SIST EN 415-3:2001+A1:2010

(Main)Safety of packaging machines - Part 3: Form, fill and seal machines

Safety of packaging machines - Part 3: Form, fill and seal machines

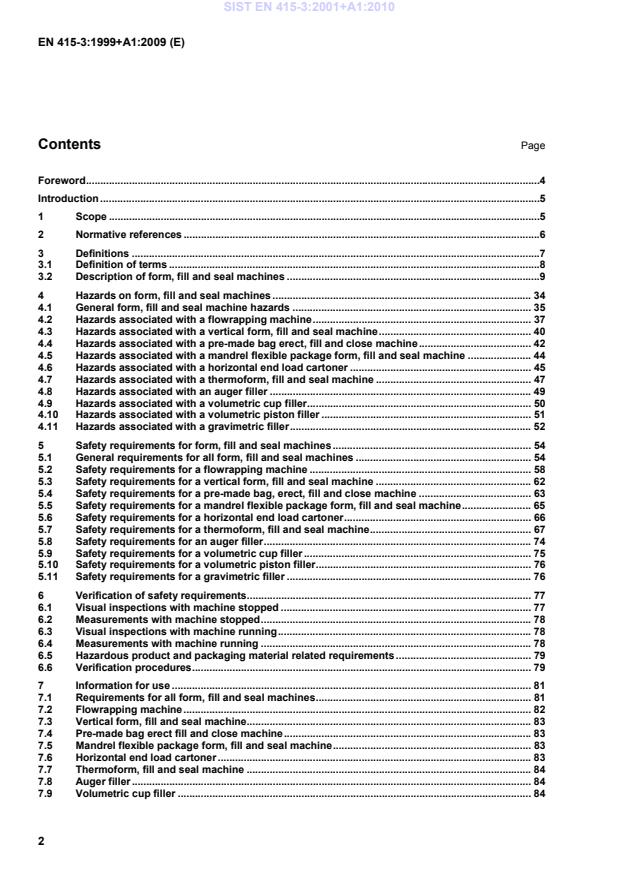

This European Standard establishes safety requirements for form, fill and seal packaging machines and the filling machines which are particularly associated with them. This group of machines is defined in detail in clause 3 of this standard, with diagrams illustrating examples of the principle of operation of each machine type. However briefly, this standard covers the following broad groups of machines:

- horizontal form, fill and seal machines;

- vertical form, fill and seal machines;

- pre-made bag erect fill and seal machines;

- mandrel flexible package or carton form, fill and seal machines;

- carton erect, fill and close machines;

- thermoform, fill and seal machines.

Filling machines commonly fitted to form, fill and seal machines including:

- auger fillers;

- volumetric cup fillers;

- volumetric piston fillers;-

- counters;

- gravimetric fillers (weighers).

This standard covers the safety requirements for machine design, construction, installation, commissioning, operation, adjustment, maintenance and cleaning.

This part of prEN 415 applies primarily to machines manufactured after the date of issue of this standard.

This standard does not cover in detail the safety or hygiene hazards associated with the products which may be handled on form, fill and seal machines, but does include general advice.

This standard does not cover thermoforming machines. These machines are covered in prEN 12409.

This standard does not cover blow mould, fill and seal machines. The main hazards and safety requirements for these machines are described in EN 422.

Sicherheit von Verpackungsmaschinen - Teil 3: Form-, Füll- und Verschließmaschinen

Diese Europäische Norm stellt Sicherheitsanforderungen für Form-, Füll- und Verschließmaschinen und die

speziell mit ihnen verbundenen Füllmaschinen auf. Diese Gruppe von Maschinen wird im Einzelnen in

Abschnitt 3 dieser Norm definiert und mit Schemazeichnungen versehen, die Beispiele der Arbeitsprinzipien

jeder Maschinenart aufzeigen. Kurzgefasst erstreckt sich diese Norm auf folgende Maschinengruppen:

⎯ Horizontal-Form-, Füll- und Verschließmaschinen

⎯ Vertikal-Form-, Füll- und Verschließmaschinen

⎯ Aufricht-, Füll und Verschließmaschinen für vorgefertigte Beutel

⎯ Form-, Füll- und Verschließmaschinen für dornradgeformte flexible Packungen oder Faltschachteln

⎯ Faltschachtel-Aufricht-, Füll- und Verschließmaschinen

⎯ Tiefzieh-Form-, Füll- und Verschließmaschinen

Füllmaschinen, die gewöhnlich mit Form-, Füll- und Verschließmaschinen verbunden sind:

⎯ Schnecken-Füllmaschinen

⎯ Messbecher-Füllmaschine

⎯ Kolben-Füllmaschinen

⎯ Zähl-Füllmaschinen

⎯ Wäge-Füllmaschinen

Diese Norm erstreckt sich auf die Sicherheitsanforderungen für Entwurf, Konstruktion, Montage, Inbetriebnahme,

Betrieb, Einstellung, Wartung und Reinigung der Maschinen. Dieser Teil der prEN 415 gilt in erster

Linie für Maschinen, die nach dem Erscheinungsdatum dieser Norm hergestellt werden.

Diese Norm enthält keine detaillierten Angaben zu den Sicherheits- oder Hygienegefährdungen, die von den

auf Form-, Füll- und Verschließmaschinen verarbeiteten Produkten ausgehen können, wohl aber dazu einige

grundsätzliche Hinweise.

Diese Norm erstreckt sich nicht auf Thermoform-Maschinen. Sie werden in der prEN 12409 behandelt. Diese

Norm gilt auch nicht für Blasform-, Füll- und Verschließmaschinen. Die wichtigsten Gefährdungen und

Sicherheitsanforderungen für diese Maschinen werden in der EN 422 beschrieben.

!Diese Norm ist nicht anwendbar auf Form-, Füll- und Verschließmaschinen, die vor Veröffentlichung dieser

geänderten Fassung des Dokuments EN 415-3:1999 hergestellt wurden."

Sécurité des machines d'emballage - Partie 3: Machines d'emballage à former, remplir et sceller

Pakirne naprave - Varnost pakirnih naprav - 3. del: Oblikovalne, polnilne in zapiralne naprave

Ta evropski standard vzpostavlja varnostne zahteve za oblikovalne, polnilne in zapiralne naprave ter polnilne naprave, ki so še posebej povezane z njimi. Ta skupina naprav je podrobno opredeljena v Klavzuli 3 tega standarda, z diagrami, ki prikazujejo primere principov delovanja posameznih tipov naprav. Čeprav na kratko, ta standard zajema naslednje velike skupine naprav: - vodoravne oblikovalne, polnilne in zapiralne naprave, - naprave za pokončno polnenje in zapiranje vnaprej narejenih vrečk, - naprave za oblikovanje, polnjenje in zapiranje prožne embalaže vretenaste oblike ali iz kartona, - naprave za polnjenje in zapiranje pokončnie kartonaste embalaže, - naprave za polnjenje in zapiranje toplotno oblikovane embalaže. Polnilne naprave, vgrajene skupaj z napravami za oblikovanje, polnjenje in zapiranje vključno z/s: - polnilci s svedrom; - volumetrični polnilci skodelic, - volumetrični polnilci z batom, - števci, gravimetrični polnilci (tehtnice). Ta standard zajema varnostne zahteve za načrtovanje, izgradnjo, namestitvijo, začetek obratovanja, delovanje, prilagajanje, vzdrževanje in čiščenje naprave. Ta del EN 415 velja predvsem za naprave, izdelane po datumu izdaje tega standarda. Ta standard ne zajema podrobno varnostne ali higienske nevarnosti v povezavi s proizvodi, ki se obdelujejo v oblikovalnih, polnilnih in zapiralnih napravah, ampak vsebuje splošne nasvete. Ta standard ne zajema naprav za toplotno oblikovanje. Te naprave so zajete v prEN 12409. Ta standard ne zajema naprav za oblikovanje s pihanjem, polnjenje in zapiranje. Glavne nevarnosti in varnostne zahteve za te naprave so opisane v EN 422. Ta dokument ne velja na oblikovne, polnilne in zapiralne naprave, ki so bile izdelane pred datumom njegove objave kot EN 415-3:1999 z vsemi spremembami.

General Information

- Status

- Withdrawn

- Publication Date

- 21-Dec-2009

- Withdrawal Date

- 07-Nov-2021

- Technical Committee

- DTN - Lift and transport appliances

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 26-Oct-2021

- Due Date

- 18-Nov-2021

- Completion Date

- 08-Nov-2021

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 01-Feb-2010

- Effective Date

- 20-Oct-2021

- Consolidates

SIST EN 415-3:2001 - Safety of packaging machines - Part 3: Form, fill and seal machines - Effective Date

- 18-Jan-2023

Frequently Asked Questions

SIST EN 415-3:2001+A1:2010 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Safety of packaging machines - Part 3: Form, fill and seal machines". This standard covers: This European Standard establishes safety requirements for form, fill and seal packaging machines and the filling machines which are particularly associated with them. This group of machines is defined in detail in clause 3 of this standard, with diagrams illustrating examples of the principle of operation of each machine type. However briefly, this standard covers the following broad groups of machines: - horizontal form, fill and seal machines; - vertical form, fill and seal machines; - pre-made bag erect fill and seal machines; - mandrel flexible package or carton form, fill and seal machines; - carton erect, fill and close machines; - thermoform, fill and seal machines. Filling machines commonly fitted to form, fill and seal machines including: - auger fillers; - volumetric cup fillers; - volumetric piston fillers;- - counters; - gravimetric fillers (weighers). This standard covers the safety requirements for machine design, construction, installation, commissioning, operation, adjustment, maintenance and cleaning. This part of prEN 415 applies primarily to machines manufactured after the date of issue of this standard. This standard does not cover in detail the safety or hygiene hazards associated with the products which may be handled on form, fill and seal machines, but does include general advice. This standard does not cover thermoforming machines. These machines are covered in prEN 12409. This standard does not cover blow mould, fill and seal machines. The main hazards and safety requirements for these machines are described in EN 422.

This European Standard establishes safety requirements for form, fill and seal packaging machines and the filling machines which are particularly associated with them. This group of machines is defined in detail in clause 3 of this standard, with diagrams illustrating examples of the principle of operation of each machine type. However briefly, this standard covers the following broad groups of machines: - horizontal form, fill and seal machines; - vertical form, fill and seal machines; - pre-made bag erect fill and seal machines; - mandrel flexible package or carton form, fill and seal machines; - carton erect, fill and close machines; - thermoform, fill and seal machines. Filling machines commonly fitted to form, fill and seal machines including: - auger fillers; - volumetric cup fillers; - volumetric piston fillers;- - counters; - gravimetric fillers (weighers). This standard covers the safety requirements for machine design, construction, installation, commissioning, operation, adjustment, maintenance and cleaning. This part of prEN 415 applies primarily to machines manufactured after the date of issue of this standard. This standard does not cover in detail the safety or hygiene hazards associated with the products which may be handled on form, fill and seal machines, but does include general advice. This standard does not cover thermoforming machines. These machines are covered in prEN 12409. This standard does not cover blow mould, fill and seal machines. The main hazards and safety requirements for these machines are described in EN 422.

SIST EN 415-3:2001+A1:2010 is classified under the following ICS (International Classification for Standards) categories: 55.200 - Packaging machinery. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 415-3:2001+A1:2010 has the following relationships with other standards: It is inter standard links to SIST EN 415-3:2001, SIST EN 415-3:2021, SIST EN 415-3:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 415-3:2001+A1:2010 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 415-3:2001+A1:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Pakirne naprave - Varnost pakirnih naprav - 3. del: Oblikovalne, polnilne in zapiralne napraveSicherheit von Verpackungsmaschinen - Teil 3: Form-, Füll- und VerschließmaschinenSécurité des machines d'emballage - Partie 3: Machines d'emballage à former, remplir et scellerSafety of packaging machines - Part 3: Form, fill and seal machines55.200Pakirni strojiPackaging machineryICS:Ta slovenski standard je istoveten z:EN 415-3:1999+A1:2009SIST EN 415-3:2001+A1:2010en,fr01-februar-2010SIST EN 415-3:2001+A1:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 415-3:1999+A1

October 2009 ICS 55.200 Supersedes EN 415-3:1999English Version

Safety of packaging machines - Part 3: Form, fill and seal machines

Sécurité des machines d'emballage - Partie 3: Machines d'emballage à former, remplir et sceller

Sicherheit von Verpackungsmaschinen - Teil 3: Form-, Füll-und Verschließmaschinen This European Standard was approved by CEN on 26 December 1998 and includes Amendment 1 approved by CEN on 7 September 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 415-3:1999+A1:2009: ESIST EN 415-3:2001+A1:2010

Safety requirements . 86Annex ZA (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC"""" . 87Annex ZB (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""" . 88 SIST EN 415-3:2001+A1:2010

EN 415 Safety of packaging machines; Part 1: Terminology and classification of packaging machines and associated equipment; Part 2: Pre-formed rigid container packaging machines; Part 4: Palletisers and depalletisers; !Part 5: Wrapping machines; Part 6: Pallet wrapping machines; Part 7: Group and secondary packaging machines; Part 8: Strapping machines; Part 9: Noise measurement methods for packaging machines, packaging lines and associated equipment, grade of accuracy 2 and 3." According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

However briefly, this standard covers the following broad groups of machines: horizontal form, fill and seal machines; vertical form, fill and seal machines; pre-made bag erect fill and seal machines; mandrel flexible package or carton form, fill and seal machines; carton erect, fill and close machines; thermoform, fill and seal machines. Filling machines commonly fitted to form, fill and seal machines including: auger fillers; volumetric cup fillers; volumetric piston fillers; counters; gravimetric fillers (weighers). This standard covers the safety requirements for machine design, construction, installation, commissioning, operation, adjustment, maintenance and cleaning.

This part of EN 415 applies primarily to machines manufactured after the date of issue of this standard. SIST EN 415-3:2001+A1:2010

These machines are covered in prEN 12409. This standard does not cover blow mould, fill and seal machines.

The main hazards and safety requirements for these machines are described in EN 422. !This document is not applicable to form, fill and seal machines which are manufactured before the date of its publication as EN 415-3:1999 as amended." 2 Normative references This European Standard incorporates by dated or undated reference, provisions from other publications.

These normative references are cited at the appropriate places in the text and the publications are listed hereafter.

For dated references subsequent amendments to, or revisions of, any of these publications apply to this European Standard only when incorporated in it by amendment or revision.

For undated references the latest edition of the publication referred to applies. EN 292-1:1991, Safety of machinery – Basic concepts, general principles for design – Part 1: Basic terminology, methodology EN 292-2:1991, Safety of machinery – Basic concepts, general principles for design – Part 2: Technical principles and specifications EN 294:1992, Safety of machinery; Safety distances to prevent danger zones being reached by the upper limbs EN 349:1993, Safety of Machinery; Minimum gaps to prevent crushing of parts of the human body EN 415-1:1999, Safety of packaging machines – Part 1: Terminology and classification of packaging machines and associated equipment EN 418:1992, Safety of machinery; Emergency stop equipment; functional aspects - Principles for design EN 422:1995, Rubber and plastics machines – Safety - Blow moulding machines intended for the production of hollow articles – Requirements for the design and construction EN 457:1992, Safety of machinery - Auditory danger signals - General requirements design EN 563:1994, Safety of machinery - Temperatures of touchable surfaces - Ergonomics data to establish temperature limit values for hot surfaces EN 614-1:1995, Safety of machinery - Ergonomic design principles – Part 1: Terminology and general principles prEN 614-2, Safety of machinery - Ergonomic design principles – Part 2 : Interaction between the design of machinery and work tasks EN 626-1:1994, Safety of machinery - Reduction of risks to health from hazardous substances emitted by machinery – Part 1: Principles and specifications for machinery manufacturers EN 811:1996, Safety of Machinery - Safety distances to prevent danger zones being reached by the lower limbs EN 842:1996, Safety of machinery - Visual danger signals - General requirements, design and testing SIST EN 415-3:2001+A1:2010

EN ISO 11688-1:1998, Acoustics – Recommended practice for the design of low noise machinery and equipment – Part 1: Planning (ISO/TR 11688-1:1995) 3 Definitions In addition to those terms defined in EN292-1, EN 1070 and EN 415-1, the following definitions apply, for the purposes of this standard. SIST EN 415-3:2001+A1:2010

horizontally and a longitudinal seal formed below the pack (see figure 1). The characteristic features are: a horizontal product infeed mechanism; a film unwind mechanism; a film folding box; a longitudinal seal mechanism; a transverse seal mechanism; a transverse cutting mechanism and;

a discharge conveyor.

Figure 1 — Flowrapping machine 3.2.1.2 lower reel flowrapping machine horizontally operating form, fill and

seal machine, with film reel mounted below the operating level, product placed on to the film web and a longitudinal seal formed above the pack (see figure 2). The characteristic features are: a film unwind mechanism positioned below a horizontal product infeed mechanism; SIST EN 415-3:2001+A1:2010

Figure 2 — Lower reel flowrapping machine 3.2.1.3 vertical form, fill and seal machine a packaging machine which uses flexible packaging film to form a tube, which is then filled vertically

with product and sealed in a sequence of operations whilst the film is transported vertically downwards (see figure 3).

The characteristic features are: a film unwind mechanism; a film forming tube; an automatic filling device (some machines are fed manually); a film transport mechanism; a longitudinal seal mechanism; a transverse seal mechanism and; a transverse cutting mechanism. SIST EN 415-3:2001+A1:2010

Figure 3 — Vertical form, fill and seal machine 3.2.1.4 mandrel flexible package form, fill and seal machine a packaging machine which forms packs from a reel of flexible material before filling the packs with product and sealing the top of the packs (see figure 4). The characteristic features are: a film unwind mechanism; a transverse cutting mechanism; SIST EN 415-3:2001+A1:2010

Figure 4 — Mandrel flexible package form, fill and seal machine 3.2.1.5 tubular bag form, fill and seal machine a packaging machine which forms a bag from a reel of lay flat tubular flexible packaging film.

The bag is then filled with product and sealed within the machine (see figure 5). The characteristic features are: a film unwind mechanism; a transverse sealing and cutting mechanism; a bag transport mechanism; an automatic filling device, and; a bag sealing mechanism.

Figure 5 — Tubular bag form, fill and seal machine 3.2.1.6 pre-made bag, erect, fill and close machine a packaging machine in which a pre-made and folded bag is erected, filled with product and closed within the machine (see figure 6). The characteristic features are: a bag magazine; a bag opening mechanism; a bag transport mechanism; an automatic filling device; a bag closing mechanism and: a compression conveyor. SIST EN 415-3:2001+A1:2010

Figure 6 — Pre-made bag erect, fill and close machine

3.2.2 sachet form, fill and seal machines the three form, fill and seal machines described in 3.2.2.1 to 3.2.2.3 produce four side or three side sealed sachet style packs 3.2.2.1 edge sealing machine a horizontally operating

form, fill and seal machine in which product is placed on a horizontal web of film before being sealed on three or four sides to an upper web of film. Machines can have one or two reels of film and can produce one or more lanes of packs (see figure 7). The characteristic features are: a film unwind mechanism positioned under a horizontal product infeed mechanism a film unwind mechanism positioned above the working level; a longitudinal seal mechanism; a transverse seal mechanism; a transverse cutting mechanism and; a discharge conveyor.

Figure 7 — Edge sealing machine 3.2.2.2 horizontal sachet form, fill and seal machine a horizontally operating form, fill and seal machine in which packs are formed, sealed on two or three sides, filled vertically with product and sealed on the remaining side whilst the film web is moved horizontally with the pack vertical (see figure 8). The characteristic features are: a film unwind mechanism; a film folding or cutting device; a vertical seal mechanism; an automatic filling device; a longitudinal seal mechanism; a transverse cutting mechanism and; a discharge mechanism.

Figure 8 — Horizontal sachet form, fill and seal machine 3.2.2.3 vertical sachet form, fill and seal machine a vertically operating form, fill and seal machine which uses one or two webs of film which are formed vertically, filled with product and sealed to produce a three or four side sealed sachet.

Machines can have one or two reels of film and can produce one or more lanes of packs (see figure 9). The characteristic features are: one or two film unwind mechanisms; an automatic filling device; a film transport mechanism; a longitudinal seal mechanism; a transverse seal mechanism and; a cutting mechanism.

Figure 9 — Vertical sachet form, fill and seal machine 3.2.3 carton form, fill and seal machines the seven form, fill and seal machines described in 3.2.3.1 - 3.2.3.7 produce cartons or carton shaped packs 3.2.3.1 horizontal end load cartoner a cartoning machine which erects a folded and side seam sealed carton and places it on a horizontal indexing mechanism so that the carton can be filled with product horizontally through an end flap of the carton before being closed (see figure 10). The characteristic features are: a horizontal product feed mechanism; a carton blank magazine; a carton erecting mechanism; a carton transport mechanism; a carton loading mechanism and; a carton closing mechanism.

Figure 10 — Horizontal end load cartoner 3.2.3.2 vertical cartoner a cartoning machine which erects a folded and side seam sealed carton and places it on a horizontal indexing mechanism so that the carton can be filled with product vertically through the carton top flap before being closed (see figure 11). The characteristic features are: a carton blank magazine; a carton erecting mechanism; a carton transport mechanism; a carton base closing mechanism; a carton loading area or automatic filling device; a carton top closing mechanism and; a carton compression conveyor.

Figure 11 — Vertical cartoner

3.2.3.3 mandrel carton form, fill and seal machine a packaging machine which forms cartons either from magazine fed or reel fed carton blanks, before filling the cartons with product and closing the cartons (see figure 12). The characteristic features are: a carton blank magazine or reel unwind mechanism; a transverse cutting mechanism; a mandrel carton forming mechanism; carton folding and sealing mechanisms; a carton transport mechanism; an automatic filling device and; a carton sealing mechanism.

Figure 12 — Mandrel carton form, fill and seal machine 3.2.3.4 vertical form, fill and seal machine for cartonboard a vertically operating form, fill and seal machine which uses a cartonboard laminate, which is formed, filled with product and sealed to produce a pack resembling a carton (see figure 13). The characteristic features are: a cartonboard unwind mechanism; a cartonboard sterilising mechanism; a cartonboard forming tube; an automatic filling device; a cartonboard transport mechanism; a longitudinal seal mechanism; a transverse seal mechanism; a transverse cutting mechanism and; a gusset sealing mechanism.

Figure 13 — Vertical form, fill and seal machine for cartonboard 3.2.3.5 tray erect load and seal machine a cartoning machine in which a carton tray blank is partly formed before being loaded horizontally with product.

After loading the carton tray is fully formed and sealed within the machine (see figure 14). The characteristic features are: a tray blank magazine; a tray erecting mechanism; a tray transport mechanism; a product feed and collation mechanism; a product loading mechanism and; a tray sealing mechanism.

Figure 14 — Tray erect, load and seal machine 3.2.3.6 top load carton form, fill and seal machine a cartoning machine in which a carton blank is partly formed into an open top carton before being loaded vertically with product.

After loading the carton is fully formed and closed within the machine (see figure 15). The characteristic features are: a carton blank magazine; a carton erecting mechanism; carton transport mechanism; a carton base closing mechanism; a product feed and collation mechanism; a product loading mechanism and; a carton top closing mechanism.

Figure 15 — Top load carton form, fill and seal machine 3.2.3.7 wraparound cartoner a cartoning machine which wraps a cartonboard blank around a product, usually with the aid of a mandrel, before closing the carton with adhesive or by tucking (see figure 16). The characteristic features are: a carton blank magazine; a carton erecting mechanism; a product feed mechanism; a carton forming mandrel; a manufacturer’s join sealing mechanism and; an end flap closing mechanism. SIST EN 415-3:2001+A1:2010

Figure 16 — Wraparound cartoner 3.2.4 bag-in-box form, fill and seal machines the three form, fill and seal machines described in 3.2.4.1 to 3.2.4.3 produce bag-in-box packages 3.2.4.1 mandrel bag-in-box machine a mandrel packaging machine which forms a bag, made from a reel of flexible material

on a mandrel, around which a carton blank is formed to produce a bag-in-box package.

This package is then filled with product before first the bag and then the carton are closed (see figure 17). The characteristic features are: a film unwind mechanism; a transverse cutting mechanism; a carton blank magazine or reel unwind mechanism a mandrel forming mechanism; folding and sealing mechanisms; a carton transport mechanism; an automatic filling device; a bag sealing mechanism and; a carton sealing mechanism.

Figure 17 — Mandrel bag-in-box machine 3.2.4.2 pre-made bag-in-box cartoner a vertical cartoner which erects side seam sealed and folded cartons which contain a tube of flexible film.

The base of the tube is sealed before it is filled vertically with product.

After filling the top of the tube is sealed before the carton flaps are closed (see figure 18). The characteristic features are: a carton blank magazine;

a carton erecting mechanism;

a carton transport mechanism;

a bag base sealing mechanism;

a carton base closing mechanism; an automatic filling device;

a bag top sealing or folding mechanism and;

a carton top closing mechanism.

Figure 18 — Pre-made bag-in-box cartoner

3.2.4.3 reel fed bag-in-box cartoner a vertical cartoner which erects a side seam sealed and folded carton before forming a bag from a reel of flexible film and placing it in the carton.

The bag is filled vertically with product before the top of the bag is sealed and the carton flaps are closed (see figure 19). The characteristic features are: a carton blank magazine;

a carton erecting mechanism;

a carton transport mechanism;

a carton base closing mechanism;

a film reel unwind mechanism;

a forming tube; a longitudinal bag sealing mechanism;

a transverse bag sealing mechanism; a transverse bag cutting mechanism; a bag placing mechanism; an automatic filling device; SIST EN 415-3:2001+A1:2010

Figure 19 — Reel fed bag-in-box cartoner 3.2.5 deep draw form, fill and seal machines the two form, fill and seal machines described in 3.2.5.1 - 3.2.5.2 produce deep drawn packs. 3.2.5.1 cold form, fill and seal machine a deep draw form, fill and seal machine in which a web of deformable material is formed under pressure in a die press, before being filled vertically with product sealed, with a top film or magazine fed lid, and finally cut to produce individual packs. Machines can produce one or more lanes of packs (see figure 20). The characteristic features are: a reel unwind mechanism; a forming die a cutting mechanism; a loading area or automatic feeding device; a transport mechanism; a top lid dispensing mechanism or reel unwind mechanism; a lid sealing mechanism; a cutting mechanism and; a discharge mechanism. SIST EN 415-3:2001+A1:2010

Figure 20 — Cold form, fill and seal machine 3.2.5.2 thermoform, fill and seal machine a deep draw form, fill and seal machine in which a

web of thermoformable material is heated and formed with pressure and/or vacuum, before being filled vertically with product, sealed with a top film or magazine fed lid and finally cut to produce individual packs. Machines can produce one or more lanes of packs and may incorporate equipment to evacuate packages before they are sealed (see figure 21). The characteristic features are: a reel unwind mechanism; a film heating mechanism; a forming die; a transport mechanism; a product loading area or automatic feeding device; a top lid dispensing mechanism or reel unwind mechanism; a lid sealing mechanism; a cutting mechanism and; a discharge mechanism.

Figure 21 — Thermoform, fill and seal machine 3.3 description of filling machines for form, fill and seal machines form, fill and seal machines will frequently be supplied with filling machines attached to them. The following types of filling machine are representative of those which are typically fitted to form, fill and seal machines 3.3.1 auger filler a filling machine in which a vertical helix rotating in a hopper and funnel, is used to dispense a volume of product (see figure 22). The characteristic features are: SIST EN 415-3:2001+A1:2010

Figure 22 — Auger filler 3.3.2 volumetric cup filler a filling machine in which free flowing solids are measured out in telescopic cups, usually mounted on a rotating assembly (see figure 23).

The characteristic features are: a filling mechanism; a cup or series of cups; a levelling mechanism and; a discharge mechanism.

Figure 23 — Volumetric cup filler 3.3.3 volumetric piston filler a filling machine in which a piston is used to dispense a predetermined volume of liquid or paste (see figure 24).

The characteristics features are: a piston; a cylinder; a means of controlling the bulk product and; a means of controlling the discharge of the product.

Figure 24 — Volumetric piston filler 3.3.4 counter a filling machine which counts solid products and discharges them in a predetermined count (see figure 25). The characteristic features are: a bulk product container; a product separating mechanism; a product counting device and; a means of controlling the discharge of the product.

Figure 25 — Counter SIST EN 415-3:2001+A1:2010

C - cut-off weight; T - target weight

Figure 26 — Gravimetric filler 3.3.6 selective combination weigher; associative weigher (multihead computer weigher) a gravimetric filler comprising multiple weighing units and which computes an appropriate combination of the loads and combines them for subsequent discharge as a fill (see figure 27). The characteristic features are: a bulk product container; a product separating mechanism; a series of weigh pans; a microprocessor to compute the optimum combination of loads and; a hopper to combine the selected loads into a fill.

A = target weight Figure 27 — Selective combination weigher 4 Hazards on form, fill and seal machines Form, fill and seal machines and their filling machines, can generate a great variety of hazards, in particular from mechanisms, electrical equipment and hot surfaces.

Moreover, the hazards on a particular machine can vary depending on the product being packed, the pack size, the packaging materials being used, the use of special packing atmospheres, the use of sterilising agents and the environment in which the machine is sited. This clause first identifies the hazards which occur on most form, fill and seal machines and then describes hazards specific to particular types of form, fill and seal machines or associated filling equipment. Ten machines have been selected as being typical of a group of machines and for each of these machines a risk assessment has been carried out and appropriate methods of safeguarding proposed in clause 5. The machines selected are as follows: SIST EN 415-3:2001+A1:2010

3.2.1.5; Mandrel flexible package form, fill and seal machine (3.2.1.4) typical of 3.2.3.3, 3.2.4.1; Horizontal end load cartoner (3.2.3.1) typical of 3.2.3.2, 3.2.3.5, 3.2.3.6, 3.2.3.7, 3.2.4.2 and 3.2.4.3; Thermoform, fill and seal machine (3.2.5.2) typical of 3.2.5.1; Auger filler (3.3.1); Volumetric cup filler (3.3.2); Volumetric piston filler (3.3.3); Gravimetric filler (Nett weigher) (3.3.5) typical of 3.3.4 and 3.3.6. In addition, a risk assessment, has been carried out for all of the machines identified in clause 3 (including those not listed in the paragraph above), and the hazards of these machines have been identified

and are presented in tabular form in Annex A and cross-referenced to the appropriate safeguarding measures detailed in clause 5. NOTE Before this standard is used, a hazard identification and risk assessment should be carried out, to check that the hazards for the machine to be designed are the same as those identified in this standard. 4.1 General form, fill and seal machine hazards The following hazards occur on most form, fill and seal machines. 4.1.1 Drive Systems

Form, fill and seal machines may incorporate mechanical, electrical, pneumatic or hydraulic

mechanisms which present a variety of different hazards including crushing, shearing, cutting, drawing-in and entanglement. 4.1.2 Handwheels

Handles or spoked handwheels are sometimes provided to operate machines manually for adjustment or cleaning. These devices can present impact or entanglement hazards. 4.1.3 Size changing

Typically, form, fill and seal machines are constructed to handle a range of product and pack sizes. Changes from size to size may be performed manually or automatically. Where change parts are involved excessive effort or strain hazards can arise if the weight of the parts is greater than 25 kg or their location on the machine is awkward. Where size changing is automatic, shearing and crushing hazards are likely to be present. SIST EN 415-3:2001+A1:2010

Pneumatic and hydraulic equipment presents crushing, shearing, ejection of parts, explosion and injection of fluids hazards. In addition hydraulic oil and pneumatic lubricating oil are a potential fire hazard and can contaminate agri-foodstuffs. 4.1.5 Electrical equipment

Electrical equipment on the machine is a potential electric shock hazard and in the presence of certain materials a potential fire and explosion hazard. 4.1.6 Agri-foodstuffs and pharmaceuticals

On machines which are used to pack agri-foodstuffs and pharmaceuticals, contamination hazards can result if inappropriate contact materials or construction methods are used or lubricated compressed air is allowed to come into contact with the product. 4.1.7 Packaging materials and products

Form, fill and seal machines are used to pack a wide range of products in many types of packaging materials, some of which are potentially hazardous to persons operating or in the vicinity of t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...