SIST EN 474-12:2022

(Main)Earth-moving machinery - Safety - Part 12: Requirements for cable excavators

Earth-moving machinery - Safety - Part 12: Requirements for cable excavators

This document together with EN 474 1:2022 deals with all significant hazards, hazardous situations and events relevant to cable excavators when used as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex A) associated with the whole lifetime of the machine as described in EN ISO 12100:2010, 5.4.

The requirements of this document are complementary to the common requirements formulated in EN 474 1:2022. This document does not repeat the requirements of EN 474 1:2022 but supplements or modifies the requirements for cable excavators.

This document does not provide requirements for main electrical circuits and drives of machinery when the primary source of energy is an external electrical supply.

This document does not provide performance requirements for safety related functions of control system(s).

The following significant and relevant hazards are not covered in this document:

— Laser;

— Lightning.

Drilling and foundation equipment (covered by EN 16228 1:2014+A1:2021 to EN 16228 7:2014+A1:2021) are not dealt with in this document.

This document does not provide requirements for main electrical circuits and drives of machinery when the primary source of energy is an external electrical supply.

This document does not deal with demolition machinery.

This document is not applicable to cable excavators which are manufactured before the date of publication of this document by CEN.

Erdbaumaschinen - Sicherheit - Teil 12: Anforderungen für Seilbagger

Dieses Dokument behandelt zusammen mit EN 474 1:2022 alle signifikanten Gefährdungen, Gefährdungssituationen und ‑ereignisse von Seilbaggern, wenn diese Maschinen bestimmungsgemäß verwendet werden sowie unter den vernünftigerweise vom Hersteller vorhersehbaren Fehlanwendungen (siehe Anhang A) für die gesamte Lebensdauer der Maschine betrieben werden wie in EN ISO 12100:2010, 5.4, beschrieben betrieben werden.

Die Anforderungen dieses Dokuments gelten ergänzend zu den allgemeinen Anforderungen in EN 474 1:2022. Dieses Dokument wiederholt nicht die Anforderungen in EN 474 1:2022, sondern ergänzt oder ändert diese für den Einsatz von Seilbaggern.

Dieses Dokument enthält keine Anforderungen an den Hauptstromkreis und den Antrieb, wenn die primäre Energiequelle eine externe Stromversorgung ist.

Dieses Dokument enthält keine Leistungsanforderungen an Sicherheitsfunktionen von Steuerungssystemen.

Die folgenden signifikanten und relevanten Gefährdungen werden in diesem Dokument nicht behandelt:

— Laserstrahlung;

— Blitzschlag.

Diese Norm behandelt keine Geräte für Bohr- und Gründungsarbeiten (die von EN 16228 1:2014+A1:2021 bis EN 16228 7:2014+A1:2021 abgedeckt werden).

Dieses Dokument enthält keine Anforderungen an den Hauptstromkreis und den Antrieb, wenn die primäre Energiequelle eine externe Stromversorgung ist.

Dieses Dokument behandelt keine Abrissmaschinen.

Dieses Dokument ist nicht anwendbar für Seilbagger, die vor der Veröffentlichung dieser Norm durch CEN hergestellt worden sind.

Engins de terrassement - Sécurité - Partie 12 : Prescriptions applicables aux pelles à câbles

Le présent document associé à l’EN 474-1:2022 traite de tous les phénomènes dangereux significatifs, situations dangereuses et événements se rapportant aux pelles à câbles, lorsqu'elles sont utilisées normalement et dans les conditions prévues, mais en tenant également compte des mauvais usages raisonnablement prévisibles (voir Annexe A), associés à toute la durée de vie de l'engin, tel que décrit dans l'EN ISO 12100:2010, 5.4.

Les prescriptions du présent document viennent en complément des prescriptions communes présentées dans l’EN 474 1:2022. Le présent document ne répète pas les prescriptions de l’EN 474 1:2022 mais complète ou modifie les prescriptions pour les pelles à câbles.

Le présent document ne spécifie aucune prescription relative aux circuits électriques principaux et aux commandes des engins lorsque la principale source d'énergie est une alimentation électrique externe.

Le présent document ne spécifie aucune prescription de performance relative aux fonctions de sécurité du (des) système(s) de commande.

Les phénomènes dangereux significatifs et pertinents suivants ne sont pas couverts par le présent document :

— laser ;

— foudre.

Les équipements de forage et de fondation (couverts par les normes EN 16228 1:2014+A1:2021 à EN 16228 7:2014+A1:2021) ne sont pas traités dans le présent document.

Le présent document ne spécifie aucune prescription relative aux circuits électriques principaux et aux commandes des engins lorsque la principale source d'énergie est une alimentation électrique externe.

Le présent document ne traite pas des engins de démolition.

Le présent document n'est pas applicable aux pelles à câbles fabriquées avant la date de publication du présent document par le CEN.

Stroji za zemeljska dela - Varnost - 12. del: Zahteve za bagre s kablom

Ta dokument skupaj s 1. delom obravnava vsa večja tveganja za stroje za zemeljska dela – bagre s kablom (kot so opredeljeni v standardu EN ISO 6165), kadar se uporabljajo v skladu s predvidenim namenom in pod pogoji pričakovane nepravilne uporabe, ki jih določa proizvajalec, v zvezi s celotno življenjsko dobo stroja (glej točko 4).

Ta evropski standard se uporablja tudi za bagre s kablom ter njihovo ogrodje in zgornjo strukturo, če so namenjeni za uporabo v kombinaciji z drugo opremo ali priključkom, kot je oprema za dvigovanje, ekstrakcijo in premikanje (npr. tirnice, premične noge, pontoni, ladje), ali s stacionarnim ogrodjem. Oprema za vrtanje in temeljenje, zajeta v standardu EN 16228 (deli 1–7:2014), v tem standardu ni obravnavana.

Zahteve iz tega dela dopolnjujejo splošne zahteve iz standarda

prEN 474-1. Ta dokument ne navaja ponovno zahtev iz standarda prEN 474-1, temveč dodaja ali nadomešča zahteve za uporabo strojev za zemeljska dela – bagrov s kablom.

General Information

- Status

- Published

- Public Enquiry End Date

- 21-Jun-2017

- Publication Date

- 11-Apr-2022

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 06-Apr-2022

- Due Date

- 11-Jun-2022

- Completion Date

- 12-Apr-2022

Relations

- Effective Date

- 06-Apr-2022

Overview

EN 474-12:2022 - "Earth-moving machinery - Safety - Part 12: Requirements for cable excavators" is a CEN type‑C safety standard that supplements the general requirements of EN 474-1:2022. It addresses significant hazards, hazardous situations and events relevant to cable excavators over the machine’s lifetime (per EN ISO 12100). The document updates and replaces earlier editions and is intended for machines manufactured on or after its publication date. Notable exclusions include hazards from laser and lightning, demolition machinery, drilling/foundation equipment (covered by EN 16228), and main electrical circuits/drives where the primary energy source is an external electrical supply.

Key topics and technical requirements

This standard focuses on machine design, safety verification and information for use. Major technical topics include:

- Scope and definitions specific to cable excavators (e.g., hoisting rope, digging rope, free‑fall)

- List of significant hazards (Annex A) and risk reduction context aligned with EN ISO 12100

- Operator access and operator’s station: requirements for safe ingress/egress and ergonomic controls

- Seat, controls and indicators: occupant protection, vibration and control layout

- Steering, swing brakes and verification: performance and test requirements for swing brakes (Annex B)

- Stability: design measures to prevent overturning during normal and foreseeable misuse

- Excavator and lifting operations: lift systems, boom hoist systems, lifting/lowering and free‑fall definitions and requirements

- Free‑fall function: classifications (manual vs automatic), free‑fall brake and lifting winch disconnecting systems; examples in Annex D

- Maintenance and verification: tests and documentation to confirm compliance

- Information for use: operator’s manual requirements and safety information

The standard contains informative illustrations (Annex C), test conditions for swing brakes, and Annex ZA linking the standard to EU machinery directive requirements.

Applications and who uses it

EN 474-12:2022 is used by:

- Manufacturers of cable excavators to design and certify machines that meet European safety expectations

- Design engineers and safety specialists for machine risk assessment and safety integration

- Regulators, market surveillance and certification bodies assessing conformity with the Machinery Directive

- Fleet owners, operators and maintenance providers referencing safe operation, inspection and maintenance practices

Practical uses include design checks for operator protection, specifying swing‑brake performance, stability assessments, and preparing compliant operator manuals.

Related standards

- EN 474-1:2022 (General requirements for earth‑moving machinery) - complementary

- EN 16228 (Parts 1–7) - drilling and foundation equipment (excluded topics)

- EN 60204-32, EN 13000, EN ISO 12100, EN ISO 6165, EN ISO 7096 - referenced normative documents for electrical, crane and safety principles.

Keywords: EN 474-12:2022, cable excavators, earth-moving machinery, safety standard, CEN, free-fall, swing brakes, stability, operator’s manual, EN 474-1.

Frequently Asked Questions

SIST EN 474-12:2022 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Earth-moving machinery - Safety - Part 12: Requirements for cable excavators". This standard covers: This document together with EN 474 1:2022 deals with all significant hazards, hazardous situations and events relevant to cable excavators when used as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex A) associated with the whole lifetime of the machine as described in EN ISO 12100:2010, 5.4. The requirements of this document are complementary to the common requirements formulated in EN 474 1:2022. This document does not repeat the requirements of EN 474 1:2022 but supplements or modifies the requirements for cable excavators. This document does not provide requirements for main electrical circuits and drives of machinery when the primary source of energy is an external electrical supply. This document does not provide performance requirements for safety related functions of control system(s). The following significant and relevant hazards are not covered in this document: — Laser; — Lightning. Drilling and foundation equipment (covered by EN 16228 1:2014+A1:2021 to EN 16228 7:2014+A1:2021) are not dealt with in this document. This document does not provide requirements for main electrical circuits and drives of machinery when the primary source of energy is an external electrical supply. This document does not deal with demolition machinery. This document is not applicable to cable excavators which are manufactured before the date of publication of this document by CEN.

This document together with EN 474 1:2022 deals with all significant hazards, hazardous situations and events relevant to cable excavators when used as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex A) associated with the whole lifetime of the machine as described in EN ISO 12100:2010, 5.4. The requirements of this document are complementary to the common requirements formulated in EN 474 1:2022. This document does not repeat the requirements of EN 474 1:2022 but supplements or modifies the requirements for cable excavators. This document does not provide requirements for main electrical circuits and drives of machinery when the primary source of energy is an external electrical supply. This document does not provide performance requirements for safety related functions of control system(s). The following significant and relevant hazards are not covered in this document: — Laser; — Lightning. Drilling and foundation equipment (covered by EN 16228 1:2014+A1:2021 to EN 16228 7:2014+A1:2021) are not dealt with in this document. This document does not provide requirements for main electrical circuits and drives of machinery when the primary source of energy is an external electrical supply. This document does not deal with demolition machinery. This document is not applicable to cable excavators which are manufactured before the date of publication of this document by CEN.

SIST EN 474-12:2022 is classified under the following ICS (International Classification for Standards) categories: 53.100 - Earth-moving machinery. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 474-12:2022 has the following relationships with other standards: It is inter standard links to SIST EN 474-12:2007+A1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 474-12:2022 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 474-12:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2022

Nadomešča:

SIST EN 474-12:2007+A1:2008

Stroji za zemeljska dela - Varnost - 12. del: Zahteve za bagre s kablom

Earth-moving machinery - Safety - Part 12: Requirements for cable excavators

Erdbaumaschinen - Sicherheit - Teil 12: Anforderungen für Seilbagger

Engins de terrassement - Sécurité - Partie 12 : Prescriptions applicables aux pelles à

câbles

Ta slovenski standard je istoveten z: EN 474-12:2022

ICS:

53.100 Stroji za zemeljska dela Earth-moving machinery

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 474-12

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2022

EUROPÄISCHE NORM

ICS 53.100 Supersedes EN 474-12:2006+A1:2008

English Version

Earth-moving machinery - Safety - Part 12: Requirements

for cable excavators

Engins de terrassement - Sécurité - Partie 12 : Erdbaumaschinen - Sicherheit - Teil 12: Anforderungen

Prescriptions applicables aux pelles à câbles für Seilbagger

This European Standard was approved by CEN on 14 February 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 474-12:2022 E

worldwide for CEN national Members.

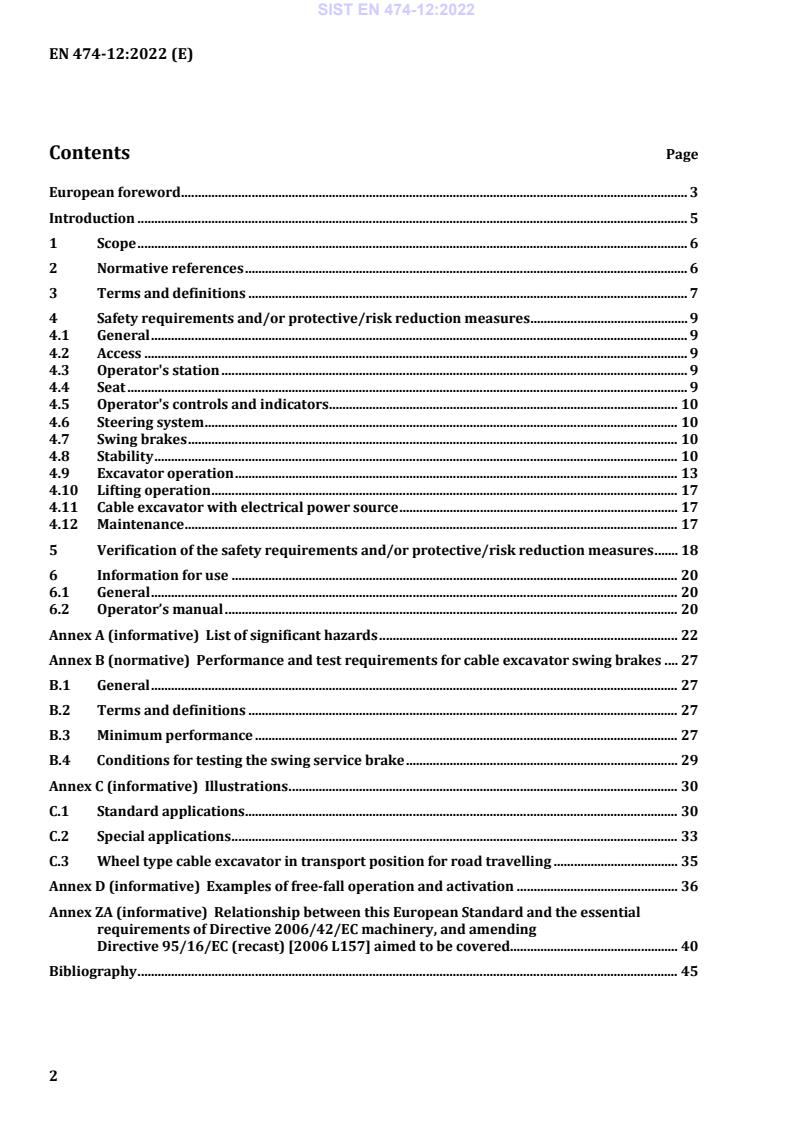

Contents Page

European foreword . 3

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Safety requirements and/or protective/risk reduction measures . 9

4.1 General . 9

4.2 Access . 9

4.3 Operator's station . 9

4.4 Seat . 9

4.5 Operator's controls and indicators . 10

4.6 Steering system . 10

4.7 Swing brakes . 10

4.8 Stability . 10

4.9 Excavator operation . 13

4.10 Lifting operation . 17

4.11 Cable excavator with electrical power source . 17

4.12 Maintenance . 17

5 Verification of the safety requirements and/or protective/risk reduction measures . 18

6 Information for use . 20

6.1 General . 20

6.2 Operator’s manual . 20

Annex A (informative) List of significant hazards . 22

Annex B (normative) Performance and test requirements for cable excavator swing brakes . 27

B.1 General . 27

B.2 Terms and definitions . 27

B.3 Minimum performance . 27

B.4 Conditions for testing the swing service brake . 29

Annex C (informative) Illustrations . 30

C.1 Standard applications. 30

C.2 Special applications . 33

C.3 Wheel type cable excavator in transport position for road travelling . 35

Annex D (informative) Examples of free-fall operation and activation . 36

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/EC machinery, and amending

Directive 95/16/EC (recast) [2006 L157] aimed to be covered. 40

Bibliography . 45

European foreword

This document (EN 474-12:2022) has been prepared by Technical Committee CEN/TC 151 “Construction

equipment and building material machines - Safety”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2022, and conflicting national standards shall

be withdrawn at the latest by March 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 474-12:2006+A1:2008.

This document has been prepared under a standardization request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of

EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

For bibliographic references, see EN 474-1:2022.

EN 474 “Earth-moving machinery — Safety” comprises the following parts:

— Part 1: General requirements

— Part 2: Requirements for tractor-dozers

— Part 3: Requirements for loaders

— Part 4: Requirements for backhoe-loaders

— Part 5: Requirements for hydraulic excavators

— Part 6: Requirements for dumpers

— Part 7: Requirements for scrapers

— Part 8: Requirements for graders

— Part 9: Requirements for pipelayers

— Part 10: Requirements for trenchers

— Part 11: Requirements for earth and landfill compactors

— Part 12: Requirements for cable excavators

— Part 13: Requirements for rollers

This document is intended for use in combination with part 1 of the series.

The main differences between this document and EN 474-12:2006+A1:2008 are as follows:

a) normative references (Clause 2) (revised and updated);

b) definitions (Clause 3) (revised and updated);

c) list of significant hazards (Annex A) (revised and updated);

d) requirements for operative protective structures (revised);

e) free-fall requirements (revised);

f) verification methods table (Clause 5) (added);

g) stability requirements (revised and updated);

h) requirements for swing brake (revised);

i) illustrations (updated);

j) Annex ZA (updated).

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document is a type-C standard as stated in EN ISO 12100.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events are

covered are indicated in the scope of this document.

When requirements of this type-C standard are different from those which are stated in type-A or type-B

standards, the requirements of this type-C standard take precedence over the requirements of the other

standards for machines that have been designed and built according to the requirements of this type-C

standard.

1 Scope

This document together with EN 474-1:2022 deals with all significant hazards, hazardous situations and

events relevant to cable excavators when used as intended and under the conditions of misuse which are

reasonably foreseeable by the manufacturer (see Annex A) associated with the whole lifetime of the

machine as described in EN ISO 12100:2010, 5.4.

The requirements of this document are complementary to the common requirements formulated in

EN 474-1:2022. This document does not repeat the requirements of EN 474-1:2022 but supplements or

modifies the requirements for cable excavators.

This document does not provide requirements for main electrical circuits and drives of machinery when

the primary source of energy is an external electrical supply.

This document does not provide performance requirements for safety related functions of control

system(s).

The following significant and relevant hazards are not covered in this document:

— Laser;

— Lightning.

Drilling and foundation equipment (covered by EN 16228-1:2014+A1:2021 to

EN 16228-7:2014+A1:2021) are not dealt with in this document.

This document does not provide requirements for main electrical circuits and drives of machinery when

the primary source of energy is an external electrical supply.

This document does not deal with demolition machinery.

This document is not applicable to cable excavators which are manufactured before the date of

publication of this document by CEN.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 474-1:2022, Earth-moving machinery — Safety — Part 1: General requirements

EN 16228-1:2014+A1:2021, Drilling and foundation equipment — Safety — Part 1: Common

requirements

EN 13000:2010+A1:2014, Cranes — Mobile cranes

EN 14502-2:2005+A1:2008, Cranes — Equipment for the lifting of persons — Part 2: Elevating control

stations

EN 60204-32:2008, Safety of machinery — Electrical equipment of machines — Part 32: Requirements for

hoisting machines (IEC 60204-32:2008)

EN ISO 2867:2011, Earth-moving machinery — Access systems (ISO 2867:2011)

EN ISO 6165:2012, Earth-moving machinery — Basic types — Identification and terms and definitions

(ISO 6165:2012)

EN ISO 7096:2020, Earth moving machinery — Laboratory evaluation of operator seat vibration

(ISO 7096:2020)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

ISO 7546:1983, Earth-moving machinery — Loader and front loading excavator buckets — Volumetric

ratings

ISO 10262:1998+Cor. 1:2009, Earth-moving machinery — Hydraulic excavators — Laboratory tests and

performance requirements for operator protective guards; Technical Corrigendum 1

ISO 10567:2007, Earth-moving machinery — Hydraulic excavators — Lift capacity

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 474-1:2022, EN ISO 12100:2010

and the following apply.

NOTE 1 Terminology for hydraulic excavators are specified in ISO 7135:2009.

NOTE 2 Terminology for cable excavators are specified in ISO 15219:2004 and illustrated in Annex C of this

document.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

cable excavator

excavator (see 4.4 of EN ISO 6165:2012), having a wire rope-operated upper structure primarily

designed for excavating (e.g. with a dragline bucket, a front shovel or grab, a chisel), for compacting

material (e.g. with a compaction plate), for demolition work (e.g. by hook or ball) and for material

handling with special equipment and attachment

[SOURCE: EN ISO 6165:2012, 4.4.3, modified]

3.2

boom hoist system

system which consists of the boom and its adjustment mechanism

Note 1 to entry: Boom hoist system can consist of e.g. lower-, intermediate- and head-section, the A- frame system

and the boom hoist winch system, hydraulic-mechanical adjustment mechanism.

3.3

lift system

parts of the machine used for earth-moving-, demolition-, compaction- and lifting operation (e.g. with

hook assembly) application which consists of the main winch system

3.4

lifting and lowering operation

lifting and lowering of a load without disengaging the lifting drum and the lift drive system

3.5

free-fall

intentional drop of a tool enabled by a complete or partially controlled disengagement of the lifting drum

and the lift drive system

Note 1 to entry: The lifted tool is falling only by gravity.

3.5.1

free-fall operation

setting up of the machine in which the free-fall function can be activated

3.5.1.1

automatic free-fall operation

triggering and braking of free-fall is done by the control system without intervention of the operator

3.5.1.2

manual free-fall operation

triggering and braking of free-fall is done by the operator

3.5.2

free-fall function

function to enable free-fall

3.5.3

triggering of free-fall

action (manual or automatic) that causes the starting of the free-fall

3.5.4

free-fall brake

device to decelerate and hold a winch drum which is disconnected from its drive by a lifting winch

disconnecting system

3.5.5

lifting winch disconnecting system

system to disengage the lift drive system from the lifting drum

Note 1 to entry: This system can also be used as free-fall brake.

3.6

dynamic compaction

compacting ground by dynamic impact of a pounder weight

3.7

hoisting rope

rope intended to lift the load in vertical direction

3.8

digging rope

rope intended to be used for earth moving application to pull the tool, e.g. a dragline bucket

3.9

closing rope

rope intended to be used for opening and closing, e.g. a grab

Note 1 to entry: A closing rope can also be used to lift the load, mainly in vertical direction.

4 Safety requirements and/or protective/risk reduction measures

4.1 General

4.1.1 Context

Cable excavators shall comply with the safety requirements and/or protective/risk reduction measures

of this clause. In addition, the machines shall be designed according to the principles of

EN ISO 12100:2010 for relevant but not significant hazards which are not dealt with by this document.

4.1.2 Specific relation to EN 474-1

Cable excavators shall comply with the requirements of EN 474-1:2022, as far as not modified or replaced

by the requirements of this part.

4.2 Access

EN 474-1:2022, 4.2.1 shall apply with the following addition:

Access systems shall be provided to ensure access to the positions for assembly/dismantling of elements

assembled on the site; particularly boom sections, shrouds, ropes and shall comply with

EN ISO 2867:2011.

4.3 Operator's station

4.3.1 General

EN 474-1:2022, 4.3 shall apply with the following modifications in 4.3.2 to 4.3.3.

4.3.2 Roll-over protective structures (ROPS)

EN 474-1:2022, 4.3.3 does not apply for cable excavators.

4.3.3 Operator's protective guard

EN 474-1:2022, 4.3.4 shall be replaced by the following:

Cable excavators shall be designed so that operator’s protective structures can be fitted.

For cable excavators, intended for dynamic compaction operation, protective structures shall be provided

by the manufacturer. The protective structures shall provide performance of level II in accordance with

8.1b (top guard) and 8.2b (front guard) of ISO 10262:1998+Cor. 1:2009.

Rope shovels and draglines equipped with boom and dipper handle are not required to provide a front

guard.

4.3.4 Moveable operator station

EN 474-1:2022, 4.3.5 does not apply.

Moveable operation station shall be in accordance with EN 14502-2:2005+A1:2008.

4.4 Seat

EN 474-1:2022, 4.4.1.4 shall apply with the following additions:

The seat shall meet the requirements of EN ISO 7096:2020, the input spectral class shall meet the class

EM 6 for the test excitation vibrations.

4.5 Operator's controls and indicators

4.5.1 General

EN 474-1:2022, 4.5.1 shall apply with the following addition to 4.5.1 d):

The movements of the controls for driving and steering (see 4.6) do not need to correspond to the

intended direction of movement if the upper structure is not in the normal driving direction.

4.5.2 Operating mode

Cable excavators intended for use in different modes shall be fitted with a lockable operating mode

selector for at least:

a) excavator operation mode (see 4.9);

NOTE 1 Excavator operation mode can include e.g. excavating, compaction, demolition.

b) lifting operation mode (see 4.10).

The activation of the selected operation mode shall be optically indicated at the operator's station(s).

NOTE 2 A remote control is also considered as an operator’s station.

The selection of an operation mode shall not initiate any machine movement.

4.5.3 Controls on stabilizers

Control devices (except remote controls) for extending/retracting the stabilizers (e.g. outriggers,

retractable crawlers) shall be in a position or provided with means where the movements of the

stabilizers can clearly be seen by the operator and from where crushing of the operator is not possible.

If the horizontal movement of the stabilizers is controlled from a fixed control on the ground level, it shall

only be possible to affect that movement on the side where the controls are situated.

4.6 Steering system

EN 474-1:2022, 4.6 shall apply with the following modification:

EN 474-1:2022, 4.6.1 does not apply for cable excavators.

The movements of the controls for steering do not need to correspond to the intended direction of

movement if the upper structure is not in the normal driving direction (see 4.5.1).

4.7 Swing brakes

Cable excavators shall be equipped with swing service and swing parking brake systems which shall meet

the performance and test requirements as defined in Annex B.

4.8 Stability

4.8.1 General

The level of the cable excavator shall be indicated so that it is clearly visible to the operator in the

operator’s station (e.g. inclinometer in the cab).

Cable excavators with outriggers shall be fitted with a level indicating device (e.g. inclinometer) in every

control station where the levelling movements can be controlled.

The accuracy of the level indicating device (e.g. inclinometer) shall be better or equal to ± 0,1°.

EN 474-1:2022, 4.11 applies with the following addition:

The calculation of the lift capacity of cable excavators shall be made on the basis of the following criteria:

— the machine is standing on flat and firm surface;

— if the machine is intended to be used on inclined surfaces, the slope has to be considered in the

calculation;

— the tipping lines shall be taken from ISO 10567:2007, 4.1.3 and 4.1.4. For track type undercarriages

the tipping line in travelling direction is given either by the line connecting the centreline of the

support idlers/sprockets or the line connecting the centreline of the first and last support rollers,

depending on the slope of the chain (according to EN 16228-1:2014+A1:2021, 5.2.3.3.2, Figure 1);

A table of the rated lift capacity shall be available at the operator’s station (see Clause 6).

4.8.2 Calculation of tipping load

The tipping load of a cable excavator P shall be calculated as follows:

tip

9,81××mX

PN=

[ ]

tip

R

where

m is the mass of the cable excavator including the mass of the equipment (e.g. boom, jib)

[kg];

X is the horizontal distance of the centre of gravity of m to the smallest tipping line

according to EN 16228-1:2014+A1:2021, 5.2.3.3 [m];

R is the horizontal distance from the application point of P to the smallest tipping line

according to EN 16228-1:2014+A1:2021, 5.2.3.3 [m].

The rear tipping load of a cable excavator P shall be calculated as follows:

tip, rear

9,81××mX

PN=

[ ]

tip,rear

R

1

where

m is the mass of the cable excavator including the mass of the equipment (e.g. boom, jib)

[kg];

X is the horizontal distance of the centre of gravity of m to the smallest rear tipping line

according to EN 16228-1:2014+A1:2021, 5.2.3.3 [m];

R1 is the horizontal distance from the application point of P to the smallest rear tipping

line according to EN 16228-1:2014+A1:2021, 5.2.3.3 [m].

4.8.3 Stability in different applications

4.8.3.1 General

The mass of the intended load and the location of its centre of gravity as well as the mass of the attachment

shall be included in the determination of the rated operating load and the capacity of the attachment.

4.8.3.2 Compacting material application

The rated lift capacity Pr for cable excavators in compacting material application shall be determined

either by:

a) 75 % of the tipping load Ptip as calculated according to 4.8.2, or

b) maximum winches lift capacity,

whichever is less.

The dynamic effect of release of suspended load is an upward load P :

upward

PP×0,10 N

[ ]

upward r

where

P is the rated load;

r

P shall not exceed P ;

upward tip,rear

P shall not cause unintended backward motions of parts of the machine.

upward

4.8.3.3 Lifting operation

4.8.3.3.1 Stability

For lifting operation mode stability shall comply with EN 13000:2010+A1:2014, 4.1.2.6.

4.8.3.3.2 Verification

EN 474-1:2022, 4.12.7 does not apply.

Each cable excavator intended to be used in lifting operation mode shall be tested according to

EN 13000:2010+A1:2014, 5.2.

If suitable methods ensure (e.g. quality management system) that the manufactured machines comply

with the tested prototype, it is not necessary to test every machine individually and verification methods

according to 5.1 of EN 13000:2010+A1:2014 apply.

4.8.3.4 Dragline bucket

The rated lift capacity for cable excavators in dragline bucket application shall be determined either by:

a) 75 % of the tipping load P as calculated according to 4.8.2, or

tip

b) maximum winch lift capacity

whichever is less.

The mass and the volumetric rating of the bucket and the density of the material have to be taken into

account when a bucket is designed/selected for a specific application.

=

4.8.3.5 Grab and front shovel

The rated lift capacity for cable excavators in grab and front shovel application shall be determined either

by:

a) 66 % of the tipping load Ptip as calculated according to 4.8.2, or

b) maximum winch lift capacity

whichever is less.

The volumetric rating of the front shovel shall be determined according to ISO 7546:1983.

The mass and the volumetric rating of the front shovel and the grab as well as the density of the material

have to be taken into account where these attachments are designed/selected for a specific application.

4.9 Excavator operation

4.9.1 Holding brake

The lift system of cable excavators shall be fitted with a brake, which actuates immediately after releasing

operational controls (e.g. levers or pedals) or in case of loss of energy.

The holding brake for hoisting and for derricking systems operated by winches shall be able to exert a

restraining torque at least 33 % greater than the maximum torque transmitted from the rope drum to

the brake under working or erection conditions, whichever is greater.

4.9.2 Limiting devices

4.9.2.1 Limit switch for the boom hoist system

The boom hoist system of cable excavators shall be equipped with a limiting switch to stop the movement

at the maximum allowable boom upper position/angle. Boom lowering shall be possible after actuation

of this limiting switch.

4.9.2.2 Limit switch for unwinding of the hoisting winch

All cable excavators shall be fitted with a limit switch for unwinding the hoisting winch(es). As a minimum

the limit switch shall ensure three revolutions of rope on the drum. Temporary deactivation of the limit

switch shall only be possible during free-fall, rigging operations, transport and changing of the rope.

4.9.3 Free-fall operation

4.9.3.1 General

Cable excavators designed for free-fall operation shall comply with 4.9.3.2 to 4.9.3.5.

4.9.3.2 Common requirements for free-fall operation

The free-fall system shall be designed that an uncontrolled run-up or run-off of the rope is avoided, e.g.

by a rope guide.

There shall be a specific lockable selector (e.g. could be integrated in the mode selector according to 4.5.2)

to enable/disable the free-fall operation.

There may be one selector for all winches or one selector per winch.

The design of the free-fall system may provide different types of operation (automatic/manual) as well

as different types of deactivation (automatic/manual) and triggering (automatic/manual) as described

in 4.9.3.3 to 4.9.3.5.

These different types shall be selected either by a separate control or by the lockable free-fall operation

selector.

The selected type shall be indicated at the operator´s station.

Examples to illustrate some of the procedure of free-fall operation and the activation are shown in

Annex D, Figures D.1 to D.4.

4.9.3.3 Free-fall brake

The lift system of cable excavators shall be fitted with a free-fall brake.

The use of the main winch disconnecting system shall only be possible when the free-fall function is

activated.

The free-fall brake shall be designed that the deceleration of a dynamic load shall be possible.

A proportional actuation of the free-fall brake shall be possible.

4.9.3.4 Manual free-fall operation

4.9.3.4.1 General

Manual free-fall operation shall only be possible for following conditions:

— free-fall operation is selected;

— free-fall function is activated.

4.9.3.4.2 Activation/deactivation of free-fall function

Activation of free-fall function shall only be possible by actuation of two independent controls

simultaneously (e.g. pedals and additional control).

There shall be no lowering at activating/deactivating the free-fall function.

The free-fall function can be with an automatic deactivation (see 4.9.3.4.3) or manual deactivation (see

4.9.3.4.4).

Triggering after activation of the free-fall function shall be done by a separate control (e.g. by releasing

the pedals).

4.9.3.4.3 Automatic deactivation of free-fall function

Free-fall function is deactivated automatically for following conditions:

— hoist winch stands still;

and

— moving the control for winch to lifting or lowering position.

4.9.3.4.4 Manual deactivation of free-fall function

Free-fall function has to be deactivated manually by operator.

Triggering of free-fall after lifting or lowering can be done by the following options:

— automatic (triggering of free-fall will start automatically when returning the control for lifting or

lowering to neutral position);

NOTE 1 In this case, the holding brake (see 4.9.1) will not be activated automatically after returning the

control for lifting or lowering to neutral position.

or

— manual (triggering of free-fall will start by actuation by the operator after returning the control for

lifting or lowering to neutral position).

NOTE 2 Triggering of free-fall will start by actuation by the operator e.g. by releasing the brake pedal.

4.9.3.5 Automatic free-fall operation

When a cable excavator is fitted with an automatic cycle mode, including free-fall operation (e.g. ramming

operations with a compaction plate), the activation of the automatic cycle mode shall be possible only

after selecting free-fall operation mode.

The cable excavator shall be equipped with a system to control the automatic cycle mode.

The control system shall be designed to:

— operate repeated and continuous ramming cycles, according to a sequence set by the operator;

— control the cycles (lifting, free-fall, braking);

— automatically stop the operations when the initiated sequence has been completed;

— stop the initiated sequence when a fault or an abnormal behaviour is detected.

The control system shall not stop the cycle during the free-fall.

If the automatic cycle is deactivated by a stopping device according to EN 474-1:2022, 4.5.1 or an

emergency stop (if equipped) the cycle shall not be stopped during the free-fall.

After stop of the automatic cycle or loss of energy, restarting of the automatic operation shall only be

possible by an intentional action by the operator.

4.9.4 Boom

The boom of cable excavators shall be secured against repulsing in case of a sudden release of the load.

The connection (bolts) of the boom-pieces shall be so designed that mounting and disassembling can be

made without the need for a person staying under the boom.

4.9.5 Ropes, rope drum, rope pulley

4.9.5.1 General

The rope drum and rope pulley shall be built and designed so that trip-out of the rope is avoided when

used as intended.

There shall always remain at least three revolutions of rope on the winch drum.

4.9.5.2 Ropes

The ropes of cable excavators shall have safety factors according to Table 1.

Table 1 — Safety factors of ropes

All modes of Hoisting or Digging ropes Boom holding ropes

operation, closing ropes

Operation with load Lifting the boom

except lifting

connected without load

mode and

foundation running stationary running stationary

application

ropes ropes ropes ropes

3,55 3,00 3,55 3,00 3,05 2,73

NOTE The factors are the relation between the minimum breaking force of the rope and the maximum static

load on the rope. For safety factor of ropes for foundation application, e.g. diaphragm walling application, see

EN 16228 (parts 1 to 7). For safety factor of ropes for lifting application see EN 13000:2010+A1:2014.

4.9.5.3 Rope drum

The ratio between the nominal rope diameter and the pitch circle diameter of the drum shall be 1:20 at a

minimum.

In working operation, the beaded edge of the winch drums shall extend at least 1,5 times the rope

diameter beyond the outer layer of the rope (see Figure 1).

Key

1 D (pitch circle diameter)

2 d (nominal rope diameter)

3 minimum 1,5d

4 drum

5 flange

Figure 1 — Hoist drum

4.9.5.4 Rope pulley

The ratio between the nominal rope diameter and the pitch circle diameter of the pulley shall be 1:20 at

a minimum.

Exceptions from the above requirements can be made for fair leads of drag ropes, rope guidance pulleys

and auxiliary ropes, such as grab guidance rope, digging guidance rope, ballast guidance rope of fair leads.

4.10 Lifting operation

4.10.1 General

EN 474-1:2022, 4.12 shall be replaced by the following clauses.

If the lifting operation mode is selected, the control system shall be designed in such a way that the free-

fall function is not possible to be activated.

4.10.2 Lifting and lowering operation

The holding brake for lifting and lowering shall be in accordance to 4.9.2.

4.10.3 Limiting and indicating device for the lifting operation mode

EN 474-1:2022, 4.12.4, 4.12.5, 4.12.6 do not apply.

Cable excavators intended for lifting operation mode shall be fitted with limiters and indicators and event

recorder according to EN 13000:2010+A1:2014, 4.2.6.2.

Recording load data in the event recorder is only required for the lifting operation mode.

If there is only one working position for the crawler extension and the undercarriage is fitted with a

mechanical lock that blocks the crawler in the extended track position, EN 13000:2010+A1:2014,

4.2.6.2.5 does not apply.

Change of operation mode from lifting operation to earth moving operation shall be possible with actual

load not in excess of 30 % of the rated load in lifting operation for the actual configuration.

4.11 Cable excavator with electrical power source

Cable excavators with electrical power source shall meet the requirements of EN 60204-32:2008 as far

as the electrical power source and the electrically driven systems are concerned.

4.12 Maintenance

4.12.1 General

EN 474-1:2022, 4.22 shall apply with the following addition:

Winches and ropes are subject to frequent inspection or replacement because of the wear pattern.

The manufacturer shall make due provision for access (see EN ISO 2867:2011) for the inspection or

replacement of ropes, or provide a mechanical system that eliminates the need to access the mast/boom

for replacement.

4.12.2 Control of winches for maintenance purpose

For maintenance purpose, the maximum rotation speed of winches shall be reduced to 2 rpm.

The control of the reduced rotation speed shall be lockable.

This control can either be the operating mode selector (see 4.5.2) or a separate control which interlocks

other operating functions (e.g. machine driving, movement of the boom) of the machine.

It shall not be possible to operate more than one winch at the same time. This control shall be of hold-to-

run type.

From the control station for this mode it shall be possible to have a view to the winch and the person

guiding the rope for handling and communication.

5 Verification of the safety requirements and/or protective/risk reduction

measures

Safety requirements and/or protective/risk reduction measures of Clause 4 of this document shall be

verified according to Table 2.

Table 2 sets out verification methods which shall be applied for each safety requirement in this document.

Where X(s) is indicated in the table, the corresponding verification method(s) shall be applied.

Table 2 shall be read in conjunction with the corresponding clauses.

Table 2 includes the following verification methods:

a) calculation: to establish that the requirements of this document have been met;

b) visual verification: to establish that something is present (e.g. a guard, a marking, a document);

c) measurement: to show that the required numerical values have been met (e.g. geometric dimensions,

safety distances, resistance of insulation of the electric circuits, results of physical tests);

d) functional tests: to show that the adequate signals intended to be forwarded to the main control

system of the complete machine are available and comply with the requirements and with the

technical documentation;

e) special verification: by reference to a standard which is mentioned in the corresponding clause.

Table 2 — Verification of safety requirements and/or protective/risk reduction measures

4.1 General X

4.2 Access X

4.3.3 Operator’s protective guard X

4.3.4 Movable operator station X

4.4 Seat X

4.5.1 Operator's controls and indicators, General X

4.5.2 Operating mode X X

Clause number

Title

a) Calculation

b) Visual verification

c) Measurement

d) Functional test

e) Special verification

4.5.3 Controls on stabilizers X

4.6 Steering system X

4.7 Swing brakes X

4.8.1 Stability, General X X

4.8.2 Calculation of the tipping load X X

4.8.3.2 Compacting material application X

4.8.3.3 Lifting operation X

4.8.3.4 Dragline bucket X

4.8.3.5 Grab and front shovel X

4.9.1 Holding brake X

4.9.2 Limiting devices X

4.9.3 Free-fall operation X

4.9.4 Boom X

4.9.5.1 Ropes, rope drum, rope pulley, General X X

4.9.5.2 Ropes X

4.9.5.3 Rope drum X

4.9.5.4 Rope pulley X

4.10.1 Lifting operation, General X

4.10.2 Lifting and lowering operation X

4.10.3 Limiting and indicating device for the lifting X X

operation mode

4.11 Cable excavator with electrical power X

source

4.12.1 Maintenance, General X X

4.12.2 Control of winches for maintenance purpose X

Clause number

Title

a) Calculation

b) Visual verification

c) Measurement

d) Functional test

e) Special verification

6 Information for use

6.1 General

Information for use shall be provided in accordance with EN ISO 12100:2010, 6.4.

6.2 Operator’s manual

EN 474-1:2022, 6.3 applies, with the following additions:

The operation manual shall contain the following information:

— indication that all rated load lift capacities are based on the machine being on a level and firm

supporting surface. For safe working loads, the user is expected to make due allowance for the

particular job conditions such as soft or uneven ground, non-level conditions, side loads, hazardous

conditions, experience of personnel; In particular, instructions shall be done about the necessity to

take measures to guarantee that the ground shall support the machine and can reliably withstand

the supporting forces in all tramming, travelling and working conditions, to avoid any negative effect

on stability;

— information about rated load lift capacity in relation to the various boom configurations and about

the maximum ground pressure;

— safety instructions for the selection and use of additional protection (e.g. top guard, front guard) see

4.3.3 related to the application (e.g. dynamic soil compaction);

— information regarding operation, adjustment and maintenance of the swing brake;

— safety instructions for the lifting operation, excavator operation and the free-fall operation;

— instructions for mounting and dismantling;

— information regarding maintenance and check of ropes, description of danger zone of the winch and

the need for activation of the selector according to 4.12.2;

— safety instructions for maintenance of the machine;

— instructions for inspection and replacement;

— information that tests for lifting operation were carried out (see Clause 5, Table 2 and 4.8.3.3);

— condition for stopping the operation of the machine in relation to the maximum permissible wind

speed (the reference value of 1,2 m /t used to determine the lifting load);

— information on necessary activities in relation to the wind speed (e.g. reducing of the load capacity,

lowering the boom, fixing the boom);

— information how to calculate the minimum rated load at typical load shapes, where the wind area

per load deviates from the value 1,2 m /t, usually used in the load chart calculation (for examples see

Table 3);

— information if the used load deviates from this typical configuration, a special calculation for the

allowable wind velocity is necessary (for calculation see EN 13000:2010+A1:2014, N.4).

EN 4

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...