ASTM D6186-98

(Test Method)Standard Test Method for Oxidation Induction Time of Lubricating Oils by Pressure Differential Scanning Calorimetry (PDSC)

Standard Test Method for Oxidation Induction Time of Lubricating Oils by Pressure Differential Scanning Calorimetry (PDSC)

SCOPE

1.1 This test method covers the determination of oxidation induction time of lubricating oils subjected to oxygen at 3.5 Mpa (500 psig) and temperatures between 130 and 210 degrees celcius.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6186 – 98

Standard Test Method for

Oxidation Induction Time of Lubricating Oils by Pressure

Differential Scanning Calorimetry (PDSC)

This standard is issued under the fixed designation D 6186; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope oxidation stability. This test method is faster than other oil

oxidation tests and requires a very small amount of sample. It

1.1 This test method covers the determination of oxidation

may be used for research and development, quality control, and

induction time of lubricating oils subjected to oxygen at 3.5

specification purposes. However, no correlation has been

MPa (500 psig) and temperatures between 130 and 210°C.

established between the results of this test method and service

1.2 The values stated in SI units are to be regarded as the

performance.

standard.

1.3 This standard does not purport to address all of the

5. Apparatus

safety concerns, if any, associated with its use. It is the

5.1 Pressure Differential Scanning Calorimeter (PDSC),

responsibility of the user of this standard to establish appro-

equipped with the following items:

priate safety and health practices and determine the applica-

5.1.1 Sample Enclosure, with capability to 3.5 60.2 MPa

bility of regulatory limitations prior to use.

(500 6 25 psig) at 210°C and pressure gage graduated

2. Terminology ainintervals of 200 KPa (28.6 psig) or less.

5.1.2 Thermal Analyzer.

2.1 Definitions of Terms Specific to This Standard:

5.1.3 Aluminum Solid Fat Index (SFI) Sample Pan—See

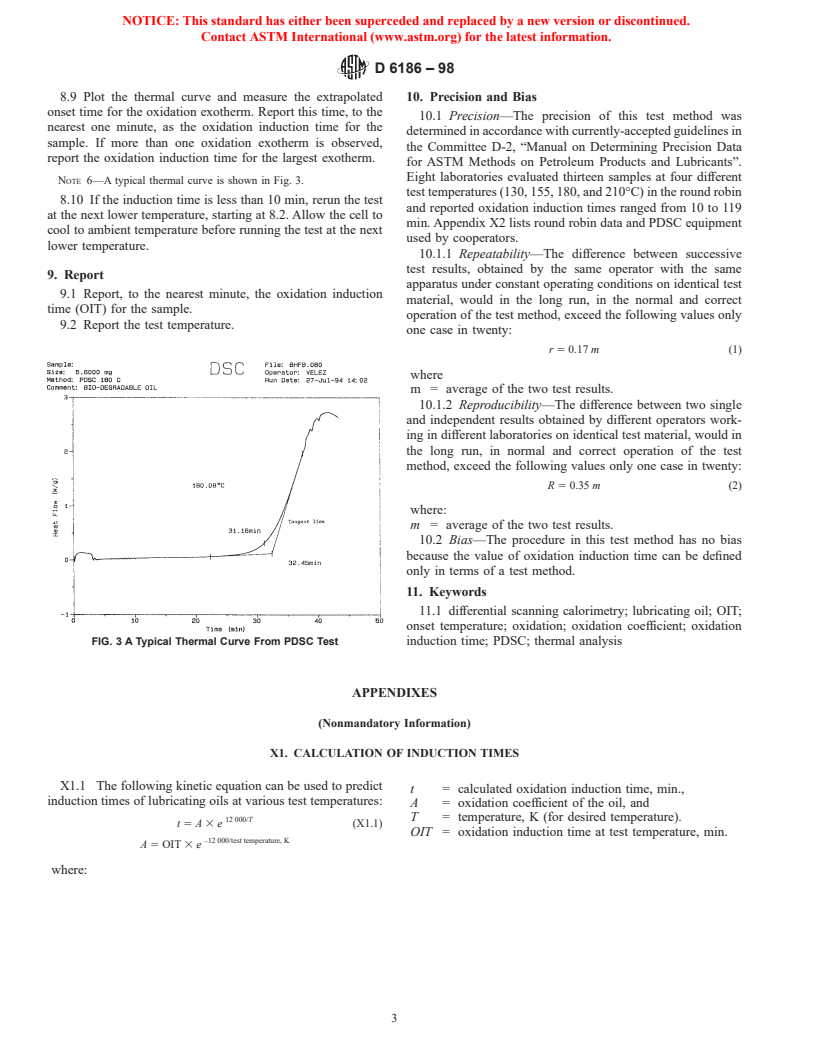

2.1.1 extrapolated onset time, n—a time determined on a

Note 1.

thermal curve, as the intersection of the extrapolated baseline

5.1.4 Oxidation Stability Software.

and a line tangent to the oxidation exotherm constructed at its

5.1.5 Calibration Software.

maximum rate.

5.1.6 Calibrated Flowmeter, with a capacity of at least 200

2.1.2 oxidation induction time, (OIT), n—a period of time

mL/min and graduated in intervals of 5 mL or less.

during which the oxidation rate accelerates from zero to a

5.1.7 Sample Encapsulation Press.

maximum and which corresponds to the extrapolated onset

time.

NOTE 1—It has been found that when oil samples are prepared with SFI

2.1.3 thermal curve, n—a graph of sample heat flow versus pans which have more consistent surface areas than standard flat bottom

pans, reproducibility is improved.

time.

NOTE 2—Stainless steel or copper tubing is compatible with oxygen.

NOTE 3—See Fig. 1 for a diagram of a typical test unit.

3. Summary of Test Method

3.1 A small quantity of oil is weighed into a sample pan and

6. Reagents and Materials

placed in a test cell. The cell is heated to a specified

6.1 Oxygen, a minimum purity of 99.5 % oxygen by vol-

temperature and then pressurized with oxygen. The cell is held

ume.

at a regulated temperature and pressure until an exothermic

reaction occurs. The extrapolated onset time is measured and NOTE 4—Warning: Oxidizer. Gas under pressure.

reported as the oxidation induction time for the lubricating oil

6.2 Indium, of not less than 99.9 % indium by mass.

at the specified test temperature.

7. Calibration

4. Significance and Use

7.1 Sample Temperature Calibration:

4.1 Oxidation induction time, as determined under the

7.1.1 Weigh approximately 10 mg of indium into an alumi-

conditions of this test method, may be used as an indication of

num sample pan, insert a lid and crimp the lid to the pan using

the encapsulation press. Place the crimped pan onto the sample

This test method is under the jurisdiction of ASTM Committee D-2 on

platform in the pressure cell. Seal an empty pan in the same

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.09 on Oxidation.

Current edition approved June 10, 1998. Published August 1998. Originally

Rhee, In-Sik, “Development of New Oxidation Stability Test Method for

published as D 6186–97. Last previous edition D 6186–97.

Lubricating Oils Using a Pressure Differential Scanning Calorimeter (PDSC),”

NLGI Spokesman, Vol 65, No. 3, June 2001, pp. 16–23.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D6186–98

conditions of this test method, 3.5 MPa (500 psig) of oxygen.

7.2 Temperature Controller Calibration:

7.2.1 Remove both the sample pan and the reference pan

from the cell, then close the cell. Slowly pressurize the cell

with 3.5 6 0.2 MPa (500 6 25 psig) oxygen and adjust the

purge rate to 100 6 10 mL/min using the cell outlet valve.

Select the desired test temperature (either 210, 180, 155, or

130°C).

7.2.2 Program the cell to maintain the selected test tempera-

ture. If, after 10 mins., the displayed cell temperature differs by

more than 6 0.2°C from the selected temperature, slowly

adjust the temperature controller until they agree. After making

FIG. 1 PDSC Test Unit

an adjustment, wait at least 5 mins. to make certain that the

temperature is stable before continuing. If the PDSC equip-

ment does not have this function, the control calibration shall

manner and place it on the reference platform. Set the cell

be followed according to the equipment manufacture’s recom-

cover in place and close the cell.

mendations.

7.1.2 Open the oxygen cylinder valve slightly and set a

7.3 Cell Base Pressure Gage Calibration—Conduct the

pressure of 3.5 6 0.2 MPa (500 6 25 psig) on the cell inlet line

calibration using a calibrated pressure transducer or a previ-

with the pressure regulator. Partially open the inlet valve on the

ously calibrated gage according to the pressure cell manufac-

cell and allow the pressure to slowly build up in the cell. This

turer’s instructions.

requires approximately 2 mins. Using the outlet valve, adjust

and maintain the oxygen purge rate through the flowmeter at

8. Procedure

100 6 10 mL/min.

8.1 Before starting a test, the control thermocouple calibra-

7.1.3 Set the thermal analyzer to heat from ambient tem-

tion shall be conducted at the test temperature (either 210, 180,

perature (approximately 22°C) to 180°C at a programmed rate

155, or 130°C) according to 7.2.1 and 7.2.2. When the test

of 10°C/min. After completion of the run measure the melting

temperature is not known, conduct the calibration at 210°C.

temperature of the indium. If the melting temperature differs

8.2 Weigh 3.0 6 0.2 mg of oil into a new sample pan.

from 157.4 6 0.2°C (see Note 5) correct the difference by

Spread the sample evenly upon the flat portion. Do not spill

using either the hardware or software calibration procedure

any of the sample into the trough portion of the pan. A flat

described in the manufacturer’s instruction manual. If the

bottom pan can be used if the sample is placed upon a 0.5 cm

hardware calibration procedure is used, perform the tempera-

diameter circle in the center of the pan.

ture correction under 3.5 MPa (500 psig) oxygen pressure with

8.3 Place the uncovered pan containing the sample onto the

a 100 mL/min purge rate. A typical melting calibration curve is

platform of the cell according to the PDSC manufacturer’s

shown in Fig. 2.

instructions for placing the sample pan. Place a new empty pan

NOTE 5—The melting temperature of indium is 156.6°C at atmospheric

of the same configuration onto the cell platform according to

pressure, but has been found to be elevated to 157.4°C under the

the PDSC manufacturer’s instructions for placing the reference

pan. Clo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.