ASTM D4466-02

(Terminology)Standard Terminology for Multicomponent Textile Fibers

Standard Terminology for Multicomponent Textile Fibers

SCOPE

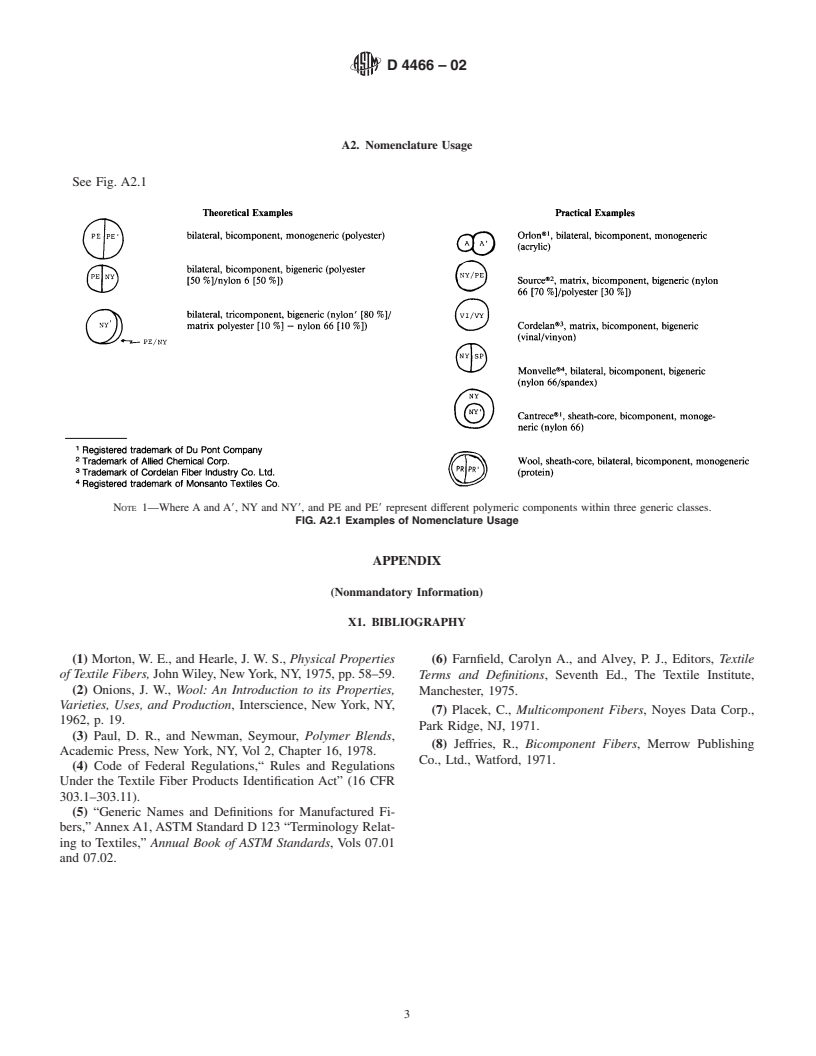

1.1 Man-made polymers can be combined during manufacture, or natural polymers can be formed during growth, to produce multicomponent fibers having special properties such as cross dyeability, differential shrinkage, or bulk. This standard contains terms which can be used to describe the physical arrangement of components of such fibers. The schematic diagram in Annex A1 provides a guide for interpreting the terminology used in describing two- and three-component fibers, but is not intended to be limiting. Some examples of usage are given in Annex A2, and a bibliography of related literature is given in Appendix X1.

1.2 For definitions of other textile terms, refer to Terminology D123.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4466 – 02

Standard Terminology for

1

Multicomponent Textile Fibers

This standard is issued under the fixed designation D 4466; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope bicomponent fiber, n—a fiber consisting of two polymers

which are chemically different or physically different, or

1.1 Man-made polymers can be combined during manufac-

both.

ture, or natural polymers can be formed during growth, to

biconstituent fiber, n—deprecated term. Use the preferred

produce multicomponent fibers having special properties such

term bicomponent bigeneric fiber.

as cross dyeability, differential shrinkage, or bulk. This stan-

dard contains terms which can be used to describe the physical

DISCUSSION—As used in the Federal Trade Commission’s “Rules and

arrangement of components of such fibers. The schematic Regulations Under the Textile Fiber Products Identification Act,”

“biconstituent fiber” is “essentially a physical combination or mixture

diagram in Annex A1 provides a guide for interpreting the

of two or more chemically distinct constituents or components com-

terminology used in describing two- and three-component

bined at or prior to the time of extrusion, which if separately extruded,

fibers, but is not intended to be limiting. Some examples of

would fall within different .” generic classes. In the preferred ASTM

usage are given in Annex A2, and a bibliography of related

terminology, a biconstituent fiber is a bicomponent bigeneric fiber. It is

literature is given in Appendix X1.

not clear from the “Rules” whether a biconstituent fiber has a

1.2 For definitions of other textile terms, refer to Terminol-

sheath-core, bilateral, or matrix configuration.

ogy D 123.

tricomponent fiber, n—a fiber consisting of three polymers

which are chemically different, physically different, or any

2. Referenced Documents

combination of such differences.

2.1 ASTM Standards:

2

D 123 Terminology Relating to Textiles

Physical Arrangement of Components

Generic Class

lateral, adj—a descriptive term for a textile fiber composed of

two or more polymers at least two of which have a

3. Terminology

continuous longitudinal external surface.

sheath-core, adj—a descriptive term for a multicomponent

genericclass, n—as used with textile fibers, a grouping having

similar chemical compositions or specific chemical charac- textile fiber consisting of a continuous envelope which

encases a continuous, central, internal region. (See also

teristics.

component.)

DISCUSSION—In the United States, the generic names and definitions

of man-made fibers, such as nylon, polyester, and acrylic, are published

DISCUSSION—Both the sheath and the core can consist of more than

by the FederalTrade Commission in “Rules and Regulations Under the

one component arranged laterally, concentrically, or in matrix.

Textile Fiber Products Identification Act.” Technically, fibers may be

matrix, adj—a descriptive term for a textile fiber in which one

bigeneric, trigeneric, etc.

ormorepolymericfibrousmaterial(s)isdispersedinanother.

Components

Order for Naming Multicomponent Fibers

polymer, n—a macromolecular material formed by the chemi-

1. Trademark.

cal combination of monomers having either the same or

2. Physical arrangement of components: bilateral, matrix,

different chemical composition.

sheath-core.

component, n—as used with textile fiber polymers, a polymer

3. Number of components: bicomponent, tricomponent, etc.

with distinguishable properties.

4. Number of generic classes: monogeneric, bigeneric,

trigeneric, etc.

1

5. Subparts 1 through 4 to be separated by commas.

ThisterminologyisunderthejurisdictionofASTMCommitteeD13onTextiles

and is the direct responsibility of Subcommittee D13.57 on Fiber Test Methods,

6. Generic class(es): polyester, nylon, spandex, etc.

General.

7. Makeup of generic classes:

Current edition approved Jan. 10, 2002. Published May 2002. Originally

1 (a) Generic class(es) in parentheses.

published as D 4466 – 85e . Last previous edition D 4466 – 94.

2

Annual Book of ASTM Standards, Vol 07.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4466–02

(b) For matrix structures—Generic classes to be sepa- 9. Name the fiber in the form in which it is produced rather

rated by a hyphen. than after any subsequent treatment(s) that might separate the

(c) For lateral structures—Generic classes to be sepa-

components.

rated by a slash mark (/) (virgule).

(d) For sheath-core structures—Generic classes to be

4. Keywords

separat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.