SIST EN 14318-1:2013

(Main)Thermal insulating products for buildings - In-situ formed dispensed rigid polyurethane (PUR) and polyisocyanurate (PIR) foam products - Part 1: Specification for the rigid foam dispensed system before installation

Thermal insulating products for buildings - In-situ formed dispensed rigid polyurethane (PUR) and polyisocyanurate (PIR) foam products - Part 1: Specification for the rigid foam dispensed system before installation

This European Standard specifies requirements for in-situ formed dispensed rigid polyurethane (PUR) and rigid polyisocyanurate (PIR) foam products when installed into cavity walls.

This Part 1 of this European Standard is a specification for the rigid foam dispensing system before installation.

Part 1 of this European Standard describes the product characteristics and includes procedures for testing, marking and labelling and the rules for evaluation of conformity.

This European Standard does not specify the required levels of all properties that should be achieved by a product to demonstrate fitness for purpose in a particular end-use application. The required levels are to be found in regulations or non-conflicting standards.

This European Standard does not cover factory made rigid polyurethane (PUR) or polyisocyanurate (PIR) foam insulation products or in-situ products intended to be used for the insulation of building equipment and industrial installations.

NOTE Foam products are either called flexible or rigid. The flexible products are used in upholstery and mattresses and are characterised by their ability to deflect, support and recover to their original thickness continually during their in-use phase. Those that are not flexible are termed rigid and do not possess these flexible characteristics. They are mostly used for thermal insulation purposes and vary widely in their compression strength values. Once the cell structure is crushed in a rigid foam, it does not recover its thickness fully. Some of these rigid foams are very low in density with very low compression strengths and are sometimes described “commercially” as “soft foams” or “semi-rigid” foams. This note has been included to clarify that all foams with such descriptions are covered by this standard’s used of the term rigid foam.

Wärmedämmstoffe für das Bauwesen - An der Verwendungsstelle hergestellte Wärmedämmung aus dispensiertem Polyurethan (PUR)- und Polyisocyanurat (PIR)-Hartschaum - Teil 1: Spezifikation für das Schaumsystem vor dem Einbau

Diese Europäische Norm legt Anforderungen an Wärmedämmprodukte aus dispensiertem Poly-urethan(PUR)- und Polyisocyanurat (PIR)-Hartschaum fest, die an der Verwendungsstelle hergestellt und in Hohlwänden eingebaut werden.

Dieser Teil 1 der Europäischen Norm ist eine Spezifikation für das Schaumsystem vor dem Einbau.

Dieser Teil 1 der Europäischen Norm beschreibt die Produktmerkmale und enthält Verfahren für die Prüfung, Kennzeichnung und Etikettierung sowie die Regeln der Konformitätsbewertung.

Diese Europäische Norm legt keine Leistungsstufen für Eigenschaften fest, die ein Produkt erreichen sollten, um für eine bestimmte Endanwendung tauglich zu sein. Die erforderlichen Stufen sind Vorschriften oder nicht entgegenstehenden Normen zu entnehmen.

Diese Europäische Norm gilt weder für werkmäßig hergestellte Wärmedämmstoffe aus Polyurethan (PUR)- oder Polyisocyanurat (PIR)-Schaum noch für Produkte, die für den Einsatz zur Dämmung von technischen Gebäudeausrüstungen und betriebstechnischen Anlagen vorgesehen sind.

ANMERKUNG Schaumstoffprodukte werden in „Weichschaumstoffe“ und „Hartschaumstoffe“ eingeteilt. Weichschaumstoffe werden in Polstermöbeln oder Matratzen verwendet und werden durch ihre Fähigkeit charakterisiert, kontinuierlich während ihrer Nutzungsdauer sich zu verformen, zu stützen und ihre ursprüngliche Dicke wieder anzunehmen. Hartschaumstoffe dagegen weisen diese flexiblen Eigenschaften nicht auf. Sie werden überwiegend als Wärmedämmstoffe eingesetzt und weisen sehr unterschiedliche Druckfestigkeitswerte auf. Wird die Zellstruktur eines Hartschaumstoffes zusammengedrückt, nimmt sie ihre ursprüngliche Dicke nicht wieder an. Einige Hartschaumstoffe besitzen sowohl eine sehr geringe Dichte als auch eine sehr geringe Druckfestigkeit und werden im Handel manchmal als „halbharte“ Hartschaumstoffe bezeichnet. Diese Anmerkung ist eingefügt worden, um klarzustellen, dass alle derart bezeichneten Hartschaumstoffe von dem in dieser Norm verwendeten Begriff „Hartschaum“ abgedeckt sind.

Produits isolant thermiques destinés aux applications du bâtiment - Produits en mousse rigide de polyuréthanne (PUR) ou de polyisocyanurate (PIR) injectée, formés en place - Partie 1: Spécifications relatives aux systèmes d'injection du polyuréthanne ou du polyisocyanurate avant mise en oeuvre

La présente Norme européenne spécifie les exigences relatives aux produits en mousse rigide de polyuréthanne (PUR) ou de polyisocyanurate (PIR) injectée, formés en place, lorsqu'ils sont mis en œuvre dans des murs creux.

Cette Partie 1 de la présente Norme européenne est une spécification du système d'injection de mousse rigide avant mise en œuvre.

Cette Partie 1 de la présente Norme européenne décrit les caractéristiques du produit et contient des modes opératoires d'essai, de marquage et d'étiquetage ainsi que les règles d'évaluation de la conformité.

La présente Norme européenne ne spécifie pas, pour toutes les propriétés, les niveaux exigés que doit atteindre un produit pour démontrer son aptitude à l'emploi dans une application finale particulière. Les niveaux exigés figurent dans des réglementations ou dans des normes non divergentes.

La présente Norme européenne ne couvre pas les produits isolants en mousse rigide de polyuréthanne (PUR) ou de polyisocyanurate (PIR) manufacturés ou formés en place et destinés à être utilisés pour l'isolation des équipements du bâtiment et des installations industrielles.

NOTE Les produits en mousse sont dits flexibles ou rigides. Les produits flexibles sont utilisés dans les garnitures et les matelas et sont caractérisés par leur aptitude à se déformer, supporter et reprendre continuellement leur épaisseur initiale durant leur phase d'utilisation. Les produits qui ne sont pas flexibles sont dits rigides et ne possèdent pas ces caractéristiques flexibles. Ils sont essentiellement utilisés à des fins d'isolation thermique et présentent des valeurs de résistance à la compression très diverses. Lorsque la structure cellulaire d'une mousse rigide est écrasée, elle ne reprend pas totalement son épaisseur initiale. Certaines de ces mousses rigides ont une masse volumique très faible avec une très faible résistance à la compression et sont parfois décrites « commercialement » comme des « mousses souples » ou des « mousses semi-rigides ». Cette note a été incluse pour indiquer clairement que toutes les mousses répondant à ces descriptions sont couvertes par l'utilisation du terme « mousse rigide » dans la présente norme.

Toplotnoizolacijski proizvodi za stavbe - Proizvodi iz trde poliuretanske pene (PUR) in poliizocianuratne pene (PIR), oblikovani na mestu vgradnje - 1. del: Specifikacija penastega sistema pred vgradnjo

Ta evropski standard določa zahteve za proizvode iz brizgane trde poliuretanske pene (PUR) in trde poliizocianuratne pene (PIR), vgrajene v zidove z votlino. 1. del tega evropskega standarda je specifikacija penastega sistema pred vgradnjo. 1. del tega evropskega standarda opisuje lastnosti proizvoda in vključuje postopke za preskušanje, označevanje in etiketiranje ter pravila za ocenjevanje skladnosti. Ta evropski standard ne določa zahtevanih ravni vseh lastnosti, ki jih mora proizvod doseči, da se dokaže njegova primernost namenu za posamezno vrsto končne uporabe. Zahtevane ravni so določene v uredbah ali standardih, ki niso v nasprotju s tem standardom. Ta evropski standard ne zajema izolacijskih proizvodov iz trde poliuretanske pene (PUR) in poliizocianuratne pene (PIR) ali proizvodov, izdelanih na kraju samem, namenjenih za izolacijo opreme stavb in industrijskih inštalacij.

General Information

- Status

- Published

- Public Enquiry End Date

- 31-Oct-2012

- Publication Date

- 05-Jun-2013

- Technical Committee

- TOP - Thermal insulation

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 23-Apr-2013

- Due Date

- 28-Jun-2013

- Completion Date

- 06-Jun-2013

- Directive

- 89/106/EEC - Construction products

Overview

SIST EN 14318-1:2013 - Thermal insulating products for buildings - Part 1 - is the European specification for in‑situ formed dispensed rigid polyurethane (PUR) and polyisocyanurate (PIR) foam systems before installation. The standard defines product characteristics, test procedures, marking and labelling requirements, and rules for evaluation of conformity for foam dispensing systems used to insulate cavity walls. It is the harmonised (pre‑installation) part of the EN 14318 series and supports CE marking under the EU Construction Products Directive.

Key topics and technical requirements

This standard covers the specification and conformity assessment of dispensed rigid PUR/PIR foam systems and includes, among others:

- Scope and definitions clarifying rigid vs flexible foam and exclusions (factory-made products and insulation for building equipment/industrial installations).

- Product requirements for dispensed systems used in cavity wall insulation.

- Testing methods and procedures for sampling, specimen preparation, conditioning and specific tests (e.g., thermal conductivity, thermal resistance, substrate adhesion, reaction to fire).

- Aged performance: procedures to determine declared aged thermal conductivity and thermal resistance (accelerated aging and fixed increment procedures).

- Reaction to fire testing and guidance for testing in standardised assemblies and end‑use simulations.

- Evaluation of conformity including Initial Type Testing (ITT) and Factory Production Control (FPC).

- Marking, labelling and technical information obligations for manufacturers (including Annex ZA provisions related to CE marking and attestation of conformity).

- Annexes providing normative test methods and informative examples (e.g., determination of reaction profile, free‑rise density, and performance chart instructions).

Practical applications and who uses this standard

SIST EN 14318-1:2013 is used by:

- Manufacturers of in‑situ dispensed PUR/PIR foam systems to prepare technical datasheets, demonstrate conformity, and obtain CE marking.

- Test laboratories and QA teams implementing the specified test methods for thermal performance, adhesion and fire reaction.

- Specifiers, architects and engineers evaluating products for cavity wall insulation projects and comparing declared thermal properties.

- Regulatory bodies and certification bodies assessing compliance with EU Construction Products Directive requirements.

- Installers and contractors who need to understand pre‑installation product characteristics, marking, and performance claims.

Practical uses include product development, compliance documentation, tender specifications, and producing thermal resistance performance charts for design validation.

Related standards

- EN 14318-2: Specification for the installed product (companion document)

- Applicable referenced standards cited in EN 14318-1 (examples): EN 1602, EN 1604, EN 823 and other EN test methods used for thermal insulation products.

Keywords: SIST EN 14318-1:2013, in-situ formed dispensed rigid polyurethane, polyisocyanurate, PUR, PIR, cavity walls, thermal insulation, CE marking, evaluation of conformity, thermal conductivity.

Frequently Asked Questions

SIST EN 14318-1:2013 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Thermal insulating products for buildings - In-situ formed dispensed rigid polyurethane (PUR) and polyisocyanurate (PIR) foam products - Part 1: Specification for the rigid foam dispensed system before installation". This standard covers: This European Standard specifies requirements for in-situ formed dispensed rigid polyurethane (PUR) and rigid polyisocyanurate (PIR) foam products when installed into cavity walls. This Part 1 of this European Standard is a specification for the rigid foam dispensing system before installation. Part 1 of this European Standard describes the product characteristics and includes procedures for testing, marking and labelling and the rules for evaluation of conformity. This European Standard does not specify the required levels of all properties that should be achieved by a product to demonstrate fitness for purpose in a particular end-use application. The required levels are to be found in regulations or non-conflicting standards. This European Standard does not cover factory made rigid polyurethane (PUR) or polyisocyanurate (PIR) foam insulation products or in-situ products intended to be used for the insulation of building equipment and industrial installations. NOTE Foam products are either called flexible or rigid. The flexible products are used in upholstery and mattresses and are characterised by their ability to deflect, support and recover to their original thickness continually during their in-use phase. Those that are not flexible are termed rigid and do not possess these flexible characteristics. They are mostly used for thermal insulation purposes and vary widely in their compression strength values. Once the cell structure is crushed in a rigid foam, it does not recover its thickness fully. Some of these rigid foams are very low in density with very low compression strengths and are sometimes described “commercially” as “soft foams” or “semi-rigid” foams. This note has been included to clarify that all foams with such descriptions are covered by this standard’s used of the term rigid foam.

This European Standard specifies requirements for in-situ formed dispensed rigid polyurethane (PUR) and rigid polyisocyanurate (PIR) foam products when installed into cavity walls. This Part 1 of this European Standard is a specification for the rigid foam dispensing system before installation. Part 1 of this European Standard describes the product characteristics and includes procedures for testing, marking and labelling and the rules for evaluation of conformity. This European Standard does not specify the required levels of all properties that should be achieved by a product to demonstrate fitness for purpose in a particular end-use application. The required levels are to be found in regulations or non-conflicting standards. This European Standard does not cover factory made rigid polyurethane (PUR) or polyisocyanurate (PIR) foam insulation products or in-situ products intended to be used for the insulation of building equipment and industrial installations. NOTE Foam products are either called flexible or rigid. The flexible products are used in upholstery and mattresses and are characterised by their ability to deflect, support and recover to their original thickness continually during their in-use phase. Those that are not flexible are termed rigid and do not possess these flexible characteristics. They are mostly used for thermal insulation purposes and vary widely in their compression strength values. Once the cell structure is crushed in a rigid foam, it does not recover its thickness fully. Some of these rigid foams are very low in density with very low compression strengths and are sometimes described “commercially” as “soft foams” or “semi-rigid” foams. This note has been included to clarify that all foams with such descriptions are covered by this standard’s used of the term rigid foam.

SIST EN 14318-1:2013 is classified under the following ICS (International Classification for Standards) categories: 91.100.60 - Thermal and sound insulating materials. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14318-1:2013 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/103. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 14318-1:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Toplotnoizolacijski proizvodi za stavbe - Proizvodi iz trde poliuretanske pene (PUR) in poliizocianuratne pene (PIR), oblikovani na mestu vgradnje - 1. del: Specifikacija penastega sistema pred vgradnjoWärmedämmstoffe für das Bauwesen - An der Verwendungsstelle hergestellte Wärmedämmung aus dispensiertem Polyurethan (PUR)- und Polyisocyanurat (PIR)-Hartschaum - Teil 1: Spezifikation für das Schaumsystem vor dem EinbauProduits isolant thermiques destinés aux applications du bâtiment - Produits en mousse rigide de polyuréthanne (PUR) ou de polyisocyanurate (PIR) injectée, formés en place - Partie 1: Spécifications relatives aux systèmes d'injection du polyuréthanne ou du polyisocyanurate avant mise en oeuvreThermal insulating products for buildings - In-situ formed dispensed rigid polyurethane (PUR) and polyisocyanurate (PIR) foam products - Part 1: Specification for the rigid foam dispensed system before installation91.100.60Thermal and sound insulating materialsICS:Ta slovenski standard je istoveten z:EN 14318-1:2013SIST EN 14318-1:2013en,fr,de01-julij-2013SIST EN 14318-1:2013SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14318-1

January 2013 ICS 91.100.60 English Version

Thermal insulating products for buildings - In-situ formed dispensed rigid polyurethane (PUR) and polyisocyanurate (PIR) foam products - Part 1: Specification for the rigid foam dispensed system before installation

Produits isolants thermiques destinés aux applications du bâtiment - Produits en mousse rigide de polyuréthanne (PUR) ou de polyisocyanurate (PIR) injectée, formés en place - Partie 1 : Spécifications relatives aux systèmes d'injection de mousse rigide avant mise en œuvre

Wärmedämmstoffe für das Bauwesen - An der Verwendungsstelle hergestellter Wärmedämmstoff aus dispensiertem Polyurethan (PUR)- und Polyisocyanurat (PIR)-Hartschaum - Teil 1: Spezifikation für das Schaumsystem vor dem Einbau This European Standard was approved by CEN on 17 November 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14318-1:2013: ESIST EN 14318-1:2013

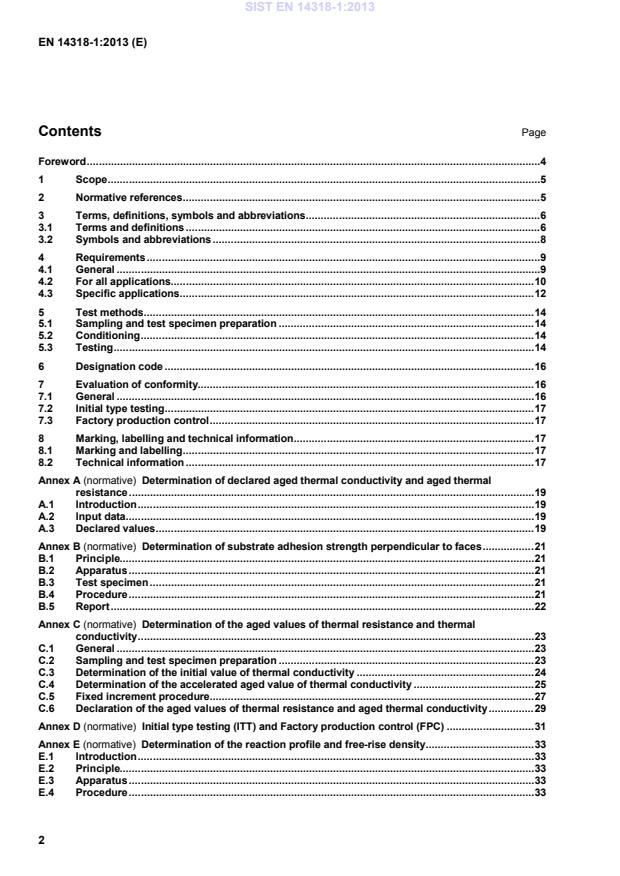

Determination of declared aged thermal conductivity and aged thermal resistance . 19 A.1 Introduction . 19 A.2 Input data . 19 A.3 Declared values . 19 Annex B (normative)

Determination of substrate adhesion strength perpendicular to faces . 21 B.1 Principle. 21 B.2 Apparatus . 21 B.3 Test specimen . 21 B.4 Procedure . 21 B.5 Report . 22 Annex C (normative)

Determination of the aged values of thermal resistance and thermal conductivity . 23 C.1 General . 23 C.2 Sampling and test specimen preparation . 23 C.3 Determination of the initial value of thermal conductivity . 24 C.4 Determination of the accelerated aged value of thermal conductivity . 25 C.5 Fixed increment procedure . 27 C.6 Declaration of the aged values of thermal resistance and aged thermal conductivity . 29 Annex D (normative)

Initial type testing (ITT) and Factory production control (FPC) . 31 Annex E (normative)

Determination of the reaction profile and free-rise density . 33 E.1 Introduction . 33 E.2 Principle. 33 E.3 Apparatus . 33 E.4 Procedure . 33 SIST EN 14318-1:2013

Sample preparation method for the test specimens for the thermal conductivity test . 35 Annex G (normative)

Sample preparation method for the test specimens other than thermal conductivity . 36 G.1 Principle . 36 G.2 Procedure . 36 Annex H (normative)

Testing for reaction to fire of products . 37 H.1 Scope . 37 H.2 Product and installation parameters . 37 H.3 Mounting and fixing . 38 H.4 Field of application . 40 Annex I (normative)

Testing for reaction to fire of products in standardised assemblies simulating end-use application(s) . 42 I.1 Scope . 42 I.2 Product and installation parameters . 42 I.3 Mounting and fixing . 43 I.4 Field of application . 46 Annex J (informative)

Example for the determination of the declared aged values of thermal conductivity and thermal resistance for a product . 48 Case where both thermal conductivity and thermal resistance are declared . 48 Annex K (normative)

Instructions for compiling thermal resistance performance charts. 50 K.1 Introduction . 50 K.2 General . 50 K.3 Procedure for the manufacturer to create the performance charts . 52 Annex ZA (informative)

Clause of this European Standard addressing the provisions of the provisions of the EU Construction Products Directive . 57 ZA.1 Scope and relevant characteristics . 57 ZA.2 Procedure for attestation of conformity of in-situ formed dispensed rigid polyurethane (PUR) and rigid polyisocyanurate foam (PIR) products. 59 ZA.3 CE marking and labelling . 62 Bibliography . 64

1 Scope This European Standard specifies requirements for in-situ formed dispensed rigid polyurethane (PUR) and rigid polyisocyanurate (PIR) foam products when installed into cavity walls. This Part 1 of this European Standard is a specification for the rigid foam dispensing system before installation. Part 1 of this European Standard describes the product characteristics and includes procedures for testing, marking and labelling and the rules for evaluation of conformity. This European Standard does not specify the required levels of all properties that should be achieved by a product to demonstrate fitness for purpose in a particular end-use application. The required levels are to be found in regulations or non-conflicting standards. This European Standard does not cover factory made rigid polyurethane (PUR) or polyisocyanurate (PIR) foam insulation products or in-situ products intended to be used for the insulation of building equipment and industrial installations. NOTE Foam products are either called flexible or rigid. The flexible products are used in upholstery and mattresses and are characterised by their ability to deflect, support and recover to their original thickness continually during their in-use phase. Those that are not flexible are termed rigid and do not possess these flexible characteristics. They are mostly used for thermal insulation purposes and vary widely in their compression strength values. Once the cell structure is crushed in a rigid foam, it does not recover its thickness fully. Some of these rigid foams are very low in density with very low compression strengths and are sometimes described “commercially” as “soft foams” or “semi-rigid” foams. This note has been included to clarify that all foams with such descriptions are covered by this standard’s used of the term rigid foam. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 312, Particleboards — Specifications EN 508-1, Roofing products from metal sheet — Specification for self-supporting products of steel, aluminium or stainless steel sheet — Part 1: Steel EN 520, Gypsum plasterboards — Definitions, requirements and test methods EN 823, Thermal insulating products for building applications — Determination of thickness

EN 1602, Thermal insulating products for building applications — Determination of the apparent density EN 1604, Thermal insulating products for building applications — Determination of dimensional stability under specified temperature and humidity conditions EN 1609, Thermal insulating products for building applications — Determination of short term water absorption by partial immersion EN 12086:1997, Thermal insulating products for building applications — Determination of water vapour transmission properties EN 12667:2001, Thermal performance of building materials and products — Determination of thermal resistance by means of guarded hot plate and heat flow meter methods — Products of high and medium thermal resistance SIST EN 14318-1:2013

For the purposes of this document, the terms and definitions given in EN ISO 9229:2007 and the following apply. 3.1.1 polyurethane foam PUR

(in-situ formed products) rigid cellular plastics insulation material or product with a structure based on polymers mainly of the polyurethane type 3.1.2 polyisocyanurate foam PIR

(in-situ formed products) rigid cellular plastics insulation material or product with a structure based on polymers mainly of the polyisocyanurate type 3.1.3 polyurethane foam PU rigid cellular plastics insulation materials or products including both polymer types based mainly on polyurethane (PUR) or mainly on polyisocyanurate (PIR) groups SIST EN 14318-1:2013

is the practical sound absorption coefficient - αw

is the weighted sound absorption coefficient - dN

is the nominal thickness of the product mm ∆0l

is the relative change in length % ∆0b

is the relative change in width % ∆0d

is the relative change in thickness % k is a factor related to the number of test results available - ka is a factor related to the number of aged test results - ki is a factor related to the number of initial test results - λ90/90 is the 90 % fractile with a confidence level of 90 % for the thermal conductivity

W/(m·K) λD is the declared thermal conductivity (aged) W/(m·K) λi

is one test result of thermal conductivity

W/(m·K) λmean is the mean thermal conductivity

W/(m·K) λmean,a is the mean thermal conductivity of aged values

W/(m·K) λmean,i is the mean thermal conductivity of initial values

W/(m·K) ûλa is the ageing increment from measured aged values of thermal conductivity

W/(m·K) ûλf is the fixed ageing increment

W/(m·K) µ==is the water vapour diffusion resistance factor - n

is the number of test results - R90/90 is the 90 % fractile with a confidence level of 90 % for the thermal resistance

m2K/W RD

is the declared thermal resistance

m2K/W Ri

is one test result of thermal resistance

m2K/W Rmean

is the mean thermal resistance

m2K/W sλ

is the estimate of the standard deviation of the thermal conductivity

W/(m·K) sλa

is the estimate of the standard deviation of the aged values of thermal conductivity

W/(m·K) sλi

is the estimate of the standard deviation of the initial values of thermal conductivity

W/(m·K) SIST EN 14318-1:2013

is the estimate of the standard deviation of the values of thickness

m σa

is the substrate adhesion strength perpendicular to faces

kPa Wp.

is the short term water absorption by partial immersion

kg/m2 3.2.2 Designation code in this standard AP(d) is the symbol for the declared level of practical sound absorption coefficient with d for the thickness or the range of thicknesses, expressed in millimetres, in which the declared value is valid

AW(d) is the symbol for the declared level of weighted sound absorption coefficient with d for the thickness or the range of thicknesses, expressed in millimetres, in which the declared value is valid CCC is the symbol for the declared level for closed cell content DS (TH) is the symbol for the declared level for dimensional stability under specified temperature and humidity CT is the symbol for the declared cream time GT is the symbol for the declared gel time TFT is the symbol for the declared tack-free time W is the symbol for the declared short term water absorption by partial immersion FRC is the symbol for the declared core free-rise density FRB is the symbol for the declared beaker free-rise density TS is the symbol for substrate adhesion strength perpendicular to faces MU is the symbol for the declared water vapour resistance 3.2.3 Abbreviations used in this standard PIR

is Rigid PolyIsocyanurate Foam PU

is Rigid PolyUrethane foam including PUR and PIR types PUR

is Rigid PolyUrethane Foam ITT

is Initial Type Test

4 Requirements

4.1 General The foam properties shall be assessed in accordance with Clause 5. To conform with this standard, foam systems shall meet the requirements of 4.2 and 4.3 as appropriate. NOTE The range of properties exhibited by PUR products is very wide. The same is true for PIR products and these two ranges often overlap. Although not in every case, generally PIR products have a higher upper service temperature and can perform better in reaction to fire tests. In all cases, for both PIR and PUR products, their individual performance claimed by the manufacturer are described by the levels of properties obtained. Accordingly, therefore, all the declaration clauses will be completed using the term PU to include both PUR and PIR products (see 3.1.3). SIST EN 14318-1:2013

Unless otherwise specified by the test method, in all the other test methods involving the measurement of thickness, this shall be carried out using the method given in EN 823. 4.2.2 Thermal resistance and thermal conductivity

Thermal resistance and thermal conductivity shall be based upon measurements carried out in accordance with EN 12667 or EN 12939 for thick products.

The thermal resistance and thermal conductivity (both the initial and the aged values) shall be determined in accordance with Annex A, Annex C and 5.3.2 and the aged values declared by the manufacturer according to the following: The reference mean temperature shall be 10 °C. The measured values shall be expressed with three significant figures. The thermal resistance, RD, shall always be declared. The thermal conductivity, λD, shall be declared wherever this is possible. The declared thermal resistance, RD, and the thermal conductivity, λD, shall be given as limit values representing at least 90 % of the production, determined with a confidence level of 90 %. The value of thermal conductivity, λ90/90, shall be rounded upwards to the nearest 0,001 W/(m·K) and declared as λD in levels with steps of 0,001 W/(m·K). The declared thermal resistance, RD, shall be calculated from the nominal thickness, dN, and the corresponding thermal conductivity, λ90/90 unless measured directly. The value of thermal resistance, R90/90, when calculated from the nominal thickness, dN, and the corresponding thermal conductivity, λ90/90; shall be rounded downwards to the nearest 0,05 m2·K/W, and declared as RD in levels with steps of 0,05 m2·K/W (see Note). An example of the determination of the declared aged values of thermal conductivity and thermal resistance is given in Annex J. NOTE In EN 14318-2, the declaration of the declared installed aged thermal resistance for an installed dispensed rigid PU foam is made by the installer. 4.2.3 Reaction profile and free-rise density

The appropriate values for the reaction profile and free-rise density (either FRC or FRB) for the dispensing foam system shall be declared, having been determined in accordance with the procedures given in Annex E. 4.2.4 Short term water absorption by partial immersion The short term water absorption by partial immersion, Wp, in kg/m2, shall be determined using EN 1609, Method B and shall be declared in kg/m2. No test result shall be higher than the declared value. SIST EN 14318-1:2013

4.3.5 Reaction to fire of products in standardised assemblies simulating end-use applications 4.3.5.1 General The reaction to fire classification taking into account the end-use applications, shall be determined in accordance with Annex I using EN 13501-1 and using data obtained from tests carried out according to procedures in EN ISO 11925-2 and EN 13823 and using test specimens conforming to 4.3.5.2 and mounting and fixing procedures in accordance with 4.3.5.3. NOTE The ignitability procedure using EN ISO 11925-2 in Annex I is identical to the procedure given under H.3.1 and therefore need not be repeated. Accordingly, this clause contains only information relevant to testing carried out according to EN 13823 in Annex I. 4.3.5.2 Test specimens for the EN 13823 test Prepare five long and five short wing specimens in accordance with I.3.2.1. 4.3.5.3 Mounting and fixing procedure 4.3.5.3.1 EN 13823 Test specimens prepared in accordance with 4.3.5.2 shall be mounted so that the inner face of the test specimen which is typical of the end use application is in contact with the flame source. Only the corner joint shall be incorporated and this shall be protected by a steel angle bracket. In all other respects, the products shall be mounted as specified in EN 13823:2010, 5.2.2. 4.3.6 Continuous glowing combustion Where subject to regulations, the manufacturer shall declare the continuous glowing combustion of the product. In the absence of a European test method, the compliance with the requirement shall be made on the basis of any existing national test method. NOTE A European test method is under development and the standard will be amended when this is available. 4.3.7 Dimensional stability under specified temperature and humidity conditions Dimensional stability under specified temperature and humidity conditions shall be determined in accordance with EN 1604. The tests, each on different sets of specimens, shall be carried out for (48 ± 1) h at both (-20 ± 3) °C and at (70 ± 2) °C and a relative humidity of (90 ± 5) %. The relative changes in length, ∆0I, with ∆0b and thickness ∆0d, shall not exceed the values given in Table 3 for the labelled level. SIST EN 14318-1:2013

1 (70 ± 2) °C and

(90 ± 5) % r.h. ∆0l

∆0b

% ≤ 5 ≤ 2 ≤ 1 ∆0d

% ≤ 9 ≤ 6 ≤ 4

2 (-20 ± 3) °C ∆0l

∆0b

% ≤

≤ 0,5 ≤ 0,5 ∆0d

% ≤ 2 ≤ 2 ≤ 2 5 Test methods 5.1 Sampling and test specimen preparation 5.1.1 Thermal conductivity Prepare a test sample and test specimens in accordance with the method given in Annex F. 5.1.2 Other characteristics Prepare a test sample and the appropriate test specimens in accordance with Annex G. 5.2 Conditioning No special conditioning of the test specimens shall be used unless otherwise specified in the test standards. In case of dispute, the test specimens shall be stored at (23 ± 2) °C and (50 ± 5) % relative humidity for at least 16 h prior to testing. 5.3 Testing 5.3.1 General Table 4 gives the dimensions of the test specimens, the minimum number of test specimens required to get one test result and any specific conditions which are necessary. 5.3.2 Thermal resistance and thermal conductivity Thermal resistance and thermal conductivity shall be determined in accordance with EN 12667 or EN 12939 for thick products and under the following conditions: at a mean reference temperature of (10 ± 0,3) °C; after conditioning in accordance with 5.2; after preparation of the test specimen in accordance with C.2. Thermal resistance and thermal conductivity may also be measured at mean temperatures other than 10 °C, providing that the accuracy of the relationship between temperature and thermal properties is sufficiently well documented. SIST EN 14318-1:2013

4.2.2 Thermal resistance – Thermal conductivity EN 12667 EN 12939 See Annex C and 5.3.2 1 See Annex C 4.2.3 Reaction profile and free-rise density Annex E See Annex E 1

4.2.4 Short term water absorption by partial immersion EN 1609 200 x 200 x 50 4

4.2.5 Water vapour transmission

EN 12086 See EN 12086:1997 (6.1) ≤ 500cm2 x 50 or > 500cm2 x 50

5 3

4.2.7 Reaction to fire of the products EN 13501-1 See EN 13501-1

4.2.8 Closed cell content ISO 4590 See ISO 4590 3 sets

4.3.2 Sound absorption EN ISO 354 min. 10 m2

1 To be reported 4.3.3 Release of dangerous substances

- - - a 4.3.4 Substrate adhesion strength perpendicular to faces Annex B 228 x 114 x 76 2 b 4.3.5 Reaction to fire of products in standardised assemblies simulating end-use applications EN 13501-1 See EN 13501-1 - 4.3.6 Continuous glowing combustion - - - a 4.3.7 Dimensional stability under specified temperature and humidity conditions EN 1604 200 x 200 x 25 3

a

Not yet available. b

No individual value may be more than 25 % below the average value which corresponds to the fixed level.

A designation code for the product shall be given by the manufacturer. The following shall be included except where there is no requirement for a property described in 4.3. PU This European Standard number Dimensional stability under specified temperature and humidity conditions

DS(TH)i Closed cell content

CCCi Substrate adhesion strength perpendicular to faces

TSi Reaction profile and free-rise density

cream time

CTi(*) gel time

GTi(*) tack free time

TFTi(*) free-rise density by the core (or beaker) methods

FRCi(*)(or FRB)i(*) Water vapour diffusion resistance

MUi Short term water absorption by partial immersion

Wi

Practical sound absorption coefficient

APi(d) Weighted sound absorption coefficient

AWi(d) Declared thermal conductivity (aged)

See performance

charts in Annex K where "i" shall be used to indicate the relevant level. Inside (*) replace the * by the temperature of measurement in °C. The designation code for a PUR/PIR product is illustrated by the following example: EXAMPLE PU EN14318-1-DS(TH)2-CCC1-CT5(20)-GT15(20)-TFT25(20)-FRC30(20)- MU120-W0.9 7 Evaluation of conformity

7.1 General The manufacturer or his authorised representative established in the EEA shall be responsible for the conformity of his products with the requirements of this European Standard. The evaluation of conformity shall be carried out in accordance with EN 13172 and shall be demonstrated by

initial type testing (ITT); factory production control by the manufacturer, including product assessment and tests on samples taken at the factory. SIST EN 14318-1:2013

7.3 Factory production control Factory production control characteristics shall be made for the characteristics in Annex D. The minimum frequencies of test in the factory

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...