ASTM D5034-95

(Test Method)Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)

Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)

SCOPE

1.1 This test method covers the grab and modified grab test procedures for determining the breaking strength and elongation of most textile fabrics. Provisions are made for wet testing.

1.1.1 The grab test procedure is applicable to woven, nonwoven, and felted fabrics, while the modified grab test procedure is used primarily for woven fabrics.

1.2 This test method is not recommended for glass fabrics, or for knitted fabrics and other textile fabrics which have high stretch (more than 11 %).

Note 1—For the determination of the breaking force and elongation of textile fabrics using the raveled strip test procedure and the cut strip test procedure, refer to Test Method D 5035.

1.3 This test method provides the values in both inch-pound units and SI units. Inch-pound units is the technically correct name for the customary units used in the United States. SI units is the technically correct name for the system of metric units known as the International System of Units. The values stated in either acceptable metric units or in other units shall be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining in any way.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5034 – 95

Standard Test Method for

Breaking Strength and Elongation of Textile Fabrics (Grab

Test)

This standard is issued under the fixed designation D 5034; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1776 Practice for Conditioning Textiles for Testing

D 5035 Test Method for Breaking Force and Elongation of

1.1 This test method covers the grab and modified grab test

Textile Fabrics (Strip Force)

procedures for determining the breaking strength and elonga-

tion of most textile fabrics. Provisions are made for wet testing.

3. Terminology

1.1.1 The grab test procedure is applicable to woven,

3.1 Definitions:

nonwoven, and felted fabrics, while the modified grab test

3.1.1 breaking force, n—the maximum force applied to a

procedure is used primarily for woven fabrics.

material carried to rupture. (Compare breaking point, breaking

1.2 This test method is not recommended for glass fabrics,

strength. Syn. force-at-break.)

or for knitted fabrics and other textile fabrics which have high

3.1.1.1 Discussion—Materials that are brittle usually rup-

stretch (more than 11 %).

ture at the maximum force. Materials that are ductile usually

NOTE 1—For the determination of the breaking force and elongation of

experience a maximum force before rupturing.

textile fabrics using the raveled strip test procedure and the cut strip test

3.1.2 breaking load, n—deprecated term. Use breaking

procedure, refer to Test Method D 5035.

force.

1.3 This test method provides the values in both inch-pound

3.1.3 constant-rate-of-extension (CRE) tensile testing

units and SI units. Inch-pound units is the technically correct

machine—a testing machine in which the rate of increase of

name for the customary units used in the United States. SI units

specimen length is uniform with time.

is the technically correct name for the system of metric units

3.1.4 constant-rate-of-load (CRL) tensile testing

known as the International System of Units. The values stated

machine—a testing machine in which the rate of increase of the

in either acceptable metric units or in other units shall be

load being applied to the specimen is uniform with time after

regarded separately as standard. The values stated in each

the first 3 s.

system may not be exact equivalents; therefore, each system

3.1.5 constant-rate-of-traverse (CRT) tensile testing

must be used independently of the other, without combining in

machine—a testing machine in which the pulling clamp moves

any way.

at a uniform rate and the load is applied through the other

1.4 This standard does not purport to address all of the

clamp which moves appreciably to actuate a weighing mecha-

safety concerns, if any, associated with its use. It is the

nism, so that the rate of increase of load or elongation is

responsibility of the user of this standard to establish appro-

dependent upon the extension characteristics of the specimen.

priate safety and health practices and determine the applica-

3.1.6 elongation, n—the ratio of the extension of a material

bility of regulatory limitations prior to use.

to the length of the material prior to stretching, expressed as a

percent.

2. Referenced Documents

3.1.7 extension, n—the change in length of a material due to

2.1 ASTM Standards:

stretching. (Compare elongation.)

D 76 Specification for Tensile Testing Machines for Tex-

3.1.8 grab test, n—in fabric testing, a tensile test in which

tiles

the central part of the width of the specimen is gripped in the

D 123 Terminology Relating to Textiles

clamps.

D 629 Test Methods for Quantitative Analysis of Textiles

3.1.8.1 Discussion—For example, if the specimen width is

D 1059 Test Method for Yarn Number on Short-Length

100 mm (4.0 in.), and the width of the jaw faces 25 mm (1.0

Specimens

in.), the specimen is gripped in the clamp with approximately

37.5 mm (1.5 in.) of fabric protruding from each side of the

jaws.

This test method is under the jurisdiction of ASTM Committee D-13 on Textiles

3.1.9 modified grab test, n—in fabric testing, a tensile test in

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods,

which the control part of the width of the specimen is gripped

Specific.

Current edition approved May 15, 1995. Published July 1995. Replaces Grab

Testing sections of Test Method D 1682 – 90.

2 3

Annual Book of ASTM Standards, Vol 07.01. Annual Book of ASTM Standards, Vol 07.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5034

in the clamps and in which lateral slits are made midlength of of commercial shipments of most woven textile fabrics, since

the specimen severing all yarns bordering that portion of the the procedures have been used extensively in the trade for

specimen held between the two clamps. acceptance testing.

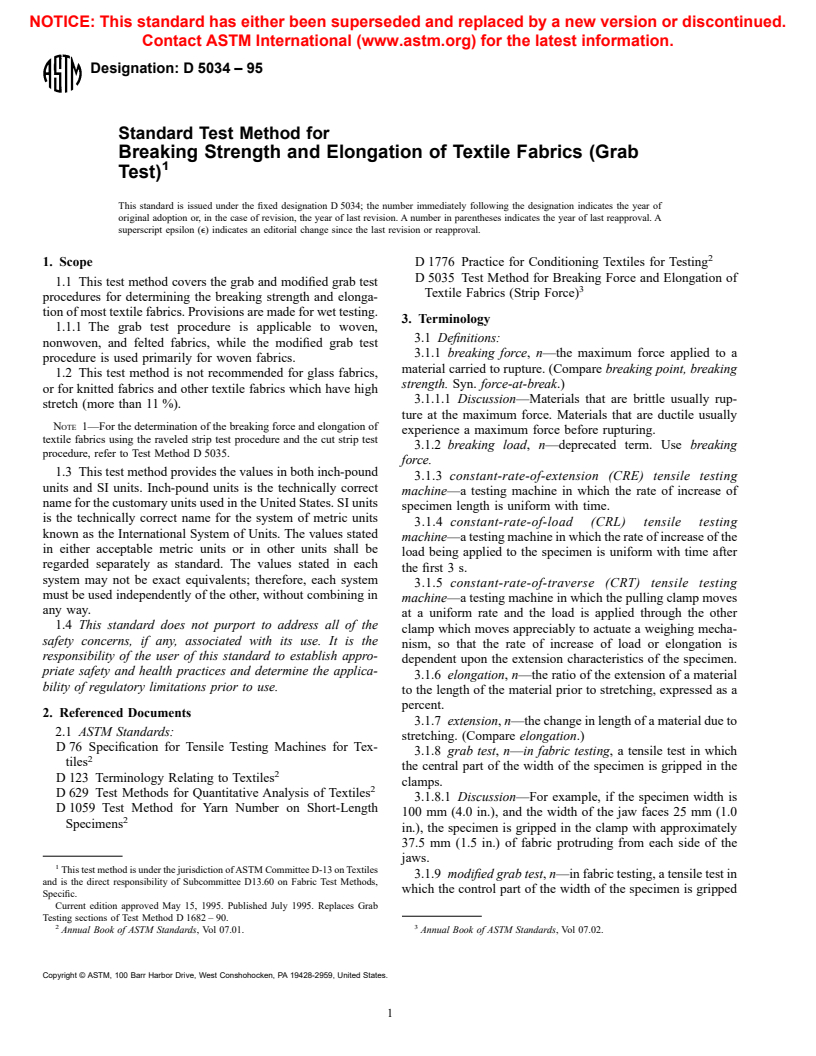

3.1.9.1 Discussion—The slot modification reduces the fab- 5.1.1 In case of disagreement arising from differences in

ric assistance inherent in the grab test procedure to a practical reported test values when using this test method for acceptance

minimum (see Fig. 1). testing of commercial shipments, the purchaser and the sup-

3.1.10 tensile test, n—in textiles, a test in which a textile plier should conduct comparative tests to determine if there is

material is stretched in one direction to determine the load- a statistical bias between their laboratories. Competent statis-

elongation characteristics, the breaking load, or the breaking tical assistance is recommended for the investigation of bias.

elongation. As a minimum, the two parties should take a group of test

3.1.11 For definitions of other terms used in this test specimens which are as homogeneous as possible and which

method, refer to Terminology D 123. are from a lot of material of the type in question. The test

specimens should then be randomly assigned in equal numbers

4. Summary of Test Method

to each laboratory for testing. The average results from the two

4.1 A 100-mm (4.0-in.) wide specimen is mounted centrally laboratories should be compared using Student’s t-test for

in clamps of a tensile testing machine and a force applied until unpaired data and an acceptable probability level chosen by the

the specimen breaks. Values for the breaking force and the two parties before testing is begun. If a bias is found, either its

elongation of the test specimen are obtained from machine cause must be found and corrected, or the purchaser and the

scales, dials, autographic recording charts, or a computer supplier must agree to interpret future test results in light of the

known bias.

interfaced with the testing machine.

4.2 This test method describes procedures for carrying out 5.2 This test method is not recommended for knitted fabrics

because of their high stretch.

fabric grab tensile tests using two types of specimens and three

alternative types of testing machines. For reporting, use the 5.3 Some modification of technique may be necessary for

any fabric having a strength in excess of 200-N/cm (1140-lb/

following identification system of specific specimen and ma-

chine combinations. in.) width. Special precautionary measures are provided for use

when necessary for strong fabrics.

4.2.1 Type of specimen:

4.2.1.1 G—Grab 5.4 All of the procedures are applicable for testing fabrics

4.2.1.2 MG—Modified grab either conditioned or wet.

4.2.2 Type of tensile testing machine: 5.5 Comparison of results from tensile testing machines

4.2.2.1 E—Constant-rate-of-extension (CRE) operating on different principles is not recommended. When

4.2.2.2 L—Constant-rate-of-load (CRL) different types of machines are used for comparison testing,

4.2.2.3 T—Constant-rate-of -traverse (CRT) constant-time-to-break at 20 6 3 s is the established way of

4.2.3 Possible combinations can be identified as follows: producing data. Even then the data may differ significantly.

5.6 Although a constant-rate-of-extension is preferred in

Type of Tester

Constant-Rate- Constant-Rate- Constant-Rate-

these procedures, in cases of dispute, unless there is agreement

Test Specimen of-Extension of-Load of-Traverse

to the contrary between the purchaser and the supplier, a

Grab G-E G-L G-T

Modified Grab MG-E MG-L MG-T constant-time-to-break (20 6 3 s) is to be used.

For example, Test Method D 5034, G-E refers to a grab test carried out on a

5.7 The grab test procedure is applicable to the determina-

constant rate-of-extension tensile testing machine.

tion of the effective strength of the fabric; that is, the strength

of the yarns in a specific width together with the fabric

5. Significance and Use

assistance from the adjacent yarns. The breaking force deter-

5.1 The grab test procedure in this test method for the

mined by the grab procedure is not a reflection of the strength

determination of breaking force and elongation is considered

of the yarns actually gripped between clamps and cannot be

satisfactory for acceptance testing of commercial shipments of

used for direct comparison with yarn strength determinations.

most woven or nonwoven textile fabrics, and the modified grab

Grab test specimens require much less time to prepare although

test procedure is considered satisfactory for acceptance testing

they require more fabric per specimen. There is no simple

relationship between grab tests and strip tests since the amount

of fabric assistance depends on the type of fabric and construc-

tion variables.

5.8 The modified grab test procedure is applicable to the

determination of the breaking force of fabrics with construc-

tions in which the application of tensile stress on raveled strip

specimens produces further unraveling. This test method is

particularly applicable to high-strength fabrics.

6. Apparatus, Reagents, and Materials

Metric Equivalents

in. 4 8 to 10 6.1 Tensile Testing Machine, of the CRE, CRL, or CRT type

mm 100 200 to 250

conforming to Specification D 76, with respect to force indi-

FIG. 1 Illustration of Modified Grab Test Specimens cation, working range, capacity, and elongation indicator, and

D 5034

7. Sampling

7.1 Lot Sample—Take a lot sample as directed in the

applicable material specification. In the absence of such a

specification, randomly take rolls or pieces that constitute the

lot sample using the following schedule:

Number of Rolls, Pieces in Lot, Number of Rolls or Pieces in Lot

Inclusive Sample

1to3 all

4to24 4

25 to 50 5

over 50 10 % to a maximum of 10 rolls or

pieces

NOTE 3—An adequate specification or other agreement between the

purchaser and the supplier requires taking into account the variability

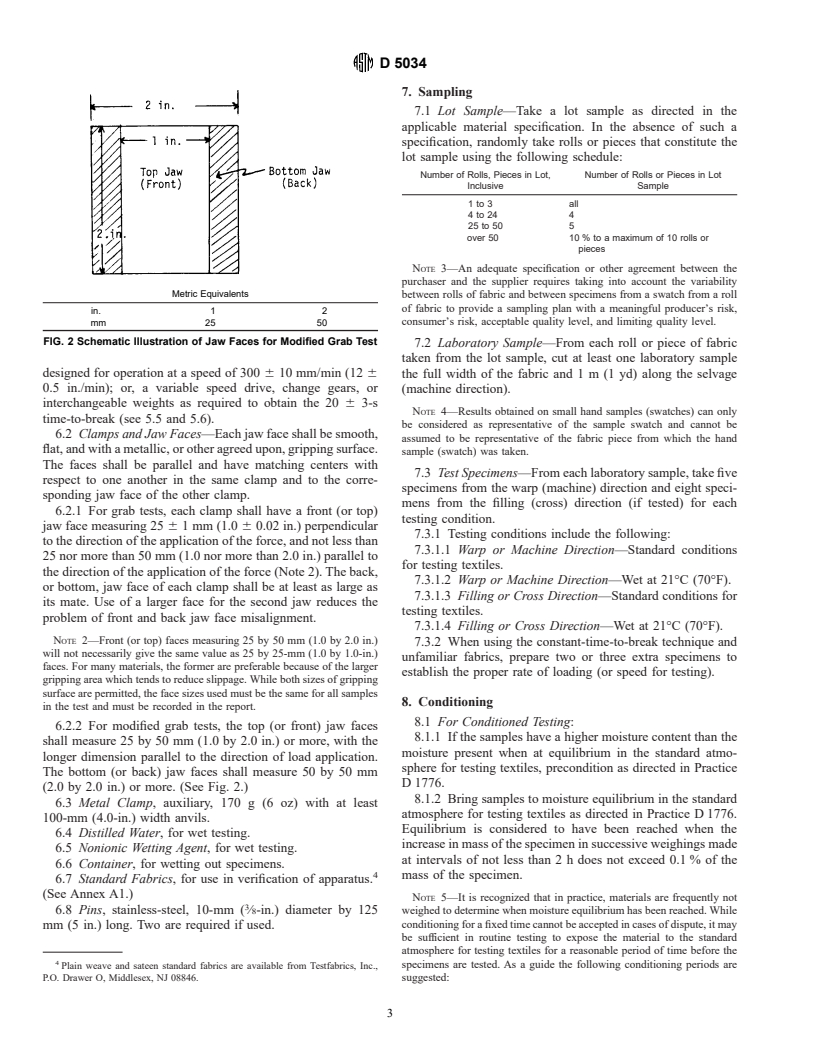

Metric Equivalents

between rolls of fabric and between specimens from a swatch from a roll

of fabric to provide a sampling plan with a meaningful producer’s risk,

in. 1 2

consumer’s risk, acceptable quality level, and limiting quality level.

mm 25 50

FIG. 2 Schematic Illustration of Jaw Faces for Modified Grab Test

7.2 Laboratory Sample—From each roll or piece of fabric

taken from the lot sample, cut at least one laboratory sample

designed for operation at a speed of 300 6 10 mm/min (12 6

the full width of the fabric and1m(1yd) along the selvage

0.5 in./min); or, a variable speed drive, change gears, or (machine direction).

interchangeable weights as required to obtain the 20 6 3-s

NOTE 4—Results obtained on small hand samples (swatches) can only

time-to-break (see 5.5 and 5.6).

be considered as representative of the sample swatch and cannot be

6.2 Clamps and Jaw Faces—Each jaw face shall be smooth,

assumed to be representative of the fabric piece from which the hand

flat, and with a metallic, or other agreed upon, gripping surface.

sample (swatch) was taken.

The faces shall be parallel and have matching centers with

7.3 Test Specimens—From each laboratory sample, take five

respect to one another in the same clamp and to the corre-

specimens from the warp (machine) direction and eight speci-

sponding jaw face of the other clamp.

mens from the filling (cross) direction (if tested) for each

6.2.1 For grab tests, each clamp shall have a front (or top)

testing condition.

jaw face measuring 25 6 1 mm (1.0 6 0.02 in.) perpendicular

7.3.1 Testing conditions include the following:

to the direction of the application of the force, and not less than

7.3.1.1 Warp or Machine Direction—Standard conditions

25 nor more than 50 mm (1.0 nor more than 2.0 in.) parallel to

for testing textiles.

the direction of the application of the force (Note 2). The back,

7.3.1.2 Warp or Machine Direction—Wet at 21°C (70°F).

or bottom, jaw face of each clamp shall be at least as large as

7.3.1.3 Filling or Cross Direction—Standard conditions for

its mate. Use of a larger face for the second jaw reduces the

testing textiles.

problem of front and back jaw face misalignment.

7.3.1.4 Filling or Cross Direction—Wet at 21°C (70°F).

NOTE 2—Front (or top) faces measuring 25 by 50 mm (1.0 by 2.0 in.)

7.3.2 When using the constant-time-to-break technique and

will not necessarily give the same value as 25 by 25-mm (1.0 by 1.0-in.)

unfamiliar fabrics, prepare two or three extra specimens to

faces. For many materials, the former are preferable because of the larger

establish the proper rate of loading (or speed for testing).

gripping area which tends to reduce slippage. While both sizes of gripping

surface are permitted, the face sizes used must be the same for all samples

8. Conditioning

in the test and must be recorded in the report.

8.1 For Conditioned Testing:

6.2.2 For modified grab tests, the top (or front) jaw faces

8.1.1 If the samples have a higher moisture content than the

shall measure 25 by 50 mm (1.0 by 2.0 in.) or more, with the

moisture present when at equilibrium in the standard atmo-

longer dimension parallel to the direction of load application.

sphere for testing textiles, precondition as directed in Practice

The bottom (or back) jaw faces shall measure 50 by 50 mm

D 1776.

(2.0 by 2.0 in.) or more. (See Fig. 2.)

8.1.2 Bring samples to moisture equilibrium in the standard

6.3 Metal Clamp, auxiliary, 170 g (6 oz) with at least

atmosphere for testing textiles as directed in Practice D 1776.

100-mm (4.0-in.) width anvils.

Equilibrium is considered to have been reached when the

6.4 Distilled Water, for wet testing.

increase in mass of the specimen in successive weighings made

6.5 Nonionic Wetting Agent, for wet testing.

at intervals of not less than 2 h does not exceed 0.1 % of the

6.6 Container, for wetting out specimens.

mass of the specimen.

6.7 Standard Fabrics, for use in verification of ap

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.