ASTM D7772-15

(Test Method)Standard Test Method for Carbon Black Extractables – Absorbance of Cyclohexane Extract

Standard Test Method for Carbon Black Extractables – Absorbance of Cyclohexane Extract

SIGNIFICANCE AND USE

4.1 This procedure serves as a screening process for carbon blacks used in the manufacturing of products that are to come into contact with food. The cyclohexane extract absorbance at 386 nm must be less than 0.10 for a 50 mm cuvette in order to fulfill various regulatory requirements.

SCOPE

1.1 This method covers the determination of extinction (absorbance) of carbon black cyclohexane extract at 386 nm using a UV spectrophotometer.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7772 − 15

Standard Test Method for

Carbon Black Extractables – Absorbance of Cyclohexane

1

Extract

This standard is issued under the fixed designation D7772; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 386 nm must be less than 0.10 for a 50 mm cuvette in order to

fulfill various regulatory requirements.

1.1 This method covers the determination of extinction

(absorbance) of carbon black cyclohexane extract at 386 nm

5. Apparatus

using a UV spectrophotometer.

5.1 Spectrophotometer, 20 nm maximum spectral bandpass,

1.2 The values stated in SI units are to be regarded as

capable of measuring absorbance at 386 nm.

standard. No other units of measurement are included in this

standard.

5.2 Cuvettes, with an optical light path of 50 mm.

1.3 This standard does not purport to address all of the

5.3 Balance, analytical, sensitivity 0.01 g.

safety concerns, if any, associated with its use. It is the

5.4 Filter Paper, with a particle retention in liquid less than

responsibility of the user of this standard to establish appro-

2 µm.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5.5 Glass Filtering Funnels, 75 mm diameter at top.

3

5.6 Volumetric Flask, 100 cm .

2. Referenced Documents

2 5.7 Lens Cleaning Tissue, lint free.

2.1 ASTM Standards:

D4483 Practice for Evaluating Precision for Test Method 5.8 Timer, with 1 s divisions.

Standards in the Rubber and Carbon Black Manufacturing

5.9 Oven, gravity-convection type, capable of temperature

Industries

regulation of 125 6 5°C.

5.10 Desiccator.

3. Summary of Test Method

5.11 Asagoodlaboratorypractice,itcouldbesuggestedthe

3.1 Acarbon black sample is gently agitated in cyclohexane

at room temperature to remove any extractable material. The use of a Neutral Density Filter with a spectral absorbance

calibrated at 386 nm to ensure the spectrophotometer is

mixture is left standing in the dark for 24 h at room tempera-

ture. The carbon black is separated from the cyclohexane by correctly calibrated.

filtration, with subsequent determination of the extinction of

the filtrate at 386 nm using a 50-mm cuvette. 6. Reagents and Materials

6.1 Cyclohexane, analytical reagent grade.

4. Significance and Use

4.1 This procedure serves as a screening process for carbon

7. Hazards

blacks used in the manufacturing of products that are to come

7.1 This test involves hazardous materials, operations and

into contact with food. The cyclohexane extract absorbance at

equipment. This procedure does not attempt to address the

safety problems associated with this test. A hazards review

mustbeconductedbyallpersonnelperformingthetest.Itisthe

1

This test method is under the jurisdiction ofASTM Committee D24 on Carbon

responsibility of the user to review all MSDS, manuals and

Black and is the direct responsibility of Subcommittee D24.66 on Environment,

Health, and Safety.

hazards procedures and establish the appropriate safety mea-

Current edition approved June 1, 2015. Published September 2015. Originally

sures.

approved in 2011. Last previous edition approved in 2011 as D7772 – 11. DOI:

10.1520/D7772-15.

2

8. Calibration, Standardization, and Environmental

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Conditions

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 8.1 Standard Laboratory Test Conditions:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7772 − 15

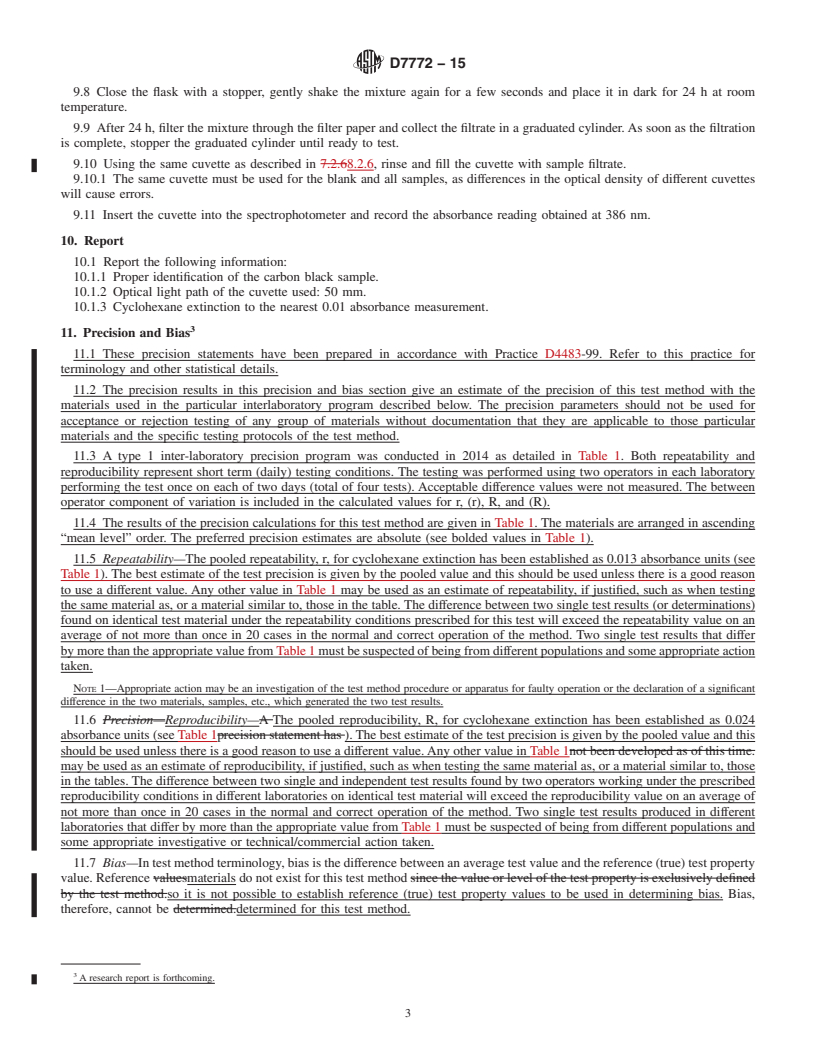

TABLE 1 Precision Parameters for Test Method D7772, Carbon Black Extractables-Absorbance of Cyclohexane Extract (Type 1 Preci-

sion)

Number of Unit Absor-

Material Sr r (r) SR R (R)

Labs bance

N772 4 0.008 0.005 0.015 203.78 0.007 0.020 269.58

N683 (SRB

4 0.011 0.004 0.011 101.72 0.009 0.026 249.15

8F)

Average 0.009

Pooled 0.005 0.013 146.05 0.008 0.024 259.90

8.1.1 Unless stated elsewhere, all testing, calibration and are recommended for cyclohexane to prevent skin exposure

standardization should be carried out in the ambient tempera- (cyclohexane can cause skin irritation).

ture range of 23 6 3°C. 3

9.5 Add25to30cm ofcyclohexanetothesampleflaskand

8.1.2 The date of calibration or testing should also be

stopper the flask.

recorded with any relevant data.

9.6 Shake the mixture gently for a few seconds.

8.1.3 All calibration data should be recorded on a dedicated

file. 9.7 Fill up to the mar

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7772 − 11 D7772 − 15

Standard Test Method for

Carbon Black Extractables – Absorbance of Cyclohexane

1

Extract

This standard is issued under the fixed designation D7772; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This method covers the determination of extinction (absorbance) of carbon black cyclohexane extract at 386 nm using a UV

spectrophotometer.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

3. Summary of Test Method

3.1 A carbon black sample is gently agitated in cyclohexane at room temperature to remove any extractable material. The

mixture is left standing in the dark for 24 h at room temperature. The carbon black is separated from the cyclohexane by filtration,

with subsequent determination of the extinction of the filtrate at 386 nm using a 50-mm cuvette.

4. Significance and Use

4.1 This procedure serves as a screening process for carbon blacks used in the manufacturing of products that are to come into

contact with food. The cyclohexane extract absorbance at 386 nm must be less than 0.10 for a 50 mm cuvette in order to fulfill

various regulatory requirements.

5. Apparatus

5.1 Spectrophotometer, 20 nm maximum spectral bandpass, capable of measuring absorbance at 386 nm.

5.2 Cuvettes, with an optical light path of 50 mm.

5.3 Balance, analytical, sensitivity 0.01 g.

5.4 Filter Paper, with a particle retention in liquid less than 2 μm.

5.5 Glass Filtering Funnels, 75 mm diameter at top.

3

5.6 Volumetric Flask, 100 cm .

5.7 Lens Cleaning Tissue, lint free.

5.8 Timer, with 1 s divisions.

5.9 Oven, gravity-convection type, capable of temperature regulation of 125 6 5°C.

5.10 Desiccator.

1

This test method is under the jurisdiction of ASTM Committee D24 on Carbon Black and is the direct responsibility of Subcommittee D24.66 on Environment, Health,

and Safety.

Current edition approved Nov. 1, 2011June 1, 2015. Published January 2012September 2015. Originally approved in 2011. Last previous edition approved in 2011 as

D7772 – 11. DOI: 10.1520/D7772-11.10.1520/D7772-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7772 − 15

5.11 As a good laboratory practice, it could be suggested the use of a Neutral Density Filter with a spectral absorbance calibrated

at 386 nm to ensure the spectrophotometer is correctly calibrated.

6. Reagents and Materials

6.1 Cyclohexane, analytical reagent grade.

7. Hazards

7.1 This test involves hazardous materials, operations and equipment. This procedure does not attempt to address the safety

problems associated with this test. A hazards review must be conducted by all personnel performing the test. It is the responsibility

of the user to review all MSDS, manuals and hazards procedures and establish the appropriate safety measures.

8. Calibration, Standardization, and Environmental Conditions

8.1 Standard Laboratory Test Conditions:Conditions:

8.1.1 Unless stated elsewhere, all testing, calibration and standardization should be carried out in the ambient temperature range

of 23 6 3°C.

8.1.2 The date of calibration or testing should also be recorded with any relevant data.

8.1.3 All calibration data should be recorded on a dedicated file.

8.2 Instrument Set-Up Frequency – Day of Test:

8.2.1 Turn on the spectrophotometer and allow it to warm up for 30 min.

8.2.2 Set the wavelength to 386 nm and zero the instrument.

8.2.3 Place the Neutral Density Filter inside the sample compartme

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.