ASTM D6624-01

(Practice)Standard Practice for Determining a Flow-Proportioned Average Property Value (FPAPV) for a Collected Batch of Process Stream Material Using Stream Analyzer Data

Standard Practice for Determining a Flow-Proportioned Average Property Value (FPAPV) for a Collected Batch of Process Stream Material Using Stream Analyzer Data

SCOPE

1.1 This practice covers a technique for calculating a flow-proportioned average property value (FPAPV) for a batch of in-line blended product or process stream material that is collected over time and isolated in a storage tank or vessel, using a combination of on-line or at-line measurements of the property and flow rates.

1.2 The FPAPV methodology uses regularly collected on- line or at-line process analyzer measurements, flow, and assessment of other appropriate process measurements or values, to calculate a flow-proportioned average property value in accordance with flow quantity units of material produced.

1.3 When the collecting vessel contains a heel (retained material prior to receipt of the production batch), both the property value and quantity of the heel material can be pre-determined and factored into the calculation of the FPAPV for the new batch.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D6624–01

Standard Practice for

Determining a Flow-Proportioned Average Property Value

(FPAPV) for a Collected Batch of Process Stream Material

Using Stream Analyzer Data

This standard is issued under the fixed designation D 6624; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The determination of an average property value that is representative of a batch of petroleum

product collected and isolated in a tank or vessel has always been a challenge. Historically, the

industry practice has been to follow the appropriate procedures prescribed in Practices D 4057,

D 5842, or D 4177 to extract one sample (or a limited few, taken from top, middle, and bottom) from

the tank or vessel after the content is mixed by any of several means to ensure the material is

homogeneouspriortosampleextraction.Theextractedsampleisthensenttoalaboratoryforanalysis.

Depending on the property and its criticality, the average property value can also be obtained by

independently analyzing each of the top, middle, and bottom samples and the results averaged, or, the

three tank samples are mixed and testing for the property is performed on the mixture.

With the introduction of in-line blending and process stream analysis in the 1960s, the potential for

real-time delivery to a pipeline, barge, ship, or tank car compartment was envisioned.

To determine the average property value that is representative of a batch of product from a blend

or process stream, two approaches have been developed and implemented. One depends on the use of

a composite sampler, a vessel into which a sample of the flowing process or blended product stream

is introduced at a flow-rate proportional to the flow-rate of the product stream (Practice D 4177). This

sample, collected over the period of time required to generate the batch quantity of product, is then

analyzed using a primary test method in the laboratory. Multiple laboratory analyses on one or more

aliquots of composite sample can be averaged to provide a more precise estimate of the property value

than a single analysis.

A second technique utilizes the results produced by on-line, at-line, or in-line analytical

measurement systems that continually test material from the process or in-line blended stream for the

desired property as it flows to a collection tank, pipeline, or shipping compartment. To determine the

average property value of all the material collected (or shipped) at any time during the production

process, a unique real time flow-proportioned averaging technique evolved. By appropriate selection

of a production time period or cycle, the average property value for the collected (or shipped) material

at any time in the production or shipment cycle is obtained by recursively calculating a flow-

proportionaverageusingallavailablepropertyvaluesfromtheanalyticalmeasurementsystemandthe

measured incremental quantity of product flow associated with each cycle. The determination of this

flow-proportioned average property value is the subject of this practice.

1. Scope of in-line blended product or process stream material that is

collected over time and isolated in a storage tank or vessel,

1.1 This practice covers a technique for calculating a

using a combination of on-line or at-line measurements of the

flow-proportioned average property value (FPAPV) for a batch

property and flow rates.

1.2 The FPAPV methodology uses regularly collected on-

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum

line or at-line process analyzer measurements, flow, and

Products and Lubricantsand is the direct responsibility of Subcommittee D02.25on

assessment of other appropriate process measurements or

Performance Assessment and Validation of Process Stream Analyzer Systems for

values, to calculate a flow-proportioned average property value

Petroleum and Petroleum Products.

in accordance with flow quantity units of material produced.

Current edition approved Jan. 10, 2001. Published March 2001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6624–01

A · P 1 A · P 1 A · P 1 A · P 1. 1 A · P

1.3 When the collecting vessel contains a heel (retained

1 1 2 2 3 3 4 4 N N

P 5

MIXED

A 1 A 1 A 1 A 1. 1 A

material prior to receipt of the production batch), both the 1 2 3 4 N

(1)

property value and quantity of the heel material can be

A 5 A 1 A 1 A 1 A 1. 1 A (2)

pre-determined and factored into the calculation of the FPAPV

MIXED 1 2 3 4 N

for the new batch.

where:

1.4 This standard does not purport to address all of the

A = quantity of material N,

N

safety concerns, if any, associated with its use. It is the

P = property of material N,

N

responsibility of the user of this standard to establish appro-

P = property of mixed material, and

MIXED

priate safety and health practices and determine the applica-

A = quantity of mixed material.

MIXED

bility of regulatory limitations prior to use.

3.1.4.2 Discussion—The material being mixed can be from

the same process stream over time.

2. Referenced Documents

4. Significance and Use

2.1 ASTM Standards:

D 3764 Practice for Validation of Process StreamAnalyzers

4.1 Contractual or local regulation, or both, permitting, the

FPAPV calculated according to this practice can be used to

D 4057 Practice for Manual Sampling of Petroleum and

represent the average property of the quantity of material

Petroleum Products

collected.

D 4177 Practice for Automatic Sampling of Petroleum and

4.2 Due to the averaging and appropriate weighting of

Petroleum Products

analysis results, the FPAPV estimate of the property for the

D 5842 Practice for Sampling and Handling of Fuels for

collected material is expected to be more representative and

Volatility Measurement

more precise than an estimate based on a small number of

D 6299 Practice for Applying Statistical Quality Assurance

analyses on a few samples.

Techniques to Evaluate Analytical Measurement System

4.3 If the measured property value can be used to predict

Performance

another property value through the use of an appropriate

correlation equation, the FPAPV can also be used as a suitable

3. Terminology

prediction of that property.

4.4 The most recently updated FPAPV can be used to

3.1 Definitions:

represent the property of the material currently accumulated in

3.1.1 analysis cycle time, n—the period of time required to

the tank or vessel for process control or material, or both,

properly obtain and analyze a representative sample of the

disposition decisions.

process stream material.

3.1.2 flow-proportioned average property value (FPAPV),

5. General Requirements

n—the average property value of the collected material in the

5.1 The analytical and flow measurement instrumentation

tank or vessel, calculated by using the flow-proportioned

systems shall be installed in compliance with the principles set

average technique described in the practice of all measure-

forth in API TP-550.

ments performed on aliquots of the material while it is flowing

5.2 The property being measured shall be linearly mixable

into the tank or vessel.

within the range of the property measurements used to calcu-

3.1.2.1 Discussion—The term property as used in this

late FPAPV, and with respect to the quantity units (volume or

practicecanbethephysical,chemical,orperformanceproperty

mass).

measurements as provided by on-line, at-line analyzer systems,

5.3 The integrity of the design, physical components and

or, can be the deviation of such measurements from a desired

assemblies of both the analytical measurement system (inclu-

value.

sive of the sampling subsystem), and the instrumentation for

3.1.2.2 Discussion—The FPAPV can include a value con-

flow quantity measurement shall be determined and docu-

tributed by material (commonly referred to as a tank heel)

mented at the

...

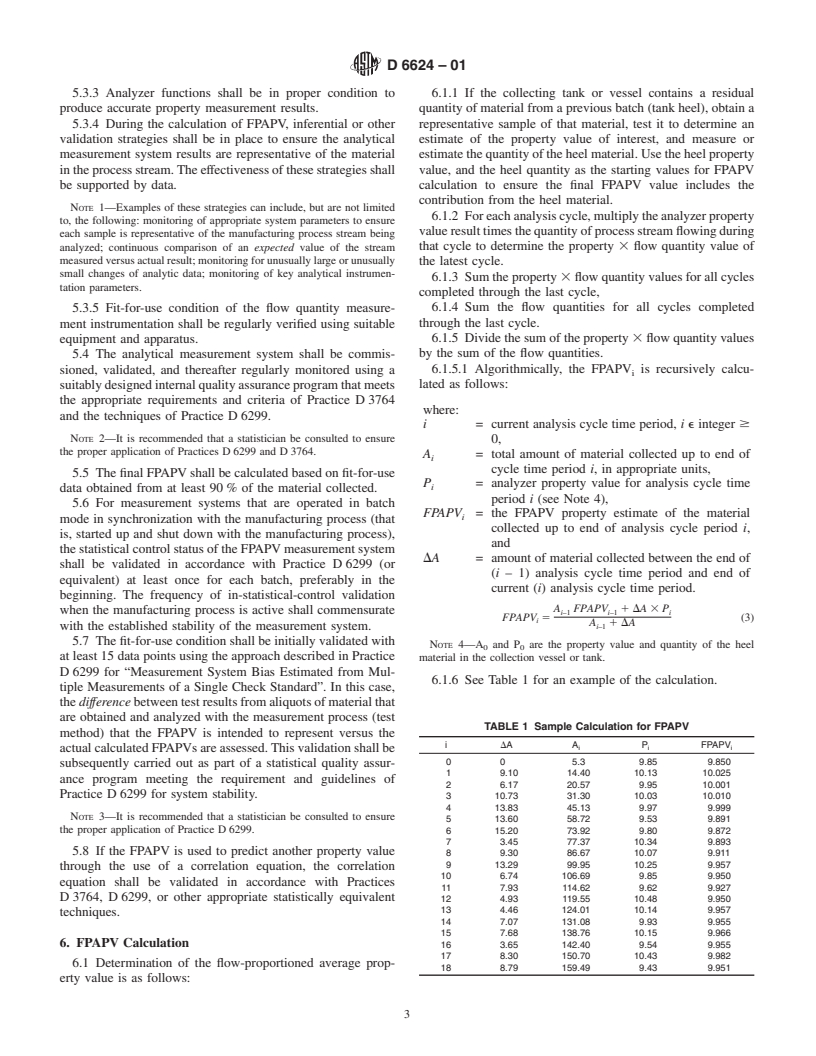

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.