ASTM E1998-02(2007)

(Guide)Standard Guide for Assessing Depressurization-Induced Backdrafting and Spillage from Vented Combustion Appliances

Standard Guide for Assessing Depressurization-Induced Backdrafting and Spillage from Vented Combustion Appliances

SCOPE

1.1 This guide describes and compares different methods for assessing the potential for, or existence of, depressurization-induced backdrafting and spillage from vented residential combustion appliances.

1.2 Assessment of depressurization-induced backdrafting and spillage is conducted under either induced depressurization or natural conditions.

1.3 Residential vented combustion appliances addressed in this guide include hot water heaters and furnace. The guide also is applicable to boilers.

1.4 The methods given in this guide are applicable to Category I (draft-hood- and induced-fan-equipped) furnaces. The guide does not apply to Category III (power-vent-equipped) or Category IV (direct-vent) furnaces.

1.5 The methods in this guide are not intended to identify backdrafting or spillage due to vent blockage or heat-exchanger leakage.

1.6 This guide is not intended to provide a basis for determining compliance with code requirements on appliance and venting installation, but does include a visual assessment of the installation. This assessment may indicate the need for a thorough inspection by a qualified technician.

1.7 Users of the methods in this guide should be familiar with combustion appliance operation and with making house-tightness measurements using a blower door. Some methods described in this guide require familiarity with differential-pressure measurements and use of computer-based data-logging equipment.

This guide does not purport to address all safety concerns, if any, associated with its use. It is the responsibility of the user to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use. Carbon monoxide (CO) exposure or flame roll-out may occur when performing certain procedures given in this guide. See Section , for precautions that must be taken in conducting such procedures.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1998–02(Reapproved 2007)

Standard Guide for

Assessing Depressurization-Induced Backdrafting and

Spillage from Vented Combustion Appliances

This standard is issued under the fixed designation E1998; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 Thisguidedescribesandcomparesdifferentmethodsfor

assessing the potential for, or existence of, depressurization- D1356 Terminology Relating to Sampling and Analysis of

induced backdrafting and spillage from vented residential Atmospheres

combustion appliances. E631 Terminology of Building Constructions

1.2 Assessment of depressurization-induced backdrafting E779 Test Method for Determining Air Leakage Rate by

andspillageisconductedundereitherinduceddepressurization Fan Pressurization

or natural conditions. E1827 Test Methods for DeterminingAirtightness of Build-

1.3 Residential vented combustion appliances addressed in ings Using an Orifice Blower Door

thisguideincludehotwaterheatersandfurnace.Theguidealso 2.2 CGSB Standard:

is applicable to boilers. 51.71 The Spillage Test—Method to Determine the Poten-

1.4 The methods given in this guide are applicable to tial for Pressure-Induced Spillage from Vented, Fuel-

Category I (draft-hood- and induced-fan-equipped) furnaces. Fired; Space Heating Appliances; Water Heaters, and

The guide does not apply to Category III (power-vent- Fireplaces

equipped) or Category IV (direct-vent) furnaces. 2.3 ANSI Standard:

1.5 The methods in this guide are not intended to identify Z21.47 Gas-fired Central Furnace

backdrafting or spillage due to vent blockage or heat- 2.4 NFPA Standard:

exchanger leakage. 54 National Fuel Gas Code

1.6 This guide is not intended to provide a basis for

3. Terminology

determining compliance with code requirements on appliance

3.1 Definitions—For definitions of terms used in this guide,

and venting installation, but does include a visual assessment

refer to Terminologies E631 and D1356.

of the installation. This assessment may indicate the need for a

thorough inspection by a qualified technician. 3.2 Definitions of Terms Specific to This Standard:

3.2.1 air leakage, n—the movement or flow of air through

1.7 Users of the methods in this guide should be familiar

with combustion appliance operation and with making house- the building envelope which is driven by a pressure differential

across the envelope.

tightness measurements using a blower door. Some methods

described in this guide require familiarity with differential- 3.2.2 air leakage rate, n—the volume of air movement per

unit time across the building envelope.

pressure measurements and use of computer-based data-

logging equipment. 3.2.3 airtightness, n—the degree to which the building

envelope resists flow of air.

1.8 This guide does not purport to address all safety

concerns, if any, associated with its use. It is the responsibility 3.2.4 blower door, n—a fan pressurization device incorpo-

rating a controllable fan and instruments for airflow measure-

of the user to establish appropriate safety and health practices

and to determine the applicability of regulatory limitations ment and building pressure difference measurement that

mounts securely in a door or other opening.

prior to use.Carbonmonoxide(CO)exposureorflameroll-out

may occur when performing certain procedures given in this

guide. See Section 7, for precautions that must be taken in

conducting such procedures.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This guide is under the jurisdiction of ASTM Committee E06 on Performance the ASTM website.

ofBuildingsandisthedirectresponsibilityofSubcommitteeE06.41onAirLeakage Available from the CGSB Sales Centre, Ottawa, Canada K1A 1G6.

and Ventilation Performance. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Current edition approved Aug. 1, 2007. Published August 2007. Originally 4th Floor, New York, NY 10036, http://www.ansi.org.

approved in 1999. Last previous edition approved in 2002 as E1998 – 02. DOI: Available from National Fire Protection Association (NFPA), 1 Batterymarch

10.1520/E1998-02R07. Park, Quincy, MA 02169-7471, http://www.nfpa.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1998–02 (2007)

3.2.5 Category 1 appliance, n—an appliance that operates 3.2.17 vented combustion appliance, n—includes fossil-

with non-positive static pressure and with a vent gas tempera- fuel-fired furnace, boiler or water heater vented to outside.

ture that avoids excessive condensate production in the vent

3.2.17.1 Discussion—The term vented combustion appli-

(see NFPA 54). ances in this standard excludes fireplaces and gas logs vented

3.2.6 Category III appliance, n—an appliance that operates to outside. Also, it does not include appliances such as gas

with a positive vent pressure and with a vent gas temperature ranges or unvented space heaters.

that avoids excessive condensate production in the vent (see

NFPA 54). 4. Summary of Guide

3.2.7 Category IV appliance, n—an appliance that operates

4.1 This guide summarizes different methods for assessing

with a positive vent pressure and with a vent gas temperature

backdrafting and spillage from vented combustion appliances.

that may cause excessive condensate production in the vent

For each method the equipment needed, test procedures, data

(see NFPA 54).

reporting, results and interpretation, and technician and test

3.2.8 combustion system spillage, n—entry of combustion

time required are presented. Advantages and uncertainties of

products into a building from dilution air inlets, vent connector

each method are discussed.

joints, induced draft fan case opening, combustion air inlets, or

4.2 Assessment of depressurization-induced backdrafting

otherlocationsinthecombustionorventingsystemofavented

andspillageisconductedundereitherinduceddepressurization

combustion appliance (boiler, fireplace, furnace, or water

or natural conditions. Depressurization is induced in a resi-

heater), caused by backdrafting, vent blockage, or leaks in the

dence by deliberately operating exhaust fans or a blower-door

venting system.

fan. Assessments conducted under induced conditions can

3.2.9 continuous pressure differential, n—the incremental

indicate only the potential for backdrafting and spillage.

house depressurization due to fans that can be operated

Assessments under natural conditions can indicate actual

continuously, such as furnace blower or supply/exhaust venti-

backdrafting and spillage events. Assessments under either

lator.

induced or natural conditions may not be valid for weather,

3.2.10 downdrafting, n—the reversal of the ordinary (up-

house tightness, or operational conditions beyond those en-

ward)directionofairflowinachimneyorfluewhennovented

countered during the period of measurements.

combustion appliances are operating (as opposed to backdraft-

4.3 The guide includes four types of short term tests

ing, which occurs when vented combustion appliances are

conducted under induced conditions: (1) house depressuriza-

operating).

tion test with preset criteria; (2) downdrafting test; (3) appli-

3.2.11 house depressurization, n—the situation, pertaining ancebackdraftingtest;and(4)coldventestablishmentpressure

to a specific location in a house, whereby the static pressure at

(CVEP) test.Acontinuous backdraft test to identify backdraft-

that location is lower than the static pressure in the immediate ingeventsundernaturalconditions,whichinvolvescontinuous

vicinity outside the house.

monitoring of vent differential pressures, is also described. For

3.2.11.1 Discussion—The pressure difference between in- identification of spillage events or consequences thereof under

doors and outdoors is affected by building tightness (including natural conditions, a continuous spillage test that involves

the distribution of leakage sites across the building envelope), continuous monitoring of spillage-zone temperatures and in-

indoor-outdoor temperature difference, local winds, and the doorairqualityisdescribed.Becausetheyareconductedunder

operation of indoor appliances such as exhaust fans, forced-air a variety of naturally occurring conditions, the continuous

system fans, and vented combustion appliances (boilers, fire- methods can provide more definitive results for conditions

places, furnaces, or water heaters). Thus, the existence and under which tests are conducted. However, the continuous

extent of house depressurization at a specific location varies methods also can be more time-consuming and resource-

over time, depending on outdoor conditions and the operation intensive to apply.

of indoor appliances. 4.4 A purpose of the guide is to encourage the use of

consistent procedures for any selected method.

3.2.12 induced conditions, n—conditions for house depres-

surization created with the use of exhaust fans or blower door.

5. Significance and Use

3.2.13 induced draft (ID) fan, n—a fan used in a venting

system that removes flue gases under non-positive static vent

5.1 Although a number of different methods have been used

pressure.

to assess backdrafting and spillage (see NFPA 54,, CAN/

3.2.13.1 Discussion—An appliance with an ID fan is a

CGSB-51.71,and1-4)asinglewell-acceptedmethodisnotyet

Category I appliance, as its venting system is under non-

available. At this point, different methods can yield different

positive static vent pressure.

results. In addition, advantages and drawbacks of different

3.2.14 intermittent pressure differential, n—the incremental

methods have not been evaluated or described.

house depressurization due to fans that are operated intermit-

5.2 To provide a consistent basis for selection of methods,

tently, such as clothes dryer, kitchen exhaust or bathroom fan.

this guide summarizes different methods available to assess

3.2.15 natural conditions, n—outdoor temperature and

backdrafting and spillage. Advantages and limitations of each

wind conditions that create house depressurization. method are addressed.

3.2.16 pressure differential, n—pressure difference across 5.3 One or more of the methods described in this guide

the building envelope, expressed in pascals (inches of water or should be performed when backdrafting or spillage from

pound-force per square foot or inches of mercury). vented combustion appliances is suspected to be the cause of a

E1998–02 (2007)

potential problem such as elevated carbon monoxide (CO) provides a basis for any refinements that may be appropriate.

levels or excessive moisture. Continuedeffortsalongtheselineswillenablethedevelopment

of specifications for a single method that is acceptable to all

5.4 The following are examples of specific conditions under

which such methods could be performed: concerned.

5.4.1 When debris or soot is evident at the draft hood,

6. Principles and Methods

indicating that backdrafting may have occurred in the past,

6.1 Background—Residences can be depressurized due to

5.4.2 When a new or replacement combustion appliance is

operationofexhaustequipmentandimbalancedairdistribution

added to a residence,

systems, as well as local weather. The extent of house

5.4.3 When a new or replacement exhaust device or system,

depressurization depends on the capacity of the exhaust equip-

such as a downdraft range exhaust fan, a fireplace, or a

ment, the degree of imbalance in the air distribution system,

fan-powered radon mitigation system, is added,

and the airtightness of the building envelope. Outdoor tem-

5.4.4 When a residence is being remodeled or otherwise

peratures also can affect the depressurization of the house. For

altered to increase energy efficiency, as with various types of

example, the natural depressurization of a house would be a

weatherization programs, and

few to several pascals greater under winter conditions in the

5.4.5 When a CO alarm device has alarmed and a combus-

northern parts of the country than during summer.The changes

tion appliance is one of the suspected causes of the alarm.

in depressurization of the house due to outdoor conditions

5.5 Dependingonthenatureofthetest(s)conductedandthe

(temperature and wind) often can be greater than changes

test results, certain preventive or remedial actions may need to

caused by exhaust appliances. Downdrafting, which can result

be taken. The following are examples:

from house depressurization, is the reversal of the ordinary

5.5.1 If any of the short-term tests indicates a potential for

(upward) direction of air flow in a chimney or flue when no

backdrafting, and particularly if more than one test indicates

vented combustion appliances are operating. Backdrafting

suchpotential,thentheapplianceandventingsystemshouldbe

generally occurs when an appliance starts up against a down-

further tested by a qualified technician, or remedial actions

drafting chimney and cannot establish draft. Vented combus-

could be taken in accordance with 5.5.3

tion appliances equipped with draft hoods or diverters or

5.5.2 If continuous monitoring indicates that backdrafting is

induced-draft fans depend on hot flue gases to create a thermal

occurring, and particularly if it indicates that spillage is

buoyancy that exhausts combustion products through a chim-

occurringthatimpactsindoorairquality(forexample,elevated

ney. When the natural or induced draft or thermal buoyancy

CO concentrations or excessive moisture in the house), then

cannot overcome backdrafting, there will be spillage of com-

remedial action is indicated.

bustion products including carbon dioxide (CO ), carbon

5.5.3 Possible remedial actions include the following:

monoxide (CO), nitrogen oxides (NO ) and water vapor into

x

5.5.3.1 Ataminimum,aCOalarmdevicecouldbeinstalled

indoor spaces.

in the house.

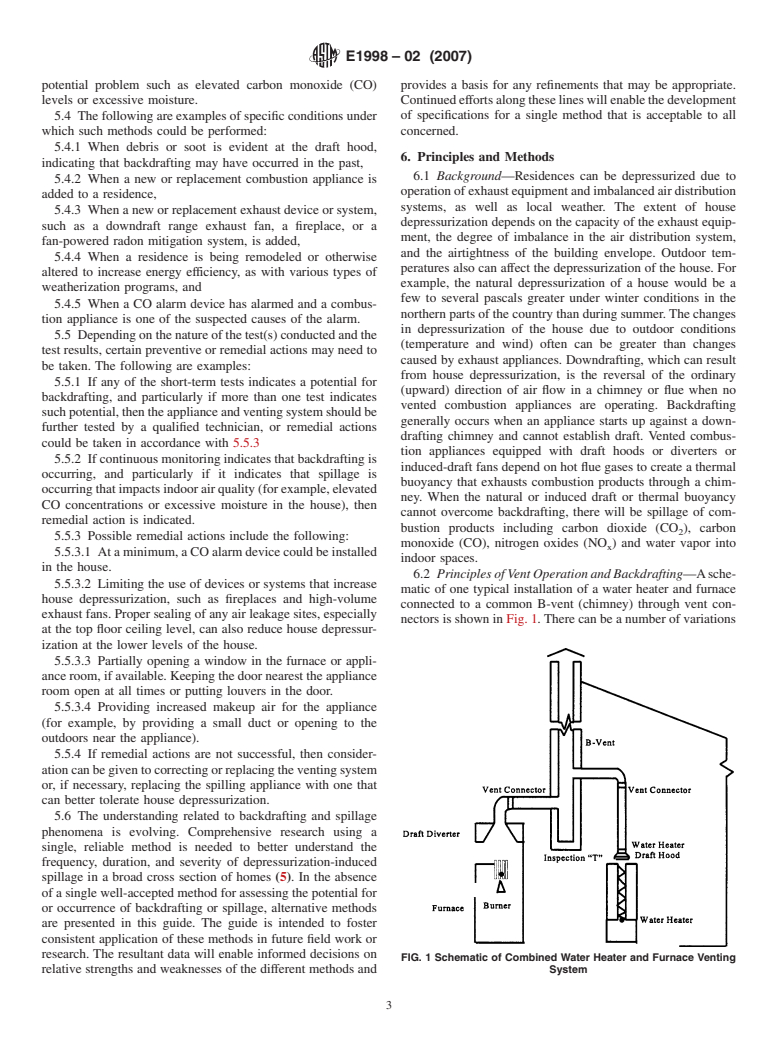

6.2 PrinciplesofVentOperationandBackdrafting—Asche-

5.5.3.2 Limiting the use of devices or systems that increase

matic of one typical installation of a water heater and furnace

house depressurization, such as fireplaces and high-volume

connected to a common B-vent (chimney) through vent con-

exhaust fans. Proper sealing of any air leakage sites, especially

nectors is shown in Fig. 1.There can be a number of variations

at the top floor ceiling level, can also reduce house depressur-

ization at the low

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.