ASTM E3096-18

(Guide)Standard Guide for Definition, Selection, and Organization of Key Performance Indicators for Environmental Aspects of Manufacturing Processes

Standard Guide for Definition, Selection, and Organization of Key Performance Indicators for Environmental Aspects of Manufacturing Processes

SIGNIFICANCE AND USE

4.1 This guide provides methods for developing environmental sustainability KPIs at the manufacturing process level.

4.2 This guide provides standard approaches for systematically identifying, defining, selecting, and organizing KPIs for determining the impact of manufacturing processes on the environment.

4.3 This guide is intended for those who need effective KPIs to assess manufacturing process performance, raise understanding, inform decision-makers, and establish objectives for improvement.

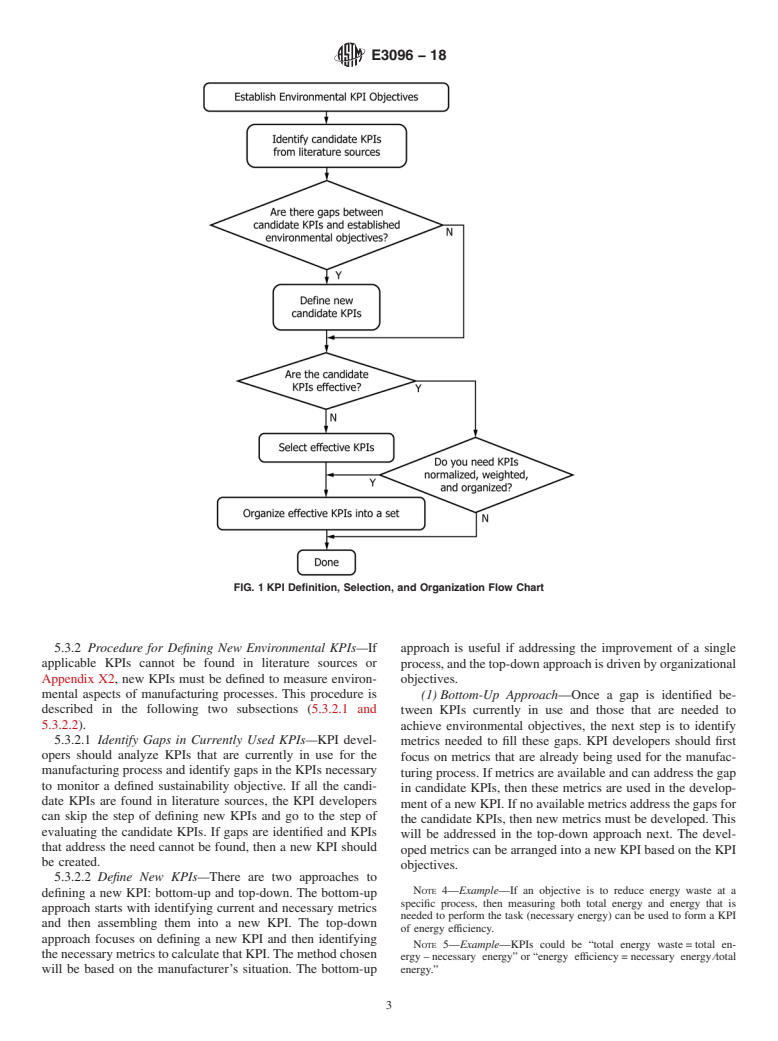

4.4 If the number of stakeholders is small and the manufacturing processes are simple, KPI developers can follow the first two steps (5.2 Establishing KPI Objectives and 5.3 Defining needed KPIs) of this guide. The steps that follow include KPI selection, normalization and weighting, and KPI organization. They can be applied to larger groups of stakeholders and more complex manufacturing processes. Users of this guide can determine the number of steps they will follow because the decision is highly dependent upon the products that they make and the processes that they use.

4.5 The guide enables the development of tools for KPI management and performance evaluation that will support decision-making capabilities in a manufacturing facility, including the development and extension of standardized data, performance information, and environmental knowledge.

4.6 Procedures outlined in this guide are intended for environmental KPIs, and they also can be applied to broader sustainability KPIs as in Guide E2986.

4.7 A quick guide on how to use this guide can be found in Appendix X7.

SCOPE

1.1 This guide addresses Key Performance Indicators (KPIs) for environmental aspects of manufacturing processes.

1.2 This guide provides a procedure for identifying candidate KPIs from existing sources for environmental aspects of manufacturing processes.

1.3 This guide provides a procedure for defining new candidate KPIs that are not available from existing sources for environmental aspects of manufacturing processes.

1.4 This guide defines a methodology for selecting effective KPIs from a list of candidate KPIs based on KPI criteria selected from Appendix X3 or defined by users.

1.5 This guide provides a procedure for normalizing KPIs, assigning weights to those KPIs, and aligning them to environmental objectives.

1.6 KPIs of Manufacturing Operation Management activities as defined in IEC 62264-1 are out of the scope since they are specifically addressed in ISO 22400-2.

1.7 How to evaluate environmental impacts is out of the scope since it is addressed in Guide E2986.

1.8 This guide can be used to complement other standards that address environmental aspects of manufacturing processes, for example, Guide E2986, Terminology E2987/E2987M, and Guide E3012.

1.9 This guide does not purport to address the security risks associated with manufacturing and environmental information. It is the responsibility of the user of this standard to follow practices and establish appropriate information technology related security measures.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.11 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:E3096 −18

Standard Guide for

Definition, Selection, and Organization of Key Performance

Indicators for Environmental Aspects of Manufacturing

1

Processes

This standard is issued under the fixed designation E3096; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

1.1 This guide addresses Key Performance Indicators

mine the applicability of regulatory limitations prior to use.

(KPIs) for environmental aspects of manufacturing processes.

1.11 This international standard was developed in accor-

1.2 This guide provides a procedure for identifying candi-

dance with internationally recognized principles on standard-

date KPIs from existing sources for environmental aspects of

ization established in the Decision on Principles for the

manufacturing processes.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

1.3 This guide provides a procedure for defining new

candidate KPIs that are not available from existing sources for Barriers to Trade (TBT) Committee.

environmental aspects of manufacturing processes.

2. Referenced Documents

1.4 Thisguidedefinesamethodologyforselectingeffective

2

2.1 ASTM Standards:

KPIs from a list of candidate KPIs based on KPI criteria

E2114TerminologyforSustainabilityRelativetothePerfor-

selected from Appendix X3 or defined by users.

mance of Buildings

1.5 This guide provides a procedure for normalizing KPIs,

E2986Guide for Evaluation of Environmental Aspects of

assigning weights to those KPIs, and aligning them to envi-

Sustainability of Manufacturing Processes

ronmental objectives.

E2987/E2987MTerminologyforSustainableManufacturing

1.6 KPIs of Manufacturing Operation Management activi- E3012Guide for Characterizing Environmental Aspects of

ties as defined in IEC 62264-1 are out of the scope since they Manufacturing Processes

3

are specifically addressed in ISO 22400-2. 2.2 IEC Standard:

IEC 62264-1Enterprise-control system integration–Part 1:

1.7 How to evaluate environmental impacts is out of the

Models and terminology

scope since it is addressed in Guide E2986.

4

2.3 ISO Standards:

1.8 This guide can be used to complement other standards

ISO 14001Environmental management–Requirements with

that address environmental aspects of manufacturing

guidance for use

processes, for example, Guide E2986, Terminology E2987/

ISO 14044Environmental management–Life cycle assess-

E2987M, and Guide E3012.

ment–Requirements and guidelines

1.9 This guide does not purport to address the security risks ISO 20140-1Automation systems and integration–Eval-

uating energy efficiency and other factors of manufactur-

associatedwithmanufacturingandenvironmentalinformation.

It is the responsibility of the user of this standard to follow ing systems that influence the environment–Part 1: Over-

view and general principles

practices and establish appropriate information technology

related security measures.

2

1.10 This standard does not purport to address all of the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

safety concerns, if any, associated with its use. It is the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

This guide is under the jurisdiction ofASTM Committee E60 on Sustainability Available from International Electrotechnical Commission (IEC), 3, rue de

and is the direct responsibility of Subcommittee E60.13 on Sustainable Manufac- Varembé, 1st Floor, P.O. Box 131, CH-1211, Geneva 20, Switzerland, http://

turing. www.iec.ch.

4

Current edition approved Sept. 1, 2018. Published September 2018. Originally Available from International Organization for Standardization (ISO), ISO

approved in 2017. Last previous edition approved in 2017 as E3096–17. DOI: Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier,

10.1520/E3096–18. Geneva, Switzerland, http://www.iso.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E3096−18

ISO 22400-1Automation systems and integration–Key Per- 4.6 Procedures

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E3096 − 17 E3096 − 18

Standard Guide for

Definition, Selection, and Organization of Key Performance

Indicators for Environmental Aspects of Manufacturing

1

Processes

This standard is issued under the fixed designation E3096; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This guide addresses Key Performance Indicators (KPIs) for environmental aspects of manufacturing processes.

1.2 This guide provides a procedure for identifying candidate KPIs from existing sources for environmental aspects of

manufacturing processes.

1.3 This guide provides a procedure for defining new candidate KPIs that are not available from existing sources for

environmental aspects of manufacturing processes.

1.4 This guide defines a methodology for selecting effective KPIs from a list of candidate KPIs based on KPI criteria selected

from Appendix X3 or defined by users.

1.5 This guide provides a procedure for normalizing KPIs, assigning weights to those KPIs, and aligning them to environmental

objectives.

1.6 KPIs of Manufacturing Operation Management activities as defined in IEC 62264-1 are out of the scope since they are

specifically addressed in ISO 22400-2.

1.7 How to evaluate environmental impacts is out of the scope since it is addressed in Guide E2986.

1.8 This guide can be used to complement other standards that address environmental aspects of manufacturing processes, for

example, Guide E2986, Terminology E2987/E2987M, and Guide E3012.

1.9 This guide does not purport to address the security risks associated with manufacturing and environmental information. It

is the responsibility of the user of this standard to follow practices and establish appropriate information technology related

security measures.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.11 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E2114 Terminology for Sustainability Relative to the Performance of Buildings

E2986 Guide for Evaluation of Environmental Aspects of Sustainability of Manufacturing Processes

E2987/E2987M Terminology for Sustainable Manufacturing

E3012 Guide for Characterizing Environmental Aspects of Manufacturing Processes

3

2.2 IEC Standard:

IEC 62264-1 Enterprise-control system integration–Part 1: Models and terminology

1

This guide is under the jurisdiction of ASTM Committee E60 on Sustainability and is the direct responsibility of Subcommittee E60.13 on Sustainable Manufacturing.

Current edition approved July 1, 2017Sept. 1, 2018. Published August 2017September 2018. Originally approved in 2017. Last previous edition approved in 2017 as

E3096–17. DOI: 10.1520/E3096-17.10.1520/E3096–18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from International Electrotechnical Commission (IEC), 3, rue de Varembé, 1st Floor, P.O. Box 131, CH-1211, Geneva 20, Switzerland, http://www.iec.ch.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E3096 − 18

4

2.3 ISO Standards:

ISO 14001 Environmental management–Requirements with guidance for use

ISO 14044 Environmental management–Life cycle assessment–Requirements and guidelines

ISO 20140-1 Automation systems and integration–Eval-

uating energy efficiency and other factors of manufacturing systems that influence the environment–Part 1: Overview and

general principles

4

Available from International Organization for Standardizati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.