SIST EN 10301:2004

(Main)Steel tubes and fittings for on and offshore pipelines - Internal coating for the reduction of friction for conveyance of non corrosive gas

Steel tubes and fittings for on and offshore pipelines - Internal coating for the reduction of friction for conveyance of non corrosive gas

This European Standard specifies the application requirements and methods of test of liquid applied epoxy paints on the internal surface for the reduction of friction of tubes and pipeline fittings for conveyance of non-corrosive gas.

Other paints or paint systems are not excluded provided they comply with the requirements given in this standard.

The coating consist of one layer of liquid product, normally shop applied onto abrasive blast cleaned steel by airless spray or conventional spray techniques. Brush application may be used only for repairs.

The coating qualified in accordance with this standard is considered suitable for operating temperatures between

- 20 °C and + 110 °C.

In this European Standard the word "components" is used for tubes and fittings.

Stahlrohre und -formstücke für On- und Offshore-Rohrleitungen - Innenbeschichtung zur Verringerung der Reibung beim Transport von nicht korrosivem Gas

Diese Norm legt die Anforderungen für die Beschichtung und Prüfverfahren für flüssig aufgebrachte Epoxidharzbeschichtungen auf die Innenoberfläche von Stahlrohren und Formstücken zur Reibungsverminderung beim Transport von nicht korrosivem Gas fest.

Andere Beschichtungen oder Beschichtungssysteme sind nicht ausgeschlossen, soweit sie die Anforderungen dieser Norm entsprechen.

Die Beschichtung muss in einer Lage, in der Regel als Werksbeschichtung, auf die strahlgereinigte Stahloberfläche durch airless - Spritzen oder andere konventionelle Spritztechniken eines flüssigen Produktes aufgebracht werden. Anstriche dürfen nur für Reparaturen angewendet werden.

Die nach dieser Norm zugelassene Beschichtung wird für Arbeitstemperaturen zwischen -20 °C und +110 °C als geeignet betrachtet.

In dieser Norm wird die Bezeichnung Komponente für Rohre und Formstücke benutzt.

Tubes et raccords en acier pour canalisations enterrées et immergées - Revetement interne antifriction pour le transport de gaz non corrosifs

La présente Norme européenne spécifie les prescriptions relatives à l'application et les méthodes d'essai des peintures époxydes appliquées à l'état liquide sur la surface interne des tubes et les raccords de canalisations pour le transport de gaz non corrosifs, pour la réduction des frottements.

D'autres peintures ou systèmes de peinture ne sont pas exclus pour autant qu'ils soient conformes aux prescriptions indiquées dans la présente norme.

Le revêtement consiste en une couche de produit liquide, qui est généralement appliquée en atelier sur de l'acier nettoyé par projection d'abrasif, par des techniques de pulvérisation à dépression ou des techniques classiques de pulvérisation. L'application au pinceau peut être utilisée uniquement pour des travaux de réparation.

Le revêtement qualifié conformément à la présente norme est considéré convenir pour des températures de service comprises entre - 20 °C et + 110 °C.

Dans la présente Norme européenne, le terme « éléments » est utilisé pour les tubes et raccords.

Steel tubes and fittings for on and offshore pipelines - Internal coating for the reduction of friction for conveyance of non corrosive gas

General Information

- Status

- Published

- Publication Date

- 31-May-2004

- Technical Committee

- IFEK - Ferrous metals

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Jun-2004

- Due Date

- 01-Jun-2004

- Completion Date

- 01-Jun-2004

Overview

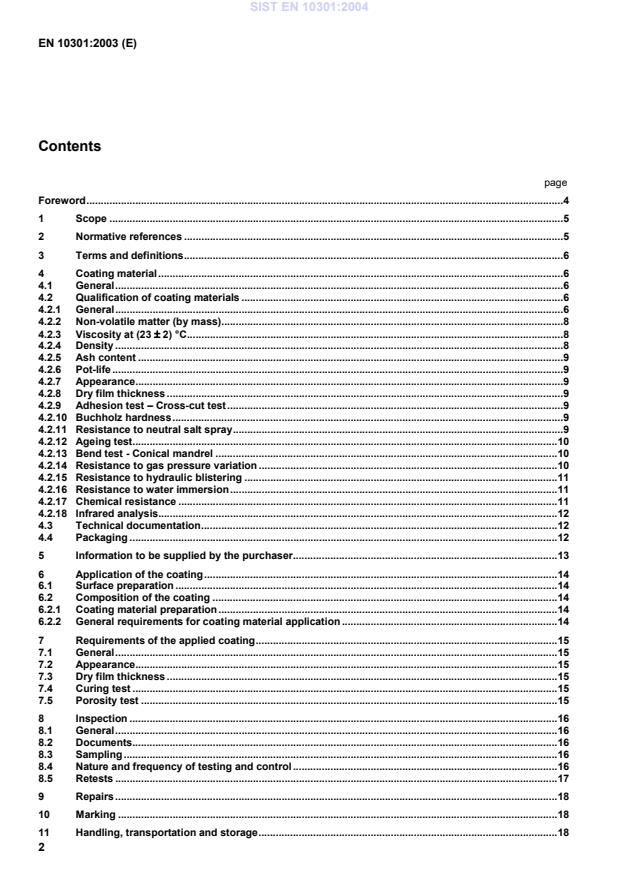

EN 10301:2003 is a CEN European Standard for internal coatings of steel tubes and fittings used in onshore and offshore pipelines that convey non‑corrosive gas. The standard specifies the application requirements and test methods for liquid‑applied epoxy paints intended primarily to reduce internal friction (hydraulic drag) in pipeline components. The coating is normally a single, shop‑applied liquid layer laid onto abrasive blast‑cleaned steel by airless or conventional spray; brush application is permitted only for repairs. Coatings qualified to EN 10301:2003 are suitable for service temperatures between –20 °C and +110 °C.

Key Topics and Requirements

- Coating type: Liquid applied epoxy paints (other systems allowed if they meet the standard).

- Application: One layer; shop application by airless or conventional spray; brush only for repairs.

- Surface preparation: Abrasive blast cleaning of steel prior to coating.

- Temperature range: Qualified coatings suitable from –20 °C to +110 °C.

- Qualification and testing: Detailed test regime and acceptance criteria, including:

- Physical properties: non‑volatile matter, viscosity, density, pot‑life, appearance.

- Film properties: dry film thickness (DFT), adhesion (cross‑cut), Buchholz hardness, porosity.

- Durability tests: resistance to neutral salt spray, ageing, water immersion, chemical resistance.

- Mechanical performance: bend (conical mandrel) test, resistance to gas pressure variation, hydraulic blistering.

- Analytical checks: ash content, infrared analysis.

- Inspection & documentation: Sampling, frequency of testing, technical documentation, packaging, marking, storage, handling and repair procedures are covered.

Applications and Who Uses This Standard

EN 10301:2003 is used by stakeholders involved in pipeline design, manufacture, installation and operation where friction reduction inside steel pipelines is required for non‑corrosive gas services. Typical users:

- Pipeline manufacturers and fabricators (tubes and fittings)

- Coating material suppliers and applicators (shop applicators)

- Pipeline engineering and design teams focusing on flow efficiency

- Inspection and quality control personnel (testing and acceptance)

- Asset owners, operators and procurement teams specifying coatings for new builds or replacements

Practical benefits include lower frictional losses, improved hydraulic efficiency and standardized qualification/acceptance procedures for internal epoxy coatings in gas pipeline systems.

Related Standards

EN 10301 references several EN/ISO test standards used for coating evaluation and measurement, for example:

- EN ISO 2808 - Determination of film thickness

- EN ISO 2409 - Cross‑cut adhesion test

- EN ISO 2811 - Determination of density

- EN ISO 1519 / EN ISO 1513 - Sample preparation and bend test

(Refer to the normative references in EN 10301:2003 for the full list.)

Keywords: EN 10301:2003, internal coating, epoxy paint, pipeline coatings, friction reduction, onshore offshore pipelines, non‑corrosive gas, liquid applied epoxy.

Frequently Asked Questions

SIST EN 10301:2004 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Steel tubes and fittings for on and offshore pipelines - Internal coating for the reduction of friction for conveyance of non corrosive gas". This standard covers: This European Standard specifies the application requirements and methods of test of liquid applied epoxy paints on the internal surface for the reduction of friction of tubes and pipeline fittings for conveyance of non-corrosive gas. Other paints or paint systems are not excluded provided they comply with the requirements given in this standard. The coating consist of one layer of liquid product, normally shop applied onto abrasive blast cleaned steel by airless spray or conventional spray techniques. Brush application may be used only for repairs. The coating qualified in accordance with this standard is considered suitable for operating temperatures between - 20 °C and + 110 °C. In this European Standard the word "components" is used for tubes and fittings.

This European Standard specifies the application requirements and methods of test of liquid applied epoxy paints on the internal surface for the reduction of friction of tubes and pipeline fittings for conveyance of non-corrosive gas. Other paints or paint systems are not excluded provided they comply with the requirements given in this standard. The coating consist of one layer of liquid product, normally shop applied onto abrasive blast cleaned steel by airless spray or conventional spray techniques. Brush application may be used only for repairs. The coating qualified in accordance with this standard is considered suitable for operating temperatures between - 20 °C and + 110 °C. In this European Standard the word "components" is used for tubes and fittings.

SIST EN 10301:2004 is classified under the following ICS (International Classification for Standards) categories: 75.180.10 - Exploratory, drilling and extraction equipment; 77.140.75 - Steel pipes and tubes for specific use. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 10301:2004 is associated with the following European legislation: Standardization Mandates: M/005. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 10301:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Steel tubes and fittings for on and offshore pipelines - Internal coating for the reduction of friction for conveyance of non corrosive gasStahlrohre und -formstücke für On- und Offshore-Rohrleitungen - Innenbeschichtung zur Verringerung der Reibung beim Transport von nicht korrosivem GasTubes et raccords en acier pour canalisations enterrées et immergées - Revetement interne antifriction pour le transport de gaz non corrosifsSteel tubes and fittings for on and offshore pipelines - Internal coating for the reduction of friction for conveyance of non corrosive gas77.140.75Jeklene cevi in cevni profili za posebne nameneSteel pipes and tubes for specific use75.180.10Oprema za raziskovanje in odkopavanjeExploratory and extraction equipmentICS:Ta slovenski standard je istoveten z:EN 10301:2003SIST EN 10301:2004en01-junij-2004SIST EN 10301:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 10301August 2003ICS 23.040.99; 25.220.60; 75.180.10English versionSteel tubes and fittings for on and offshore pipelines - Internalcoating for the reduction of friction for conveyance of noncorrosive gasTubes en acier et raccords pour canalisations enterrées etimmergées - Revêtement interne antifriction pour letransport de gaz non corrosifsStahlrohre und -formstücke für On- und Offshore-Rohrleitungen - Innenbeschichtung zur Verringerung derReibung beim Transport von nicht korrosivem GasThis European Standard was approved by CEN on 9 January 2003.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and UnitedKingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2003 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 10301:2003 ESIST EN 10301:2004

Ash content.19A.1General.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...