ASTM D143-22

(Test Method)Standard Test Methods for Small Clear Specimens of Timber

Standard Test Methods for Small Clear Specimens of Timber

SIGNIFICANCE AND USE

4.1 These test methods cover tests on small clear specimens of wood that are made to provide the following:

4.1.1 Data for comparing the mechanical properties of various species,

4.1.2 Data for the establishment of correct strength functions, which in conjunction with results of tests of timbers in structural sizes (see Test Methods D198 and Test Methods D4761), afford a basis for establishing allowable stresses, and

4.1.3 Data to determine the influence on the mechanical properties of such factors as density, locality of growth, position in cross section, height of timber in the tree, change of properties with seasoning or treatment with chemicals, and change from sapwood to heartwood.

SCOPE

1.1 These test methods cover the determination of various strength and related properties of wood by testing small clear specimens.

1.1.1 These test methods represent procedures for evaluating the different mechanical and physical properties, controlling factors such as specimen size, moisture content, temperature, and rate of loading.

1.1.2 Sampling and collection of material is discussed in Practice D5536. Sample data, computation sheets, and cards have been incorporated, which were of assistance to the investigator in systematizing records.

1.1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. When a weight is prescribed, the basic inch-pound unit of weight (lbf) and the basic SI unit of mass (Kg) are cited.

1.2 The procedures for the various tests appear in the following order:

Sections

Photographs of Specimens

5

Control of Moisture Content and Temperature

6

Record of Heartwood and Sapwood

7

Static Bending

8

Compression Parallel to Grain

9

Impact Bending

10

Toughness

11

Compression Perpendicular to Grain

12

Hardness

13

Shear Parallel to Grain

14

Cleavage

15

Tension Parallel to Grain

16

Tension Perpendicular to Grain

17

Nail Withdrawal

18

Specific Gravity and Shrinkage in Volume

19

Radial and Tangential Shrinkage

20

Moisture Determination

21

Permissible Variations

22

Calibration

23

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

- Status

- Historical

- Publication Date

- 14-May-2022

- Technical Committee

- D07 - Wood

- Drafting Committee

- D07.01 - Fundamental Test Methods and Properties

- Current Stage

Relations

- Effective Date

- 15-Nov-2023

- Effective Date

- 01-Mar-2020

- Effective Date

- 01-Apr-2019

- Effective Date

- 01-Nov-2018

- Effective Date

- 15-Nov-2017

- Effective Date

- 15-Nov-2016

- Effective Date

- 01-Nov-2015

- Effective Date

- 01-Jun-2015

- Effective Date

- 01-Jun-2014

- Effective Date

- 01-May-2014

- Effective Date

- 01-May-2014

- Effective Date

- 01-Feb-2014

- Effective Date

- 01-Feb-2014

- Effective Date

- 01-Oct-2013

- Effective Date

- 01-Apr-2013

ASTM D143-22 - Standard Test Methods for Small Clear Specimens of Timber

REDLINE ASTM D143-22 - Standard Test Methods for Small Clear Specimens of Timber

ASTM D143-22 - Standard Test Methods for Small Clear Specimens of Timber

Frequently Asked Questions

ASTM D143-22 is a standard published by ASTM International. Its full title is "Standard Test Methods for Small Clear Specimens of Timber". This standard covers: SIGNIFICANCE AND USE 4.1 These test methods cover tests on small clear specimens of wood that are made to provide the following: 4.1.1 Data for comparing the mechanical properties of various species, 4.1.2 Data for the establishment of correct strength functions, which in conjunction with results of tests of timbers in structural sizes (see Test Methods D198 and Test Methods D4761), afford a basis for establishing allowable stresses, and 4.1.3 Data to determine the influence on the mechanical properties of such factors as density, locality of growth, position in cross section, height of timber in the tree, change of properties with seasoning or treatment with chemicals, and change from sapwood to heartwood. SCOPE 1.1 These test methods cover the determination of various strength and related properties of wood by testing small clear specimens. 1.1.1 These test methods represent procedures for evaluating the different mechanical and physical properties, controlling factors such as specimen size, moisture content, temperature, and rate of loading. 1.1.2 Sampling and collection of material is discussed in Practice D5536. Sample data, computation sheets, and cards have been incorporated, which were of assistance to the investigator in systematizing records. 1.1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. When a weight is prescribed, the basic inch-pound unit of weight (lbf) and the basic SI unit of mass (Kg) are cited. 1.2 The procedures for the various tests appear in the following order: Sections Photographs of Specimens 5 Control of Moisture Content and Temperature 6 Record of Heartwood and Sapwood 7 Static Bending 8 Compression Parallel to Grain 9 Impact Bending 10 Toughness 11 Compression Perpendicular to Grain 12 Hardness 13 Shear Parallel to Grain 14 Cleavage 15 Tension Parallel to Grain 16 Tension Perpendicular to Grain 17 Nail Withdrawal 18 Specific Gravity and Shrinkage in Volume 19 Radial and Tangential Shrinkage 20 Moisture Determination 21 Permissible Variations 22 Calibration 23 1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SIGNIFICANCE AND USE 4.1 These test methods cover tests on small clear specimens of wood that are made to provide the following: 4.1.1 Data for comparing the mechanical properties of various species, 4.1.2 Data for the establishment of correct strength functions, which in conjunction with results of tests of timbers in structural sizes (see Test Methods D198 and Test Methods D4761), afford a basis for establishing allowable stresses, and 4.1.3 Data to determine the influence on the mechanical properties of such factors as density, locality of growth, position in cross section, height of timber in the tree, change of properties with seasoning or treatment with chemicals, and change from sapwood to heartwood. SCOPE 1.1 These test methods cover the determination of various strength and related properties of wood by testing small clear specimens. 1.1.1 These test methods represent procedures for evaluating the different mechanical and physical properties, controlling factors such as specimen size, moisture content, temperature, and rate of loading. 1.1.2 Sampling and collection of material is discussed in Practice D5536. Sample data, computation sheets, and cards have been incorporated, which were of assistance to the investigator in systematizing records. 1.1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. When a weight is prescribed, the basic inch-pound unit of weight (lbf) and the basic SI unit of mass (Kg) are cited. 1.2 The procedures for the various tests appear in the following order: Sections Photographs of Specimens 5 Control of Moisture Content and Temperature 6 Record of Heartwood and Sapwood 7 Static Bending 8 Compression Parallel to Grain 9 Impact Bending 10 Toughness 11 Compression Perpendicular to Grain 12 Hardness 13 Shear Parallel to Grain 14 Cleavage 15 Tension Parallel to Grain 16 Tension Perpendicular to Grain 17 Nail Withdrawal 18 Specific Gravity and Shrinkage in Volume 19 Radial and Tangential Shrinkage 20 Moisture Determination 21 Permissible Variations 22 Calibration 23 1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM D143-22 is classified under the following ICS (International Classification for Standards) categories: 79.040 - Wood, sawlogs and sawn timber. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM D143-22 has the following relationships with other standards: It is inter standard links to ASTM D143-23, ASTM D4442-20, ASTM D4761-19, ASTM D4761-18, ASTM D3043-17, ASTM D4442-16, ASTM D5536-15, ASTM D4442-15, ASTM E4-14, ASTM D2395-14e1, ASTM D2395-14, ASTM D198-14, ASTM D198-14e1, ASTM D198-13, ASTM D4761-13. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ASTM D143-22 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D143 − 22

Standard Test Methods for

Small Clear Specimens of Timber

This standard is issued under the fixed designation D143; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The need to classify wood species by evaluating the physical and mechanical properties of small

clear specimens has always existed. Because of the great variety of species, variability of the material,

continually changing conditions of supply, many factors affecting test results, and ease of comparing

variables, the need will undoubtedly continue to exist.

In the preparation of these methods for testing small clear specimens, consideration was given both

to the desirability of adopting test methods that would yield results comparable to those already

available and to the possibility of embodying such improvements as experience has shown desirable.

In view of the many thousands of tests made under a single comprehensive plan by the U.S. Forest

Service, the former Forest Products Laboratories of Canada (now FPInnovations), and other similar

organizations, these test methods naturally conform closely to the methods used by those institutions.

These test methods are the outgrowth of a study of both American and European experience and

methods. The general adoption of these test methods will tend toward a world-wide unification of

results, permitting an interchange and correlation of data, and establishing the basis for a cumulative

body of fundamental information on the timber species of the world. Many of the figures in this

standard use sample data and computation sheets from testing done in the 1950s and earlier. These

figures remain in the standard because they are still valid depictions of the recording and plotting of

test results and also provide a historical link to the large body of test data on small clear specimens

already in existence for this long-standing test method.

Descriptionsofsomeofthestrengthtestsrefertoprimarymethodsandsecondarymethods.Primary

methods provide for specimens of 2-in. by 2-in. (50 mm by 50 mm) cross section. This size of

specimen has been extensively used for the evaluation of various mechanical and physical properties

of different species of wood, and a large number of data based on this primary method have been

obtained and published.

The 2-in. by 2-in. (50 mm by 50 mm) size has the advantage in that it embraces a number of growth

rings, is less influenced by earlywood and latewood differences than smaller size specimens, and is

large enough to represent a considerable portion of the sampled material. It is advisable to use primary

method specimens wherever possible. There are circumstances, however, when it is difficult or

impossible to obtain clear specimens of 2 by 2-in. cross section having the required 30 in. (760 mm)

length for static bending tests. With the increasing incidence of smaller second growth trees, and the

desirability in certain situations to evaluate a material which is too small to provide a 2-in. by 2-in.

cross section, a secondary method which utilizes a 1-in. by 1-in. (25 mm by 25 mm) cross section has

been included. This cross section is established for compression parallel to grain and static bending

tests, while the 2-in. by 2-in. cross section is retained for impact bending, compression perpendicular

to grain, hardness, shear parallel to grain, cleavage, and tension perpendicular to grain.Toughness and

tension parallel to grain are special tests using specimens of smaller cross section.

The user is cautioned that test results between two different sizes of specimens are not necessarily

directly comparable. Guidance on the effect of specimen size on a property being evaluated is beyond

the scope of these test methods and should be sought elsewhere.

Wheretheapplication,measurement,orrecordingofloadanddeflectioncanbeaccomplishedusing

electronic equipment and computerized apparatus, such devices are encouraged. It is important that all

data measurement and recording equipment, whether electronic or mechanical, be accurate and

reliable to the degree specified.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D143 − 22

1. Scope 2. Referenced Documents

1.1 These test methods cover the determination of various 2.1 ASTM Standards:

strength and related properties of wood by testing small clear D9 Terminology Relating to Wood and Wood-Based Prod-

specimens. ucts

1.1.1 These test methods represent procedures for evaluat- D198 Test Methods of Static Tests of Lumber in Structural

ing the different mechanical and physical properties, control- Sizes

ling factors such as specimen size, moisture content, D2395 TestMethodsforDensityandSpecificGravity(Rela-

temperature, and rate of loading. tive Density) of Wood and Wood-Based Materials

1.1.2 Sampling and collection of material is discussed in D3043 Test Methods for Structural Panels in Flexure

Practice D5536. Sample data, computation sheets, and cards D4442 Test Methods for Direct Moisture Content Measure-

have been incorporated, which were of assistance to the ment of Wood and Wood-Based Materials

investigator in systematizing records. D4761 Test Methods for Mechanical Properties of Lumber

1.1.3 The values stated in inch-pound units are to be and Wood-Based Structural Materials

regarded as the standard. The values given in parentheses are D5536 Practice for Sampling ForestTrees for Determination

mathematical conversions to SI units that are provided for of Clear Wood Properties

information only and are not considered standard. When a E4 Practices for Force Calibration and Verification of Test-

weight is prescribed, the basic inch-pound unit of weight (lbf) ing Machines

and the basic SI unit of mass (Kg) are cited. E2309 Practices for Verification of Displacement Measuring

Systems and Devices Used in Material Testing Machines

1.2 The procedures for the various tests appear in the

following order:

3. Summary of Test Methods

Sections

3.1 The mechanical tests are static bending, compression

Photographs of Specimens 5

Control of Moisture Content and Temperature 6 parallel to grain, impact bending toughness, compression

Record of Heartwood and Sapwood 7

perpendicular to grain, hardness, shear parallel to grain,

Static Bending 8

cleavage, tension parallel to grain, tension-perpendicular-to-

Compression Parallel to Grain 9

Impact Bending 10

grain, and nail-withdrawal tests. These tests are permitted for

Toughness 11

both green and air-dry material as specified in these test

Compression Perpendicular to Grain 12

methods. In addition, test methods for evaluating such physical

Hardness 13

Shear Parallel to Grain 14

properties as specific gravity, shrinkage in volume, radial

Cleavage 15

shrinkage, and tangential shrinkage are presented.

Tension Parallel to Grain 16

Tension Perpendicular to Grain 17

NOTE 1—The test for shearing strength perpendicular to the grain

Nail Withdrawal 18

(sometimes termed “vertical shear”) is not included as one of the principal

Specific Gravity and Shrinkage in Volume 19

mechanical tests since in such a test the strength is limited by the shearing

Radial and Tangential Shrinkage 20

resistance parallel to the grain.

Moisture Determination 21

Permissible Variations 22

4. Significance and Use

Calibration 23

1.3 This standard does not purport to address all of the

4.1 These test methods cover tests on small clear specimens

safety concerns, if any, associated with its use. It is the

of wood that are made to provide the following:

responsibility of the user of this standard to establish appro-

4.1.1 Data for comparing the mechanical properties of

priate safety, health, and environmental practices and deter-

various species,

mine the applicability of regulatory limitations prior to use.

4.1.2 Data for the establishment of correct strength

1.4 This international standard was developed in accor-

functions, which in conjunction with results of tests of timbers

dance with internationally recognized principles on standard-

in structural sizes (see Test Methods D198 and Test Methods

ization established in the Decision on Principles for the

D4761), afford a basis for establishing allowable stresses, and

Development of International Standards, Guides and Recom-

4.1.3 Data to determine the influence on the mechanical

mendations issued by the World Trade Organization Technical

properties of such factors as density, locality of growth,

Barriers to Trade (TBT) Committee.

position in cross section, height of timber in the tree, change of

properties with seasoning or treatment with chemicals, and

change from sapwood to heartwood.

These test methods are under the jurisdiction of ASTM Committee D07 on

Wood and are the direct responsibility of Subcommittee D07.01 on Fundamental

Test Methods and Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 15, 2022. Published June 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1922. Last previous edition approved in 2021 as D143 – 21. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D0143-22. the ASTM website.

D143 − 22

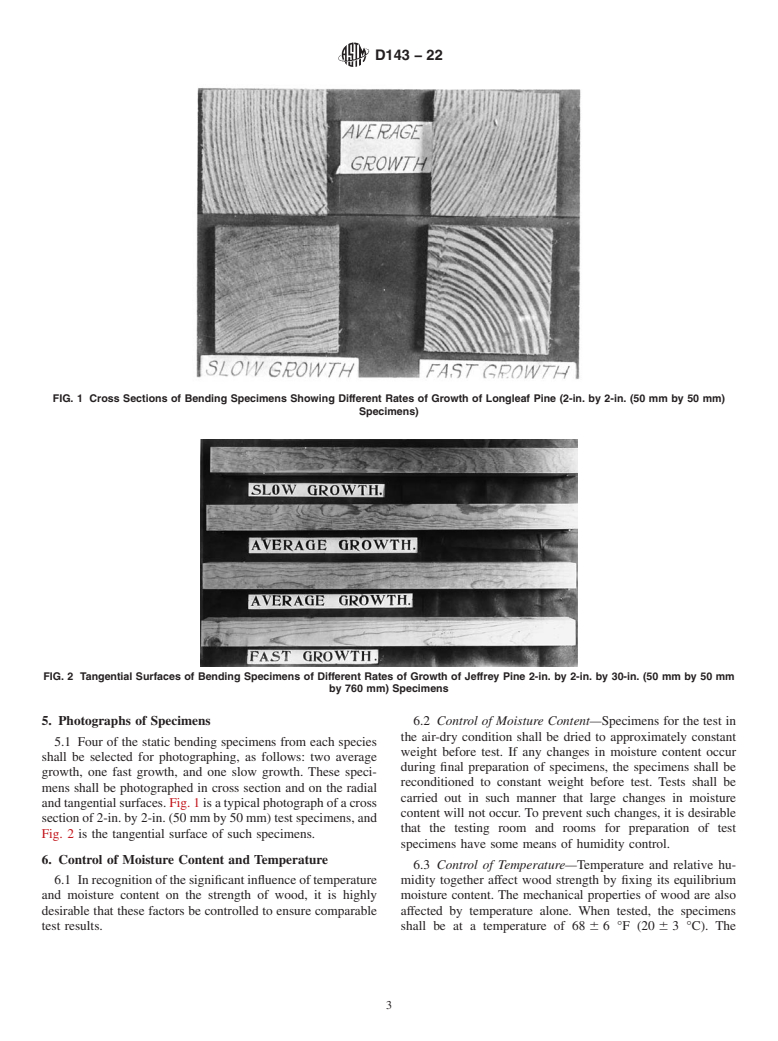

FIG. 1 Cross Sections of Bending Specimens Showing Different Rates of Growth of Longleaf Pine (2-in. by 2-in. (50 mm by 50 mm)

Specimens)

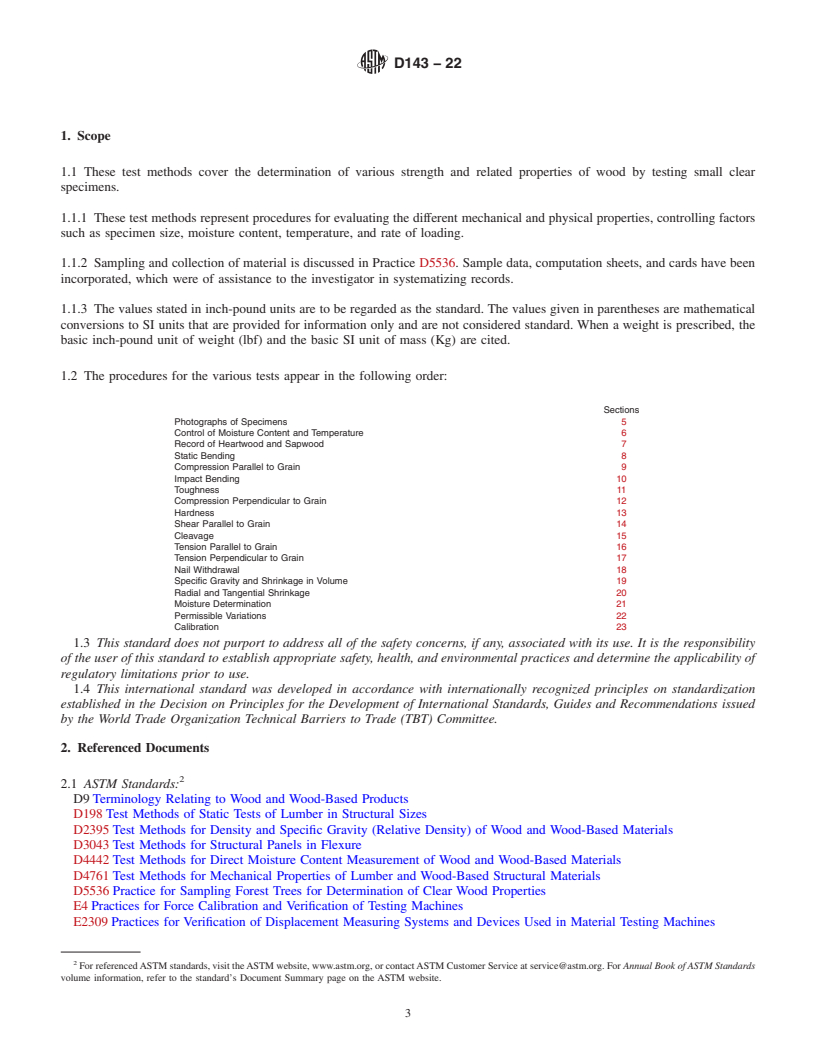

FIG. 2 Tangential Surfaces of Bending Specimens of Different Rates of Growth of Jeffrey Pine 2-in. by 2-in. by 30-in. (50 mm by 50 mm

by 760 mm) Specimens

5. Photographs of Specimens 6.2 Control of Moisture Content—Specimens for the test in

the air-dry condition shall be dried to approximately constant

5.1 Four of the static bending specimens from each species

weight before test. If any changes in moisture content occur

shall be selected for photographing, as follows: two average

during final preparation of specimens, the specimens shall be

growth, one fast growth, and one slow growth. These speci-

reconditioned to constant weight before test. Tests shall be

mens shall be photographed in cross section and on the radial

carried out in such manner that large changes in moisture

andtangentialsurfaces.Fig.1isatypicalphotographofacross

content will not occur. To prevent such changes, it is desirable

sectionof2-in.by2-in.(50mmby50mm)testspecimens,and

that the testing room and rooms for preparation of test

Fig. 2 is the tangential surface of such specimens.

specimens have some means of humidity control.

6. Control of Moisture Content and Temperature

6.3 Control of Temperature—Temperature and relative hu-

6.1 Inrecognitionofthesignificantinfluenceoftemperature midity together affect wood strength by fixing its equilibrium

and moisture content on the strength of wood, it is highly moisture content. The mechanical properties of wood are also

desirable that these factors be controlled to ensure comparable affected by temperature alone. When tested, the specimens

test results. shall be at a temperature of 68 66°F(20 6 3 °C). The

D143 − 22

temperature at the time of test shall in all instances be recorded

as a specific part of the test record.

7. Record of Heartwood and Sapwood

7.1 Proportion of Sapwood—If heartwood and sapwood

present in the specimen can be distinguished by visual

inspection, the proportion of sapwood present shall be esti-

mated as required for the purposes of the test program and

recorded for each test specimen.

8. Static Bending

8.1 Size of Specimens—The static bending tests shall be

made on 2 in. by 2 in. by 30 in. (50 mm by 50 mm by 760 mm)

primary method specimens or 1 in. by 1 in. by 16 in. (25 mm

by 25 mm by 410 mm) secondary method specimens. The

actual height and width at the center and the length shall be

measured (see 22.2).

8.2 Loading Span and Supports—Use center loading and a

span length of 28 in. (710 mm) for the primary method and 14

in. (360 mm) for the secondary method. These spans were

established in order to maintain a minimum span-to-depth ratio

of 14. Both supporting knife edges shall be provided with

FIG. 4 Example of a Bearing Block for Static Bending Tests

bearing plates and rollers of such thickness that the distance

fromthepointofsupporttothecentralplaneisnotgreaterthan

a chord length of not less than 2 in. (50 mm) shall be used for

the depth of the specimen (Fig. 3). The knife edges shall be

secondary method specimens. The bearing block shall be

adjustable laterally to permit adjustment for slight twist in the

fabricated with a material that will not appreciably deform

specimen.

under load.

NOTE 2—An example of laterally adjustable supports is provided in

8.4 Placement of Growth Rings—The specimen shall be

Figure 1 of Test Methods D3043.

placed so that the load will be applied through the bearing

8.3 Bearing Block—Arigid bearing block having a radius of

block to the tangential surface nearest the pith.

3 in. (76 mm) and a chord length of not less than 3 ⁄16 in. (97

mm) that is fixed from rotation shall be used for applying the 8.5 Speed of Testing—The load shall be applied continu-

load for primary method specimens.An example is provided in ously throughout the test at a rate of motion of the movable

Fig. 4. A similar block having a radius of 1 ⁄2 in. (38 mm) for crosshead of 0.10 in. (2.5 mm)/min, for primary method

FIG. 3 Static Bending Test Assembly Showing Test Method of Load Application, Specimen Supported on Rollers and Laterally Adjust-

able Knife Edges, and Test Method of Measuring Deflection at Neutral Axis by Means of Yoke and Displacement Measurement Device

D143 − 22

specimens,andatarateof0.05in.(1.3mm)/minforsecondary 9. Compression Parallel to Grain

method specimens (see 22.3).

9.1 Size of Specimens—The compression-parallel-to-grain

tests shall be made on 2 in. by 2 in. by 8 in. (50 mm by 50 mm

8.6 Load-Deflection Curves:

by 200 mm) primary method specimens, or 1 by 1 by 4 in. (25

8.6.1 At a minimum, the load-deflection curves shall be

by 25 by 100 mm) secondary method specimens. The actual

recorded and the test continued up to the maximum load for all

cross-sectional dimensions and the length shall be measured

static bending tests. If required for the purposes of the study, it

(see 22.2).

shall be permitted to continue both loading and the load-

deflection measurement beyond the maximum load. 9.2 End Surfaces Parallel—Special care shall be used in

preparing the compression-parallel-to-grain test specimens to

NOTE 3—One situation where the user may choose to continue the test

ensure that the end grain surfaces will be parallel to each other

and the load-deflection measurements beyond the maximum load is if the

and at right angles to the longitudinal axis. At least one platen

total energy under the flexural load-deflection curve is a parameter of

of the testing machine shall be equipped with a spherical

concern. In these instances for primary method specimens, it has been

customarytocontinuethetestandrecordtheload-deflectioncurvebeyond bearing to obtain uniform distribution of load over the ends of

the maximum load to a 6 in. (152 mm) deflection or until the specimen

the specimen.

fails to support a load of 200 lbf (890 N). For secondary method

9.3 Speed of Testing—The load shall be applied continu-

specimens, it has been customary to continue loading to a 3 in. (76 mm)

deflection, or until the specimen fails to support a load of 50 lbf (222 N). ously throughout the test at a rate of motion of the movable

crosshead of 0.003 in./in. (mm/mm) of nominal specimen

8.6.2 Deflections of the neutral plane at the center of the

length/min (see 22.3).

length shall be taken with respect to points in the neutral plane

above the supports.Alternatively, deflection shall be permitted 9.4 Load-Compression Curves:

to be taken relative to the tension surface at midspan, provided 9.4.1 Load-compression curves shall be taken over a central

gauge length not exceeding 6 in. (150 mm) for primary method

that vertical displacements which occur at the reactions are

taken into account. specimens, and 2 in. (50 mm) for secondary method speci-

mens. Load-compression readings shall be continued until the

8.6.3 Within the proportional limit, deflection readings shall

proportional limit is well passed, as indicated by the curve.

be taken with a yoke-mounted displacement measurement

device capable of at least a Class B rating when evaluated in

NOTE 5—See Fig. 7 for a sample compression-parallel-to-grain data

accordance with Practice E2309.After the proportional limit is

sheet form.

reached, less refinement is necessary in observing deflections.

9.4.2 Deformations shall be recorded using displacement

It shall be permissible to continue the deflection measurement

measurement devices that are capable of a ClassArating when

beyond the proportional limit using an alternative means of

evaluated in accordance with Practice E2309.

deflection measurement capable of at least a Class C rating

9.4.3 Figs. 8 and 9 illustrate two types of compressometers

when evaluated in accordance with Practice E2309. To char-

that have been found satisfactory for wood testing. Similar

acterize the load-deflection curve, the load and deflection shall

apparatus is available for measurements of compression over a

be measured and recorded at a maximum interval spacing of

2 in. (50 mm) gauge length.

0.10 in. (2.5 mm) and after abrupt changes in load. Continuous

9.5 Position of Failures—In order to obtain satisfactory and

load and deflection data acquisition is preferred.

uniform results, it is necessary that the failures be made to

8.6.4 When data are recorded manually, the load and de-

develop in the body of the specimen. With specimens of

flection of the first failure, the maximum load, and points of

uniform cross section, this result can best be obtained when the

sudden change shall be read and shown on the curve sheet,

ends are at a very slightly lower moisture content than the

eveniftheydonotoccuratoneoftheregularloadordeflection

body. With green material, it will usually suffice to close-pile

increments. When data are recorded electronically, the data

the specimens, cover the body with a damp cloth, and expose

recording rate shall be sufficient to capture the same points so

the ends for a short time. For dry material, it shall be permitted

that they can be similarly reported.

to pile the specimens in a similar manner and place them in a

desiccator, if failures in test indicate that a slight end-drying is

NOTE 4—See Fig. 5 for a sample static bending data sheet form.

necessary.

8.7 Description of Failure—Static bending (flexural) fail-

9.6 Descriptions of Failure—Compression failures shall be

ures shall be classified in accordance with the appearance of

classified in accordance with the appearance of the fractured

the fractured surface and the manner in which the failure

surface(Fig.10).Incasetwoormorekindsoffailuresdevelop,

develops (Fig. 6). Where appropriate, the fractured surfaces

all shall be described in the order of their occurrence; for

shall be roughly divided into “brash” and “fibrous”, the term

example, shearing followed by brooming. Each type of ob-

“brash” indicating abrupt failure and “fibrous” indicating a

served failure mode shall be photographed or sketched.

fracture showing splinters. Each type of observed failure mode

shall be photographed or sketched.

9.7 Weight and Moisture Content—See 8.8.

8.8 Weight and Moisture Content—The specimen shall be

9.8 Ring and Latewood Measurement—When practicable,

weighed immediately before test, and after the test a moisture the number of rings per inch (average ring width in millime-

sectionapproximately1in.(25mm)inlengthshallbecutfrom

ters) and the proportion of summerwood shall be measured

the specimen near the point of failure (see 21.1 and 22.1). over a representative inch (centimeter) of cross section of the

D143 − 22

FIG. 5 Sample Data Sheet for a Manually Recorded Static Bending Test

test specimen. In determining the proportion of summerwood, 10.2 Loading and Span—Use center loading and a span

it is essential that the end surface be prepared so as to permit length of 28 in. (710 mm).

accurate latewood measurement. When the fibers are broomed

10.3 Bearing Block—A metal tup of curvature correspond-

over at the ends from sawing, a light sanding, planing, or

ing to the bearing block shown in Fig. 4 shall be used in

similar treatment of the ends is recommended.

applying the load.

10.4 Placement of Growth Rings—The specimen shall be

10. Impact Bending

placed so that the load will be applied through the bearing

10.1 Size of Specimens—The impact bending tests shall be

block to the tangential surface nearest the pith.

made on 2 in. by 2 in. by 30 in. (50 mm by 50 mm by 760 mm)

specimens. The actual height and width at the center and the 10.5 Procedure—Make the tests by increment drops in a

length shall be measured (see 22.2). Hatt-Turner or similar impact machine (see Fig. 11). The first

D143 − 22

NOTE 7—See Fig. 13 for a sample of a manually recorded impact

bending data sheet form. A sample data and computation card are shown

in Fig. 14.

10.10 Weight and Moisture Content—See 8.8.

11. Toughness

11.1 A single-blow impact test on a small specimen is

recognized as a valuable and desirable test. Several types of

machines such as the Toughness, Izod and Amsler have been

used,butinsufficientinformationisavailabletodecidewhether

one procedure is superior to another, or whether the results by

the different test methods can be directly correlated. If the

Toughness machine is used, the following procedure has been

found satisfactory. To aid in standardization and to facilitate

comparisons, the size of the toughness specimen has been

made equal to that accepted internationally.

11.2 Size of Specimen—The toughness tests shall be made

on 0.79 in. by 0.79 in. by 11 in. (20 mm by 20 mm by 280 mm)

specimens. The actual height and width at the center and the

length shall be measured (see 22.2).

11.3 Loading and Span—Center loading and a span length

of 9.47 in. (240 mm) shall be used. The load shall be applied

to a radial or tangential surface on alternate specimens.

11.4 Bearing Block—An aluminum tup (Fig. 15) having a

radius of ⁄4 in. (19 mm) shall be used in applying the load.

NOTE 1—The term “cross grain” shall be considered to include all 11.5 Apparatus and Procedure—Make the tests in a pendu-

deviations of grain from the direction of the longitudinal axis or

lum type toughness machine (See Fig. 15).Adjust the machine

longitudinal edges of the specimen. It should be noted that spiral grain

before test so that the pendulum hangs vertically, and adjust it

may be present even to a serious extent without being evident from a

to compensate for friction. Adjust the cable so that the load is

casual observation.

applied to the specimen when the pendulum swings to 15°

NOTE 2—The presence of cross grain having a slope that deviates more

from the vertical, so as to produce complete failure by the time

than 1 in 20 from the longitudinal edges of the specimen shall be cause for

culling the test.

the downward swing is completed. Choose the weight position

FIG. 6 Types of Failures in Static Bending

and initial angle (30, 45, or 60°) of the pendulum, so that

complete failure of the specimen is obtained on one drop. Most

drop shall be 1 in. (25 mm), after which increase the drops by

satisfactory results are obtained when the difference between

1 in. increments until a height of 10 in. (250 mm) is reached.

the initial and final angle is at least 10°.

Then use a 2 in. (50 mm) increment until complete failure

NOTE 8—Many pendulum-type toughness machines are based on a

occurs or a 6 in. (150 mm) deflection is reached.

design developed and used at the USDA F

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D143 − 21 D143 − 22

Standard Test Methods for

Small Clear Specimens of Timber

This standard is issued under the fixed designation D143; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The need to classify wood species by evaluating the physical and mechanical properties of small

clear specimens has always existed. Because of the great variety of species, variability of the material,

continually changing conditions of supply, many factors affecting test results, and ease of comparing

variables, the need will undoubtedly continue to exist.

In the preparation of these methods for testing small clear specimens, consideration was given both

to the desirability of adopting test methods that would yield results comparable to those already

available and to the possibility of embodying such improvements as experience has shown desirable.

In view of the many thousands of tests made under a single comprehensive plan by the U.S. Forest

Service, the former Forest Products Laboratories of Canada (now FP Innovations), FPInnovations),

and other similar organizations, these test methods naturally conform closely to the methods used by

those institutions. These test methods are the outgrowth of a study of both American and European

experience and methods. The general adoption of these test methods will tend toward a world-wide

unification of results, permitting an interchange and correlation of data, and establishing the basis for

a cumulative body of fundamental information on the timber species of the world. Many of the figures

in this standard use sample data and computation sheets from testing done in the 1950s and earlier.

These figures remain in the standard because they are still valid depictions of the recording and

plotting of test results and also provide a historical link to the large body of test data on small clear

specimens already in existence for this long-standing test method.

Descriptions of some of the strength tests refer to primary methods and secondary methods. Primary

methods provide for specimens of 22-in. by 2-in. (50 mm by 50 mm) cross section. This size of

specimen has been extensively used for the evaluation of various mechanical and physical properties

of different species of wood, and a large number of data based on this primary method have been

obtained and published.

The 22-in. by 2-in. (50 mm by 50 mm) size has the advantage in that it embraces a number of

growth rings, is less influenced by earlywood and latewood differences than smaller size specimens,

and is large enough to represent a considerable portion of the sampled material. It is advisable to use

primary method specimens wherever possible. There are circumstances, however, when it is difficult

or impossible to obtain clear specimens of 2 by 2-in. cross section having the required 30 in. (760 mm)

length for static bending tests. With the increasing incidence of smaller second growth trees, and the

desirability in certain situations to evaluate a material which is too small to provide a 22-in. by 2-in.

cross section, a secondary method which utilizes a 11-in. by 1-in. (25 mm by 25 mm) cross section

has been included. This cross section is established for compression parallel to grain and static bending

tests, while the 22-in. by 2-in. cross section is retained for impact bending, compression perpendicular

to grain, hardness, shear parallel to grain, cleavage, and tension perpendicular to grain. Toughness and

tension parallel to grain are special tests using specimens of smaller cross section.

These test methods are under the jurisdiction of ASTM Committee D07 on Wood and are the direct responsibility of Subcommittee D07.01 on Fundamental Test Methods

and Properties.

Current edition approved June 1, 2021May 15, 2022. Published July 2021June 2022. Originally approved in 1922. Last previous edition approved in 20142021 as

D143 – 14.D143 – 21. DOI: 10.1520/D0143-21.10.1520/D0143-22.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D143 − 22

The user is cautioned that test results between two different sizes of specimens are not necessarily

directly comparable. Guidance on the effect of specimen size on a property being evaluated is beyond

the scope of these test methods and should be sought elsewhere.

Where the application, measurement, or recording of load and deflection can be accomplished using

electronic equipment and computerized apparatus, such devices are encouraged. It is important that all

data measurement and recording equipment, whether electronic or mechanical, be accurate and

reliable to the degree specified.

D143 − 22

1. Scope

1.1 These test methods cover the determination of various strength and related properties of wood by testing small clear

specimens.

1.1.1 These test methods represent procedures for evaluating the different mechanical and physical properties, controlling factors

such as specimen size, moisture content, temperature, and rate of loading.

1.1.2 Sampling and collection of material is discussed in Practice D5536. Sample data, computation sheets, and cards have been

incorporated, which were of assistance to the investigator in systematizing records.

1.1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard. When a weight is prescribed, the

basic inch-pound unit of weight (lbf) and the basic SI unit of mass (Kg) are cited.

1.2 The procedures for the various tests appear in the following order:

Sections

Photographs of Specimens 5

Control of Moisture Content and Temperature 6

Record of Heartwood and Sapwood 7

Static Bending 8

Compression Parallel to Grain 9

Impact Bending 10

Toughness 11

Compression Perpendicular to Grain 12

Hardness 13

Shear Parallel to Grain 14

Cleavage 15

Tension Parallel to Grain 16

Tension Perpendicular to Grain 17

Nail Withdrawal 18

Specific Gravity and Shrinkage in Volume 19

Radial and Tangential Shrinkage 20

Moisture Determination 21

Permissible Variations 22

Calibration 23

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D9 Terminology Relating to Wood and Wood-Based Products

D198 Test Methods of Static Tests of Lumber in Structural Sizes

D2395 Test Methods for Density and Specific Gravity (Relative Density) of Wood and Wood-Based Materials

D3043 Test Methods for Structural Panels in Flexure

D4442 Test Methods for Direct Moisture Content Measurement of Wood and Wood-Based Materials

D4761 Test Methods for Mechanical Properties of Lumber and Wood-Based Structural Materials

D5536 Practice for Sampling Forest Trees for Determination of Clear Wood Properties

E4 Practices for Force Calibration and Verification of Testing Machines

E2309 Practices for Verification of Displacement Measuring Systems and Devices Used in Material Testing Machines

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

D143 − 22

3. Summary of Test Methods

3.1 The mechanical tests are static bending, compression parallel to grain, impact bending toughness, compression perpendicular

to grain, hardness, shear parallel to grain, cleavage, tension parallel to grain, tension-perpendicular-to-grain, and nail-withdrawal

tests. These tests are permitted for both green and air-dry material as specified in these test methods. In addition, test methods for

evaluating such physical properties as specific gravity, shrinkage in volume, radial shrinkage, and tangential shrinkage are

presented.

NOTE 1—The test for shearing strength perpendicular to the grain (sometimes termed “vertical shear”) is not included as one of the principal mechanical

tests since in such a test the strength is limited by the shearing resistance parallel to the grain.

4. Significance and Use

4.1 These test methods cover tests on small clear specimens of wood that are made to provide the following:

4.1.1 Data for comparing the mechanical properties of various species,

4.1.2 Data for the establishment of correct strength functions, which in conjunction with results of tests of timbers in structural

sizes (see Test Methods D198 and Test Methods D4761), afford a basis for establishing allowable stresses, and

4.1.3 Data to determine the influence on the mechanical properties of such factors as density, locality of growth, position in cross

section, height of timber in the tree, change of properties with seasoning or treatment with chemicals, and change from sapwood

to heartwood.

5. Photographs of Specimens

5.1 Four of the static bending specimens from each species shall be selected for photographing, as follows: two average growth,

one fast growth, and one slow growth. These specimens shall be photographed in cross section and on the radial and tangential

surfaces. Fig. 1 is a typical photograph of a cross section of 22-in. by 2-in. (50 mm by 50 mm) test specimens, and Fig. 2 is the

tangential surface of such specimens.

6. Control of Moisture Content and Temperature

6.1 In recognition of the significant influence of temperature and moisture content on the strength of wood, it is highly desirable

that these factors be controlled to ensure comparable test results.

FIG. 1 Cross Sections of Bending Specimens Showing Different Rates of Growth of Longleaf Pine (2(2-in. by 2-in. (50 mm by 50 mm)

Specimens)

D143 − 22

FIG. 2 Tangential Surfaces of Bending Specimens of Different Rates of Growth of Jeffrey Pine 22-in. by 22-in. by 30-in. (50 mm by 50

mm by 760 mm) Specimens

6.2 Control of Moisture Content—Specimens for the test in the air-dry condition shall be dried to approximately constant weight

before test. If any changes in moisture content occur during final preparation of specimens, the specimens shall be reconditioned

to constant weight before test. Tests shall be carried out in such manner that large changes in moisture content will not occur. To

prevent such changes, it is desirable that the testing room and rooms for preparation of test specimens have some means of

humidity control.

6.3 Control of Temperature—Temperature and relative humidity together affect wood strength by fixing its equilibrium moisture

content. The mechanical properties of wood are also affected by temperature alone. When tested, the specimens shall be at a

temperature of 68 6 6 °F (20 6 3 °C). The temperature at the time of test shall in all instances be recorded as a specific part of

the test record.

7. Record of Heartwood and Sapwood

7.1 Proportion of Sapwood—If heartwood and sapwood present in the specimen can be distinguished by visual inspection, the

proportion of sapwood present shall be estimated as required for the purposes of the test program and recorded for each test

specimen.

8. Static Bending

8.1 Size of Specimens—The static bending tests shall be made on 2 in. by 2 in. by 30 in. (50 mm by 50 mm by 760 mm) primary

method specimens or 1 in. by 1 in. by 16 in. (25 mm by 25 mm by 410 mm) secondary method specimens. The actual height and

width at the center and the length shall be measured (see 22.2).

8.2 Loading Span and Supports—Use center loading and a span length of 28 in. (710 mm) for the primary method and 14 in. (360

mm) for the secondary method. These spans were established in order to maintain a minimum span-to-depth ratio of 14. Both

supporting knife edges shall be provided with bearing plates and rollers of such thickness that the distance from the point of support

to the central plane is not greater than the depth of the specimen (Fig. 3). The knife edges shall be adjustable laterally to permit

adjustment for slight twist in the specimen.

NOTE 2—An example of laterally adjustable supports is provided in Figure 1 of Test Methods D3043.

8.3 Bearing Block—A rigid bearing block having a radius of 3 in. (76 mm) and a chord length of not less than 3 ⁄16 in. (97 mm)

that is fixed from rotation shall be used for applying the load for primary method specimens. An example is provided in Fig. 4.

A similar block having a radius of 1 ⁄2 in. (38 mm) for a chord length of not less than 2 in. (50 mm) shall be used for secondary

method specimens. The bearing block shall be fabricated with a material that will not appreciably deform under load.

8.4 Placement of Growth Rings—The specimen shall be placed so that the load will be applied through the bearing block to the

tangential surface nearest the pith.

D143 − 22

FIG. 3 Static Bending Test Assembly Showing Test Method of Load Application, Specimen Supported on Rollers and Laterally Adjust-

able Knife Edges, and Test Method of Measuring Deflection at Neutral Axis by Means of Yoke and Displacement Measurement Device

FIG. 4 Example of a Bearing Block for Static Bending Tests

8.5 Speed of Testing—The load shall be applied continuously throughout the test at a rate of motion of the movable crosshead of

0.10 in. (2.5 mm)/min, for primary method specimens, and at a rate of 0.05 in. (1.3 mm)/min for secondary method specimens (see

22.3).

8.6 Load-Deflection Curves:

8.6.1 At a minimum, the load-deflection curves shall be recorded and the test continued up to the maximum load for all static

bending tests. If required for the purposes of the study, it shall be permitted to continue both loading and the load-deflection

measurement beyond the maximum load.

D143 − 22

NOTE 3—One situation where the user may choose to continue the test and the load-deflection measurements beyond the maximum load is if the total

energy under the flexural load-deflection curve is a parameter of concern. In these instances for primary method specimens, it has been customary to

continue the test and record the load-deflection curve beyond the maximum load to a 6 in. (152 mm) deflection or until the specimen fails to support a

load of 200 lbf (890 N). For secondary method specimens, it has been customary to continue loading to a 3 in. (76 mm) deflection, or until the specimen

fails to support a load of 50 lbf (222 N).

8.6.2 Deflections of the neutral plane at the center of the length shall be taken with respect to points in the neutral plane above

the supports. Alternatively, deflection shall be permitted to be taken relative to the tension surface at midspan, provided that vertical

displacements which occur at the reactions are taken into account.

8.6.3 Within the proportional limit, deflection readings shall be taken with a yoke-mounted displacement measurement device

capable of at least a Class B rating when evaluated in accordance with Practice E2309. After the proportional limit is reached, less

refinement is necessary in observing deflections. It shall be permissible to continue the deflection measurement beyond the

proportional limit using an alternative means of deflection measurement capable of at least a Class C rating when evaluated in

accordance with Practice E2309. To characterize the load-deflection curve, the load and deflection shall be measured and recorded

at a maximum interval spacing of 0.10 in. (2.5 mm) and after abrupt changes in load. Continuous load and deflection data

acquisition is preferred.

8.6.4 When data are recorded manually, the load and deflection of the first failure, the maximum load, and points of sudden change

shall be read and shown on the curve sheet, even if they do not occur at one of the regular load or deflection increments. When

data are recorded electronically, the data recording rate shall be sufficient to capture the same points so that they can be similarly

reported.

NOTE 4—See Fig. 5 for a sample static bending data sheet form.

8.7 Description of Failure—Static bending (flexural) failures shall be classified in accordance with the appearance of the fractured

surface and the manner in which the failure develops (Fig. 6). Where appropriate, the fractured surfaces shall be roughly divided

into “brash” and “fibrous”, the term “brash” indicating abrupt failure and “fibrous” indicating a fracture showing splinters. Each

type of observed failure mode shall be photographed or sketched.

8.8 Weight and Moisture Content—The specimen shall be weighed immediately before test, and after the test a moisture section

approximately 1 in. (25 mm) in length shall be cut from the specimen near the point of failure (see 21.1 and 22.1).

9. Compression Parallel to Grain

9.1 Size of Specimens—The compression-parallel-to-grain tests shall be made on 2 in. by 2 in. by 8 in. (50 mm by 50 mm by 200

mm) primary method specimens, or 1 by 1 by 4 in. (25 by 25 by 100 mm) secondary method specimens. The actual cross-sectional

dimensions and the length shall be measured (see 22.2).

9.2 End Surfaces Parallel—Special care shall be used in preparing the compression-parallel-to-grain test specimens to ensure that

the end grain surfaces will be parallel to each other and at right angles to the longitudinal axis. At least one platen of the testing

machine shall be equipped with a spherical bearing to obtain uniform distribution of load over the ends of the specimen.

9.3 Speed of Testing—The load shall be applied continuously throughout the test at a rate of motion of the movable crosshead of

0.003 in./in. (mm/mm) of nominal specimen length/min (see 22.3).

9.4 Load-Compression Curves:

9.4.1 Load-compression curves shall be taken over a central gagegauge length not exceeding 6 in. (150 mm) for primary method

specimens, and 2 in. (50 mm) for secondary method specimens. Load-compression readings shall be continued until the

proportional limit is well passed, as indicated by the curve.

NOTE 5—See Fig. 7 for a sample compression-parallel-to-grain data sheet form.

D143 − 22

FIG. 5 Sample Data Sheet for a Manually Recorded Static Bending Test

9.4.2 Deformations shall be recorded using displacement measurement devices that are capable of a Class A rating when evaluated

in accordance with Practice E2309.

9.4.3 Figs. 8 and 9 illustrate two types of compressometers that have been found satisfactory for wood testing. Similar apparatus

is available for measurements of compression over a 2 in. (50 mm) gagegauge length.

9.5 Position of Failures—In order to obtain satisfactory and uniform results, it is necessary that the failures be made to develop

in the body of the specimen. With specimens of uniform cross section, this result can best be obtained when the ends are at a very

slightly lower moisture content than the body. With green material, it will usually suffice to close-pile the specimens, cover the

D143 − 22

NOTE 1—The term “cross grain” shall be considered to include all deviations of grain from the direction of the longitudinal axis or longitudinal edges

of the specimen. It should be noted that spiral grain may be present even to a serious extent without being evident from a casual observation.

NOTE 2—The presence of cross grain having a slope that deviates more than 1 in 20 from the longitudinal edges of the specimen shall be cause for

culling the test.

FIG. 6 Types of Failures in Static Bending

body with a damp cloth, and expose the ends for a short time. For dry material, it shall be permitted to pile the specimens in a

similar manner and place them in a desiccator, if failures in test indicate that a slight end-drying is necessary.

9.6 Descriptions of Failure—Compression failures shall be classified in accordance with the appearance of the fractured surface

(Fig. 10). In case two or more kinds of failures develop, all shall be described in the order of their occurrence; for example, shearing

followed by brooming. Each type of observed failure mode shall be photographed or sketched.

9.7 Weight and Moisture Content—See 8.8.

9.8 Ring and Latewood Measurement—When practicable, the number of rings per inch (average ring width in millimeters) and

the proportion of summerwood shall be measured over a representative inch (centimeter) of cross section of the test specimen. In

determining the proportion of summerwood, it is essential that the end surface be prepared so as to permit accurate latewood

measurement. When the fibers are broomed over at the ends from sawing, a light sanding, planing, or similar treatment of the ends

is recommended.

10. Impact Bending

10.1 Size of Specimens—The impact bending tests shall be made on 2 in. by 2 in. by 30 in. (50 mm by 50 mm by 760 mm)

specimens. The actual height and width at the center and the length shall be measured (see 22.2).

10.2 Loading and Span—Use center loading and a span length of 28 in. (710 mm).

10.3 Bearing Block—A metal tup of curvature corresponding to the bearing block shown in Fig. 4 shall be used in applying the

load.

D143 − 22

FIG. 7 Sample Data Sheet for a Manually Recorded Compression-Parallel-to-Grain Test

10.4 Placement of Growth Rings—The specimen shall be placed so that the load will be applied through the bearing block to the

tangential surface nearest the pith.

10.5 Procedure—Make the tests by increment drops in a Hatt-Turner or similar impact machine (see Fig. 11). The first drop shall

be 1 in. (25 mm), after which increase the drops by 1 in. increments until a height of 10 in. (250 mm) is reached. Then use a 2

in. (50 mm) increment until complete failure occurs or a 6 in. (150 mm) deflection is reached.

10.6 Weight of Hammer—A 50 lbm (22.5 kg) hammer shall be used with drops up to the capacity of the machine provided that

complete failure or a 6 in. (150 mm) deflection will result for all specimens of a species. For all other cases, a 100 lbm (45 kg)

hammer shall be used.

D143 − 22

FIG. 8 Compression-Parallel-to-Grain Test Assembly Using an Automatic Type of Compressometer to Measure Deformations

(The wire in the lower right-hand corner connects the compressometer with the recording unit.)

FIG. 9 Compression-Parallel-to-Grain Test Assembly Showing Method of Measuring Deformations by Means of Roller-Type Compres-

someter

10.7 Deflection Records—When desired, records giving the deflection for each drop and the set, if any, shall be made until the first

failure occurs. This record will also afford data from which the exact height of drop can be scaled for at least the first four falls.

NOTE 6—See Fig. 12 for a sample drum record.

10.8 Drop Causing Failure—The height of drop causing either complete failure or a 6 in. (150 mm) deflection shall be observed

for each specimen.

D143 − 22

FIG. 10 Types of Failures in Compression

10.9 Description of Failure—The failure shall be classified in accordance with the directions for static bending in 8.7. Each type

of observed failure mode shall be photographed or sketched.

NOTE 7—See Fig. 13 for a sample of a manually recorded impact bending data sheet form. A sample data and computation card are shown in Fig. 14.

10.10 Weight and Moisture Content—See 8.8.

11. Toughness

11.1 A single-blow impact test on a small specimen is recognized as a valuable and desirable test. Several types of machines such

as the Toughness, Izod and Amsler have been used, but insufficient information

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D143 − 22

Standard Test Methods for

Small Clear Specimens of Timber

This standard is issued under the fixed designation D143; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The need to classify wood species by evaluating the physical and mechanical properties of small

clear specimens has always existed. Because of the great variety of species, variability of the material,

continually changing conditions of supply, many factors affecting test results, and ease of comparing

variables, the need will undoubtedly continue to exist.

In the preparation of these methods for testing small clear specimens, consideration was given both

to the desirability of adopting test methods that would yield results comparable to those already

available and to the possibility of embodying such improvements as experience has shown desirable.

In view of the many thousands of tests made under a single comprehensive plan by the U.S. Forest

Service, the former Forest Products Laboratories of Canada (now FPInnovations), and other similar

organizations, these test methods naturally conform closely to the methods used by those institutions.

These test methods are the outgrowth of a study of both American and European experience and

methods. The general adoption of these test methods will tend toward a world-wide unification of

results, permitting an interchange and correlation of data, and establishing the basis for a cumulative

body of fundamental information on the timber species of the world. Many of the figures in this

standard use sample data and computation sheets from testing done in the 1950s and earlier. These

figures remain in the standard because they are still valid depictions of the recording and plotting of

test results and also provide a historical link to the large body of test data on small clear specimens

already in existence for this long-standing test method.

Descriptions of some of the strength tests refer to primary methods and secondary methods. Primary

methods provide for specimens of 2-in. by 2-in. (50 mm by 50 mm) cross section. This size of

specimen has been extensively used for the evaluation of various mechanical and physical properties

of different species of wood, and a large number of data based on this primary method have been

obtained and published.

The 2-in. by 2-in. (50 mm by 50 mm) size has the advantage in that it embraces a number of growth

rings, is less influenced by earlywood and latewood differences than smaller size specimens, and is

large enough to represent a considerable portion of the sampled material. It is advisable to use primary

method specimens wherever possible. There are circumstances, however, when it is difficult or

impossible to obtain clear specimens of 2 by 2-in. cross section having the required 30 in. (760 mm)

length for static bending tests. With the increasing incidence of smaller second growth trees, and the

desirability in certain situations to evaluate a material which is too small to provide a 2-in. by 2-in.

cross section, a secondary method which utilizes a 1-in. by 1-in. (25 mm by 25 mm) cross section has

been included. This cross section is established for compression parallel to grain and static bending

tests, while the 2-in. by 2-in. cross section is retained for impact bending, compression perpendicular

to grain, hardness, shear parallel to grain, cleavage, and tension perpendicular to grain. Toughness and

tension parallel to grain are special tests using specimens of smaller cross section.

The user is cautioned that test results between two different sizes of specimens are not necessarily

directly comparable. Guidance on the effect of specimen size on a property being evaluated is beyond

the scope of these test methods and should be sought elsewhere.

Where the application, measurement, or recording of load and deflection can be accomplished using

electronic equipment and computerized apparatus, such devices are encouraged. It is important that all

data measurement and recording equipment, whether electronic or mechanical, be accurate and

reliable to the degree specified.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D143 − 22

1. Scope 2. Referenced Documents

1.1 These test methods cover the determination of various 2.1 ASTM Standards:

strength and related properties of wood by testing small clear D9 Terminology Relating to Wood and Wood-Based Prod-

specimens. ucts

1.1.1 These test methods represent procedures for evaluat- D198 Test Methods of Static Tests of Lumber in Structural

ing the different mechanical and physical properties, control- Sizes

ling factors such as specimen size, moisture content, D2395 Test Methods for Density and Specific Gravity (Rela-

temperature, and rate of loading. tive Density) of Wood and Wood-Based Materials

1.1.2 Sampling and collection of material is discussed in D3043 Test Methods for Structural Panels in Flexure

Practice D5536. Sample data, computation sheets, and cards D4442 Test Methods for Direct Moisture Content Measure-

have been incorporated, which were of assistance to the ment of Wood and Wood-Based Materials

investigator in systematizing records. D4761 Test Methods for Mechanical Properties of Lumber

1.1.3 The values stated in inch-pound units are to be and Wood-Based Structural Materials

regarded as the standard. The values given in parentheses are D5536 Practice for Sampling Forest Trees for Determination

mathematical conversions to SI units that are provided for of Clear Wood Properties

information only and are not considered standard. When a E4 Practices for Force Calibration and Verification of Test-

weight is prescribed, the basic inch-pound unit of weight (lbf) ing Machines

and the basic SI unit of mass (Kg) are cited. E2309 Practices for Verification of Displacement Measuring

Systems and Devices Used in Material Testing Machines

1.2 The procedures for the various tests appear in the

following order:

3. Summary of Test Methods

Sections

3.1 The mechanical tests are static bending, compression

Photographs of Specimens 5

Control of Moisture Content and Temperature 6

parallel to grain, impact bending toughness, compression

Record of Heartwood and Sapwood 7

perpendicular to grain, hardness, shear parallel to grain,

Static Bending 8

cleavage, tension parallel to grain, tension-perpendicular-to-

Compression Parallel to Grain 9

Impact Bending 10 grain, and nail-withdrawal tests. These tests are permitted for

Toughness 11

both green and air-dry material as specified in these test

Compression Perpendicular to Grain 12

methods. In addition, test methods for evaluating such physical

Hardness 13

Shear Parallel to Grain 14

properties as specific gravity, shrinkage in volume, radial

Cleavage 15

shrinkage, and tangential shrinkage are presented.

Tension Parallel to Grain 16

Tension Perpendicular to Grain 17

NOTE 1—The test for shearing strength perpendicular to the grain

Nail Withdrawal 18

(sometimes termed “vertical shear”) is not included as one of the principal

Specific Gravity and Shrinkage in Volume 19

mechanical tests since in such a test the strength is limited by the shearing

Radial and Tangential Shrinkage 20

resistance parallel to the grain.

Moisture Determination 21

Permissible Variations 22

4. Significance and Use

Calibration 23

1.3 This standard does not purport to address all of the

4.1 These test methods cover tests on small clear specimens

safety concerns, if any, associated with its use. It is the

of wood that are made to provide the following:

responsibility of the user of this standard to establish appro-

4.1.1 Data for comparing the mechanical properties of

priate safety, health, and environmental practices and deter-

various species,

mine the applicability of regulatory limitations prior to use.

4.1.2 Data for the establishment of correct strength

1.4 This international standard was developed in accor-

functions, which in conjunction with results of tests of timbers

dance with internationally recognized principles on standard-

in structural sizes (see Test Methods D198 and Test Methods

ization established in the Decision on Principles for the

D4761), afford a basis for establishing allowable stresses, and

Development of International Standards, Guides and Recom-

4.1.3 Data to determine the influence on the mechanical

mendations issued by the World Trade Organization Technical

properties of such factors as density, locality of growth,

Barriers to Trade (TBT) Committee.

position in cross section, height of timber in the tree, change of

properties with seasoning or treatment with chemicals, and

change from sapwood to heartwood.

These test methods are under the jurisdiction of ASTM Committee D07 on

Wood and are the direct responsibility of Subcommittee D07.01 on Fundamental

Test Methods and Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 15, 2022. Published June 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1922. Last previous edition approved in 2021 as D143 – 21. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D0143-22. the ASTM website.

D143 − 22

FIG. 1 Cross Sections of Bending Specimens Showing Different Rates of Growth of Longleaf Pine (2-in. by 2-in. (50 mm by 50 mm)

Specimens)

FIG. 2 Tangential Surfaces of Bending Specimens of Different Rates of Growth of Jeffrey Pine 2-in. by 2-in. by 30-in. (50 mm by 50 mm

by 760 mm) Specimens

5. Photographs of Specimens 6.2 Control of Moisture Content—Specimens for the test in

the air-dry condition shall be dried to approximately constant

5.1 Four of the static bending specimens from each species

weight before test. If any changes in moisture content occur

shall be selected for photographing, as follows: two average

during final preparation of specimens, the specimens shall be

growth, one fast growth, and one slow growth. These speci-

reconditioned to constant weight before test. Tests shall be

mens shall be photographed in cross section and on the radial

carried out in such manner that large changes in moisture

and tangential surfaces. Fig. 1 is a typical photograph of a cross

content will not occur. To prevent such changes, it is desirable

section of 2-in. by 2-in. (50 mm by 50 mm) test specimens, and

that the testing room and rooms for preparation of test

Fig. 2 is the tangential surface of such specimens.

specimens have some means of humidity control.

6. Control of Moisture Content and Temperature

6.3 Control of Temperature—Temperature and relative hu-

6.1 In recognition of the significant influence of temperature midity together affect wood strength by fixing its equilibrium

and moisture content on the strength of wood, it is highly moisture content. The mechanical properties of wood are also

desirable that these factors be controlled to ensure comparable affected by temperature alone. When tested, the specimens

test results. shall be at a temperature of 68 6 6 °F (20 6 3 °C). The

D143 − 22

temperature at the time of test shall in all instances be recorded

as a specific part of the test record.

7. Record of Heartwood and Sapwood

7.1 Proportion of Sapwood—If heartwood and sapwood

present in the specimen can be distinguished by visual

inspection, the proportion of sapwood present shall be esti-

mated as required for the purposes of the test program and

recorded for each test specimen.

8. Static Bending

8.1 Size of Specimens—The static bending tests shall be

made on 2 in. by 2 in. by 30 in. (50 mm by 50 mm by 760 mm)

primary method specimens or 1 in. by 1 in. by 16 in. (25 mm

by 25 mm by 410 mm) secondary method specimens. The

actual height and width at the center and the length shall be

measured (see 22.2).

8.2 Loading Span and Supports—Use center loading and a

span length of 28 in. (710 mm) for the primary method and 14

in. (360 mm) for the secondary method. These spans were

established in order to maintain a minimum span-to-depth ratio

of 14. Both supporting knife edges shall be provided with

FIG. 4 Example of a Bearing Block for Static Bending Tests

bearing plates and rollers of such thickness that the distance

from the point of support to the central plane is not greater than

a chord length of not less than 2 in. (50 mm) shall be used for

the depth of the specimen (Fig. 3). The knife edges shall be

secondary method specimens. The bearing block shall be

adjustable laterally to permit adjustment for slight twist in the

fabricated with a material that will not appreciably deform

specimen.

under load.

NOTE 2—An example of laterally adjustable supports is provided in

8.4 Placement of Growth Rings—The specimen shall be

Figure 1 of Test Methods D3043.

placed so that the load will be applied through the bearing

8.3 Bearing Block—A rigid bearing block having a radius of

block to the tangential surface nearest the pith.

3 in. (76 mm) and a chord length of not less than 3 ⁄16 in. (97

mm) that is fixed from rotation shall be used for applying the 8.5 Speed of Testing—The load shall be applied continu-

load for primary method specimens. An example is provided in ously throughout the test at a rate of motion of the movable

Fig. 4. A similar block having a radius of 1 ⁄2 in. (38 mm) for crosshead of 0.10 in. (2.5 mm)/min, for primary method

FIG. 3 Static Bending Test Assembly Showing Test Method of Load Application, Specimen Supported on Rollers and Laterally Adjust-

able Knife Edges, and Test Method of Measuring Deflection at Neutral Axis by Means of Yoke and Displacement Measurement Device

D143 − 22

specimens, and at a rate of 0.05 in. (1.3 mm)/min for secondary 9. Compression Parallel to Grain

method specimens (see 22.3).

9.1 Size of Specimens—The compression-parallel-to-grain

tests shall be made on 2 in. by 2 in. by 8 in. (50 mm by 50 mm

8.6 Load-Deflection Curves:

by 200 mm) primary method specimens, or 1 by 1 by 4 in. (25

8.6.1 At a minimum, the load-deflection curves shall be

by 25 by 100 mm) secondary method specimens. The actual

recorded and the test continued up to the maximum load for all

cross-sectional dimensions and the length shall be measured

static bending tests. If required for the purposes of the study, it

(see 22.2).

shall be permitted to continue both loading and the load-