ASTM C1639-10

(Specification)Standard Specification for Fabrication of Cellular Glass Pipe and Tubing Insulation

Standard Specification for Fabrication of Cellular Glass Pipe and Tubing Insulation

ABSTRACT

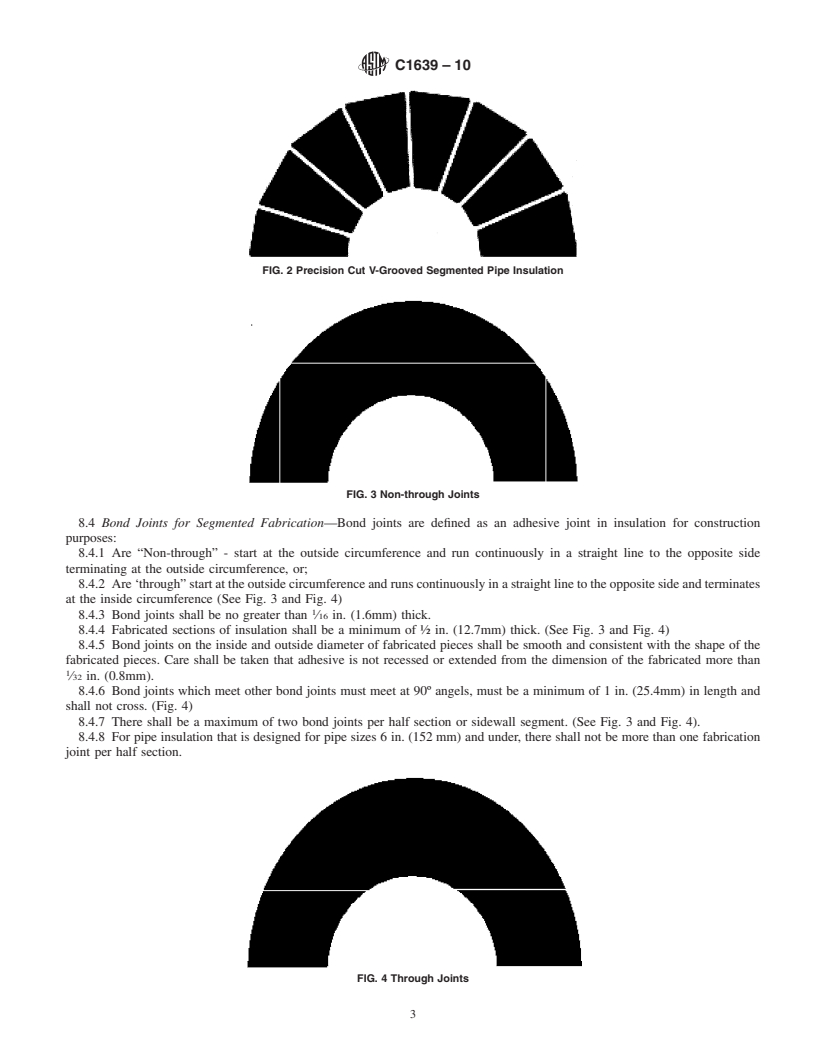

This specification covers fabrication techniques for cellular glass block into billets to fabricate pipe and tubing insulation. The optimization of the thermal performance of installed cellular glass insulation systems is discussed. This is best achieved by limiting the number of joints, in particular through joints. Cellular glass pipe and tubing insulation shall be fabricated from the minimum number of insulation blocks. Sectional pipe insulation shall contain not more than four through joints per full section of insulation, excluding the half section mating plane. Fabrication adhesive shall be hot asphalt, Type II operating at some temperature. For operating temperatures above ambient, fabrication adhesive shall include but not be limited to Type II hot asphalt, elastomeric asphalt, or gypsum-based cement of the type and grade specified. Fabricating adhesive shall be applied such that there is 100% coverage of adhesive on the mating surfaces. Billet and miter construction shall conform to the following: insulation blocks or sections shall be hand rubbed if necessary to fit prior to bonding and bond joints shall be made with a full depth of approved adhesive. Bond joints can be classified as “non-through“ joints which start at the outside circumference and run continuously in a straight line to the opposite side terminating at the outside circumference. “Through” joints start at the outside circumference and runs continuously in a straight line to the opposite side and terminates at the inside circumference. All segmented pipe insulation shall be edge trimmed at the fabrication site. Either a grinder or a saw shall be used to edge trim segmented pipe insulation. If segmented pipe insulation is edge trimmed using a saw blade, edges shall be rubbed to remove uneven patterns caused by flexing blade where needed. Fittings for all sizes shall be either factory ground or factory mitered.

SCOPE

1.1 This specification covers fabrication techniques for cellular glass block into billets to fabricate pipe and tubing insulation. All materials shall be in accordance with Specification C552.

1.2 The purpose of this specification is to optimize the thermal performance of installed cellular glass insulation systems. This is best achieved by limiting the number of joints, in particular through joints.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1639 – 10

Standard Specification for

1

Fabrication Of Cellular Glass Pipe And Tubing Insulation

This standard is issued under the fixed designation C1639; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ADJC0450A ASTMRecommendedDimensionalStandards

for Fabrication of Thermal Insulation Fitting Covers

1.1 This specification covers fabrication techniques for

cellular glass block into billets to fabricate pipe and tubing

3. Terminology

insulation. All materials shall be in accordance with Specifi-

3.1 Terminology C168 shall be considered as applying to

cation C552.

the terms in this specification.

1.2 The purpose of this specification is to optimize the

3.2 Definitions of Terms Specific to This Standard:

thermal performance of installed cellular glass insulation

3.3 billet / bun—a single piece of insulation made up from

systems.Thisisbestachievedbylimitingthenumberofjoints,

a number of smaller blocks held together with an adhesive.

in particular through joints.

3.4 lags—pieces of insulation typically curved or tapered

1.3 The values stated in inch-pound units are to be regarded

used for insulating pipes, tanks and other cylindrical equip-

as standard. The values given in parentheses are mathematical

ment.

conversions to SI units that are provided for information only

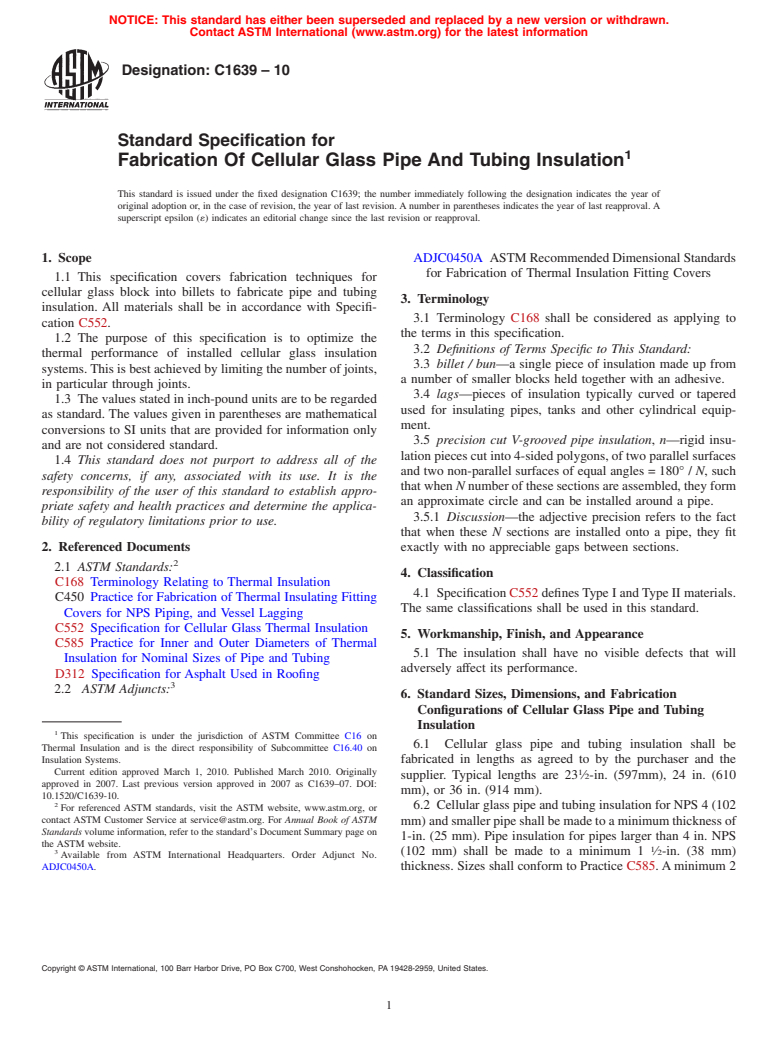

3.5 precision cut V-grooved pipe insulation, n—rigid insu-

and are not considered standard.

lationpiecescutinto4-sidedpolygons,oftwoparallelsurfaces

1.4 This standard does not purport to address all of the

and two non-parallel surfaces of equal angles = 180° / N, such

safety concerns, if any, associated with its use. It is the

thatwhen Nnumberofthesesectionsareassembled,theyform

responsibility of the user of this standard to establish appro-

an approximate circle and can be installed around a pipe.

priate safety and health practices and determine the applica-

3.5.1 Discussion—the adjective precision refers to the fact

bility of regulatory limitations prior to use.

that when these N sections are installed onto a pipe, they fit

2. Referenced Documents exactly with no appreciable gaps between sections.

2

2.1 ASTM Standards:

4. Classification

C168 Terminology Relating to Thermal Insulation

4.1 SpecificationC552definesTypeIandTypeIImaterials.

C450 Practice for Fabrication of Thermal Insulating Fitting

The same classifications shall be used in this standard.

Covers for NPS Piping, and Vessel Lagging

C552 Specification for Cellular Glass Thermal Insulation

5. Workmanship, Finish, and Appearance

C585 Practice for Inner and Outer Diameters of Thermal

5.1 The insulation shall have no visible defects that will

Insulation for Nominal Sizes of Pipe and Tubing

adversely affect its performance.

D312 Specification for Asphalt Used in Roofing

3

2.2 ASTM Adjuncts:

6. Standard Sizes, Dimensions, and Fabrication

Configurations of Cellular Glass Pipe and Tubing

Insulation

1

This specification is under the jurisdiction of ASTM Committee C16 on

6.1 Cellular glass pipe and tubing insulation shall be

Thermal Insulation and is the direct responsibility of Subcommittee C16.40 on

Insulation Systems.

fabricated in lengths as agreed to by the purchaser and the

Current edition approved March 1, 2010. Published March 2010. Originally

1

supplier. Typical lengths are 23 ⁄2-in. (597mm), 24 in. (610

approved in 2007. Last previous version approved in 2007 as C1639–07. DOI:

mm), or 36 in. (914 mm).

10.1520/C1639-10.

2

6.2 CellularglasspipeandtubinginsulationforNPS4(102

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

mm)andsmallerpipeshallbemadetoaminimumthicknessof

Standards volume information, refer to the standard’s Document Summary page on

1-in. (25 mm). Pipe insulation for pipes larger than 4 in. NPS

the ASTM website.

1

3

(102 mm) shall be made to a minimum 1 ⁄2-in. (38 mm)

Available from ASTM International Headquarters. Order Adjunct No.

ADJC0450A. thickness. Sizes shall conform to Practice C585.Aminimum 2

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1639 – 10

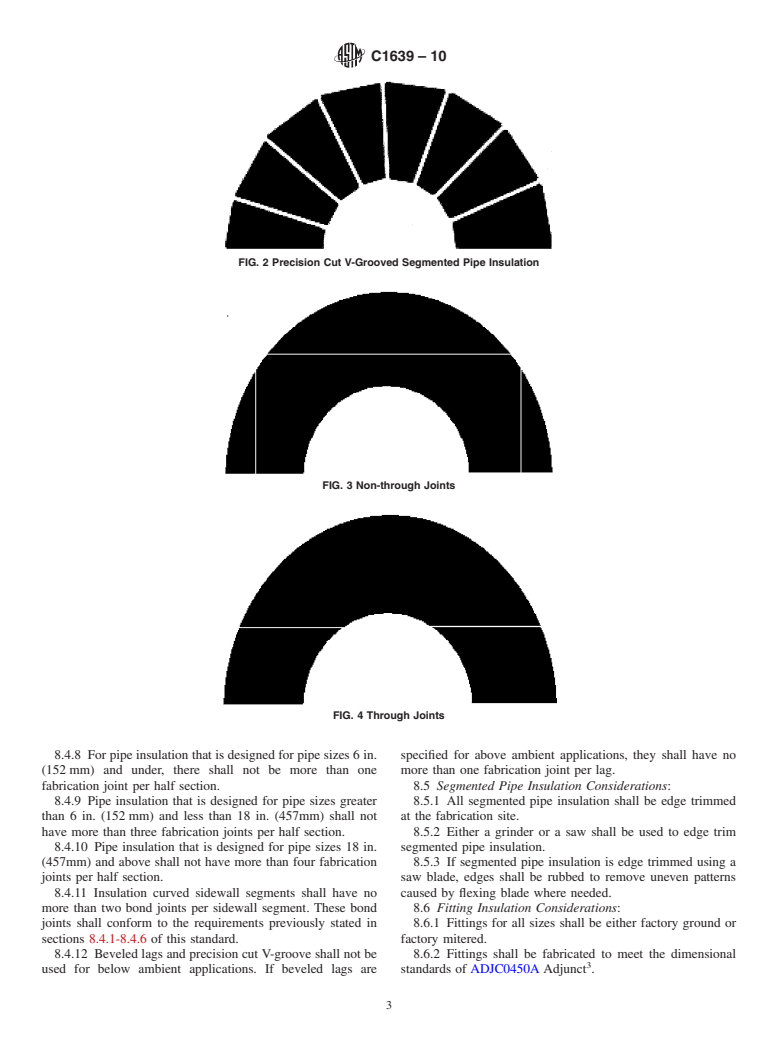

in. (51 mm) thickness should be used for pipe sizes larger than tional pipe insulation shall contain not more than four

12 in. NPS (324 mm). 9through9 joints per full section of insulation, excluding the

6.3 Cellular glass pipe insulation must be provided in half half section mating plane (Fig. 3). Precision cut v-groove

sections for up to and including 12 in. NPS (324 mm). Half fabr

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1639–07 Designation: C1639 – 10

Standard Specification for

1

Fabrication Of Cellular Glass Pipe And Tubing Insulation

This standard is issued under the fixed designation C1639; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers fabrication techniques for cellular glass block into billets to fabricate pipe and tubing insulation.

All materials shall be in accordance with Specification C552.

1.2 The purpose of this specification is to optimize the thermal performance of installed cellular glass insulation systems. This

is best achieved by limiting the number of joints, in particular through joints.

1.3The values stated in inch-pound units are to be regarded as the standard. The values given in the parentheses are provided

for information only.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C168 Terminology Relating to Thermal Insulation C450

C450 Practice for Fabrication of Thermal Insulating Fitting Covers for NPS Piping, and Vessel Lagging

C552 Specification for Cellular Glass Thermal Insulation

C585 Practice for Inner and Outer Diameters of Thermal Insulation for Nominal Sizes of Pipe and Tubing

D312 Specification for Asphalt Used in Roofing

3

2.2 ASTM Adjuncts:

ADJC0450A ASTM Recommended Dimensional Standards for Fabrication of Thermal Insulation Fitting Covers

3. Terminology

3.1 Terminology C168 shall be considered as applying to the terms in this specification.

3.2 Definitions of Terms Specific to This Standard:

3.3 billet / bun—a single piece of insulation made up from a number of smaller blocks held together with an adhesive.

3.4 lags—pieces of insulation typically curved or tapered used for insulating pipes, tanks and other cylindrical equipment.

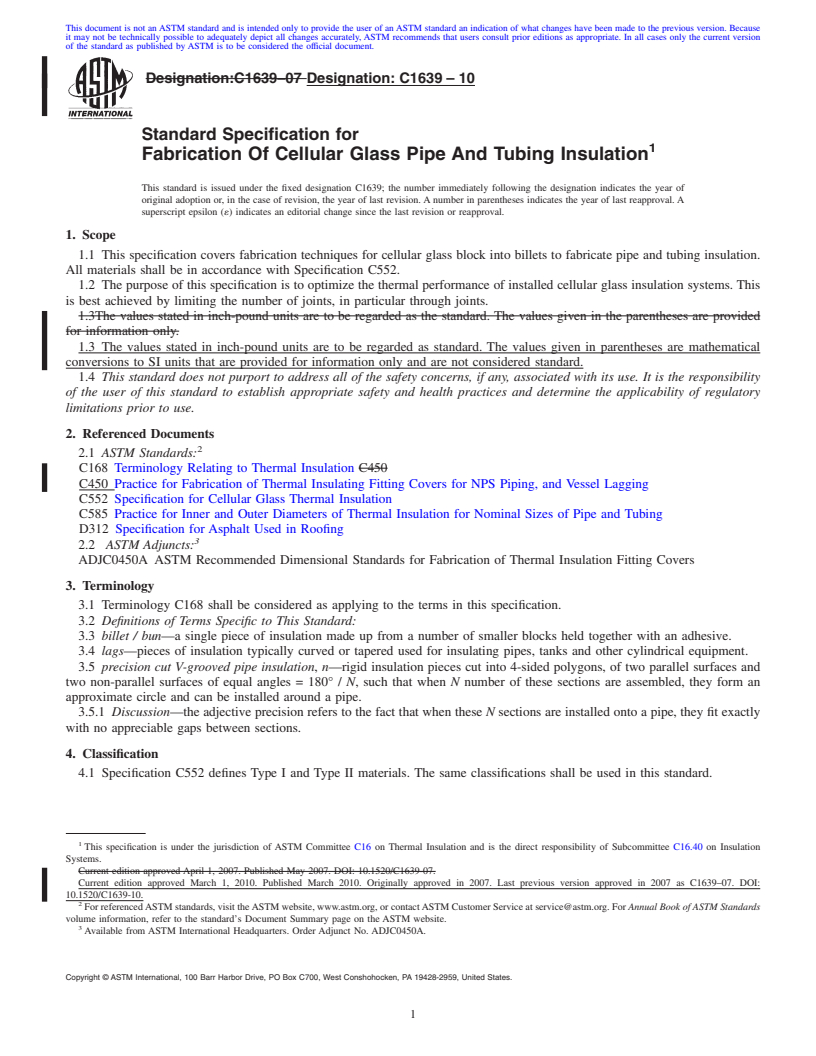

3.5 precision cut V-grooved pipe insulation, n—rigid insulation pieces cut into 4-sided polygons, of two parallel surfaces and

two non-parallel surfaces of equal angles = 180° / N, such that when N number of these sections are assembled, they form an

approximate circle and can be installed around a pipe.

3.5.1 Discussion—the adjective precision refers to the fact that when these N sections are installed onto a pipe, they fit exactly

with no appreciable gaps between sections.

4. Classification

4.1 Specification C552 defines Type I and Type II materials. The same classifications shall be used in this standard.

1

This specification is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.40 on Insulation

Systems.

Current edition approved April 1, 2007. Published May 2007. DOI: 10.1520/C1639-07.

Current edition approved March 1, 2010. Published March 2010. Originally approved in 2007. Last previous version approved in 2007 as C1639–07. DOI:

10.1520/C1639-10.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from ASTM International Headquarters. Order Adjunct No. ADJC0450A.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1639 – 10

5. Workmanship, Finish, and Appearance

5.1 The insulation shall have no visible defects that will adversely affect its performance.

6. Standard Sizes, Dimensions, and Fabrication Configurations of Cellular Glass Pipe and Tubing Insulation

6.1 Cellularglasspipeandtubinginsulationshallbefabricatedinlengthsasagreedtobythepurchaserandthesupplier.Typical

1

lengths are 23 ⁄2-in. (597mm), 24 in. (610 mm), or 36 in. (914 mm).

6.2 Cellular glass pipe and tubing insulation for NPS 4 (102 mm) and smaller pipe shall be made to a minimum thickness of

1

1-in. (25 mm).

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.