ASTM B368-09

(Test Method)Standard Test Method for Copper-Accelerated Acetic Acid-Salt Spray (Fog) Testing (CASS Test)

Standard Test Method for Copper-Accelerated Acetic Acid-Salt Spray (Fog) Testing (CASS Test)

SIGNIFICANCE AND USE

The CASS test is widely employed and is useful for specification acceptance, simulated service evaluation, manufacturing control, and research and development. It was developed specifically for use with decorative, electrodeposited nickel/chromium and copper/nickel/chromium coatings. Use of the test has improved the quality of electroplated parts and led to the development of new and superior electroplating processes.

SCOPE

1.1 This test method prescribes the conditions required in copper-accelerated acetic acid-salt spray (CASS) testing for specification purposes. The standard does not specify the type of test specimen or exposure periods to be used for a specific product, nor the interpretation to be given to the results.

1.2 This test method is applicable to evaluating the corrosive performance of decorative copper/nickel/chromium or nickel/chromium coatings on steel, zinc alloys, aluminum alloys, and plastics designed for severe service. It is also applicable to the testing of anodized aluminum. The suitability of this test and correlation of results with service experience should be determined before it is specified for coating systems or materials other than those mentioned in this paragraph.

Note 1—The following standards are not requirements. They are referenced for information only: Practices B 537 and E 50, Specifications B 456 and B 604, and Test Method B 602.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For more specific safety precautionary information see 8.1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B368 − 09

StandardTest Method for

Copper-Accelerated Acetic Acid-Salt Spray (Fog) Testing

1

(CASS Test)

This standard is issued under the fixed designation B368; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope B537 Practice for Rating of Electroplated Panels Subjected

to Atmospheric Exposure

1.1 This test method prescribes the conditions required in

B602 Test Method for Attribute Sampling of Metallic and

copper-accelerated acetic acid-salt spray (CASS) testing for

Inorganic Coatings

specification purposes. The standard does not specify the type

B604 Specification for Decorative Electroplated Coatings of

of test specimen or exposure periods to be used for a specific

Copper Plus Nickel Plus Chromium on Plastics

product, nor the interpretation to be given to the results.

D1193 Specification for Reagent Water

1.2 This test method is applicable to evaluating the corro-

E50 Practices for Apparatus, Reagents, and Safety Consid-

sive performance of decorative copper/nickel/chromium or

erations for Chemical Analysis of Metals, Ores, and

nickel/chromium coatings on steel, zinc alloys, aluminum

Related Materials

alloys, and plastics designed for severe service. It is also

E70 Test Method for pH of Aqueous Solutions With the

applicable to the testing of anodized aluminum. The suitability

Glass Electrode

of this test and correlation of results with service experience

3. Significance and Use

should be determined before it is specified for coating systems

or materials other than those mentioned in this paragraph.

3.1 The CASS test is widely employed and is useful for

specification acceptance, simulated service evaluation, manu-

NOTE 1—The following standards are not requirements. They are

referenced for information only: Practices B537 and E50, Specifications facturing control, and research and development. It was devel-

B456 and B604, and Test Method B602.

oped specifically for use with decorative, electrodeposited

1.3 This standard does not purport to address all of the nickel/chromiumandcopper/nickel/chromiumcoatings.Useof

safety concerns, if any, associated with its use. It is the the test has improved the quality of electroplated parts and led

responsibility of the user of this standard to establish appro- to the development of new and superior electroplating pro-

priate safety and health practices and determine the applica-

cesses.

bility of regulatory limitations prior to use. For more specific

4. Apparatus

safety precautionary information see 8.1.

4.1 The apparatus required for the CASS test consists of a

2. Referenced Documents

fog chamber, a salt-solution reservoir, a supply of compressed

2

air, one or more atomizing nozzles, specimen supports, provi-

2.1 ASTM Standards:

sion for heating the chamber, and necessary means of control.

B117 Practice for Operating Salt Spray (Fog) Apparatus

B162 Specification for Nickel Plate, Sheet, and Strip

4.2 The size and detailed construction of the apparatus are

B456 Specification for Electrodeposited Coatings of Copper

optional, provided the conditions meet the requirements of this

Plus Nickel Plus Chromium and Nickel Plus Chromium

test method. The construction of the apparatus is described in

the appendix of Test Method B117. For the CASS test,

however, the requirements for air pressure and temperature are

1

This test method is under the jurisdiction ofASTM Committee B08 on Metallic

typically 0.08 to 0.12 MPa and 60 to 65°C, respectively. The

and Inorganic Coatingsand is the direct responsibility of Subcommittee B08.10 on

actual air pressure will be that required to produce the proper

Test Methods.

Current edition approved April 15, 2009. Published May 2009. Originally

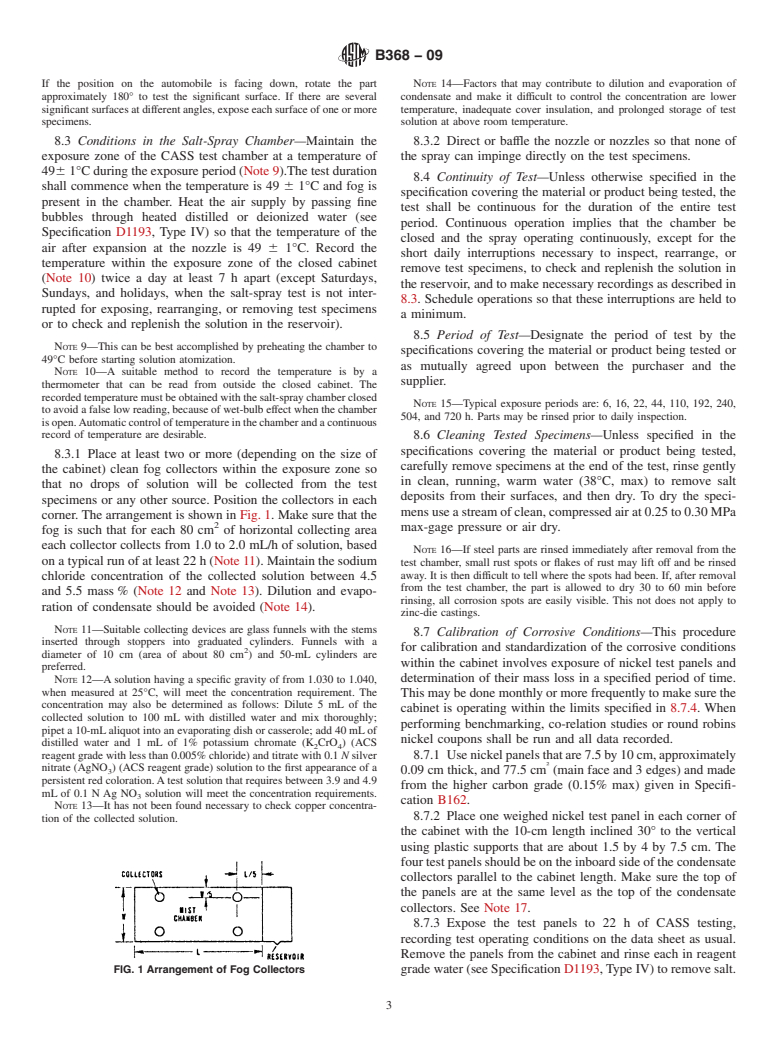

collection rate (see 8.3.1).

´1

approved in 1961. Last previous edition approved in 2003 as B368 – 97(2003) .

4.3 The apparatus shall be constructed so that drops of

The CASS test was developed by the initiative of the Research Board of the

American Electroplaters Society under AES Project 15. DOI: 10.1520/B0368-09.

solution that accumulate on the ceiling or cover of the chamber

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

do not fall on the specimens being tested. Drops of solution

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

that fall from the specimens shall not be returned to the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. solution reservoir for respraying.

Copyright © ASTM International, 100 Barr

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:B368–97(Reapproved 2003) Designation: B 368 – 09

Standard Test Method for

Copper-Accelerated Acetic Acid-Salt Spray (Fog) Testing

1

(CASS Test)

This standard is issued under the fixed designation B 368; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Sections 8.1 and 10.1.12 were editorially updated in July 2003.

1. Scope

1.1 This test method prescribes the conditions required in copper-accelerated acetic acid-salt spray (CASS) testing for

specification purposes. The standard does not specify the type of test specimen or exposure periods to be used for a specific

product, nor the interpretation to be given to the results.

1.2 This test method is applicable to evaluating the corrosive performance of decorative copper/nickel/chromium or

nickel/chromium coatings on steel, zinc alloys, aluminum alloys, and plastics designed for severe service. It is also applicable to

the testing of anodized aluminum. The suitability of this test and correlation of results with service experience should be

determined before it is specified for coating systems or materials other than those mentioned in this paragraph.

NOTE 1—The following standards are not requirements. They are referenced for information only: Practices B 537 and E 50, Specifications B 456 and

B 604, and Test Method B 602.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For more specific safety precautionary information see 8.1.

2. Referenced Documents

2

2.1 ASTM Standards:

B117 Practice for Operating Salt Spray (Fog) Apparatus

B 162 Specification for Nickel Plate, Sheet, and Strip

B 456 Specification for Electrodeposited Coatings of Copper Plus Nickel Plus Chromium and Nickel Plus Chromium

B 537 Practice for Rating of Electroplated Panels Subjected to Atmospheric Exposure

B 602 Test Method for Attribute Sampling of Metallic and Inorganic Coatings

B 604 Specification for Decorative Electroplated Coatings of Copper Plus Nickel Plus Chromium on Plastics

D 1193 Specification for Reagent Water

E50 Practices for Apparatus, Reagents, and Safety Considerations for Chemical Analysis of Metals, Ores, and Related

Materials Practices for Apparatus, Reagents, and Safety Considerations for Chemical Analysis of Metals, Ores, and Related

Materials

E70 Test Method for pH of Aqueous Solutions With the Glass Electrode

3. Significance and Use

3.1 The CASS test is widely employed and is useful for specification acceptance, simulated service evaluation, manufacturing

control, and research and development. It was developed specifically for use with decorative, electrodeposited nickel/chromium

and copper/nickel/chromium coatings. Use of the test has improved the quality of electroplated parts and led to the development

of new and superior electroplating processes.

1

This test method is under the jurisdiction ofASTM Committee B08 on Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee B08.10 on Test

Methods.

Current edition approved May 10, 2003. Published July 2003. Originally approved in 1961. Last previous edition approved in 1997 as B368–97.

´1

Current edition approved April 15, 2009. Published May 2009. Originally approved in 1961. Last previous edition approved in 2003 as B 368 – 97(2003) .

The CASS test was developed by the initiative of the Research Board of the American Electroplaters Society under AES Project 15.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

, Vol 03.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B368–09

4. Apparatus

4.1 The apparatus required for the CASS test consists of a fog chamber, a salt-solution reservoir, a supply of compressed air,

one or more atomizing nozzles, specimen supports, provision

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.