ASTM D3802-79(2005)

(Test Method)Standard Test Method for Ball-Pan Hardness of Activated Carbon

Standard Test Method for Ball-Pan Hardness of Activated Carbon

SIGNIFICANCE AND USE

Several methods have been employed in the past for determining the resistance of activated carbons to particle size degradation under service conditions, including the ball-pan method, the stirring bar method, and the dust elutriation method. None of these has proved completely satisfactory for all applications, and all have been questioned by ASTM Committee D28 on Activated Carbon as tests for establishing degradation resistance. However, the ball-pan method has been used widely in the past and has a broad history in the activated carbon industry for measuring the property loosely described as “hardness.” In this context the test is useful in establishing a measurable characteristic of a carbon. Conceding the fact that the test does not actually measure in-service resistance to degradation, it can be used to establish the comparability of lots ostensibly of the same grade of carbon.

SCOPE

1.1 This test method covers a procedure for determining the ball-pan hardness number of granular activated carbons. For the purpose of this test, granular activated carbons are those having particles 90 % of which are larger than 80 mesh (180 m) as determined by Test Method D 2862.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 sibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D3802 – 79 (Reapproved 2005)

Standard Test Method for

Ball-Pan Hardness of Activated Carbon

This standard is issued under the fixed designation D3802; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 nominal particle size: natural, granular, and irregu-

1.1 This test method covers a procedure for determining the

larly shaped particle carbons—that particle size range, ex-

ball-pan hardness number of granular activated carbons. For

pressed in terms of Specification E11 sieve sizes, whose small

the purpose of this test, granular activated carbons are those

end excludes not more than 5 % of the particle size distribu-

having particles 90 % of which are larger than 80 mesh (180

tion, and whose large end excludes not more than 5 % of the

µm) as determined by Test Method D2862.

distribution, on a weight basis.

1.2 The values stated in SI units are to be regarded as

3.2.2 nominal particle size: pelleted carbons—that particle

standard. The values given in parentheses are for information

size range, expressed in terms of Specification E11 sieve sizes,

only.

whose small end excludes not more than 10 % of the particle

1.3 This standard does not purport to address all of the

size distribution, and whose large end excludes not more than

safety concerns, if any, associated with its use. It is the

5 % of the distribution, on a weight basis.

responsibility of the user of this standard to establish appro-

3.2.3 small end nominal particle size—that particle size,

priate safety and health practices and determine the applica-

expressed by its equivalent Specification E11 sieve, which

bility of regulatory limitations prior to use.

defines the excluded portion of the particle size distribution at

2. Referenced Documents its small particle size end in accordance with 3.2.1 or 3.2.2.

2.1 ASTM Standards:

4. Summary of Test Method

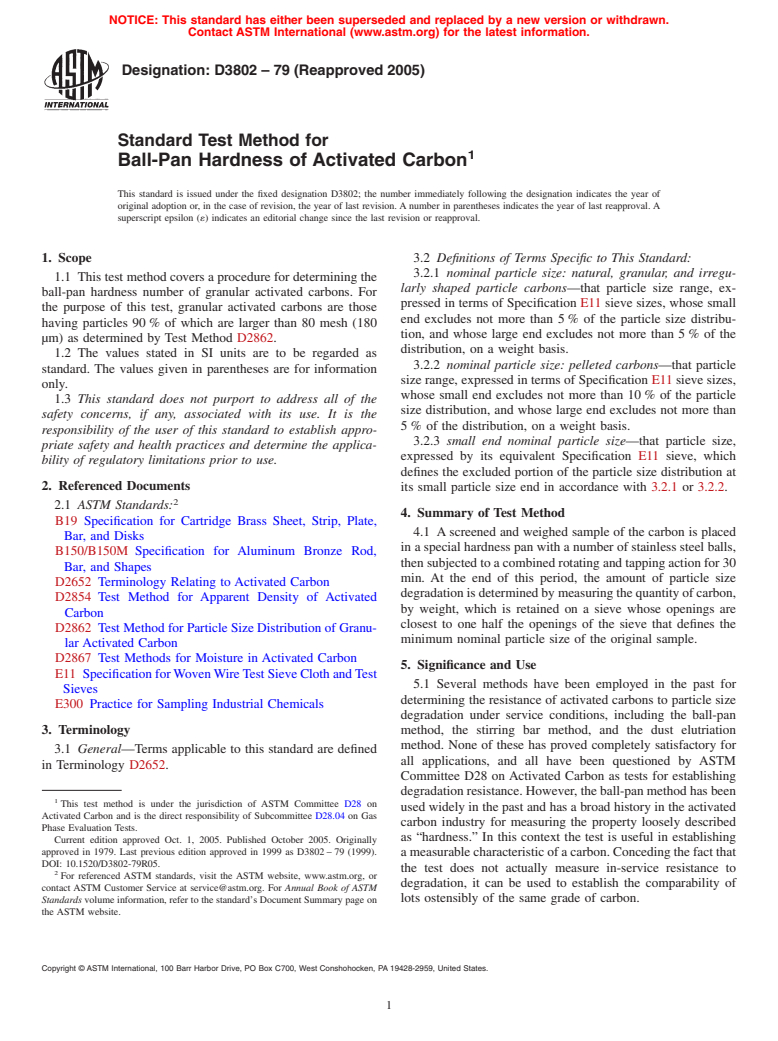

B19 Specification for Cartridge Brass Sheet, Strip, Plate,

4.1 Ascreened and weighed sample of the carbon is placed

Bar, and Disks

in a special hardness pan with a number of stainless steel balls,

B150/B150M Specification for Aluminum Bronze Rod,

thensubjectedtoacombinedrotatingandtappingactionfor30

Bar, and Shapes

min. At the end of this period, the amount of particle size

D2652 Terminology Relating to Activated Carbon

degradationisdeterminedbymeasuringthequantityofcarbon,

D2854 Test Method for Apparent Density of Activated

by weight, which is retained on a sieve whose openings are

Carbon

closest to one half the openings of the sieve that defines the

D2862 Test Method for Particle Size Distribution of Granu-

minimum nominal particle size of the original sample.

lar Activated Carbon

D2867 Test Methods for Moisture in Activated Carbon

5. Significance and Use

E11 SpecificationforWovenWireTestSieveClothandTest

5.1 Several methods have been employed in the past for

Sieves

determining the resistance of activated carbons to particle size

E300 Practice for Sampling Industrial Chemicals

degradation under service conditions, including the ball-pan

3. Terminology method, the stirring bar method, and the dust elutriation

method. None of these has proved completely satisfactory for

3.1 General—Terms applicable to this standard are defined

all applications, and all have been questioned by ASTM

in Terminology D2652.

Committee D28 on Activated Carbon as tests for establishing

degradation resistance. However, the ball-pan method has been

This test method is under the jurisdiction of ASTM Committee D28 on

used widely in the past and has a broad history in the activated

Activated Carbon and is the direct responsibility of Subcommittee D28.04 on Gas

carbon industry for measuring the property loosely described

Phase Evaluation Tests.

as “hardness.” In this context the test is useful in establishing

Current edition approved Oct. 1, 2005. Published October 2005. Originally

approved in 1979. Last previous edition approved in 1999 as D3802 – 79 (1999).

ameasurablecharacteristicofacarbon.Concedingthefactthat

DOI: 10.1520/D3802-79R05.

the test does not actually measure in-service resistance to

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

degradation, it can be used to establish the comparability of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on lots ostensibly of the same grade of carbon.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3802 – 79 (2005)

TABLE 1 Hardness Test Sieve (HTS) Corresponding to Specification E11 Sieves Defining Small-End Nominal Particle Size (SNPS)

SNPS HTS SNPS HTS

Opening, mm E11 Mesh Opening, µm E11 Mesh Opening, µm E11 Mesh Opening, µm E11 Mesh

5.6 3 ⁄2 2800 7 850 20 425 40

4.75 4 2360 8 710 25 355 45

4.00 5 2000 10 600 30 300 50

3.35 6 1700 12 500 35 250 60

2.80 7 1400 14 425 40 212 70

2.36 8 1180 16 355 45 180 80

2.00 10 1000 18 300 50 150 100

1.70 12 850 20 250 60 125 120

1.40 14 710 25 212 70 106 140

1.18 16 600 30 180 80 90 170

1.00 18 500 35

6. Apparatus and Materials 8. Calibration

6.1 Mechanical Sieve Shaker,designedtoproducefrom140

8.1 Calibration of balances shall be maintained by standard

to 160 taps and from 280 to 320 rotating motions per minute in

laboratory methods. Sieves shall be calibrated at reasonable

a stack of standard Specification E11 sieves. Adjust the sieve

intervals in accordance with the procedure described in Speci-

shaker to accommodate the desired number of sieves, receiver

fication E11.

pan, and sieve cover. Adjust the bottom stops to give a

clearance of approximately 1.6 mm between the bottom plate

9. Procedure

and the sieves so that the sieves will be free to rotate. Fit the

9.1 Determine the nominal particle size of the sample in

cover plate with a cork stopper which extends from 3.2 to 9.5

accordance with Test Method D2862, and its moisture content

mm above the metal recess.

in accordance with Test Methods D2867.

6.2 Wire Cloth Sieves,inaccordancewithSpecificationE11;

9.2 Obtain an additional representative sample of approxi-

six required, at least four of which bracket the expected

mately125mLofthecarboninaccordancewithPracticeE300.

nominal particle size distribution of the sample, and one of

9.3 Screen this sample to its nominal particle size distribu-

which, designated the hardness test sieve, has an opening as

tion using Test Method D2862. Discard the fraction

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.