SIST EN 50131-4:2019

(Main)Alarm systems - Intrusion and hold-up systems - Part 4: Warning devices

Alarm systems - Intrusion and hold-up systems - Part 4: Warning devices

This document includes requirements for warning devices used for notification in intrusion and hold up alarm systems installed in buildings. Four grades of warning device are described corresponding to each of the four security grades given in EN 50131-1. Requirements are also given for four environmental classes covering applications in indoor and outdoor locations as specified in EN 50130-5.

This document does not deal with requirements for compliance with EC regulatory Directives, such as the EMC Directive, Low Voltage Directive, etc. except that it specifies the equipment operating conditions for EMC susceptibility testing as required by EN 50130-4.

Alarmanlagen - Einbruch- und Überfallmeldeanlagen - Teil 4: Signalgeber

Dieses Dokument enthält Anforderungen an Signalgeber, die als Ausgabegeräte in Einbruch- und Überfallmeldeanlagen in Gebäuden verwendet werden. Die Anforderungen entsprechen vier Sicherheitsgraden, die in EN 50131-1 angegeben werden. Weiterhin werden Anforderungen an vier Umweltklassen gestellt, welche die Anwendungen im Innen- und Außenbereich, wie in EN 50130-5 spezifiziert, abdecken.

Dieses Dokument befasst sich nicht mit Anforderungen an die Einhaltung regulatorischer EG-Richtlinien, wie z. B. der EMV-Richtlinie, der Niederspannungsrichtlinie usw., ausgenommen, dass sie die Bedingungen für den Betrieb der Ausrüstung hinsichtlich der EMV-Störanfälligkeitsprüfung nach EN 50130-4 festlegt.

Systèmes d’alarme - Systèmes d’alarme contre l’intrusion et les hold-up - Partie 4: Dispositifs d’avertissement

Le présent document contient des exigences applicables aux dispositifs d’avertissement utilisés pour la notification dans les systèmes d’alarme contre l’intrusion et les hold-up installés dans les bâtiments. Quatre grades de dispositifs d’avertissement sont décrits, correspondant aux quatre grades de sécurité indiqués dans l’EN 50131-1. Les exigences sont également données pour les quatre classes d’environnement qui couvrent les applications situées à l’intérieur et à l’extérieur, comme cela est spécifié dans l’EN 50130-5.

Le présent document ne couvre pas les exigences de conformité aux directives réglementaires CE, comme la directive CEM, la directive Basse Tension, etc., mais il spécifie les conditions de fonctionnement des matériels en ce qui concerne les essais de susceptibilité CEM comme cela est exigé par l’EN 50130-4.

Alarmni sistemi - Sistemi za javljanje vloma in ropa - 4. del: Opozorilne naprave

Ta evropski standard vključuje zahteve za opozorilne naprave, ki se uporabljajo za obveščanje v sistemih za javljanje vloma in ropa, vgrajenih v stavbah. Opisani so štirje razredi opozorilnih naprav, ki ustrezajo štirim varnostnim razredom iz standarda EN 50131-1. Zahteve so podane tudi za štiri okoljske razrede, ki zajemajo načine uporabe na notranjih in zunanjih lokacijah, kot je določeno v standardu EN 50130-5.

Ta evropski standard ne obravnava zahtev glede skladnosti z regulativnimi direktivami ES, kot je direktiva o elektromagnetni združljivosti, direktiva o nizki napetosti itd., določa pa pogoje za uporabo opreme za preskušanje občutljivosti v okviru elektromagnetne združljivosti, kot to zahteva standard EN 50130-4.

General Information

- Status

- Published

- Publication Date

- 08-Aug-2019

- Technical Committee

- EAL - Alarm systems

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 25-Jul-2019

- Due Date

- 29-Sep-2019

- Completion Date

- 09-Aug-2019

Relations

- Replaces

SIST EN 50131-4:2009 - Alarm systems - Intrusion and hold-up systems -- Part 4: Warning devices - Effective Date

- 01-Sep-2019

Overview

EN 50131-4:2019 - "Alarm systems - Intrusion and hold‑up systems - Part 4: Warning devices" (CLC/CENELEC) defines requirements and test methods for warning devices used in building‑installed intrusion and hold‑up alarm systems. The standard describes four warning device grades that correspond to the four security grades in EN 50131-1 and defines four environmental classes (indoor/outdoor applications) aligned with EN 50130-5. It sets functional, environmental, tamper, electrical, acoustic and self‑test requirements and the test procedures to demonstrate compliance. EN 50131-4:2019 supersedes the 2009 edition and clarifies test methodology and alignment with other EN 50131 product standards.

Key topics and requirements

- Warning device grading: Defines performance expectations for the four device grades matching EN 50131-1 security grades.

- Functional requirements: Response to trigger commands, timing, acoustic characteristics and maximum sound duration limits.

- Acoustic testing: Measurement methods for audible output (referenced in Annex A) and pass/fail criteria for sound level.

- Tamper protection and detection: Requirements for enclosure protection, detection of opening or removal, and penetration resistance.

- Environmental classes: Tests and construction requirements for indoor and outdoor installations per EN 50130-5.

- EMC susceptibility: Specifies operating conditions for EMC immunity testing consistent with EN 50130-4 (note: it does not replace EC regulatory directives such as EMC or Low Voltage Directives).

- Electrical and power: Requirements and tests for operating voltage range, current consumption, remote powering vs self‑powered devices, storage device standby/operating times, recharge behaviour, loss of remote power and short‑circuit protection.

- Self‑test and remote testability: Local and remote self‑test provisions and recommended test protocols (informative examples included).

- Marking and documentation: Mandatory marking, user documentation and test record requirements.

- Test procedures: Detailed test sections for functional performance, reduced functional tests, tamper, electrical, marking and environmental testing.

Applications and who uses it

- Alarm system manufacturers designing sirens, horns, strobes and combined warning devices.

- System designers and integrators specifying devices to meet a required security grade and environmental class.

- Installers documenting compliance and selecting appropriate devices for indoor/outdoor use.

- Testing laboratories and certification bodies conducting type and performance testing.

- Specifiers and facility managers ensuring installed warning devices meet regulatory and system requirements for intrusion and hold‑up protection.

Related standards

- EN 50131-1 (system requirements)

- EN 50130-4 (EMC immunity - product family)

- EN 50130-5 (environmental test methods)

- EN 50131-6 (power supplies)

- EN 61672-1, EN 60529, EN 62262 and EN 60068-2-75 (referenced test and measurement standards)

Keywords: EN 50131-4:2019, alarm systems, warning devices, intrusion and hold‑up, warning device grades, environmental classes, EMC susceptibility, tamper detection, self‑powered, remotely powered.

Frequently Asked Questions

SIST EN 50131-4:2019 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Alarm systems - Intrusion and hold-up systems - Part 4: Warning devices". This standard covers: This document includes requirements for warning devices used for notification in intrusion and hold up alarm systems installed in buildings. Four grades of warning device are described corresponding to each of the four security grades given in EN 50131-1. Requirements are also given for four environmental classes covering applications in indoor and outdoor locations as specified in EN 50130-5. This document does not deal with requirements for compliance with EC regulatory Directives, such as the EMC Directive, Low Voltage Directive, etc. except that it specifies the equipment operating conditions for EMC susceptibility testing as required by EN 50130-4.

This document includes requirements for warning devices used for notification in intrusion and hold up alarm systems installed in buildings. Four grades of warning device are described corresponding to each of the four security grades given in EN 50131-1. Requirements are also given for four environmental classes covering applications in indoor and outdoor locations as specified in EN 50130-5. This document does not deal with requirements for compliance with EC regulatory Directives, such as the EMC Directive, Low Voltage Directive, etc. except that it specifies the equipment operating conditions for EMC susceptibility testing as required by EN 50130-4.

SIST EN 50131-4:2019 is classified under the following ICS (International Classification for Standards) categories: 13.310 - Protection against crime; 13.320 - Alarm and warning systems. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 50131-4:2019 has the following relationships with other standards: It is inter standard links to SIST EN 50131-4:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 50131-4:2019 is associated with the following European legislation: EU Directives/Regulations: 2020-01-0063. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 50131-4:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2019

Nadomešča:

SIST EN 50131-4:2009

Alarmni sistemi - Sistemi za javljanje vloma in ropa - 4. del: Opozorilne naprave

Alarm systems - Intrusion and hold-up systems - Part 4: Warning devices

Alarmanlagen - Einbruch- und Überfallmeldeanlagen - Teil 4: Signalgeber

Systèmes d’alarme - Systèmes d’alarme contre l’intrusion et les hold-up - Partie 4:

Dispositifs d’avertissement

Ta slovenski standard je istoveten z: EN 50131-4:2019

ICS:

13.310 Varstvo pred kriminalom Protection against crime

13.320 Alarmni in opozorilni sistemi Alarm and warning systems

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD EN 50131-4

NORME EUROPÉENNE

EUROPÄISCHE NORM

April 2019

ICS 13.320 Supersedes EN 50131-4:2009

English Version

Alarm systems - Intrusion and hold-up systems - Part 4: Warning

devices

Systèmes d'alarme - Systèmes d'alarme contre l'intrusion et Alarmanlagen - Einbruch- und Überfallmeldeanlagen - Teil

les hold-up - Partie 4: Dispositifs d'avertissement 4: Signalgeber

This European Standard was approved by CENELEC on 2018-12-31. CENELEC members are bound to comply with the CEN/CENELEC

Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC

Management Centre or to any CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CENELEC member into its own language and notified to the CEN-CENELEC Management Centre has the

same status as the official versions.

CENELEC members are the national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus, the Czech Republic,

Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia,

Lithuania, Luxembourg, Malta, the Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden,

Switzerland, Turkey and the United Kingdom.

European Committee for Electrotechnical Standardization

Comité Européen de Normalisation Electrotechnique

Europäisches Komitee für Elektrotechnische Normung

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CENELEC All rights of exploitation in any form and by any means reserved worldwide for CENELEC Members.

Ref. No. EN 50131-4:2019 E

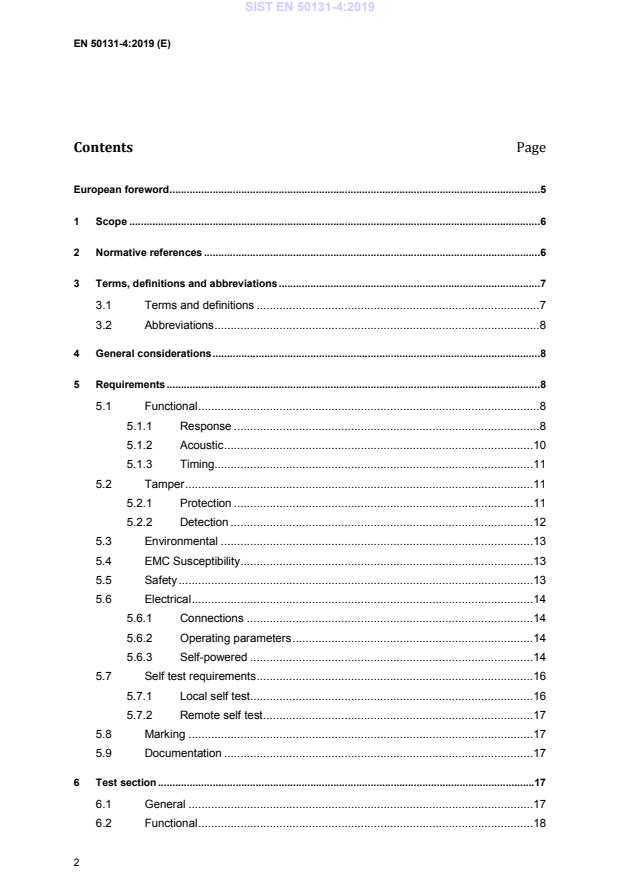

Contents Page

European foreword . 5

1 Scope . 6

2 Normative references . 6

3 Terms, definitions and abbreviations . 7

3.1 Terms and definitions . 7

3.2 Abbreviations . 8

4 General considerations . 8

5 Requirements . 8

5.1 Functional . 8

5.1.1 Response . 8

5.1.2 Acoustic . 10

5.1.3 Timing. 11

5.2 Tamper . 11

5.2.1 Protection . 11

5.2.2 Detection . 12

5.3 Environmental . 13

5.4 EMC Susceptibility . 13

5.5 Safety . 13

5.6 Electrical . 14

5.6.1 Connections . 14

5.6.2 Operating parameters . 14

5.6.3 Self-powered . 14

5.7 Self test requirements . 16

5.7.1 Local self test . 16

5.7.2 Remote self test . 17

5.8 Marking . 17

5.9 Documentation . 17

6 Test section .17

6.1 General . 17

6.2 Functional . 18

6.2.1 General conditions . 18

6.2.2 General mounting . 18

6.2.3 General testing procedures . 18

6.3 Reduced functional test . 18

6.3.1 Purpose . 18

6.3.2 Conditions . 18

6.3.3 Mounting . 18

6.3.4 Stimuli. 18

6.3.5 Measurement . 18

6.3.6 Pass/Fail criteria . 18

6.4 Response to events . 19

6.4.1 Response to trigger command . 19

6.4.2 Response to loss of trigger command interconnection integrity . 19

6.4.3 Maximum sound duration limit . 20

6.5 Acoustic output level . 20

6.5.1 Purpose . 20

6.5.2 Conditions . 20

6.5.3 Mounting . 20

6.5.4 Stimuli. 20

6.5.5 Measurement . 20

6.5.6 Pass/Fail criteria . 20

6.6 Tamper . 21

6.6.1 Opening by normal means . 21

6.6.2 Protection . 21

6.6.3 Detection of opening by normal means . 22

6.6.4 Detection of removal from mounting . 22

6.6.5 Detection of penetration . 23

6.7 Electrical tests . 23

6.7.1 Operating voltage range and current consumption . 23

6.7.2 Slow rise of remote power source voltage . 24

6.7.3 Remote power source voltage step change . 24

6.7.4 Storage device standby time . 25

6.7.5 Storage device operating time . 25

6.7.6 Storage device recharge rate . 26

6.7.7 Loss of remote power . 27

6.7.8 Remote power short circuit protection . 27

6.7.9 Storage device monitoring – Low residual energy . 28

6.7.10 Storage device monitoring – Failure . 28

6.8 Marking . 29

6.8.1 Purpose . 29

6.8.2 Conditions . 29

6.8.3 Mounting . 29

6.8.4 Stimuli. 29

6.8.5 Measurement . 29

6.8.6 Pass/Fail criteria . 29

6.9 Documentation . 29

6.9.1 Purpose . 29

6.9.2 Conditions . 29

6.9.3 Mounting . 29

6.9.4 Stimuli. 30

6.9.5 Measurement . 30

6.9.6 Pass/Fail criteria . 30

6.10 Environmental . 30

6.10.1 Impact. 30

6.10.2 Further environmental tests . 30

Annex A (normative) Sound level test for warning devices .33

A.1 General .33

A.2 Mounting arrangements .33

A.3 Instrumentation .33

A.4 Background noise level .33

A.5 Measurement of sound level .33

Annex B (informative) Example remote test protocol .36

European foreword

This document (EN 50131-4:2019) has been prepared by CLC/TC 79, “Alarm systems”.

The following dates are fixed:

• latest date by which this document has to be (dop) 2019-12-31

implemented at national level by publication of

an identical national standard or by

endorsement

• latest date by which the national standards (dow) 2021-12-31

conflicting with this document have to be

withdrawn

This document supersedes EN 50131-4:2009.

This revision includes changes:

— to remove technology specific terminology from requirements;

— to clarify the scope and detail of requirements;

— to clarify the application and methodology of tests;

— to align requirements and testing for tamper security with other parts of the EN 50131-x suite of

product standards;

— to align requirements for environmental testing with other parts of the EN 50131-x suite of product

standards;

— to improve editorial presentation.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CENELEC shall not be held responsible for identifying any or all such patent rights.

1 Scope

This document includes requirements for warning devices used for notification in intrusion and hold up

alarm systems installed in buildings. Four grades of warning device are described corresponding to

each of the four security grades given in EN 50131-1. Requirements are also given for four

environmental classes covering applications in indoor and outdoor locations as specified in

EN 50130-5.

This document does not deal with requirements for compliance with EC regulatory Directives, such as

the EMC Directive, Low Voltage Directive, etc. except that it specifies the equipment operating

conditions for EMC susceptibility testing as required by EN 50130-4.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments)

applies.

EN 50130-4, Alarm systems — Part 4: Electromagnetic compatibility — Product family standard:

Immunity requirements for components of fire, intruder, hold up, CCTV, access control and social

alarm systems

EN 50130-5, Alarm systems — Part 5: Environmental test methods

EN 50131-1, Alarm systems — Intrusion and hold-up systems — Part 1: System requirements

EN 50131-6, Alarm systems — Intrusion and hold-up systems — Part 6: Power supplies

EN 60068-2-75, Environmental testing — Part 2-75: Tests — Test Eh: Hammer tests (IEC 60068-2-

75)

EN 60529, Degrees of protection provided by enclosures (IP Code) (IEC 60529)

EN 61672-1, Electroacoustics — Sound level meters — Part 1: Specifications (IEC 61672-1)

EN 62262, Degrees of protection provided by enclosures for electrical equipment against external

mechanical impacts (IK code) (IEC 62262)

3 Terms, definitions and abbreviations

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1.1

audible alarm

distinctive sound generated in response to an alarm condition

3.1.2

warning device

device that gives an audible alarm in response to a notification

Note 1 to entry: A warning device may also provide alert indications.

3.1.3

external warning device

warning device designed to be located outside the supervised premises which gives an external

audible alarm in response to a notification

3.1.4

internal warning device

warning device designed to be located within the supervised premises which gives an internal audible

alarm in response to a notification

3.1.5

enclosure

housing that contains the warning device components, normally comprises a backplate and a cover

3.1.6

external power source

energy supply external to the I&HAS which may be non-continuous, e.g. mains supply

3.1.7

reference point

centroid of the mounting face of the warning device enclosure projected onto the mounting surface

3.1.8

remote power source

electrical supply, which is not a part of the warning device, meeting the requirements of EN 50131-6

3.1.9

remotely powered warning device

warning device that does not incorporate its own power source

3.1.10

self-powered warning device

warning device that incorporates its own power source

3.1.11

standby condition

operational mode of a self-powered warning device during which it is powered from its internal storage

device, whilst not notifying an alarm condition

3.1.12

storage device – failure

condition of the storage device where it is no longer able to power the warning device

3.1.13

storage device – low residual energy

condition specified by the warning device manufacturer which indicates that the storage device is

nearly discharged

3.1.14

trigger command

notification signal or message passed to the warning device

3.1.15

visible damage

damage that would be visible to a person of normal eyesight viewing at a distance of 2 m under an

illumination level of 2 000 lx

3.2 Abbreviations

For the purposes of this document, the following abbreviations are used:

CIE - Control and indicating Equipment

I&HAS - Intrusion and Hold-up Alarm System(s)

WD - Warning Device

4 General considerations

This European Standard considers two different categories of warning device, remotely powered and

self-powered devices.

Self-powered warning devices are classified into one of four types, dependent upon the recharge

characteristics of the storage device and the source of recharge power. These four types are defined

in Table 9.

5 Requirements

5.1 Functional

5.1.1 Response

Depending upon the grade, warning devices shall have the functionality as defined in Table 1. Where

a function is provided, the warning device shall operate in accordance with the requirements of

Table 2.

NOTE Requirements for the interconnections are given in the specific interconnection standard(s).

Table 1 — Warning device functionality

Self-powered Remotely powered

Function Grade Grade

1 2 3 4 1 2 3 4

Trigger command M M M M M M M M

Tamper signal or

M M M M M M M M

message output

Fault signal or message

b b

Op M M Op Op Op Op

Op

output

a

Monitor of remote power M M M M Op Op Op Op

Monitor integrity of trigger

Op Op M M Op Op Op Op

command interconnection

b b

Local self test Op Op M M Op Op Op Op

Remote test input Op Op Op M Op Op Op Op

Key

Op Optional

M Mandatory

a

Remote power monitoring only applies to warning devices with a remote power source and an internal storage

device, see types X and Z as defined in Table 9.

b

Mandatory for type W devices as defined in Table 9.

Table 2 — Warning device responses

Self-powered WD Remote powered WD

Tamper Fault Tamper Fault

Event

Audible Audible

signal or signal or signal or signal or

alarm alarm

a

message message message message

Trigger command M NP NP M NP NP

Tamper event at

Op M NP Op M NP

the WD

Loss of remote

b b b

Op Op Op N/A Op Op

power source

Loss of trigger

command

c c c

Op Op Op Op Op Op

interconnection

integrity

Local self test pass NP NP NP NP NP NP

a

Local self test fail NP NP M NP NP M

Remote self test

d d

NP NP M NP NP M

pass

Remote self test

d d

NP NP M NP NP M

fail

Key

M Mandatory

Op Optional

NP Not Permitted

N/A Not applicable

a

The provision of a fault signal or message is not mandatory for all grades, see Table 1.

b

At least one of these actions shall occur at the warning device. For grade 3 and grade 4 warning devices, if

the loss of remote power source can be shown to be caused by a fault then a fault signal shall be generated,

otherwise a tamper signal shall be generated.

c

At least one of these actions shall occur at the warning device. For grade 3 and grade 4 warning devices, if

the loss of trigger command integrity can be shown to be caused by a fault then a fault signal shall be

generated, otherwise a tamper signal shall be generated.

d

The response to a remote test pass shall be different from the response to a remote test fail.

5.1.2 Acoustic

A warning device shall produce a varying sound output, which is distinctive and likely to attract

attention, with a mean acoustic output of no less than that defined in Table 3 at 1 m from the mounting

surface of the warning device throughout the manufacturer’s specified operating voltage range.

Acoustic output levels as measured in accordance with Annex A, taken at 30° intervals in the

horizontal plane, shall not be below the minimum individual level defined in Table 3 at 1 m from the

mounting surface. The mean acoustic output shall be calculated by the arithmetic sum of these values

divided by the number of measurements. For surface mounted devices (e.g. wall mounted devices)

this is required at angles between 15° and 165° to the surface, and for pole mounted devices it is for

the full 360°.

Table 3 — Acoustic output levels

Internal warning device External warning device

Minimum mean acoustic

80 dB(A) 100 dB(A)

output level

Minimum individual

75 dB(A) 95 dB(A)

acoustic output level

NOTE 1 It is considered restrictive to define exact waveforms of acceptable alarm tones, therefore the only

tests that can be applied are on the acoustic output level and that the tone is varying.

NOTE 2 Voice alarms are deemed to meet the requirements of a varying sound output.

NOTE 3 A warning device may also provide audible alert indications providing such indications are easily

distinguishable from an alarm.

NOTE 4 The acoustic output (sound level and/or frequency) of a warning device may be subject to variation

depending on local or national requirements.

5.1.3 Timing

A trigger command exceeding 400 ms shall be processed by the warning device.

A warning device shall commence its audible alarm within 1 s of receiving a valid trigger command to

do so. It shall cease its audible alarm within 1 s of receiving a valid cancellation of the trigger

command.

The warning device shall sound between these signals.

The maximum time for which an audible warning device shall sound continuously is 15 min.

NOTE 1 For remote powered warning device, where applicable, this requirement may be achieved by the CIE.

NOTE 2 The duration of the operational period of a warning device may be subject to variation depending on

local or national requirements

A tamper signal or message shall be generated within 1 s of a tamper condition occurring.

There shall be a response to loss of remote power source or loss of trigger command interconnection

integrity according to Tables 1 and 2, within 10 s of the fault occurring.

A response to local test fail according to Tables 1 and 2 shall occur within 10 s of detection of the fault.

5.2 Tamper

5.2.1 Protection

All component parts shall be housed in an enclosure meeting the impact requirements of the

appropriate grade given in Table 4.

Provision shall be made to allow adequate fixing of the enclosure to the mounting surface.

Table 4 — Enclosure construction

Internal warning device External warning device

Grade

1 2 3 4 1 2 3 4

Resistance to impact

06 06 07 08 07 07 08 08

(IK rating according to EN 62262)

The cover of the enclosure shall be secured with one or more screws or bolts or alternatively by a

mechanical lock. The cover of the enclosure shall be opened only with the use of one or more keys or

suitable tools.

It shall not be possible, without causing visible damage, to gain access to any electrical connections,

or elements providing adjustment, without first generating a tamper signal or message.

When the unit is mounted normally it shall not be possible, without causing visible damage, to

introduce a tool, as defined in Table 5, such that the operation of the warning device could be

adversely affected.

Table 5 — Tool dimension for tamper protection

Dimensions in millimetres

Grade 1 Grade 2 Grade 3 Grade 4

Steel rod as specified in

2,5 2,5 1 1

EN 60529, with diameter

Flat bar dimensions (±0,05 mm) 10 × 1 × 300 10 × 1 × 300 5 × 0,5 × 300 5 × 0,5 × 300

5.2.2 Detection

The tamper detection requirements for warning devices relative to the security grade are given in

Table 7.

Opening the warning device enclosure by normal means shall generate a tamper signal or message.

The enclosure shall not permit the introduction of a tool of dimension as specified in Table 5 and

Table 6, to defeat the tamper detection.

Table 6 — Tool dimension for tamper detection

Dimensions in millimetres

Grade 1 Grade 2 Grade 3 Grade 4

Steel wire of tensile strength

650 MPa - 825 MPa and NA NA Ø 1 × 300 Ø 1 × 300

a

dimensions

a

for example, welding rod wire meeting this specification is commonly available.

Attempts to remove the warning device from its mounting surface for a distance defined in Table 8 in a

perpendicular direction shall generate a tamper signal or message according to Table 7.

It shall not be possible to defeat the removal from mounting detection by sliding a

25 mm × 1 mm × 300 mm blade, or by use of pliers (of thickness 5 mm and reach 150 mm), between

the mounting surface and the warning device.

The warning device shall include means to detect penetration of the enclosure, which could cause

mis-operation of the warning device, as specified in Table 7, when a hole of 4 mm is made in the

enclosure.

Table 7 — Tamper detection

Internal warning device External warning device

Security grade

1 2 3 4 1 2 3 4

Opening by normal means M M M M M M M M

Removal from mounting – Op M M M Op M M M

Wire free WD

Removal from mounting – Op Op M M Op Op M M

Wired WD

Detection of penetration of

Op Op Op Op Op Op Op M

enclosure

Key

Op Optional

M Mandatory

Table 8 — Removal from mounting

Grade 1 Grade 2 Grade 3 Grade 4

Maximum distance before tamper

a a

10 mm 10 mm 5 mm 5 mm

detection

a

If removal from mounting detection is provided.

5.3 Environmental

The environmental classification shall be as described in EN 50131-1. All the relevant environmental

tests shall be carried out at the appropriate level for all security grades, as given in EN 50130-5.

The warning device shall meet the requirements of the relevant environmental class as specified by

the manufacturer.

For operational tests, the warning device shall not generate unintentional activations, tamper, fault or

other signals or messages, when subjected to the specified range of environmental conditions.

For endurance tests, the warning device shall continue to meet the requirements of this European

Standard after being subjected to the specified range of environmental conditions.

See 6.10 for the relevant tests and severity.

5.4 EMC Susceptibility

For all grades the warning device shall meet the performance requirements of this European Standard

when subject to the EMC conditions and severity levels defined in EN 50130-4.

NOTE EMC emissions are covered by EC regulatory Directives.

5.5 Safety

NOTE Safety requirements are covered by EC regulatory Directives.

5.6 Electrical

5.6.1 Connections

The means of electrical connection shall be appropriate for the physical size and current carrying

capacity of the required conductors. The method of termination shall not damage the conductors.

Terminal blocks and other components utilized for connections shall be identifiable with numbers or

other marks specified in the documentation

If external metal enclosures are used with a facility to connect to the equi-potential bonding, e.g. for

the purpose of protection from lightning strikes, then there shall be the provision to clamp wires with a

2 2

cross sectional area of 4 mm to 16 mm .

5.6.2 Operating parameters

5.6.2.1 Voltage range

The warning device shall meet all the functional requirements when the supply voltage range lies

between the manufacturer’s stated values.

5.6.2.2 Slow remote power source voltage rise

−1

When the warning device is subject to a slow input voltage rise from zero of 1 Vs , then it shall

function normally when the supply voltage reaches the minimum operating voltage.

5.6.2.3 Remote power source voltage step change

When the warning device is subject to a step in the input voltage between maximum and minimum,

and vice versa, there shall be no change in the status of the warning device, and no signals or

messages shall be generated.

5.6.2.4 Current consumption

The warning device’s quiescent and peak current consumption on each connection shall not exceed

those specified by the manufacturer in the alarm sounding and non alarm sounding states, at the

nominal supply voltage.

5.6.3 Self-powered

5.6.3.1 General

Where a self-powered warning device’s own power source is not used to power other I&HAS

components, then the requirements of EN 50131-6 do not apply to that power source.

Where a self-powered warning device incorporates its own storage device, the following additional

requirements apply:

5.6.3.2 Storage device operating time

The storage device shall have sufficient capacity for at least 10 consecutive maximum sound duration

periods, or at least 30 min; whichever is the shorter. At the end of this time, the individual acoustic

output 1 m from the warning device at, at least, one of the measurement points specified in 5.1.2, shall

meet the requirements of Table 3.

5.6.3.3 Storage device standby time

The storage device shall have sufficient capacity to maintain the warning device in its standby

condition for the periods specified in Table 9.

Table 9 — Storage device standby duration

Remote Integral

Storage

Type power recharge Grade 1 Grade 2 Grade 3 Grade 4

device type

source capability

Non Not

W None 1 year 1 year 1 year 1 year

rechargeable applicable

Non Not

X

Yes 24 h 24 h 120 h 120 h

rechargeable applicable

Y None Rechargeable Yes 24 h 24 h 120 h 120 h

Yes, from

remote

Z Yes Rechargeable 12 h 12 h 60 h 60 h

power

source

NOTE 1 A type W warning device could, for example, have a dry cell as its only means of power. This

storage device has no means of recharge and will need replacing before it is completely exhausted.

NOTE 2 A type X warning device could, for example, be remotely powered from the I&HAS and with

a dry cell as its storage device. This storage device has no means of recharge and will need replacing

before it is completely exhausted.

NOTE 3 A type Y warning device could, for example, recharge its storage device by means of a solar

cell, or connection to an external power source (e.g. mains supply).

NOTE 4 A type Z warning device could, for example, be normally powered from the I&HAS, and this

power source is also used to recharge its storage device.

At the end of the standby period, the storage device shall meet the operating time requirements of

5.6.3.2.

For types X and Z, where loss of the remote power supply causes the warning device to activate (see

Table 2) a standby condition is not required, the requirements of Table 9 do not apply, and the storage

device shall only meet the operating time requirements of 5.6.3.2.

5.6.3.4 Recharge rate

Type Y and Z warning devices shall be capable of supplying current at the appropriate voltage to

recharge the storage device equivalent to 80 % of that supplied by the storage device in meeting the

requirements of 5.6.3.2 and 5.6.3.3 within the periods as specified in Table 10.

Table 10 — Recharge periods

Grade 1 Grade 2 Grade 3 Grade 4

Maximum time to

72 h 72 h 24 h 24 h

recharge

5.6.3.5 Remote power monitoring

Where the warning device has a remote power source and this power source is lost, then the warning

device shall respond according to Table 2.

5.6.3.6 Remote power short circuit protection

Where the warning device has a remote power source it shall not be possible to discharge the storage

device through a short circuit applied to the remote power source connections.

5.7 Self test requirements

5.7.1 Local self test

5.7.1.1 General

A local self test shall be performed under the control of the warning device.

A fault signal or message shall be generated within 10 s of detection of any of the conditions in

Table 11.

Table 11 — Self test monitoring

Grade 1 Grade 2 Grade 3 Grade 4

Storage device -

a a

low residual Op Op M M

energy

Storage device -

Op Op M M

failure

Key

Op Optional

M Mandatory

a

Mandatory for type W devices as defined in Table 9.

5.7.1.2 Storage device monitoring

5.7.1.2.1 Storage device monitoring – Low residual energy

The residual energy in the storage device shall be monitored in accordance with Table 11.

A storage device low residual energy fault occurs when the residual energy of the storage device falls

below that specified by the warning device manufacturer. This residual energy shall be greater than

the minimum energy required to operate the warning device.

Non rechargeable storage devices shall be monitored continuously. Rechargeable storage devices

shall only be monitored when the warning device is in its standby condition.

For type X warning devices without a standby condition, the requirements of 5.7.1.2.1 shall only apply

when the remote power source is available.

For type Z warning devices without a standby condition, the requirements of 5.7.1.2.1 do not apply.

The warning device manufacturer shall declare in their documentation the monitored condition of the

storage device that will generate this fault signal or message.

5.7.1.2.2 Storage device monitoring – Failure

Where the storage device is rechargeable and in accordance with Table 11, means shall be provided

to determine whether the storage device is no longer able to power the warning device e.g. by

applying a load to the storage device and monitoring the terminal voltage. These means shall not be

achieved by monitoring terminal voltage alone.

The maximum time period for detection of a storage device failure shall be 24 h.

For type Y and Z warning devices the requirements of 5.7.1.2.2 shall only apply when the storage

device recharge source is available.

5.7.2 Remote self test

Any remote test sequence shall not prevent the warning device from operating in accordance with

Table 2.

If a remote test is initiated, the warning device shall not remain in test mode for a period in excess of

60 s.

An audible alarm or a tamper signal or message shall not be used to communicate the pass or fail of a

remote test request. One possible test sequence is shown in Annex B.

5.8 Marking

The warning device shall be marked in accordance with EN 50131-1.

5.9 Documentation

The warning device shall be accompanied by documentation in accordance with EN 50131-1.

Additionally, the documentation shall contain the following information:

a) brief description of operation;

b) type of warning device (i.e. internal or external, remote or self-powered);

c) installation requirements, (e.g. wall or pole mounting);

d) method of adjustment/configuration;

e) operating instructions;

f) connection details, including sufficient detail to enable effective interface and operation as part of

the I&HAS;

g) supply voltage range and nominal supply voltage(s);

h) quiescent and peak current consumption on each connection in the alarm sounding and non

alarm sounding states, at the nominal supply voltage;

i) suitable storage device type, capacity and low residual energy condition (where applicable);

j) response of the warning device to loss of remote power, and trigger command interconnection

integrity (where applicable);

k) for type Y devices the conditions required to guarantee the storage device recharge time;

l) type of acoustic output, (e.g. tone, voice etc.);

m) maximum sound duration time (where applicable).

6 Test section

6.1 General

All the test parameters specified shall carry a general tolerance of ± 10 % unless otherwise stated.

All tests shall be performed at the manufacturer’s specified nominal supply voltage, unless otherwise

stated.

6.2 Functional

6.2.1 General conditions

The general atmospheric conditions in the measurement and tests laboratory shall follow the

requirements below, unless stated otherwise.

Temperature: 15 °C to 35 °C

Relative humidity: 25 % RH to 75 % RH

Air pressure: 86 kPa to 106 kPa

6.2.2 General mounting

The warning device shall be mounted in accordance with the manufacturer’s instructions.

6.2.3 General testing procedures

Manufacturer’s documented instructions regarding operation shall be read and applied to all tests.

6.3 Reduced functional test

6.3.1 Purpose

To check that the warning device is operational before undergoing other tests and that it continues to

function after these tests, e.g. impact, environmental etc.

6.3.2 Conditions

The general test conditions of 6.2.1 shall apply.

6.3.3 Mounting

The mounting conditions shall be sufficient to conduct a reduced functional test, and the requirements

of 6.2.2 do not necessarily apply.

6.3.4 Stimuli

Apply a trigger command. Once the warning device has activated, remove the trigger command.

Open the warning device by normal means.

6.3.5 Measurement

Monitor the acoustic output in response to the input stimuli.

Monitor the tamper signal or message output.

6.3.6 Pass/Fail criteria

The warning device shall generate a sound output in response to the trigger command. There is no

requirement to measure this, unless there is concern that the sound output is inadequate, in which

case the full sound output shall be measured in accordance with 6.5.1.

A tamper signal or message shall be generated when the warning device is opened by normal means.

6.4 Response to events

6.4.1 Response to trigger command

6.4.1.1 Purpose

To verify that after application of a stimulus as indicated by the manufacturer the warning device

responds within the correct time frame.

6.4.1.2 Conditions

The general test conditions of 6.2.1 shall apply.

6.4.1.3 Mounting

The general mounting conditions of 6.2.2 shall apply.

6.4.1.4 Stimuli

Apply a trigger command, of greater than 400 ms where appropriate. Wait for a period greater than

10 s but less than 1 min, and cancel the trigger command, in accordance with the manufacturer’s

instructions.

6.4.1.5 Measurement

Monitor the acoustic output in response to the input stimuli, and the time from the initial application of

the trigger command.

6.4.1.6 Pass/Fail criteria

The warning device shall activate within 1 s of the application of the trigger command. The warning

device shall continue to sound until no more than 1 s after the cancellation of the trigger command.

6.4.2 Response to loss of trigger command interconnection integrity

6.4.2.1 Purpose

To verify the correct response, according to Table 2 and as specified by the manufacturer, to a loss of

trigger command interconnection integrity.

6.4.2.2 Conditions

The general test conditions of 6.2.1 shall apply.

6.4.2.3 Mounting

The general mounting conditions of 6.2.2 shall apply.

6.4.2.4 Stimuli

Effect a loss of trigger command interconnection integrity.

6.4.2.5 Measurement

Monitor the performance of the warning device.

6.4.2.6 Pass/Fail criteria

Ensure that the warning device responds correctly to the loss of trigger command interconnection

integrity as defined in Table 2 within 10 s of the removal of the trigger command interconnection, and

that this response is in accordance with the supplied documentation.

6.4.3 Maximum sound duration limit

6.4.3.1 Purpose

To verify the maximum time for which the warning device sounder operates, and that the time limiting

device resets correctly.

NOTE This section is not applicable for warning devices without an integral time limiting device.

6.4.3.2 Conditions

The general test conditions of 6.2.1 shall apply.

6.4.3.3 Mounting

The general mounting conditions of 6.2.2 shall apply.

6.4.3.4 Stimuli

Activate the warning device using all methods identified in Table 2 which are applicable to the warning

device. Remove these stimuli after the warning device sound output ceases.

Then reapply one or all of the above stimuli.

6.4.3.5 Measurement

Monitor the acoustic output in response to the input stimuli. Record the time for which it operates.

6.4.3.6 Pass/Fail criteria

Ensure that the warning device sounds after the application of the stimuli for the time specified in the

supplied documentation, and for no longer than the time defined in 5.1.3.

Reapplication of one or all of the stimuli shall cause the warning device to sound.

6.5 Acoustic output level

6.5.1 Purpose

To verify that the warning device sound level meets the minimum requirements as defined in 5.1.2.

6.5.2 Conditions

The general test conditions of 6.2.1 shall apply. The test shall be carried out at the minimum and

maximum rated supply voltage, as specified by the manufacturer.

6.5.3 Mounting

The mounting conditions as defined in Annex A shall apply.

6.5.4 Stimuli

Apply a trigger command, and wait for the sound output to stabilize before starting to take any

readings.

6.5.5 Measurement

Measure the sound pressure level of the device under

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...