element—a filter element that, after

Machinery and Piping Systems.

being contaminated to its dirt-holding capacity (contaminated

Current edition approved May 1, 2006. Published May 2006. Originally

approved in 1997. Last previous edition approved in 2000 as F1791 – 00. DOI:

filter element pressure drop), can be restored by cleaning to

10.1520/F1791-00R06.

operational condition and with a pressure drop not exceeding

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the required clean filter element pressure drop.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3.1.6 contaminant removal rating—this is a measure of the

the ASTM website.

size of contaminants that the filter can remove from the flow

Available from American Society of Mechanical Engineers (ASME), ASME

stream.

International Headquarters, Three Park Ave., New York, NY 10016-5990.

Available from Society of Automotive Engineers (SAE), 400 Commonwealth

3.1.7 contaminated filter element pressure drop— the pres-

Dr., Warrendale, PA 15096-0001.

sure drop across the filter element when it is contaminated to

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. the point where cleaning or replacement is required.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1791−00 (2006)

TABLE 1 Filter Inlet and Outlet End Connections

3.1.8 differential pressure indicator actuation pressure—the

pressure drop across the filter element at which the differential Applicable Documents

for Dimensional

pressure indicator actuates.

Type of End Connection Pressure Rating

Details of

End Connections

3.1.9 disposable filter element—a filter element that, after

Butt-welded ASME B16.34 Class 150, ASME B16.25

being contaminated to its dirt-holding capacity (contaminated

300, 400, 600, 900,

filter element pressure drop), cannot be restored to operational

1500, 2500, or 4500

conditions and thereafter should be replaced.

Socket-welded ASME B16.34 Class 150, ASME B16.11

300, 400, 600, 900,

3.1.10 external leakage—leakage that escapes to atmo-

1500, 2500, or 4500

Threaded (tapered ASME B16.34 Class 150, ASME B1.20.1 and

sphere.

pipe thread) 300, 400, 600, 900, ASME B16.11

3.1.11 filter element bypass full-flow differential pressure—

1500, or 2500

A

Union-end, MIL-F-1183 (O-ring type) MIL-F-1183 (O-ring

the pressure drop across the filter element at which the filter

2 2

silver-brazed

400 lb/in. (2.758 MPa) type) 400 lb/in.

bypass is passing the full-flow rating of the filter.

(2.758 MPa)

A

Union-end, 803-1385946 1500 803-1385946 1500

3.1.12 filter element bypass reseat differential pressure—the

2 2

silver-brazed

lb/in. (10.342 MPa) lb/in. (10.342 MPa)

A

pressuredropacrossthefilterelementatwhichthefilterbypass

Union-end, 803-1385943 3000 803-1385943 3000

2 2

silver-brazed

lb/in. (20.684 MPa) lb/in. (20.684 MPa)

reseats after passing the full-flow rating of the filter.

A

Union-end, 803-1385884 6000 803-1385884 6000

2 2

butt/socket weld

3.1.13 filter element bypass set differential pressure—the lb/in. (41.369 MPa) lb/in. (41.369 MPa)

Other, as specified as specified as specified

pressuredropacrossthefilterelementatwhichthefilterbypass

A

For union inlet and outlet connections, only the pertinent dimensions listed in

opens.

the applicable documents (military specification or NAVESA requirements) shall

3.1.14 filter element collapse strength—the maximum pres- apply.Thefiltershallbesuppliedwiththethreadpiecesonly,withoutthetailpieces

and union nuts.

sure drop or differential across the filter element that the

element must withstand without collapse, damage, or impair-

ment of performance capabilities.

pressure rating for a filter is the maximum allowable working

3.1.15 filter element contaminant-holding capacity—also (service) pressure at 100°F (38°C).

commonly termed “dirt capacity.” The amount of a contami-

4. Classification

nant, expressed in weight, that the element can hold when its

4.1 Filters shall be of the following types, compositions,

resistance to flow causes a pressure drop equal to the contami-

styles, pressure ratings, sizes, end connections, and contami-

nated filter element pressure drop.

nation removal ratings, as specified in Section 5.

3.1.16 filter element pressure drop—the pressure drop

4.1.1 Filter Element Type:

across the filter element.

4.1.1.1 Type 1—Disposable.

3.1.17 filter housing pressure drop—the pressure drop ac-

4.1.1.2 Type 2—Cleanable.

counted for by the filter housing.

4.1.2 Filter Element Bypass Composition:

4.1.2.1 Composition A: with bypass.

3.1.18 filter pressure drop—the pressure drop across the

4.1.2.2 Composition B: without bypass.

entire filter (element and housing) at any given flow rate of the

4.1.3 Filter Element Differential Indicator Style:

service fluid (air or nitrogen).

4.1.3.1 Style I: with differential pressure indicator.

3.1.19 flow capacity—the maximum flow rate that the filter

4.1.3.2 Style II: without differential pressure indicator.

is required to pass.

4.2 Pressure Ratings— Filters shall have pressure ratings

3.1.20 hydrostatic shell test pressure—the hydrostatic test

selected from those listed in Table 1 and specified in Section 5.

pressure that the filter is required to withstand without damage.

Thepressureratingselectedshallbethesameforboththefilter

The filter must be capable of meeting all performance require-

inlet and outlet.

ments after the shell test pressure has been removed.

1 1

4.3 Size—Filter sizes shall be ⁄4 NPS (13.5 mm), ⁄2 NPS

3.1.21 media migration—any material released into the flow

3 1

(21.3 mm), ⁄4 NPS (26.9 mm), 1 NPS (33.7 mm), 1 ⁄4 NPS

stream by the filter media and its materials of construction.

(42.4 mm), 1 ⁄2 NPS (48.3 mm), and 2 NPS (60.3 mm) or as

This term refers to the tendency of the filter media or “built-in”

specified in Section 5 (see Table 2).

contamination, such as, welding scale, metal particles, or

4.4 End Connections— Filters shall have inlet and outlet

air-borne dust combined with the media during its manufac-

end connections selected from those listed in Table 1 and

ture,toleavethefilterandshedormigrateintotheflowstream.

specified in Section 5. Inlet and outlet connections shall be

3.1.22 nominal contaminant removal rating—the smallest

identical.

size of contaminant as defined in ARP 901 that the filter will

4.5 Contamination Removal Ratings —Filters shall have

retain with 98 % efficiency by weight.

contamination removal ratings selected from the following

3.1.23 operating pressure—the pressure within the filter

three categories: 20 µm nominal/50 µm absolute, 5 µm

during service.

nominal/18 µm absolute, and 0.4 µm nominal/5 µm absolute.

3.1.24 pressure ratings—the pressure rating of the filter The contamination rating selected shall be specified in Section

shall be defined in the documents listed in Table 1. The 5.

F1791−00 (2006)

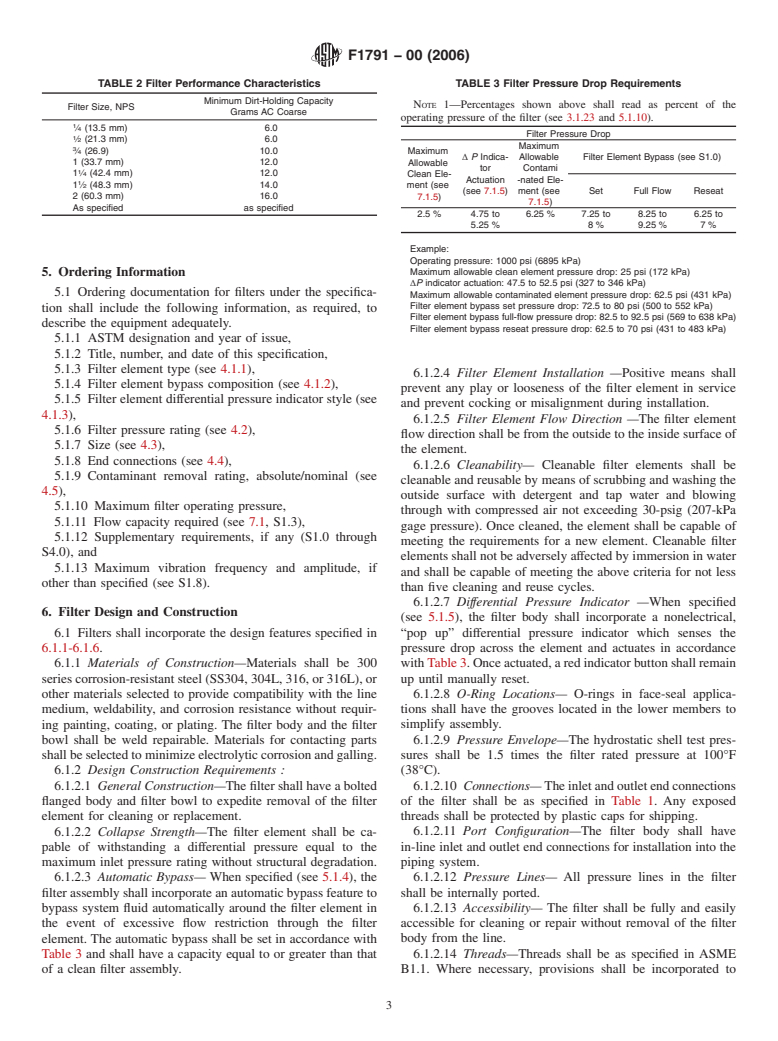

TABLE 2 Filter Performance Characteristics TABLE 3 Filter Pressure Drop Requirements

Minimum Dirt-Holding Capacity

NOTE 1—Percentages shown above shall read as percent of the

Filter Size, NPS

Grams AC Coarse

operating pressure of the filter (see 3.1.23 and 5.1.10).

⁄4 (13.5 mm) 6.0

Filter Pressure Drop

⁄2 (21.3 mm) 6.0

Maximum

⁄4 (26.9) 10.0

Maximum

∆ P Indica- Allowable Filter Element Bypass (see S1.0)

1 (33.7 mm) 12.0 Allowable

tor Contami

1 ⁄4 (42.4 mm) 12.0

Clean Ele-

Actuation -nated Ele-

1 ⁄2 (48.3 mm) 14.0 ment (see

(see 7.1.5) ment (see Set Full Flow Reseat

2 (60.3 mm) 16.0 7.1.5)

7.1.5)

As specified as specified

2.5 % 4.75 to 6.25 % 7.25 to 8.25 to 6.25 to

5.25 % 8% 9.25 % 7%

Example:

Operating pressure: 1000 psi (6895 kPa)

Maximum allowable clean element pressure drop: 25 psi (172 kPa)

5. Ordering Information

∆P indicator actuation: 47.5 to 52.5 psi (327 to 346 kPa)

5.1 Ordering documentation for filters under the specifica-

Maximum allowable contaminated element pressure drop: 62.5 psi (431 kPa)

Filter element bypass set pressure drop: 72.5 to 80 psi (500 to 552 kPa)

tion shall include the following information, as required, to

Filter element bypass full-flow pressure drop: 82.5 to 92.5 psi (569 to 638 kPa)

describe the equipment adequately.

Filter element bypass reseat pressure drop: 62.5 to 70 psi (431 to 483 kPa)

5.1.1 ASTM designation and year of issue,

5.1.2 Title, number, and date of this specification,

5.1.3 Filter element type (see 4.1.1),

6.1.2.4 Filter Element Installation —Positive means shall

5.1.4 Filter element bypass composition (see 4.1.2),

prevent any play or looseness of the filter element in service

5.1.5 Filter element differential pressure indicator style (see

and prevent cocking or misalignment during installation.

4.1.3),

6.1.2.5 Filter Element Flow Direction —The filter element

5.1.6 Filter pressure rating (see 4.2),

flow direction shall be from the outside to the inside surface of

5.1.7 Size (see 4.3),

the element.

5.1.8 End connections (see 4.4),

6.1.2.6 Cleanability— Cleanable filter elements shall be

5.1.9 Contaminant removal rating, absolute/nominal (see

cleanable and reusable by means of scrubbing and washing the

4.5),

outside surface with detergent and tap water and blowing

5.1.10 Maximum filter operating pressure,

through with compressed air not exceeding 30-psig (207-kPa

5.1.11 Flow capacity required (see 7.1, S1.3),

gage pressure). Once cleaned, the element shall be capable of

5.1.12 Supplementary requirements, if any (S1.0 through

meeting the requirements for a new element. Cleanable filter

S4.0), and

elements shall not be adversely affected by immersion in water

5.1.13 Maximum vibration frequency and amplitude, if

and shall be capable of meeting the above criteria for not less

other than specified (see S1.8).

than five cleaning and reuse cycles.

6.1.2.7 Differential Pressure Indicator —When specified

6. Filter Design and Construction

(see 5.1.5), the filter body shall incorporate a nonelectrical,

6.1 Filters shall incorporate the design features specified in “pop up” differential pressure indicator which senses the

6.1.1-6.1.6. pressure drop across the element and actuates in accordance

6.1.1 Materials of Construction—Materials shall be 300 withTable3.Onceactuated,aredindicatorbuttonshallremain

series corrosion-resistant steel (SS304, 304L, 316, or 316L), or up until manually reset.

6.1.2.8 O-Ring Locations— O-rings in face-seal applica-

other materials selected to provide compatibility with the line

medium, weldability, and corrosion resistance without requir- tions shall have the grooves located in the lower members to

simplify assembly.

ing painting, coating, or plating. The filter body and the filter

bowl shall be weld repairable. Materials for contacting parts 6.1.2.9 Pressure Envelope—The hydrostatic shell test pres-

shallbeselectedtominimizeelectrolyticcorrosionandgalling. sures shall be 1.5 times the filter rated pressure at 100°F

6.1.2 Design Construction Requirements : (38°C).

6.1.2.1 General Construction—The filter shall have a bolted 6.1.2.10 Connections—Theinletandoutletendconnections

flanged body and filter bowl to expedite removal of the filter of the filter shall be as specified in Table 1. Any exposed

element for cleaning or replacement. threads shall be protected by plastic caps for shipping.

6.1.2.2 Collapse Strength—The filter element shall be ca- 6.1.2.11 Port Configuration—The filter body shall have

pable of withstanding a differential pressure equa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.