ASTM D7843-12

(Test Method)Standard Test Method for Measurement of Lubricant Generated Insoluble Color Bodies in In-Service Turbine Oils using Membrane Patch Colorimetry

Standard Test Method for Measurement of Lubricant Generated Insoluble Color Bodies in In-Service Turbine Oils using Membrane Patch Colorimetry

SIGNIFICANCE AND USE

5.1 This test can be a guide to end-users on the formation of lubricant-generated, insoluble deposits.

5.2 The results from this test are intended to be used as a condition monitoring trending tool as part of a comprehensive program, as outlined in standards such as Practice D4378.

SCOPE

1.1 This test method extracts insoluble contaminants from a sample of in-service turbine oil onto a patch and the color of the membrane patch is analyzed by a spectrophotometer. The results are reported as a ΔE value, within the CIE LAB scale.

1.2 This test method is not appropriate for turbine oils with dyes.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7843 − 12

StandardTest Method for

Measurement of Lubricant Generated Insoluble Color

Bodies in In-Service Turbine Oils using Membrane Patch

Colorimetry

This standard is issued under the fixed designation D7843; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 CIELAB color scales, n—CIE 1976 L*, a*, b*

opponent-color scales, in which a* is positive in the red

1.1 This test method extracts insoluble contaminants from a

direction and negative in the green direction; b* is positive in

sample of in-service turbine oil onto a patch and the color of

the yellow direction and negative in the blue direction; and L*

the membrane patch is analyzed by a spectrophotometer. The

is positive in the lightness direction and negative in the

results are reported as a∆E value, within the CIE LAB scale.

darkness direction. E308

1.2 This test method is not appropriate for turbine oils with

3.1.2 colorimetry, n—the science of color measurement.

dyes.

E284

1.3 This standard does not purport to address all of the

3.1.3 in-service oil, n—lubricating oil that is present in a

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- machine that has been at operating temperature for at least one

priate safety and health practices and determine the applica- hour(forexample,anengine,gearbox,transformer,orturbine).

bility of regulatory limitations prior to use.

3.1.4 membrane color, n—a visual rating of particulate on a

filter membrane against ASTM Color Standards.

2. Referenced Documents

3.1.5 membrane filter, n—a porous article of closely con-

2.1 ASTM Standards:

trolled pore size through which a liquid is passed to separate

D4057 Practice for Manual Sampling of Petroleum and

matter in suspension.

Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and

3.2 Definitions of Terms Specific to This Standard:

Petroleum Products

3.2.1 varnish, n—a thin, hard, lustrous, oil-insoluble

D4378 Practice for In-Service Monitoring of Mineral Tur-

deposit, composed primarily of organic residue, and most

bine Oils for Steam, Gas, and Combined Cycle Turbines

readily definable by color intensity. It is not easily removed by

E177 Practice for Use of the Terms Precision and Bias in

wiping with a clean, dry, soft, lint-free wiping material and is

ASTM Test Methods

resistant to saturated solvents. Its color may vary, but it usually

E284 Terminology of Appearance

appears in gray, brown, or amber hues.

E308 PracticeforComputingtheColorsofObjectsbyUsing

the CIE System

4. Summary of Test Method

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

4.1 Insoluble deposits are extracted from an in-service

turbine oil sample using a 47 mm, 0.45-micron membrane

3. Terminology

nitro-cellulose patch. The color of the patch is then analyzed

3.1 Definitions: using a spectrophotometer and the results are reported as a∆E

value in the CIE LAB scale.

This test method is under the jurisdiction of ASTM Committee D02 on

5. Significance and Use

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.C0.01 on Turbine Oil Monitoring, Problems and Systems.

5.1 This test can be a guide to end-users on the formation of

Current edition approved Dec. 1, 2012. Published January 2013. DOI: 10.1520/

lubricant-generated, insoluble deposits.

D7843-12.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2 The results from this test are intended to be used as a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

condition monitoring trending tool as part of a comprehensive

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. program, as outlined in standards such as Practice D4378.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

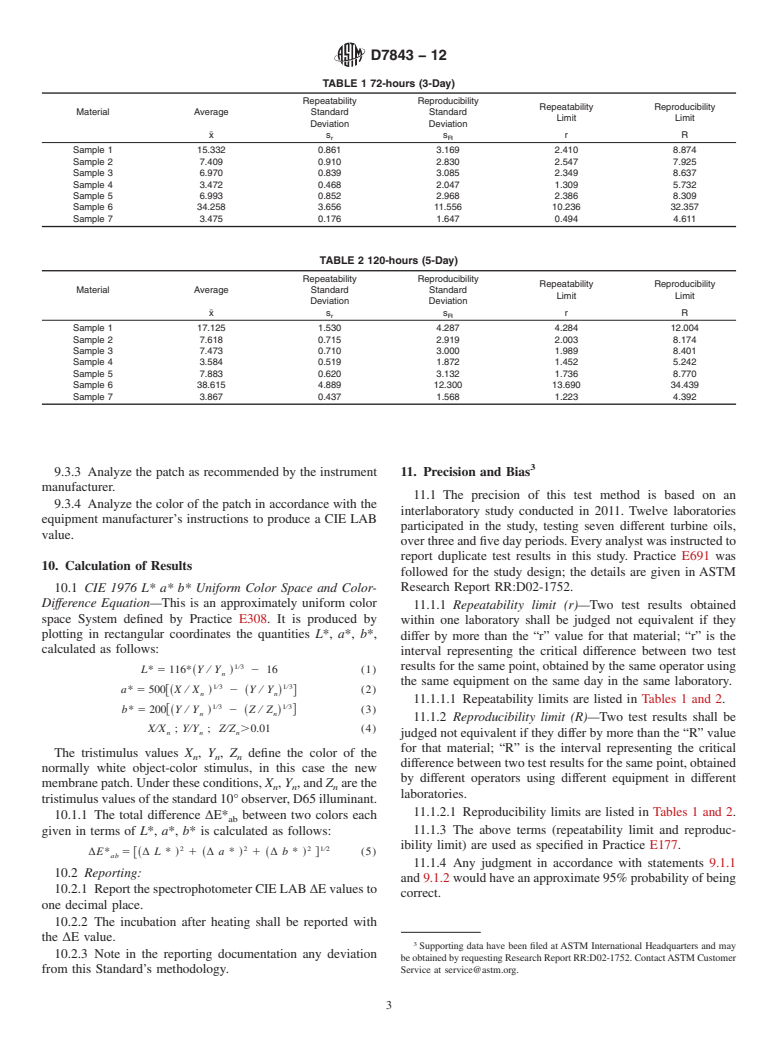

D7843 − 12

NOTE 1—Samples can be analyzed in longer or shorter intervals with

6. Apparatus

agreement of the end-user. The level of deposit and as a consequence, the

6.1 Variations of apparatus, particularly with respect to filter

test results may be affected by time duration chosen. It is sometimes

membranes and vacuum pump setting, can affect the test

suggested to additionally analyze the sample at multiple incubation

periods to fully understand the operating system.

results significantly.

6.2 When the user of this test method uses an alternate

9. Procedure

membrane filter, it is incumbent upon them to establish that the

9.1 Preparation of Sample and Materials:

alternate filter will give equal results.

9.1.1 Document the date and time at the beginning of the

6.3 Required Apparatus:

test.

6.3.1 Membrane Filter, 47 mm nitro-cellulose, 0.45-µm.

9.1.2 Vigorously mix the sample for 15 s minimum to

6.3.2 Forceps, smooth-tip.

resuspend insolubles uniformly. Visually inspect the inside of

6.3.3 Borosilicate Filter Holder.

thebottleforevidenceofmaterialadherenttothesurfaceofthe

6.3.4 Borosilicate Filtering Flask.

bottle before sampling.

6.3.5 Wash Bottle equipped with 0.22 micron membranes.

6.3.6 Vacuum Source, capable of maintaining a vacuum of

NOTE 2—If adherent material cannot be removed from bottle after

repeated attempts to vigorously mix, include as comment in the reporting

71 kPa 6 5 kPa.

documentation.

6.3.7 Graduated cylinder, 150–200 mL.

9.1.3 Transfer50mL 61mLofsampleintocleanbeakeror

6.3.8 Beaker, 100–250 mL.

6.3.9 Petri dish. Erlenmeyer flask.

6.3.10 Spectrophotometer, with capabilities of analyzing a 9.1.4 Add approximately 50 mL 6 1 mLof petroleum ether

standard 15 mm target with a 0°/45° measuring geometry, 10° to beaker containing sample.

observer, 10 nm spectral intervals minimum resolution, the 9.1.5 Stir sample for approximately 30 s to ensure that a

visible spectral range of 400–700 nm and CIELAB measuring

complete solution (and complete mixing) is attained.

indices.

9.1.6 Pour sample into filter funnel within 1–2 minutes of

initial mixing.

7. Reagents and Materials

9.2 Filtration Process:

7.1 Petroleum Spirit (also known as petroleum ether or IP

9.2.1 Using forceps, mount the filter on the center of the

Petroleum Spirit 40/60) (Warning—Extremely flammable.

filter holder.

Harmful if inhaled. Vapors are easily ignited by electrostatic

9.2.2 Mountandsecurelyclampthefilterfunneltothefilter.

discharges, causing flash fire.), having boiling range from 35 to

9.2.3 Apply a vacuum and ensure a vacuum of less than 76

60°C.

kPa is attained and held.

7.2 Coleman Camp Fuel—Coleman Fuel is a complex

9.2.4 Rinse the beaker twice with a minimum of 35 mL of

mixture of light hydrocarbons (primarily aliphatic) produced

petroleum ether and pour the rinsing into the filter funnel.

by distillation of petroleum. Carbon number range is C5 to C9,

9.2.5 Permit the filtrate to completely flow through.

and contains less than 0.001% benzene.

9.2.6 Carefully, remove the clamp and funnel. Wash any

7.3 Purity of Reagents—Reagent grade chemicals shall be

adhering insolubles from the funnel onto the membrane with

used in all tests. Unless otherwise indicated, it is intended that petroleum ether. Wash the membrane gently, particularly the

all reagents conform to the specifications of the Committee of

edges, with petroleum ether from the wash bottle.

Analytical Reagents of the American Chemical Society where

NOTE 3—If any of the deposits fails to remain on (or falls off) the dry

such specifications are available. Other grades may be used,

membrane the test must be repeated.

provided it is first ascertained that the reagent is of sufficiently

9.2.7 Carefully release the vacuum.

high purity to permit its use without lessening the accuracy of

9.2.8 Remove the clamp and filter holder.

the determination.

9.2.9 Using forceps carefully remove the filter from the

8. Sampling, Test Specimens, and Test Units

filter holder and place into a clean dry petri-dish. To facilitate

handling, the membrane filters might be rested on clean glass

8.1 Using either Practice D4057 (manual sampling) or

rods in the petri-dish.

Practice D4177 (automatic sam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.