ASTM E1641-07(2012)

(Test Method)Standard Test Method for Decomposition Kinetics by Thermogravimetry

Standard Test Method for Decomposition Kinetics by Thermogravimetry

SIGNIFICANCE AND USE

5.1 Thermogravimetry provides a rapid method for determining the temperature-decomposition profile of a material.

5.2 This test method can be used for estimating lifetimes of materials, using Test Method E1877 provided that a relationship has been established between the thermal endurance test results and actual lifetime tests.

SCOPE

1.1 This test method describes the determination of the kinetic parameters, Arrhenius activation energy, and preexponential factor by thermogravimetry, based on the assumption that the decomposition obeys first-order kinetics.

1.2 This test method is generally applicable to materials with well-defined decomposition profiles, namely, a smooth, continuous mass change with a single maximum rate.

1.3 This test method is normally applicable to decomposition occurring in the range from 400 to 1300K (100 to 1000 °C). The temperature range may be extended depending on the instrumentation used.

1.4 Computer or electronic-based instruments, techniques, or data treatment equivalent to this test method may also be used. Note 1—Users of this test method are expressly advised that all such instruments or techniques may not be equivalent. It is the responsibility of the user of this test method to determine the necessary equivalency prior to use.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This method is similar to ISO 11358-2 but differs in its mathematical treatment.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1641 − 07(Reapproved 2012)

Standard Test Method for

Decomposition Kinetics by Thermogravimetry

This standard is issued under the fixed designation E1641; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E473Terminology Relating to Thermal Analysis and Rhe-

ology

1.1 This test method describes the determination of the

E1142Terminology Relating to Thermophysical Properties

kinetic parameters, Arrhenius activation energy, and preexpo-

E1582Practice for Calibration of Temperature Scale for

nential factor by thermogravimetry, based on the assumption

Thermogravimetry

that the decomposition obeys first-order kinetics.

E1877Practice for Calculating Thermal Endurance of Ma-

1.2 This test method is generally applicable to materials

terials from Thermogravimetric Decomposition Data

with well-defined decomposition profiles, namely, a smooth,

2.2 Other Standard:

continuous mass change with a single maximum rate.

ISO11358-2 Plastics Thermogravimetry (TG) of Polymers

Part 2: Determination of Kinetic Parameters

1.3 This test method is normally applicable to decomposi-

tion occurring in the range from 400 to 1300K (100 to 1000

3. Terminology

°C).The temperature range may be extended depending on the

instrumentation used. 3.1 Definitions:Technical terms used in this test method are

defined in Terminologies E473 and E1142.

1.4 Computer or electronic-based instruments, techniques,

or data treatment equivalent to this test method may also be

4. Summary of Test Method

used.

4.1 This test method consists of heating a series of four or

NOTE 1—Users of this test method are expressly advised that all such

more test specimens, taken from the original sample, each at a

instrumentsortechniquesmaynotbeequivalent.Itistheresponsibilityof

different heating rate between 1 and 10 K/min, through their

the user of this test method to determine the necessary equivalency prior

decompositionregion.Thespecimenmassisrecordedcontinu-

to use.

ously as a function of temperature. The temperatures for

1.5 The values stated in SI units are to be regarded as

constant conversion are determined from the resultant mass

standard. No other units of measurement are included in this

losscurves.TheArrheniusactivationenergyisthendetermined

standard.

from a plot of the logarithm of heating rate versus the

1.6 This method is similar to ISO11358-2 but differs in its

reciprocal of the absolute temperature at constant conversion

mathematical treatment.

level. This activation energy may then be used to calculate

thermal endurance and an estimate of the lifetime of the

1.7 This standard does not purport to address all of the

material at a certain temperature using Test Method E1877.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

5.1 Thermogravimetry provides a rapid method for deter-

bility of regulatory limitations prior to use.

mining the temperature-decomposition profile of a material.

2. Referenced Documents

5.2 This test method can be used for estimating lifetimes of

materials, using Test Method E1877 provided that a relation-

2.1 ASTM Standards:

ship has been established between the thermal endurance test

results and actual lifetime tests.

ThistestmethodisunderthejurisdictionofASTMCommitteeE37onThermal

6. Apparatus

Measurements and is the direct responsibility of Subcommittee E37.01 on Calo-

rimetry and Mass Loss.

6.1 The essential equipment required to provide the mini-

Current edition approved Sept. 1, 2012. Published September 2012. Originally

mum thermogravimetric analytical capability of this test

approved in 1994. Last previous edition approved in 2007 as E1641–07. DOI:

10.1520/E1641-07R12.

method includes:

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1641 − 07 (2012)

NOTE 4—The specimen size and surface-to-volume ratio are known to

6.1.1 A thermobalance, composed of (a)a furnace to

affect the results of this test.Anarrow range of specimen sizes should be

provide uniform controlled heating of a specimen at a constant

used, as noted in 9.5. Uniformity in particle size can be achieved, without

rate within the temperature range from ambient to 1300 K; (b)

the loss of volatiles, by using a liquid nitrogen mill to grind the sample to

a temperature sensor to provide an indication of the specimen/

afinepowder.Topreventthecondensationofmoisture,themillshouldbe

furnace temperature to 60.1 K; (c)an electrobalance to

opened only after returning fully to ambient temperature, or the operation

should be performed in a glove box filled with dry gas.

continuously measure the specimen mass with a minimum

capacityof20mgandasensitivityof 650µg;and(d)ameans

8.2 In the absence of other information, the samples are

of sustaining the specimen/container under atmospheric con-

assumed to be analyzed as received except for the mechanical

trolofaninertorreactivepurgegasof99.99%purityatarate

treatment noted in 8.1. If some heat treatment, such as drying,

of 20 to 50 65 mL/min.

isappliedtothesamplepriortoanalysis,thistreatmentandany

6.1.2 A temperature controller, capable of executing a

resulting mass loss must be noted in the report.

specifictemperatureprogrambyoperatingthefurnacebetween

8.3 Certain materials require more sophisticated

selected temperature limits at a rate of temperature change

conditioning, such as maintaining the sample at a specified

between 1 and 10 K/min to within 60.1 K/min.

roomtemperatureandrelativehumidityforanextendedperiod

6.1.3 A recording device, capable of recording and display-

of time. Such conditioning may be conducted, but procedural

inganyportion(includingnoise)ofthechangeinmassandany

details shall be included in the report.

portion (including noise) of the temperature.

6.1.4 Containers (pans, crucibles, and so forth) which are

9. Procedure

inert to the specimen and which will remain dimensionally

stable over the temperature range from ambient to 900 K.

9.1 Prepare the thermogravimetric analyzer using any pro-

cedures described in the manufacturer’s Operations manual.

6.2 High-Purity (99.99 %) Nitrogen Supply, for purge gas.

9.2 Placethetemperaturesensorwithin2mmoftheoutside

NOTE 2—Other atmospheres may be used but shall be specified.

of the specimen holder. Care must be taken to ensure that the

7. Precautions specimen holder is not touched in any way by the sensor and

that it is not moved after temperature calibration.

7.1 It is essential that the samples be representative since

milligram quantities of specimen are to be used.

9.3 Maintain a constant flow rate of purge gas in the range

from 20 to 50 mL/min throughout the experiment.

7.2 The value of the calculated activation energy is inde-

pendent of reaction order in the early stages of decomposition.

NOTE 5—In the case of samples that may be sensitive to oxidative

This assumption does not hold for the later stages and shall be degradation, it will be necessary to maintain inert gas purging for a time

sufficient to ensure that all residual oxygen is removed from the system

used with caution. An upper limit of 10% decomposition is

prior to the start of the temperature program. It may be necessary to

suggested, although 20% is justified in certain cases. It is

evacuate the system prior to initiating inert gas purging for some

strongly suggested that calculations be made at several differ-

instruments.

ent levels of decomposition, for example, 5, 10, 15, and 20%.

9.4 Calibrate the instrument furnace temperature in accor-

Variations in the results among these determinations could

dance with the calibration procedure in Practice E1582 using

indicate the inapplicability of one of them. For instance,

the same heating rate, purge gas, and flow rate to be used for

volatile, low-level impurities would affect the results of the

the specimens. The temperature calibration shall be performed

lowest conversion determination more than those at higher

both prior to every change in heating rate and at that heating

conversions. Consistent results for all conversions validate the

rate.

method for the range of conversions examined.

9.5 Place 3 61 mg of the specimen under test into a clean,

7.3 Toxic or corrosive effluents, or both, may be released

tared instrument specimen holder. Other specimen sizes may

duringtheheatingprocessandmaybeharmfultothepersonnel

be used but shall be indicated in the report.

or apparatus.

NOTE 6—The specimen holder should be tared in the fully assembled

8. Sampling

system, with the purge gas flowing.

NOTE 7—Powdered or granular specimens should be distributed evenly

8.1 Powdered or granular specimens, which have a high

over the specimen holder so as to maximize the exposed surface. A

surface-to-volume ratio, are preferred, although films, fibers,

one-grain thick layer would be optimal.

andfabricsmaybeusedprovidingthatcareistakentomakeall

9.6 Equilibrate the specimen at a temperature, in kelvins

of the specimens uniform in size and shape. Under circum-

(K), of ten times the heating rate in kelvins per minute below

stances in which material parts are available, the specimens

the known decomposition temperature. If the percentage mass

should be prepared by filing or rasping the part.All specimens

loss is to be recorded, establish zero percent loss at this time.

should be mixed thoroughly prior to sampling if possible, and

they should be sampled by removing portions from various

NOTE8—Ifzeropercentmasslossisestablishedatthetimeatwhichthe

parts of the container. These portions should in turn be

specimen is placed into the instrument, the specimen mass at the

equilibration temperature can be greater than 100% due to buoyancy

combinedandmixedwelltoensurearepresentativesamplefor

effects.Ablank should be run for accurate determination of the buoyancy

the determination.

effect throughout the temperature range of the experiment. The blank can

NOTE 3—Care should be exercised during sample preparation to avoid beapieceofplatinumofapproximatelythesamevolumeasthespecimen.

contamination. The balance drift at any temperature can be determined in this manner.

E1641 − 07 (2012)

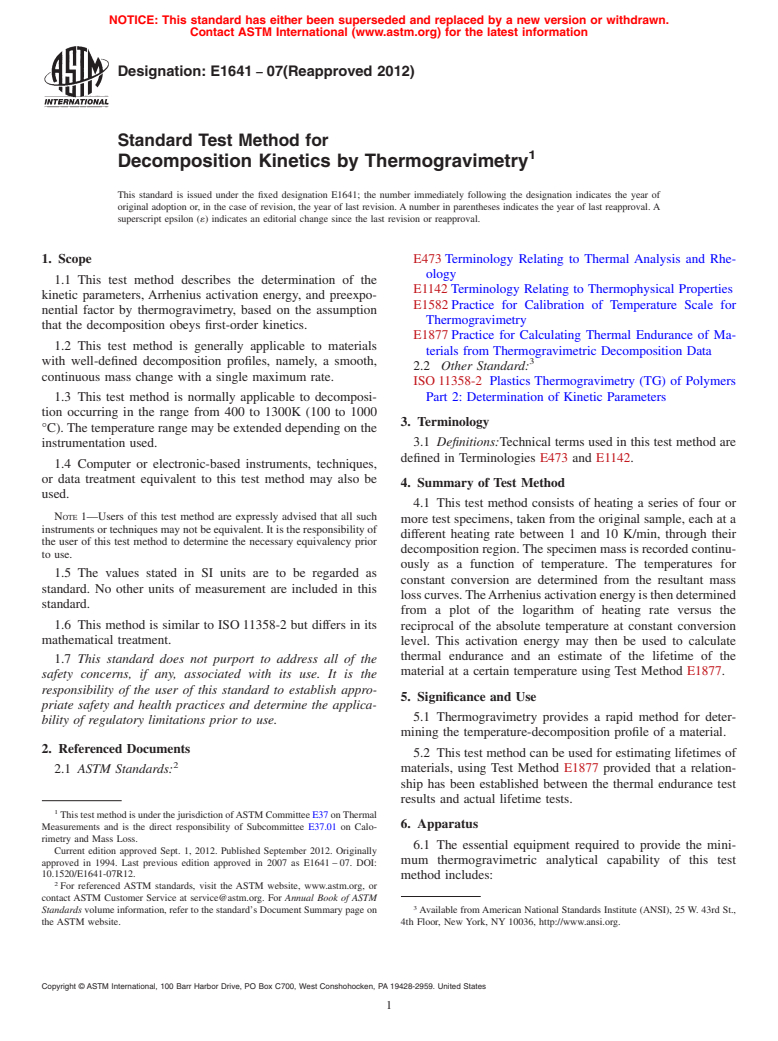

FIG. 1 Examples of Mass Loss Curves at the Following Heating Rates: 1°C/min, 2°C/min, 5°C/min, 10°C/min

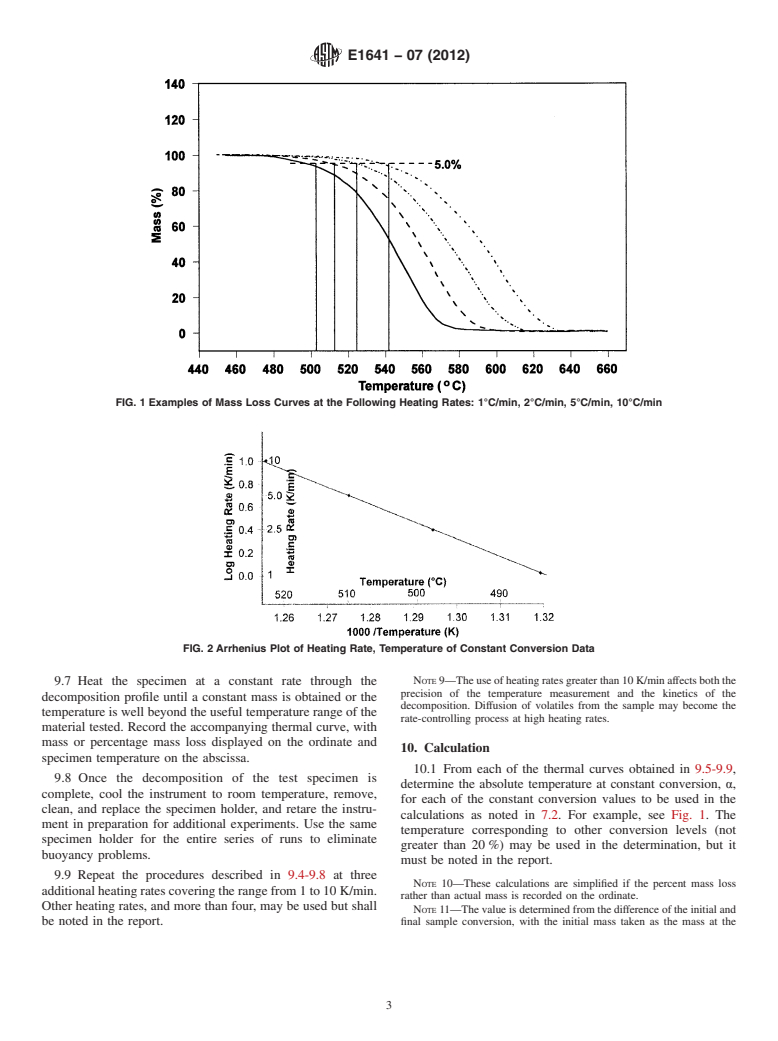

FIG. 2 Arrhenius Plot of Heating Rate, Temperature of Constant Conversion Data

NOTE9—Theuseofheatingratesgreaterthan10K/minaffectsboththe

9.7 Heat the specimen at a constant rate through the

precision of the temperature measurement and the kinetics of the

decomposition profile until a constant mass is obtained or the

decomposition. Diffusion of volatiles from the sample may become the

temperature is well beyond the useful temperature range of the

rate-controlling process at high heating rates.

material tested. Record the accompanying thermal curve, with

mass or percentage mass loss displayed on the ordinate and

10. Calculation

specimen temperature on the abscissa.

10.1 From each of the thermal curves obtained in 9.5-9.9,

9.8 Once the decomposition of the test specimen is

determine the absolute temperature at constant conversion, α,

complete, cool the instrument to room temperature, remove,

for each of the constant conversion values to be used in the

clean, and replace the specimen holder, and retare the instru-

calculations as noted in 7.2. For example, see Fig. 1. The

ment in preparation for additional experiments. Use the same

temperature corresponding to other conversion levels (not

specimen holder for the entire series of runs to eliminate

greater than 20%) may be used in the determination, but it

buoyancy problems.

must be noted in the report.

9.9 Repeat the procedures described in 9.4-9.8 at three

NOTE 10—These calculations are simplified if the percent mass loss

additionalheatingratescoveringtherangefrom1to10K/min.

rather than actual mass is recorded on the ordinate.

Other heating rates, and more than four, may be used but shall

NOTE11—Thevalueisdeterminedfromthedifferenceoftheinitialand

be noted in the report. final sample conversion, with the initial mass taken as the mass at the

E1641 − 07 (2012)

equilibration temperature and the final mass taken once the plateau has TABLE 1 Numerical Integration Constants

been reached at the end of weight loss. For example, if the initial mass is

E/RT a b (1/K)

100.3% and the final mass is 80%, 100% decomposition corresponds to

8 5.3699 0.5398

(100.3 to 80.0) or 20.3% mass loss. Thus, 5% decomposition occurs at

9 5.8980 0.5281

(0.05×20.3)or1.02%massloss,whichoccursontheordinateat99.3%

10 6.4167 0.5187

(100.3%−1.02%=99.28%).

11 6.928 0.511

12 7.433 0.505

10.2 Plot the logarithm of the heating rate expressed as

13 7.933 0.500

kelvins per minute against the reciprocal of the absolute

14 8.427 0.494

15 8.918 0.491

temperature at which the conversion level, selected in 10.1,

16 9.406 0.488

was reached. A straight line, similar to that in Fig. 2, should

17 9.890 0.484

result. This test procedure is not applicable if the curve is

18 10.372 0.482

19 10.851 0.479

nonlinear.

20 11.3277 0.4770

NOTE 12—An apparent nonlinearity may result from erroneous deter- 21 11.803 0.475

22 12.276 0.473

minations. It is recommended that any nonlinear points be repeated for

23 12.747 0.471

verification.

24 13.217 0.470

10.3 Using the least-squares method fit a straight line to

25 13.686 0.469

26 14.153 0.467

these data without weighing factors, and determine the slope:

27 14.619 0.466

∆ logβ /∆ 1/T 28 15.084 0.465

~ ! ~ !

29 15.547 0.463

NOTE13—Ifthevaluesobtainedfromthistestmethodaretobeusedin

30 16.0104 0.4629

TestMethodE1877,anestimationoftheuncertaintyforactivationenergy

31 16.472 0.462

(E) and preexponential factor (A) is required. These uncertainties may be

32 16.933 0.461

derived from the uncertainty in the slope value of m= ∆ (log β)/∆ (1/T).

33 17.394 0.461

Ifthecalculationtoolusedtoobtaintheslopeofthestraightlineprovides

34 17.853 0.459

an estimation of uncertainty in the determined slope (δm), record it.

35 18.312 0.459

Oth

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.