SIST EN 13172:2025

(Main)Thermal insulation products - Common evaluation rules

Thermal insulation products - Common evaluation rules

This document specifies common evaluation rules useful for the assessment and verification of constancy of performance of a thermal insulation product with harmonised technical specifications, product standards and any other assessment documents. Harmonised technical specifications, product standards and other assessment documents are called European product specifications in this document.

This document applies to factory made products for buildings, factory made products for building equipment and industrial installations, in situ products for buildings, in situ products for building equipment and industrial installations, to products for civil engineering applications, and to external thermal insulation composite kits.

Wärmedämmstoffe - Gemeinsame Bewertungsregeln

Dieses Dokument legt gemeinsame Bewertungsregeln fest, die für die Bewertung und Überprüfung der Leistungsbeständigkeit eines Wärmedämmstoffes mit harmonisierten technischen Spezifikationen, Produktnormen und anderen Bewertungsdokumenten nützlich sind. Harmonisierte technische Spezifikationen, Produktnormen und andere Bewertungsdokumente werden in diesem Dokument als Europäische Produktspezifikationen bezeichnet.

Dieses Dokument ist anwendbar für werkmäßig hergestellte Wärmedämmstoffe für Gebäude, für werkmäßig hergestellte Wärmedämmstoffe für die technische Gebäudeausrüstung und betriebstechnische Anlagen, für an der Verwendungsstelle hergestellte Dämmstoffe für Gebäude, für an der Verwendungsstelle hergestellte Dämmstoffe für die technische Gebäudeausrüstung und betriebstechnische Anlagen, für Wärmedämmstoffe für bautechnische Anwendungen und für außenseitige Wärmedämmverbundsysteme.

Produits isolants thermiques - Règles d’évaluation communes

Le présent document spécifie des règles d’évaluation communes utiles pour l’évaluation et la vérification de la constance des performances d’un produit isolant thermique par rapport à des spécifications techniques harmonisées, des normes de produits et tout autre document d’évaluation. Les spécifications techniques harmonisées, les normes de produits et autres documents d’évaluation sont désignés par le terme « Spécifications européennes de produit » dans le présent document.

Le présent document s’applique aux produits manufacturés pour le bâtiment, aux produits manufacturés pour l’équipement du bâtiment et les installations industrielles, aux produits mis en œuvre in situ pour le bâtiment, aux produits mis en œuvre in situ pour l’équipement du bâtiment et les installations industrielles, aux produits destinés à des applications de génie civil, ainsi qu’aux kits composites pour l’isolation thermique par l’extérieur.

Toplotnoizolacijski proizvodi - Skupna pravila vrednotenja

Ta dokument določa skupna pravila vrednotenja, ki so uporabna pri preverjanju ocene in nespremenljivosti delovanja toplotnoizolacijskega proizvoda z usklajenimi tehničnimi specifikacijami, standardi za proizvode in drugimi ocenjevalnimi dokumenti. Usklajene tehnične specifikacije, standardi za proizvode in drugi ocenjevalni dokumenti se v tem dokumentu imenujejo evropske specifikacije za proizvode.

Ta dokument se uporablja za tovarniško izdelane proizvode za stavbe, tovarniško izdelane proizvode za gradbeno opremo in industrijsko napeljavo, proizvode za stavbe, izdelane na mestu uporabe, proizvode za gradbeno opremo in industrijsko napeljavo, izdelane na mestu uporabe, proizvode za inženirske objekte ter za zunanje sestavljene toplotnoizolacijske komplete.

General Information

- Status

- Published

- Public Enquiry End Date

- 11-Jun-2023

- Publication Date

- 09-Dec-2024

- Technical Committee

- TOP - Thermal insulation

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 11-Nov-2024

- Due Date

- 16-Jan-2025

- Completion Date

- 10-Dec-2024

Relations

- Effective Date

- 01-Jan-2025

Overview

EN 13172:2024 - “Thermal insulation products - Common evaluation rules” (CEN) defines common rules for the assessment and verification of constancy of performance (AVCP) for thermal insulation products referenced by harmonised technical specifications and other European product specifications. The standard covers factory-made and in situ products for buildings, building equipment and industrial installations, civil engineering applications, and external thermal insulation composite kits (ETICS). It supports consistent application of factory production control (FPC), assessment of performance (AoP) and verification of constancy of performance (VoCP) across stakeholders.

Key Topics

- Scope and terminology: Aligns terms with the Construction Products Regulation (EU No 305/2011) and defines key abbreviations (AoP, VoCP, AVCP, FPC).

- Assessment and verification framework: Procedures for AoP and VoCP including responsibilities, documentation and inspection regimes.

- Factory production control (FPC): Requirements for organization, documentation, inspection and testing, test equipment, traceability, handling, storage and marking of products.

- Production process classification: Distinguishes continuous production lines from discontinuous/batch production units and rules for grouping products into product families.

- Testing and sampling: Guidance for product testing, sampling and record-keeping to verify declared characteristics (thermal resistance, thermal conductivity, etc.).

- Non-conformity and complaints: Criteria and procedures for managing complaints and assessing non-conformity.

- Informative annexes:

- Annex A - voluntary certification guidance (not for CE marking).

- Annex B - guidance for AVCP tasks, notified bodies and surveillance activities.

- Annex C - complaint handling and non-conformity criteria.

Applications and Who Uses It

EN 13172:2024 is intended for:

- Manufacturers of thermal insulation products (factory-made and in situ) to establish and document FPC and demonstrate constancy of performance.

- Notified bodies and certification/inspection bodies executing AVCP tasks, initial inspections, sampling, testing and ongoing surveillance.

- Testing laboratories performing AoP-related measurements and supporting compliance evidence.

- Specification writers, architects, contractors and regulators who rely on harmonised product specifications and CE-marked insulation products. Practical uses include preparing technical documentation for CE marking, designing production quality systems, conducting routine product testing, and resolving product complaints.

Related Standards

This document references and is intended to be used alongside harmonised product standards and normative test standards such as:

- EN 12664, EN 12667 and EN 12939 (thermal resistance/thermal conductivity test methods). Use EN 13172:2024 as the common evaluation rules framework when implementing or interpreting these product and test standards for thermal insulation compliance and CE marking.

Frequently Asked Questions

SIST EN 13172:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Thermal insulation products - Common evaluation rules". This standard covers: This document specifies common evaluation rules useful for the assessment and verification of constancy of performance of a thermal insulation product with harmonised technical specifications, product standards and any other assessment documents. Harmonised technical specifications, product standards and other assessment documents are called European product specifications in this document. This document applies to factory made products for buildings, factory made products for building equipment and industrial installations, in situ products for buildings, in situ products for building equipment and industrial installations, to products for civil engineering applications, and to external thermal insulation composite kits.

This document specifies common evaluation rules useful for the assessment and verification of constancy of performance of a thermal insulation product with harmonised technical specifications, product standards and any other assessment documents. Harmonised technical specifications, product standards and other assessment documents are called European product specifications in this document. This document applies to factory made products for buildings, factory made products for building equipment and industrial installations, in situ products for buildings, in situ products for building equipment and industrial installations, to products for civil engineering applications, and to external thermal insulation composite kits.

SIST EN 13172:2025 is classified under the following ICS (International Classification for Standards) categories: 91.100.60 - Thermal and sound insulating materials. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13172:2025 has the following relationships with other standards: It is inter standard links to SIST EN 13172:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13172:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2025

Nadomešča:

SIST EN 13172:2012

Toplotnoizolacijski proizvodi - Skupna pravila vrednotenja

Thermal insulation products - Common evaluation rules

Wärmedämmstoffe - Gemeinsame Bewertungsregeln

Produits isolants thermiques - Règles d’évaluation communes

Ta slovenski standard je istoveten z: EN 13172:2024

ICS:

91.100.60 Materiali za toplotno in Thermal and sound insulating

zvočno izolacijo materials

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13172

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2024

EUROPÄISCHE NORM

ICS 91.100.60 Supersedes EN 13172:2012

English Version

Thermal insulation products - Common evaluation rules

Produits isolants thermiques - Règles d'évaluation Wärmedämmstoffe - Gemeinsame Bewertungsregeln

communes

This European Standard was approved by CEN on 1 August 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13172:2024 E

worldwide for CEN national Members.

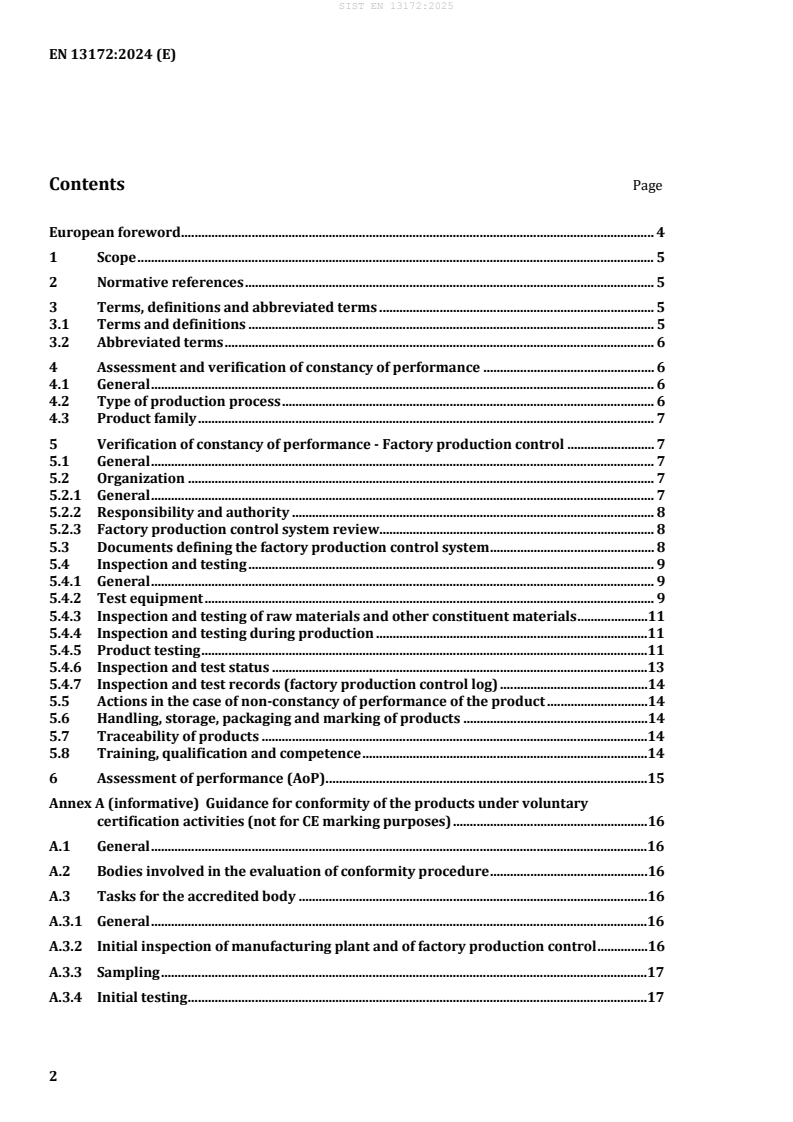

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms, definitions and abbreviated terms . 5

3.1 Terms and definitions . 5

3.2 Abbreviated terms . 6

4 Assessment and verification of constancy of performance . 6

4.1 General . 6

4.2 Type of production process . 6

4.3 Product family . 7

5 Verification of constancy of performance - Factory production control . 7

5.1 General . 7

5.2 Organization . 7

5.2.1 General . 7

5.2.2 Responsibility and authority . 8

5.2.3 Factory production control system review . 8

5.3 Documents defining the factory production control system . 8

5.4 Inspection and testing . 9

5.4.1 General . 9

5.4.2 Test equipment . 9

5.4.3 Inspection and testing of raw materials and other constituent materials .11

5.4.4 Inspection and testing during production .11

5.4.5 Product testing .11

5.4.6 Inspection and test status .13

5.4.7 Inspection and test records (factory production control log) .14

5.5 Actions in the case of non-constancy of performance of the product .14

5.6 Handling, storage, packaging and marking of products .14

5.7 Traceability of products .14

5.8 Training, qualification and competence .14

6 Assessment of performance (AoP) .15

Annex A (informative) Guidance for conformity of the products under voluntary

certification activities (not for CE marking purposes) .16

A.1 General .16

A.2 Bodies involved in the evaluation of conformity procedure .16

A.3 Tasks for the accredited body .16

A.3.1 General .16

A.3.2 Initial inspection of manufacturing plant and of factory production control .16

A.3.3 Sampling .17

A.3.4 Initial testing .17

A.3.5 Continuing surveillance . 18

A.4 Conformity mark . 22

A.4.1 General . 22

A.4.2 Issuance of certificate of conformity . 23

A.4.3 Restriction, suspension or withdrawal of certificate . 23

Annex B (informative) Guidance for common evaluation of products under AVCP system . 24

B.1 General . 24

B.2 Bodies involved in the assessment and verification of constancy of performance

(AVCP) . 24

B.3 Tasks for the notified body . 24

B.3.1 General . 24

B.3.2 Initial inspection of manufacturing plant and of factory production control . 25

B.3.3 Sampling . 25

B.3.4 Assessment of performance . 25

B.3.5 Continuing surveillance, assessment and evaluation of the factory production

control . 26

B.4 Certificate of constancy of performance . 28

B.4.1 Issuance of certificate of constancy of performance . 28

B.4.2 Restriction, suspension or withdrawal of the certificate of constancy of performance

................................................................................................................................................................... 28

Annex C (informative) Criteria for assessing non-conformity – Procedures in case of a

complaint . 29

C.1 Complaint on the product declaration . 29

C.1.1 General . 29

C.1.2 Complaint on the declared thermal resistance or thermal conductivity . 29

C.1.3 Complaint on other characteristics . 30

C.2 Complaint on a lot . 30

Bibliography . 31

European foreword

This document (EN 13172:2024) has been prepared by Technical Committee CEN/TC 88 “Thermal

insulating materials and products”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2025, and conflicting national standards shall be

withdrawn at the latest by April 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 13172:2012.

— the adaptation of this document to the terminology used in the European Regulation (EU)

No 305/2011 (i.e. Construction Products Regulation - CPR) with AVCP system;

— the removal of references to third parties, bodies and manufacturers into clauses and annexes that

can be used in conjunction with harmonised technical specifications;

— the addition of products for civil engineering applications in the scope of this document;

— the addition of a subclause for abbreviated terms;

— the split of Clause 4 into three subclauses;

— the updates and technical adjustments of Clause 5;

— the merging of Annexes B, C and D.

This document is intended to be used as a supporting standard in conjunction with harmonised technical

specifications, product standards and any other assessment documents of thermal insulation products to

ensure common evaluation rules for all stakeholders.

This document contains three informative annexes:

— Annex A, Guidance for conformity of the products under voluntary certification activities (not for CE

marking purposes);

— Annex B, Guidance for common evaluation of the products under AVCP system;

— Annex C, Criteria for assessing non-conformity – Procedure in case of a complaint.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

This document specifies common evaluation rules useful for the assessment and verification of constancy

of performance of a thermal insulation product with harmonised technical specifications, product

standards and any other assessment documents. Harmonised technical specifications, product standards

and other assessment documents are called European product specifications in this document.

This document applies to factory made products for buildings, factory made products for building

equipment and industrial installations, in situ products for buildings, in situ products for building

equipment and industrial installations, to products for civil engineering applications, and to external

thermal insulation composite kits.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12664:2001, Thermal performance of building materials and products — Determination of thermal

resistance by means of guarded hot plate and heat flow meter methods — Dry and moist products of medium

and low thermal resistance

EN 12667:2001, Thermal performance of building materials and products — Determination of thermal

resistance by means of guarded hot plate and heat flow meter methods — Products of high and medium

thermal resistance

EN 12939:2000, Thermal performance of building materials and products — Determination of thermal

resistance by means of guarded hot plate and heat flow meter methods — Thick products of high and

medium thermal resistance

3 Terms, definitions and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1.1

product

thermal insulation product produced under conditions which are presumed uniform to a given

specification and placed on the market

3.1.2

factory production control

documented, permanent and internal control of production in a factory

3.1.3

production line

assemblage of equipment that produces products using a continuous process

3.1.4

production unit

assemblage of equipment that produces products using a discontinuous process

3.1.5

manufacturing plant

all the production equipment on the same site including all production lines and units

Note 1 to entry: The term factory also refers to the manufacturing plant.

3.1.6

assessment of performance

assessment of the performance of the product carried out on the basis of testing (including sampling),

calculation, tabulated values or descriptive documentation of the product

3.1.7

verification of constancy of performance

factory production control system, procedures, regular inspections and tests and/or assessments

ensuring that the performance in relation to the declared characteristics are maintained

3.2 Abbreviated terms

AoP is the Assessment of performance

VoCP is the Verification of Constancy of Performance

AVCP is Assessment and Verification of Constancy of Performance

FPC is Factory Production Control

4 Assessment and verification of constancy of performance

4.1 General

The assessment and verification of constancy of performance shall include all parts of the tasks given in

Clause 5 of this document.

NOTE 1 Annex A is included for the purposes of voluntary activities.

NOTE 2 Annex C is included for the purposes of describing how the case of a complaint may be handled.

NOTE 3 The Annex ZA of the relevant harmonised standard or the European Assessment Document assigns the

AVCP tasks for CE marking activities.

4.2 Type of production process

Thermal insulation can be commonly manufactured using two types of production processes:

— For continuous production processes, each production line is considered separately in terms of both

AoP and VoCP.

— For discontinuous or batch production processes, production units using the same process in one

manufacturing plant are considered together (as if one production line) in terms of both AoP and

VoCP.

4.3 Product family

Products may be grouped into families for the purposes of assessment (i.e. AoP and VoCP) subject to the

following conditions:

— They shall have the same type of production process and shall be derived from the same family of

raw material; a distinction is made between glass wool and stone wool and between foams with

different blowing agents.

— They shall differ only in aspects that do not influence the characteristics defined in the relevant

European product specification.

— They shall be covered by a single European product specification.

— Products which differ only with regard to some characteristics may be grouped together by their

common characteristics.

— Products which are identical except for the facing and for which the different facings have been

shown to have the same effect on the declared characteristics (e.g. regarding thermal characteristics,

the gas tight facings of some PU products), may be grouped.

Products with a common production specification, originating from the same type of production process

and belonging to the same family of raw material may be grouped for verification of constancy of

performance, although covered by different European product specifications (e.g. for thermal insulation

products intended for buildings, civil engineering applications and for building equipment and industrial

installations).

EXAMPLE Cellular glass in accordance with EN 13167:2012+A1:2015 and EN 14305:2015 or expanded

polystyrene in accordance with EN 13163:2012+A2:2016 and EN 14309:2015.

The characteristics outside these common families shall be tested product by product.

Products which are outside the scope of a European product specification cannot be grouped for

declaration purposes with products declared under the scope of that European product specification.

Provided that a product within the family complies with a European product specification then all

products within the same family shall be deemed to comply with the European product specification for

the characteristics concerned. If the same product fails to comply with the European product specification

then the whole family shall be assumed to have failed to comply with the European product specification.

5 Verification of constancy of performance - Factory production control

5.1 General

Factory production control shall be fulfilled for each manufacturing plant.

5.2 Organization

5.2.1 General

Factory production control shall be operated according to an FPC system that shall be established,

documented, operated and maintained to ensure that the products comply with the declared

performance.

The FPC system shall consist of procedures, regular inspections and tests and/or assessments and the

use of the results to control raw and other incoming materials or components, equipment, the production

process and the product.

5.2.2 Responsibility and authority

The responsibility, authority and the interrelationships between all persons who manage, perform, or

verify work affecting constancy of performance of the product, shall be assigned. This applies particularly

to persons who need the organisational freedom and authority to

a) initiate action to prevent the occurrence of non-constancy of performance of product;

b) identify and record any product deviations from other than declared performances (e.g. aspect,

packaging, …).

5.2.3 Factory production control system review

The factory production control system shall be reviewed at appropriate intervals to ensure its continuing

suitability, adequacy and effectiveness. Records of such reviews shall be maintained.

NOTE FPC system review is usually included as part of the management review.

5.3 Documents defining the factory production control system

Documents defining the factory production control system shall be relevant to the production and

process control used during manufacture of the product. All the elements and provisions shall be

documented in a systematic manner in the form of written policies and procedures.

Documents defining the factory production control system shall provide the following details:

a) the factory production control system aims and the organizational structure, responsibilities and

authority with regard to constancy of performance of product;

b) the procedures for specifying and verifying the raw materials and other constituent materials;

c) the production control and other techniques, processes and systematic actions that will be used;

d) the inspections and tests to be carried out before, during and after manufacture, together with their

frequency (see 5.4) and possible retest procedures (see 5.5);

e) the procedures for handling, storage, packaging, marking and labelling the product (see 5.6);

f) the procedures for affixing traceability product codes and/or markings (see 5.7);

g) the procedures for all persons to receive training in the activities affecting the constancy of

performance of the product (see 5.8).

NOTE Documents defining FPC system can be in any format and media and from any source.

Documents defining the factory production control system shall be drawn up and kept up-to-date.

5.4 Inspection and testing

5.4.1 General

All necessary facilities, equipment and persons shall be available to carry out the inspections and tests.

Inspections and tests shall be performed according to the FPC system. In case of subcontracting, these

provisions shall apply too.

Inspection and testing shall be performed by persons qualified for such tasks on the basis of documented

appropriate education, training, skills or experience.

Equipment shall be used in a manner that ensures that any measurement uncertainty is not greater than

the necessary measurement capability.

5.4.2 Test equipment

5.4.2.1 General

Tests to demonstrate constancy of performance of the finished product shall be performed using

equipment in accordance with the test methods referred to in the European product specification.

The on-going suitability of the test equipment shall be ensured.

The test equipment (including software) shall be capable of achieving the accuracy specified by the test

methods referred to in the European product specification.

5.4.2.2 Calibration

The accuracy of the test equipment shall be ensured by periodic calibration. All calibrations and

calibration checks shall be traceable to relevant internationally or, failing that, nationally recognized

reference test specimens (standards). Where no such reference test specimens exist, the basis used for

calibration shall be documented.

NOTE Calibration is the right term for the first time “calibration” and if a calibration check leads to adjustment

of the equipment. The calibration check, that is performed e.g. annually for heat flow meter (HFM) equipment (see

Table 1), is the right term to use without adjustment of the equipment. To simplify the text here the term

“calibration” is used both for calibration and calibration check.

Compliance criteria for each piece of equipment shall be defined.

The equipment shall be calibrated or verified

— before being placed into service;

— periodically respecting the minimum frequencies specified in Table 1;

— after any repair or adjustment (see 5.4.2.4);

— to verify the test results obtained before being taken out of service. If internal checks are sufficient

(e.g. for heat flow meter (HFM) equipment) then this calibration is not needed.

Equipment not listed in Table 1 shall be calibrated in accordance with the documented procedures.

The calibration results shall be assessed and the results of such assessments shall be documented. The

calibration records shall be maintained for a period of 10 years.

5.4.2.3 Internal checks of equipment

In addition to the traceable calibration, internal checks to verify the stability of the equipment shall be

carried out. Compliance criteria for results of internal checks shall be defined. Internal checks shall be

carried out at frequencies respecting the minimum frequencies given in Table 1.

Equipment not listed in Table 1 shall be checked in accordance with the documented procedures. Records

of internal checks shall be maintained for a period of 10 years.

Table 1 — Minimum frequencies of internal checks and calibrations of test equipment

Characteristics Internal checks Calibration of test equipment

a, c

Thickness

Once per month

a, c

Mass

Once per month

Prior to first use of equipment, and

Mechanical characteristics -

annual calibration checks

b

Thermal characteristics :

thereafter

c

Once per two weeks

- heat flow meter

c

- guarded hot plate Once per year

a

A lower frequency of once every 3 months may be used when stability has been verified for

a period of at least one year. If any single measurement indicates significant variation, the

frequency reverts to once a month.

b

For thermal characteristics a part of the calibration shall be to compare test results

obtained by the equipment used for the FPC with those obtained by an accredited

laboratory under EN 12664:2001, EN 12667:2001 or EN 12939:2000 on the same sample,

typically once a year. Test specimens to be used for the calibration and the annual

calibration checks shall be traceably calibrated to the reference materials IRMM 440 or

ERM-FC440 defining the European thermal conductivity level. The reference materials

IRMM 440 or ERM-FC440 can be directly used for the calibration and the annual calibration

checks. Test specimens provided by a reference material producer accredited under

EN ISO 17034:2016 can be used for the calibration and the annual calibration checks.

c

For internal checks, test specimens can be used to verify the stability of the performance of

the equipment provided that the stability of the specimens is ensured.

5.4.2.4 Defective equipment

Equipment that has been subjected to abuse or mishandling, which gives suspect results or has been

shown to be defective or outside specified limits, shall be taken out of service immediately and marked

as defective.

It shall be examined whether or not defective equipment gives cause for concern regarding the constancy

of performance of the products tested using the defective equipment. This examination shall be

documented.

In case of any doubt regarding constancy of the performance of products, 5.5 applies.

After any repair, calibration shall be repeated before the equipment is placed into use.

5.4.3 Inspection and testing of raw materials and other constituent materials

The compliance of raw materials and other constituent materials shall be ensured in accordance with the

procedures specified in the FPC system. In determining the checks, necessary consideration shall be given

to the control exercised and the documented evidence of compliance supplied with raw materials and

other constituent materials.

The incoming raw materials and other constituent materials shall be used or processed only after they

have been verified as complying with the defined specifications. Where incoming material is released for

urgent production purposes prior to verification it shall be identified and recorded in order to permit

immediate recall in the event of non-compliance.

5.4.4 Inspection and testing during production

In order to manufacture products which meet the declared performances, production process shall be

controlled and inspection and tests shall be performed as described in the FPC procedures.

All equipment used in the production process shall be regularly inspected and maintained to ensure use,

wear or failure does not cause inconsistency in the production process.

5.4.5 Product testing

5.4.5.1 General

Assessment of performance of the product carried out in accordance with Clause 6 shall be ensured prior

to placing a product on the market.

The finished products shall be tested in accordance with the relevant European product specification,

using direct and/or indirect testing, in accordance with 5.4.5.3. One test is considered as the test(s) on

one sample of the product using one or more test specimens as specified in the relevant testing standard

or European product specification.

The samples shall be drawn periodically from each production line/unit according to the test plan. The

minimum testing frequencies for the relevant characteristics for regular production conditions are

specified in the relevant European product specification. For characteristics automatically recorded

during the manufacturing process at a higher frequency than given in the relevant European product

specification, the testing frequency may be lowered.

5.4.5.2 Direct testing

Direct testing shall be applied according to the test regime specified in the relevant European product

specification.

Reduced testing frequencies for direct testing may be used for well-established production lines/units

for characteristics other than reaction to fire and thermal resistance/conductivity:

— In the case of a given characteristic where a well-controlled production process can be demonstrated,

the testing frequency may be reduced as described below following the relevant statistical rule.

— The frequency for direct testing cannot be reduced to less than 10 % of the minimum frequency given

in the relevant European product specification. In no case shall that frequency be less than once a

year.

— The risk of failure in a test shall not exceed 1,0 %. For dimensional tolerances the confidence level

shall be at least 99 %, for other characteristics the confidence level shall be at least 50 %.

Three situations arise:

I) for characteristics with declared classes – tolerance interval, T (one-sided interval for dimensional

characteristics where only a plus or a minus tolerance interval is declared and two-sided interval for e.g.

dimensional characteristics where a plus-minus tolerance interval is declared).

If the Gaussian distribution can be assumed for the test results, then Formula (1) applies.

2 2

T ≥ (k ∙ s) (1)

99/99

where

T is the tolerance interval for the test results obtained over a period not exceeding 3 years;

s is the estimate of the standard deviation of the test results obtained over a period not

exceeding 3 years;

k is a factor corresponding to the number of test results, n, available over a period not

exceeding 3 years at the reduced testing frequency.

Table 2 gives the k factors corresponding to a 99 % tolerance interval with a confidence level of 99 %

(99/99).

II) for characteristics with limit values – one-sided tolerance interval.

If the Gaussian distribution can be assumed for the test results, the Formula (2) or (3) applies.

xx−≥ k ⋅ s for minimum values (2)

D 90/50

x −≥xk ⋅ s for maximum values (3)

D 90/50

where

x

is the mean of the measured values;

x is the declared value;

D

s is the estimate of the standard deviation of the test results obtained over a period not

exceeding 3 years;

k is a factor corresponding to the number of test results, n, available over a period not

exceeding 3 years at the reduced testing frequency.

Table 2 gives the k factors corresponding to a 99 % tolerance interval with a confidence level of 50 %

(99/50).

Table 2 — k factors for estimated standard deviations

k factors

k99,99 k99,50

Number of test results n

a b c

One-sided interval Two-sided interval One-sided interval

10 5,074 5,610 2,411

20 3,832 4,175 2,366

50 3,125 3,390 2,342

100 2,850 3,098 2,334

200 2,679 2,922 2,330

NOTE 1 For other numbers of test results, see ISO 16269-6:2014, Statistical interpretation of data — Part 6:

Determination of statistical tolerance intervals and ISO 12491:1997, Statistical methods for quality control of

building materials and components.

NOTE 2 Linear interpolation is acceptable.

a

Applicable for a plus or a minus-tolerance.

b

Applicable for plus-minus-tolerances.

c

Applicable for limit values.

III) For characteristics where test results are expressed in terms of pass/fail, a binominal distribution

can be assumed. To lower the frequency, it is needed that the test shall be performed on at least 100

different samples, from different production days and 99 % shall pass.

Satisfaction of the conditions for reduced testing frequencies (I, II or III) shall be verified in the event of

failure and at least once a year.

5.4.5.3 Indirect testing

Indirect testing is a means by which a given characteristic may be assessed through tests on one or more

other characteristics, with which a correlation has been established. Indirect testing may also be used to

reduce the testing frequency of direct testing.

The correlation shall be established by suitable statistical means, e.g. regression analysis on the basis of

adequate preliminary tests for each production line/unit. It shall be re-examined at prescribed intervals

and after changes or modifications if these are likely to affect the correlation.

For each indirect testing procedure applied at the place of production the sampling plan and the

compliance criteria, for the indirect characteristic, shall be specified taking into account the relevant

correlation between the corresponding characteristics.

The use of indirect testing shall result in at least the same confidence level on the characteristic concerned

as when using the direct testing.

In case of dispute, the test method specified for the relevant characteristic in the European product

specification shall be used.

5.4.6 Inspection and test status

The constancy or non-constancy of performance of a product shall be determined by tests and inspection

which records passed, failed or due to be reclassified.

5.4.7 Inspection and test records (factory production control log)

The results of finished products inspection and testing shall be recorded in the factory production control

log. The log shall contain a record of the product identification, the date and time of manufacture and for

each characteristic the test methods, the test results, the expected level or class or the declared

performance, the inspection result and the identification of the person carrying out the inspection.

Where products do not comply with the declared performance or specification defined by the FPC system,

a note shall be made in the factory production control log of the remedial measures taken.

The factory production control log shall be kept for at least 10 years after placing the product on the

market.

5.5 Actions in the case of non-constancy of performance of the product

If the result of a test or the inspection of a product is a failure, the steps necessary to rectify the deficiency

shall be immediately taken. Products, which do not comply with the declared performance, shall be

marked accordingly. When the deficiency has been identified and rectified, the test or inspection in

question shall be repeated without delay according to the FPC procedures, to provide evidence that the

defects have been overcome.

In the event that products are dispatched before the result of the inspection is available prompt

notification shall be given to prevent any consequential damage and a record maintained of such

notification.

Products, which have not met the performance intended to be declared for a given characteristic shall be

permitted to qualify for a less stringent performance of that characteristic and shall be labelled

accordingly.

5.6 Handling, storage, packaging and marking of products

In accordance with the documents defining the FPC system (see 5.3):

a) methods of handling that prevent damage or deterioration shall be provided;

b) suitable storage areas or stock rooms to prevent damage or deterioration of the product shall be

provided;

c) the packaging, storage and the marking processes shall be controlled.

The provision of dematerialised information with the product, its packaging or its label, readable by an

electronic media (e.g. QR code) shall reflect the product placed on the market.

5.7 Traceability of products

Individual products or product batches or packages shall be identifiable and traceable back to the origin

of their production.

Written procedures ensuring that processes related to affixing traceability codes and/or markings are

inspected regularly shall be maintained.

5.8 Training, qualification and competence

Procedures for the identification of the training needs shall be established and maintained. The training

of all persons performing tasks affecting the assessment and verification of constancy of performance of

the product shall be provided.

Persons performing specific assigned tasks shall be qualified and competent on the basis of appropriate

education, training, skills or experience.

Records of training shall be kept up to date.

6 Assessment of performance (AoP)

Prior to placing a product on the market, AoP shall be carried out in order to ensure the determination of

the product performance.

Assessment previously performed in accordance with the provisions of European product specifications,

may be considered, provided that this assessment was performed to the same or a more rigorous

assessment method, under the same AVCP system on the same product or products of similar design,

construction and functionality, such that the results are applicable to the product in question.

Where kit components are used whose performance in relation to their characteristics has already been

determined on the basis of assessment methods of other harmonised technical specifications and those

components bear CE marking in accordance with those harmonised technical specifications, these

performances do not need to be re-assessed, if the intended use and the assessment methods of this

standard correspond to previously used, otherwise extra assessment shall be necessary. The

specifications of these components shall be documented.

AoP of relevant characteristics shall be repeated on changes or modifications if these are likely to affect

the declared performance of the products.

Tests shall be carried out in accordance with the European product specification, by direct testing. One

test is considered as the test of one sample of the product consisting of one or more test specimens as

specified in the relevant testing standard or European product specification.

For CE marking purposes, the AoP is specified in Annexes ZA of harmonised standards or tasks included

in European Assessment Documents.

Annex A

(informative)

Guidance for conformity of the products under voluntary certification

activities (not for CE marking purposes)

A.1 General

This annex supports the European product specifications for thermal insulation products as part of the

voluntary activities for conformity of the products.

A.2 Bodies involved in the evaluation of conformity procedure

The following external bodies may be involved in the evaluation of conformity of products with this

document:

a) product certification body: an accredited body which provides conformity certification;

b) inspection body: an accredited body which performs initial inspection and surveillance inspections

of factory production control, and which selects samples of products for testing;

c) laboratory: an accredited body which measures, examines, tests, calculates or otherwise assesses the

performance of materials or products and which calibrates equipment.

NOTE The functions of these three bodies are performed by the product certification body or by different

bodies. If different bodies are involved, the inspection body and/or the laboratory carry out their functions on behalf

of the certification body.

In this annex these bodies are referred to by the term “accredited body”.

For all certification activities, the certification body shall comply with EN ISO/IEC 17065:2012. For all

testing activities, EN ISO/IEC 17025:2017 shall be complied with.

A.3 Tasks for the accredited body

A.3.1 General

A.3 specifies the tasks for the accredited body in the evaluation of conformity procedure and also the

manufacturer's duties arising in connection with them.

If a quality management system certified to a quality management system standard, such as

EN ISO 9001:2015, is used, this certification shall be taken into account by the product certification body

for those elements that are common with this document.

A.3.2 Initial inspection of manufacturing plant and of factory production control

Initial

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...