ASTM E1998-02

(Guide)Standard Guide for Assessing Depressurization-Induced Backdrafting and Spillage from Vented Combustion Appliances

Standard Guide for Assessing Depressurization-Induced Backdrafting and Spillage from Vented Combustion Appliances

SCOPE

1.1 This guide describes and compares different methods for assessing the potential for, or existence of, depressurization-induced backdrafting and spillage from vented residential combustion appliances.

1.2 Assessment of depressurization-induced backdrafting and spillage is conducted under either induced depressurization or natural conditions.

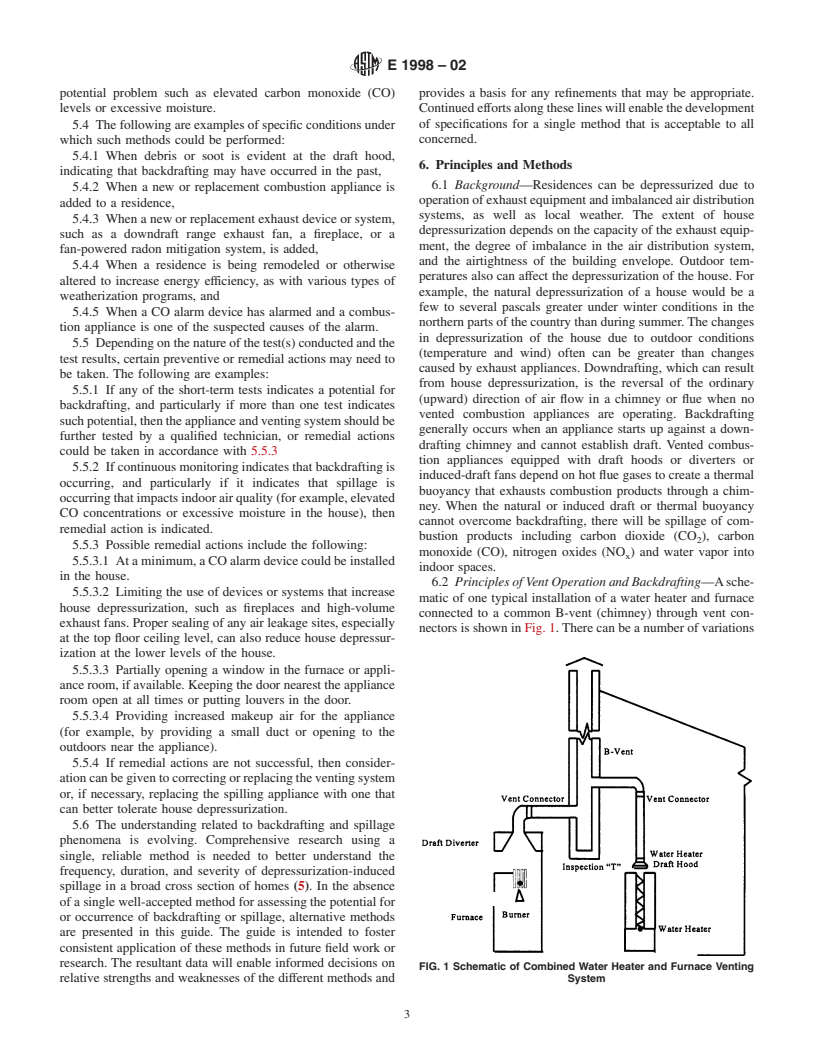

1.3 Residential vented combustion appliances addressed in this guide include hot water heaters and furnace. The guide also is applicable to boilers.

1.4 The methods given in this guide are applicable to Category I (draft-hood- and induced-fan-equipped) furnaces. The guide does not apply to Category III (power-vent-equipped) or Category IV (direct-vent) furnaces.

1.5 The methods in this guide are not intended to identify backdrafting or spillage due to vent blockage or heat-exchanger leakage.

1.6 This guide is not intended to provide a basis for determining compliance with code requirements on appliance and venting installation, but does include a visual assessment of the installation. This assessment may indicate the need for a thorough inspection by a qualified technician.

1.7 Users of the methods in this guide should be familiar with combustion appliance operation and with making house-tightness measurements using a blower door. Some methods described in this guide require familiarity with differential-pressure measurements and use of computer-based data-logging equipment.

1.8 This guide does not purport to address all safety concerns, if any, associated with its use. It is the responsibility of the user to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use. Carbon monoxide (CO) exposure or flame roll-out may occur when performing certain procedures given in this guide. See Section , for precautions that must be taken in conducting such procedures.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1998–02

Standard Guide for

Assessing Depressurization-Induced Backdrafting and

1

Spillage from Vented Combustion Appliances

This standard is issued under the fixed designation E 1998; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 Thisguidedescribesandcomparesdifferentmethodsfor 2.1 ASTM Standards:

assessing the potential for, or existence of, depressurization- D 1356 Terminology Relating to Sampling and Analysis of

2

induced backdrafting and spillage from vented residential Atmospheres

3

combustion appliances. E 631 Terminology of Building Constructions

1.2 Assessment of depressurization-induced backdrafting E 779 Test Method for Determining Air Leakage Rate by

3

andspillageisconductedundereitherinduceddepressurization Fan Pressurization

or natural conditions. E 1827 Test Methods for Determining Airtightness of

4

1.3 Residential vented combustion appliances addressed in Buildings Using an Orifice Blower Door

thisguideincludehotwaterheatersandfurnace.Theguidealso 2.2 CGSB Standard:

is applicable to boilers. 51.71 The Spillage Test—Method to Determine the Poten-

1.4 The methods given in this guide are applicable to tial for Pressure-Induced Spillage from Vented, Fuel-

Category I (draft-hood- and induced-fan-equipped) furnaces. Fired; Space Heating Appliances; Water Heaters, and

5

The guide does not apply to Category III (power-vent- Fireplaces

equipped) or Category IV (direct-vent) furnaces. 2.3 ANSI Standard:

6

1.5 The methods in this guide are not intended to identify Z21.47 Gas-fired Central Furnace

backdrafting or spillage due to vent blockage or heat- 2.4 NFPA Standard:

7

exchanger leakage. 54 National Fuel Gas Code

1.6 This guide is not intended to provide a basis for

3. Terminology

determining compliance with code requirements on appliance

and venting installation, but does include a visual assessment 3.1 Definitions—For definitions of terms used in this guide,

refer to Terminologies E 631 and D 1356.

of the installation. This assessment may indicate the need for a

thorough inspection by a qualified technician. 3.2 Definitions of Terms Specific to This Standard:

3.2.1 air leakage, n—the movement or flow of air through

1.7 Users of the methods in this guide should be familiar

with combustion appliance operation and with making house- the building envelope which is driven by a pressure differential

across the envelope.

tightness measurements using a blower door. Some methods

described in this guide require familiarity with differential- 3.2.2 air leakage rate, n—the volume of air movement per

unit time across the building envelope.

pressure measurements and use of computer-based data-

logging equipment. 3.2.3 airtightness, n—the degree to which the building

envelope resists flow of air.

1.8 This guide does not purport to address all safety

concerns, if any, associated with its use. It is the responsibility 3.2.4 blower door, n—a fan pressurization device incorpo-

rating a controllable fan and instruments for airflow measure-

of the user to establish appropriate safety and health practices

and to determine the applicability of regulatory limitations ment and building pressure difference measurement that

mounts securely in a door or other opening.

prior to use.Carbonmonoxide(CO)exposureorflameroll-out

may occur when performing certain procedures given in this

guide. See Section 7, for precautions that must be taken in

2

conducting such procedures. Annual Book of ASTM Standards, Vol 11.03.

3

Annual Book of ASTM Standards, Vol 04.11.

4

Annual Book of ASTM Standards, Vol 04.07.

1 5

This guide is under the jurisdiction of ASTM Committee E06 on Performance Available from the CGSB Sales Centre, Ottawa, Canada K1A 1G6.

6

ofBuildingsandisthedirectresponsibilityofSubcommitteeE06.41onAirLeakage Available from American National Standards Institute, 11 W. 42nd St., 13th

and Ventilation Performance. Floor, New York, NY 10036.

7

Current edition approved Dec. 10, 2002. Published January 2003. Originally Available from the National Fire ProtectionAssociation, 1 Batterymarch Park,

approved in 1999. Last previous edition approved in 1999 as E 1998–99. P.O. Box 9101, Quincy, MA 02269.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1998–02

3.2.5 Category 1 appliance, n—an appliance that operates 3.2.17 vented combustion appliance, n—includes fossil-

with non-positive static pressure and with a vent gas tempera- fuel-fired furnace, boiler or water he

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.