ASTM D3544-76(1996)

(Guide)Standard Guide for Reporting Test Methods and Results on High Modulus Fibers (Withdrawn 2003)

Standard Guide for Reporting Test Methods and Results on High Modulus Fibers (Withdrawn 2003)

SCOPE

1.1 Committee D-30, having conducted several interlaboratory tests of high modulus fibers, believes that many types of equipment and techniques will yield consistent data characterizing the tensile strength and modulus of high modulus fibers. The most important consideration is the complete description of the test methods.

1.2 This guide consists of the following three parts:

1.2.1 Part A- Description of Equipment and Techniques- This section describes the equipment and the techniques used for each series of tests. The section is complete and universal, and should be reviewed by the engineer or scientist responsible for the overall test program.

1.2.2 Part B- Description of Test Specimens- This section describes each type of fiber tested in a particular series, and can be prepared by the test technician.

1.2.3 Part C- Report of Tension Test Results- This section summarizes the results of each test series. The format simplifies the reporting of essential data. Additional information may be required to report the results of tests on specific fiber types.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

Designation: D 3544 – 76 (Reapproved 1996)

Standard Guide for

Reporting Test Methods and Results on High Modulus

Fibers

This standard is issued under the fixed designation D 3544; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope fies the reporting of essential data. Additional information may

be required to report the results of tests on specific fiber types.

1.1 Committee D-30, having conducted several interlabora-

1.3 This standard may involve hazardous materials, opera-

tory tests of high modulus fibers, believes that many types of

tions, and equipment. This standard does not purport to

equipment and techniques will yield consistent data character-

address all of the safety problems associated with its use. It is

izing the tensile strength and modulus of high modulus fibers.

the responsibility of the user of this standard to establish

The most important consideration is the complete description

appropriate safety and health practices and determine the

of the test methods.

applicability of regulatory limitations prior to use.

1.2 This guide consists of the following three parts:

1.2.1 Part A—Description of Equipment and Techniques—

2. Significance and Use

This section describes the equipment and the techniques used

2.1 The purpose of this guide is to be a research tool (1)to

for each series of tests. The section is complete and universal,

aid in the analysis and correlation of test results obtained from

and should be reviewed by the engineer or scientist responsible

the use of various types of tension testing equipment by

for the overall test program.

different investigators and (2) to identify the important details

1.2.2 Part B—Description of Test Specimens—This section

that must be made in testing to make the results easily

describes each type of fiber tested in a particular series, and can

understood and comparable with the results of other investiga-

be prepared by the test technician.

tors.

1.2.3 Part C—Report of Tension Test Results—This section

summarizes the results of each test series. The format simpli-

NOTE 1—The ASTM practice of providing units of measure in the

International System of Units (SI) has been used. The SI unit for pressure

2 2

or stress is pascal (Pa 5 N/m ) or megapascal (MPa 5 MN/m ). The

following equivalents may be helpful:

This guide is under the jurisdiction of ASTM Committee D-30 on High

1 lbf 5 4.448 N

Modulus Fibers and Their Compositesand is the direct responsibility of Subcom-

1 psi 5 6895 Pa 5 6.895 kPa

mittee D30.03 on Constituent/Precursor Properties.

1000 psi 5 6.895 MPa

Current edition approved Oct. 29, 1976. Published January 1977.

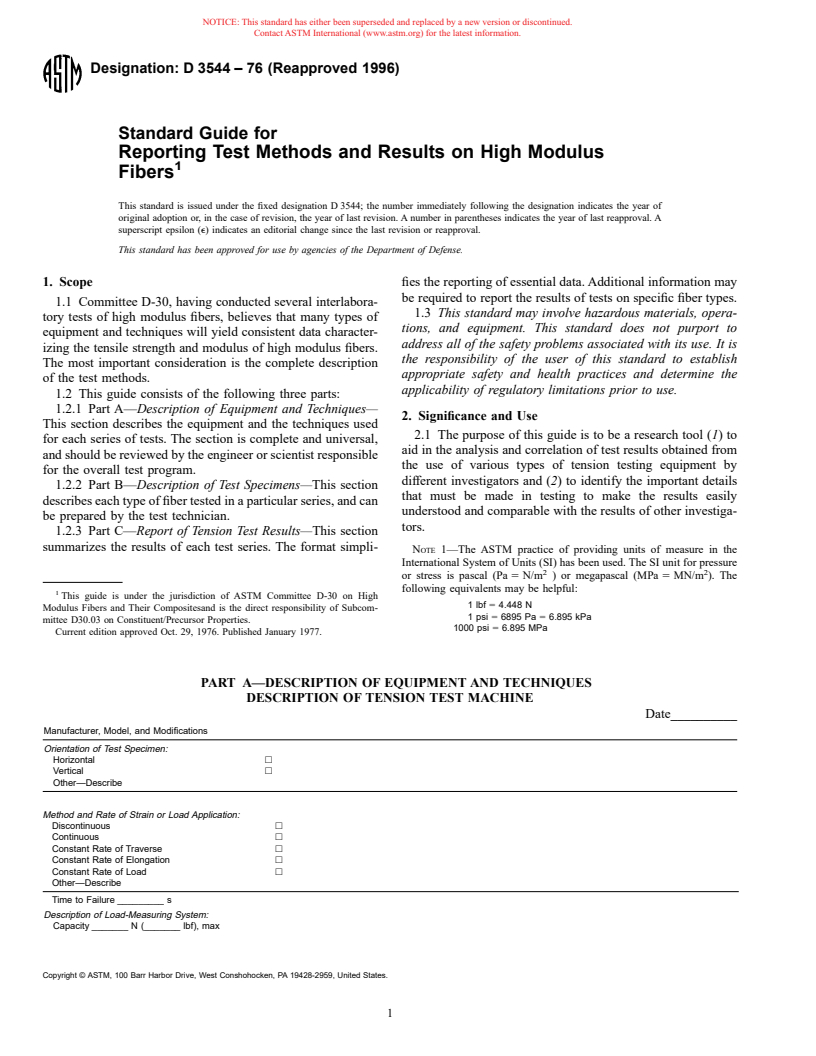

PART A—DESCRIPTION OF EQUIPMENT AND TECHNIQUES

DESCRIPTION OF TENSION TEST MACHINE

Date__________

Manufacturer, Model, and Modifications

Orientation of Test Specimen:

Horizontal h

Vertical h

Other—Describe

Method and Rate of Strain or Load Application:

Discontinuous h

Continuous h

Constant Rate of Traverse h

Constant Rate of Elongation h

Constant Rate of Load h

Other—Describe

Time to Failure _________ s

Description of Load-Measuring System:

Capacity _______ N (_______ lbf), max

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 3544

Deflection of Sensing Element at Load _______ mm (_______ in.), max

Load Range _______ N (_______lbf)

Type of Measuring Element

Resolution and Estimate of Error

Description of Elongation Measuring System:

Jaw Separation h

Extensometer on Sample h

Optical h

Continuous Tracking h

Discontinuous or Manual Tracking h

Other—Describe

Resolution and Estimate of Error

Method Used to Determine System Compliance

Compliance Correction Value _____________ mm/N (_____________ in./lbf)

Load Calibration Procedure:

Estimate of Error

Elongation Calibration Procedure:

Estimate of Error

Linearity of Recording Unit(indicate maximum departure from linear response):

Load Indication __________ %

Elongation Indication ______________ %

Response Time of Recording Unit _____________ s full scale

MEASUREMENT OF CROSS-SECTIONAL AREA

Method of Measurement:

Micrometer h

Microscopical—Longitudinal View h

Microscopical—Transverse View h

Calculated from Linear Density h

Other—Describe

Time When Measurement Was Made:

Before Test on Each Specimen h

After Test on Each Specimen h

On Group of Specimens—Average h

Location of Measurements Along Length—at fracture h in gage length h other ________________:

Number of Measurements Made on Each Fiber or Strand _________

Estimate of Error in Cross-Sectional Area _____________ %

MEASUREMENT OF SPECIMEN GAGE LENGTH

Distance Between Fiber or Strand Mounts:

Method of Measurement

Resolution and Estimate of Error

Length of Fiber or Strand over Which Elongation Was Measured:

General Description

Resolution and Estimate of Error

Location and Type of Gage Marks

METHOD OF GRIPPING AND ALIGNING FIBER OR STRAND

Fiber or Strand Mounting Technique:

Clamped Directly in Jawh

Bonded to a Tab h Bonded Between Tabs h

Tab Geometry length____mm (____in.) width____mm (____in.) thickness____mm (____in.)

Type of Adhesive

Other—Describe

Jaw Type:

Flat Faces—Exerting Transverse Pressure h

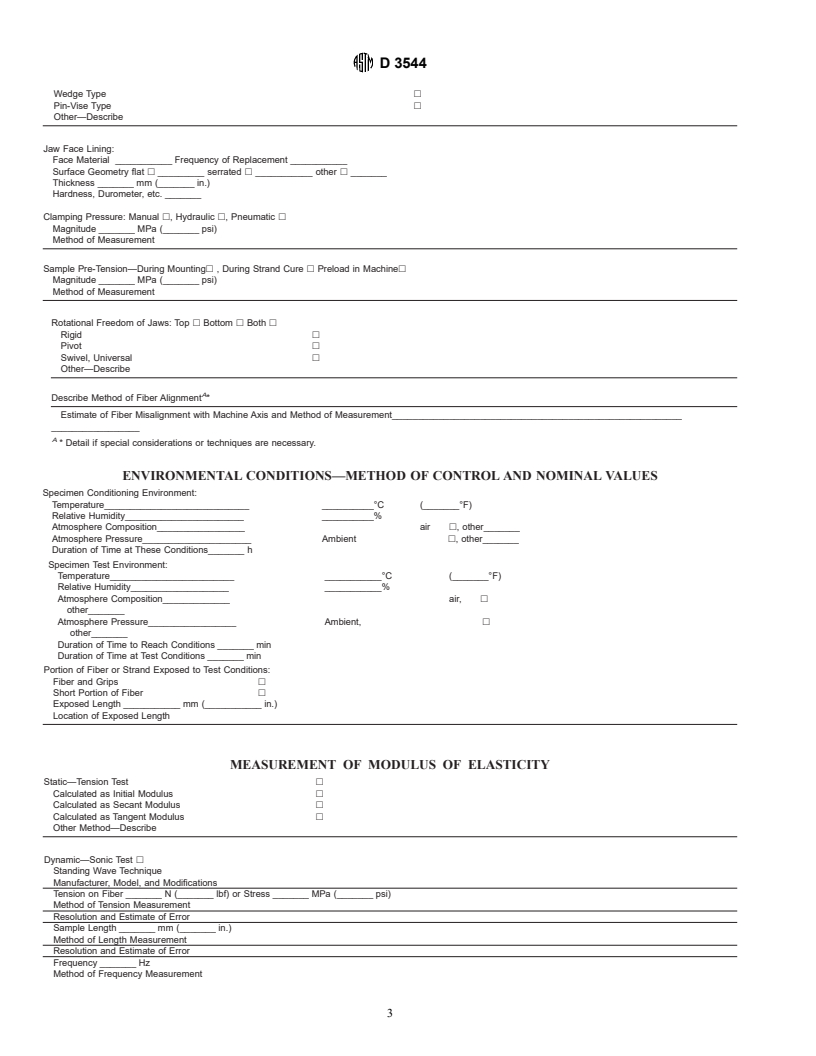

D 3544

Wedge Type h

Pin-Vise Type h

Other—Describe

Jaw Face Lining:

Face Material ___________ Frequency of Replacement ___________

Surface Geometry flat h _________ serrated h ___________ other h _______

Thickness _______ mm (_______ in.)

Hardness, Durometer, etc. _______

Clamping Pressure: Manual h, Hydraulic h, Pneumatic h

Magnitude _______ MPa (_______ psi)

Method of Measurement

Sample Pre-Tension—During Mountingh , During Strand Cure h Preload in Machineh

Magnitude _______ MPa (_______ psi)

Method of Measurement

Rotational Freedom of Jaws: Top h Bottom h Both h

Rigid h

Pivot h

Swivel, Universal h

Other—Describe

A

Describe Method of Fiber Alignment *

Estimate of Fiber Misalignment with Machine Axis and Method of Measurement________________________________________________________

_________________

A

* Detail if special considerations or techniques are necessary.

ENVIRONMENTAL CONDITIONS—METHOD OF CONTROL AND NOMINAL VALUES

Specimen Conditioning Environment:

Temperature____________________________ __________°C (_______°F)

Relative Humidity_______________________ __________%

Atmosphere Composition_________________ air h, other_______

Atmosphere Pressure_____________________ Ambient h, other_______

Duration of Time at These Conditions_______ h

Specimen Test Environment:

Temperature________________________ ___________°C (_______°F)

Relative Humidity___________________ ___________%

Atmosphere Composition_____________ air, h

other_______

Atmosphere Pressure_________________ Ambient, h

other_______

Duration of Time to Reach Conditions _______ min

Duration of Time at Test Conditions _______ min

Portion of Fiber or Strand Exposed to Test Conditions:

Fiber and Grips h

Short Portion of Fiber h

Exposed Length ___________ mm (___________ in.)

Location of Exposed Length

MEASUREMENT OF MODULUS OF ELASTICITY

Static—Tension Test h

Calculated as Initial Modulus h

Calculated as Secant Modulus h

Calculated as Tangent Modulus h

Other Method—Describe

Dynamic—Sonic Test h

Standing Wave Technique

Manufacturer, Model, and Modifications

Tension on Fiber _______ N (_______ lbf) or Stress _______ MPa (_______ psi)

Method of Tension Measurement

Resolution and Estimate of Error

Sample Length _______ mm (_______ in.)

Method of Length Measurement

Resolution and Estimate of Error

Frequency _______

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.