ASTM B88-03

(Specification)Standard Specification for Seamless Copper Water Tube

Standard Specification for Seamless Copper Water Tube

ABSTRACT

This specification covers seamless copper alloy water tubes for general plumbing and similar applications in fluid conveyance. These water tubes made from UNS C10200, C12000, and C12200 copper alloys are commonly used with solder, flared, or compression-type fittings. The materials should be cold-drawn to size and the tubes finished by cold working and annealing to produce the required temper and surface finish. When tubes are furnished in coils, annealing is done after coiling, while those furnished in straight lengths should be in the drawn temper.

SCOPE

1.1 This specification covers seamless copper water tube suitable for general plumbing, similar applications for the conveyance of fluids, and commonly used with solder, flared, or compression-type fittings. The type of copper water tube suitable for any particular application is determined by the internal or external fluid pressure, by the installation and service conditions, and by local requirements. Means of joining or bending are also factors which affect the selection of the type of tube to be used.

Note 1—Annealed tube is suitable for use with flared or compression fittings, and with solder-type fittings, provided rounding and sizing of the tube ends is performed where needed.

Note 2—Drawn temper tube is suitable for use with solder-type fittings. Types K and L tube, in the drawn temper, are suitable for use with certain types and sizes of compression fittings.

Note 3—A complete metric companion to Specification B 88 has been developed-B 88M; therefore, no metric equivalents are presented in this specification.

Note 4—Fittings used for soldered or brazed connections in plumbing systems are described in ASME B16.18 and ASME B16.22.

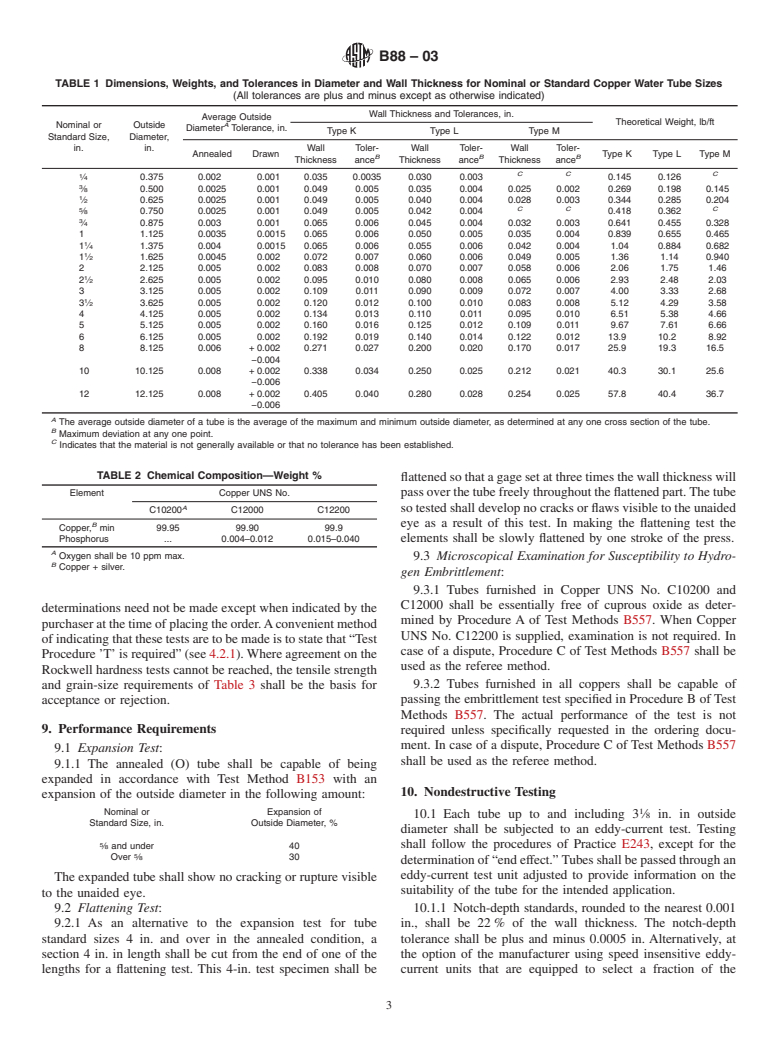

1.2 The tube shall be produced from the following coppers, and the manufacturer has the option to supply any one of them, unless otherwise specified.Copper UNS No. Previously Used DesignationDescriptionC10200OFOxygen free without residual deoxidantsC12000DLPPhosphorus deoxidized, low residual phosphorusC12200DHPPhosphorus deoxidized, high residual phosphorus

1.3 The assembly of copper plumbing or fire sprinkler systems by soldering is described in Practice B 828.

1.4 Solders for joining copper potable water or fire sprinkler systems are covered by Specification B 32. The requirements for acceptable fluxes for these systems are covered by Specification B 813.

1.5 The following safety hazards caveat pertains only to the test methods portion, Section , of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B88 – 03

Standard Specification for

1

Seamless Copper Water Tube

This standard is issued under the fixed designation B88; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 1.4 Soldersforjoiningcopperpotablewaterorfiresprinkler

systems are covered by Specification B32. The requirements

1.1 This specification covers seamless copper water tube

for acceptable fluxes for these systems are covered by Speci-

suitable for general plumbing, similar applications for the

fication B813.

conveyance of fluids, and commonly used with solder, flared,

1.5 The following safety hazards caveat pertains only to the

or compression-type fittings. The type of copper water tube

test methods portion, Section 15, of this specification: This

suitable for any particular application is determined by the

standard does not purport to address all of the safety concerns,

internal or external fluid pressure, by the installation and

if any, associated with its use. It is the responsibility of the user

serviceconditions,andbylocalrequirements.Meansofjoining

of this standard to establish appropriate safety and health

or bending are also factors which affect the selection of the

2 practices and determine the applicability of regulatory limita-

type of tube to be used.

tions prior to use.

NOTE 1—Annealed tube is suitable for use with flared or compression

fittings, and with solder-type fittings, provided rounding and sizing of the

2. Referenced Documents

tube ends is performed where needed.

2.1 The following documents of the issue in effect on date

NOTE 2—Drawn temper tube is suitable for use with solder-type

of material purchase form a part of this specification to the

fittings.Types K and Ltube, in the drawn temper, are suitable for use with

extent referenced herein:

certain types and sizes of compression fittings.

3

NOTE 3—A complete metric companion to Specification B88 has been 2.2 ASTM Standards:

developed—B88M; therefore, no metric equivalents are presented in this

B32 Specification for Solder Metal

specification.

B88M Specification for Seamless CopperWaterTube (Met-

NOTE 4—Fittings used for soldered or brazed connections in plumbing

ric)

systems are described in ASME B16.18 and ASME B16.22.

B153 Test Method for Expansion (Pin Test) of Copper and

1.2 The tube shall be produced from the following coppers,

Copper-Alloy Pipe and Tubing

and the manufacturer has the option to supply any one of them,

B557 Test Methods for Tension Testing Wrought and Cast

unless otherwise specified.

Aluminum- and Magnesium-Alloy Products

Copper Previously Used Description

B601 Classification for Temper Designations for Copper

UNS No. Designation

and Copper Alloys—Wrought and Cast

C10200 OF Oxygen free without B813 Specification for Liquid and Paste Fluxes for Solder-

residual deoxidants

ing of Copper and Copper Alloy Tube

C12000 DLP Phosphorus deoxidized,

B828 Practice for Making Capillary Joints by Soldering of

low residual phosphorus

Copper and Copper Alloy Tube and Fittings

C12200 DHP Phosphorus deoxidized,

high residual phosphorus

E2 Discontinued 1983; Methods of Preparation of Micro-

graphs of Metals and Alloys (Including Recommended

1.3 The assembly of copper plumbing or fire sprinkler

Practice for Photography As Applied to Metallography);

systems by soldering is described in Practice B828.

4

Replaced by E 883

E3 Guide for Preparation of Metallographic Specimens

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

E8 Test Methods for Tension Testing of Metallic Materials

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

and Tube.

Current edition approved Oct. 1, 2003. Published November 2003. Originally

3

approved in 1932. Last previous edition approved in 2002 as B88 – 02. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/B0088-03. contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

2

The UNS system for copper and copper alloys (see Practice E527) is a simple Standards volume information, refer to the standard’s Document Summary page on

expansion of the former standard designation system accomplished by the addition the ASTM website.

4

Withdrawn. The last approved version of this historical standard is referenced

of a prefix “C” and a suffix “00.”The suffix is permitted to be used to accommodate

on www.astm.org.

composition variations of the base alloy.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO B

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B88–02 Designation: B 88 – 03

Standard Specification for

1

Seamless Copper Water Tube

ThisstandardisissuedunderthefixeddesignationB 88;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

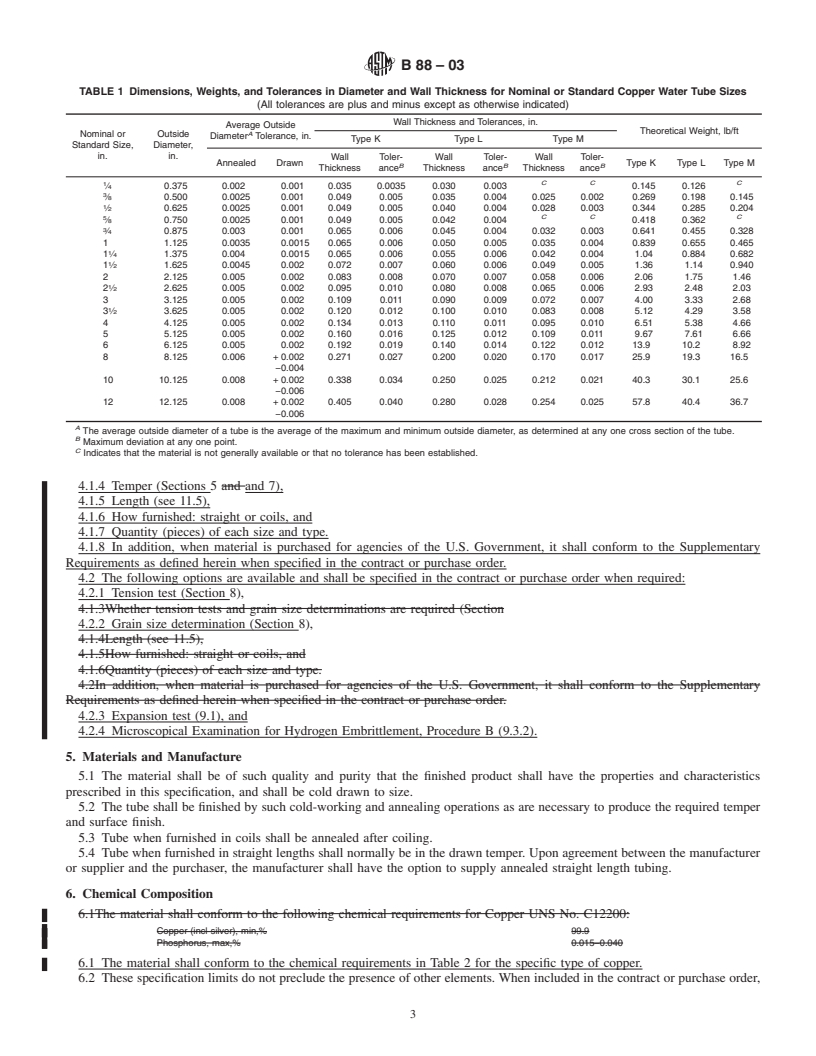

1.1 This specification covers Copper UNS No. C12200 seamless copper water tube suitable for general plumbing, similar

applications for the conveyance of fluids, and commonly used with solder, flared, or compression-type fittings. The type of copper

water tube suitable for any particular application is determined by the internal or external fluid pressure, by the installation and

service conditions, and by local requirements. Means of joining or bending are also factors which affect the selection of the type

2

of tube to be used.

NOTE 1—Annealed tube is suitable for use with flared or compression fittings, and with solder-type fittings, provided rounding and sizing of the tube

ends is performed where needed.

NOTE 2—Drawn temper tube is suitable for use with solder-type fittings. Types K and L tube, in the drawn temper, are suitable for use with certain

types and sizes of compression fittings.

NOTE 3—A complete metric companion to Specification B 88 has been developed—B 88M; therefore, no metric equivalents are presented in this

specification.

NOTE 4—Fittings used for soldered or brazed connections in plumbing systems are described in ASME B16.18 and ASME B16.22.

1.2The assembly of copper plumbing or fire sprinkler systems by soldering is described in Practice B828

1.2 The tube shall be produced from the following coppers, and the manufacturer has the option to supply any one of them,

unless otherwise specified.

Copper Previously Used Description

UNS No. Designation

C10200 OF Oxygen free without

residual deoxidants

C12000 DLP Phosphorus deoxidized,

low residual phosphorus

C12200 DHP Phosphorus deoxidized,

high residual phosphorus

1.3 The assembly of copper plumbing or fire sprinkler systems by soldering is described in Practice B 828.

1.34 Solders for joining copper potable water or fire sprinkler systems are covered by Specification B 32. The requirements for

acceptable fluxes for these systems are covered by Specification B 813.

1.4

1.5 Thefollowingsafetyhazardscaveatpertainsonlytothetestmethodsportion,Section15,ofthisspecification:This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

3

2.2 ASTM Standards:

B32 Specification for Solder Metal

1

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

´1

Current edition approved Oct. 10, 2002. Published November 2002. Originally published as B88–32T. Last previous edition B88–99 .

Current edition approved Oct. 1, 2003. Published November 2003. Originally approved in 1932. Last previous edition approved in 2002 as B 88 – 02.

2

The UNS system for copper and copper alloys (see Practice E 527) is a simple expansion of the former standard designation system accomplished by the addition of

a prefix “C” and a suffix “00.” The suffix is permitted to be used to accommodate composition variations of the base alloy.

3

Annual Book of ASTM Standards, Vol 02.04.

3

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B88–03

B 88M Specification for Seamless Copper Water Tube [Metric]

4

B 153 Test Method for Expansion (Pin Test) of Copper and Copper-Alloy Pipe and Tubing Test Method for Expansion (Pin

Test) of Copper and Copper-Alloy Pipe and Tubing

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.