ASTM D2132-03

(Test Method)Standard Test Method for Dust-and-Fog Tracking and Erosion Resistance of Electrical Insulating Materials

Standard Test Method for Dust-and-Fog Tracking and Erosion Resistance of Electrical Insulating Materials

SCOPE

1.1 This test method is intended to differentiate solid electrical insulating materials with respect to their resistance to the action of electric arcs produced by conduction through surface films of a specified contaminant containing moisture. Test Methods D 2302 and D 2303 may also be used to evaluate materials.

1.2 The values stated in inch-pound units are the standard, except in cases where SI units are more appropriate. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 11.4.

Note 1—There is no equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D2132 – 03

Standard Test Method for

Dust-and-Fog Tracking and Erosion Resistance of Electrical

1

Insulating Materials

This standard is issued under the fixed designation D2132; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method is intended to differentiate solid elec- 3.1 Definitions:

trical insulating materials with respect to their resistance to the 3.1.1 For definitions pertinent to this test method see Ter-

action of electric arcs produced by conduction through surface minology D1711.

films of a specified contaminant containing moisture. Test

4. Summary of Test Method

Methods D2302 and D2303 may also be used to evaluate

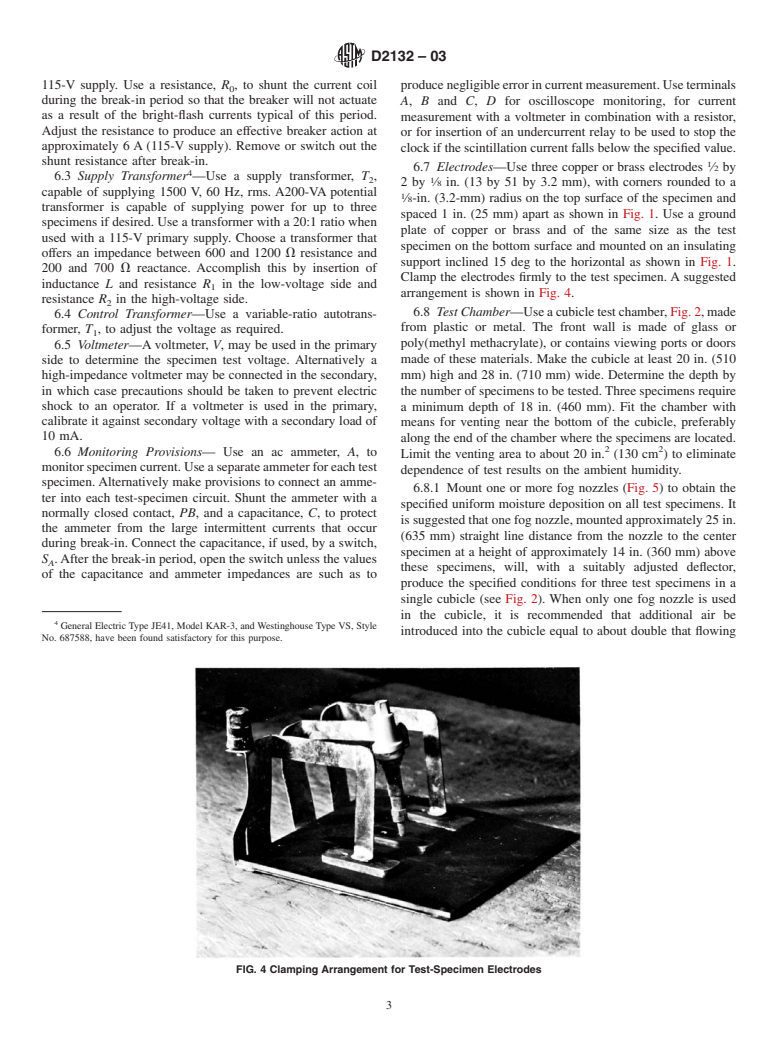

4.1 With electrodes mounted as shown in Fig. 1, coat test

materials.

1.2 The values stated in inch-pound units are the standard, specimens with a synthetic dust and test in a chamber shown in

Fig. 2. Direct a water spray at the test specimen. After the

exceptincaseswhereSIunitsaremoreappropriate.Thevalues

in parentheses are for information only. surface has been wetted, apply a 60-Hz voltage between the

electrodes.Arcingoccursacrosslocalizedhigh-resistanceareas

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the produced by nonuniform evaporation of the water from the

contaminant. These arcs produce high temperatures in the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- underlying insulation with resultant carbonization of most

organic materials. The carbonization concentrates the electric

bility of regulatory limitations prior to use. Specific precau-

tionary statements are given in 11.4. field. Further carbonization may occur in the direction of the

field. In such cases, a carbon track is formed which spans the

NOTE 1—There is no equivalent ISO standard.

distance between the electrodes and causes failure. Materials

thatdonottrackmayerodeundertheactionofthearcing.Such

2. Referenced Documents

erosion usually progresses from an upper electrode through the

2

2.1 ASTM Standards:

thickness of the specimen towards the underlying electrode.

D709 Specification for Laminated Thermosetting Materials

4.2 Rate materials that track in terms of the time required to

D1711 Terminology Relating to Electrical Insulation

form a track between the electrodes.

D2302 Method of Test for Differential Wet Tracking Resis-

4.3 Rate materials that do not track in terms of the time

tance of Electrical Insulating Materials with Controlled

required to erode to failure.

3

Water-to-Metal Discharges

4.4 Failure will be indicated when the current increases

D2303 Test Methods for Liquid-Contaminant, Inclined-

sufficiently to actuate an overcurrent device.

Plane Tracking and Erosion of Insulating Materials

NOTE 2—The conditions of this test favor the formation of a track for

several possible reasons. Most important, the continuous renewal of the

conductingpropertiesofthecontaminantbythewatersprayallowsatrack

1

This test method is under the jurisdiction of ASTM Committee D09 on

to grow progressively over long periods of time.

Electrical and Electronic Insulating Materials and is the direct responsibility of

Subcommittee D09.18 on Solid Insulations, Non-Metallic Shieldings and Coverings

5. Significance and Use

for Electrical and Telecommunication Wires and Cables.

Current edition approved Oct. 1, 2003. Published December 2003. Originally

5.1 Method—Electrical insulation in service may fail as a

approved in 1962. Last previous edition approved in 1998 as D2132 – 98. DOI:

result of tracking, erosion, or a combination of both, if it is

10.1520/D2132-03.

2

exposed to high relative humidity and contamination environ-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ments. This is particularly true of organic insulations in

Standards volume information, refer to the standard’s Document Summary page on

outdoor applications where the surface of the insulation be-

the ASTM website.

3 comes contaminated by deposits of moisture and dirt, for

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org. example, coal dust or salt spray. This test method is an

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2132 – 03

resistance to tracking-induced erosion.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.